A hydraulic push steel emergency stop device for a heating furnace

A technology of heating furnace and hydraulic pressure, which is applied in the field of hydraulic pusher for steel rolling pusher type heating furnace, which can solve the problems that the pusher cannot stop pushing steel, cannot meet the actual application requirements, and the valve is not completely closed, so as to achieve disassembly, assembly and maintenance Easy to replace, avoid damage to the furnace wall, and ensure continuous effectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to deepen the understanding and recognition of the present invention, the present invention will be further described and introduced below in conjunction with the accompanying drawings.

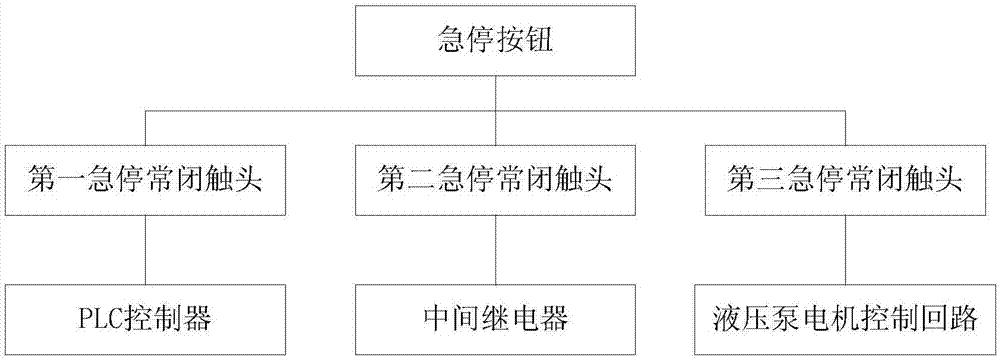

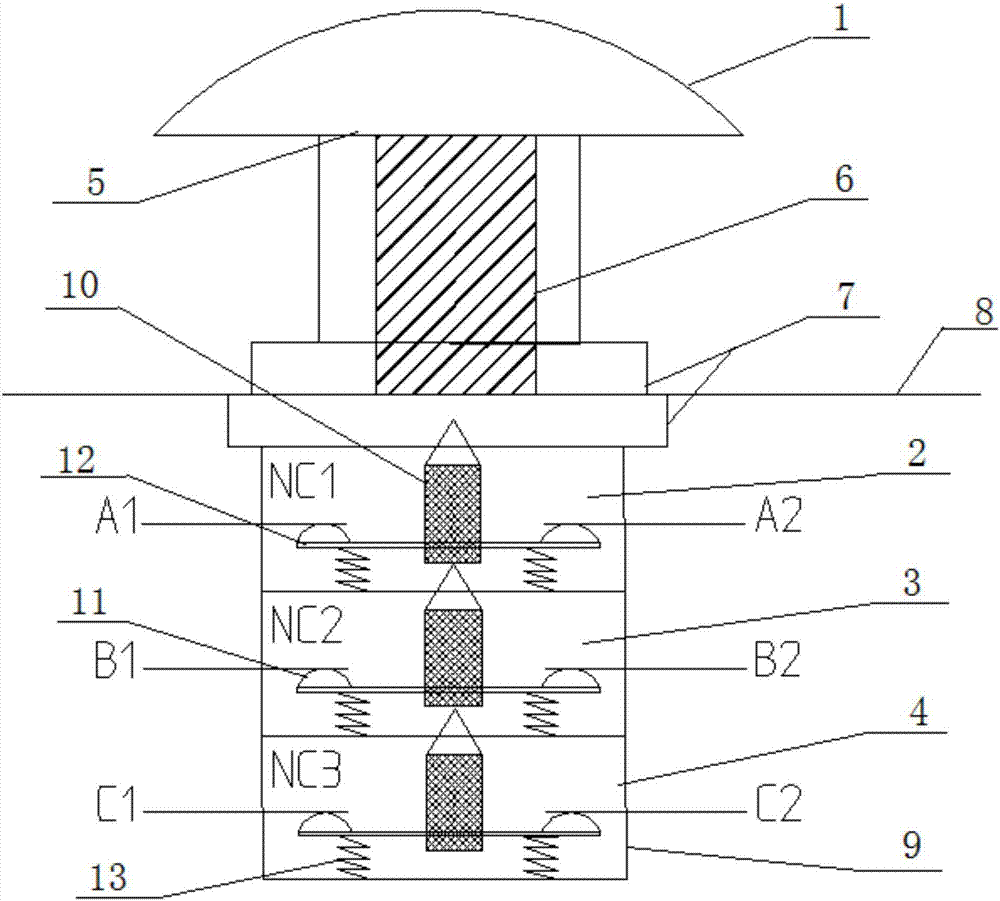

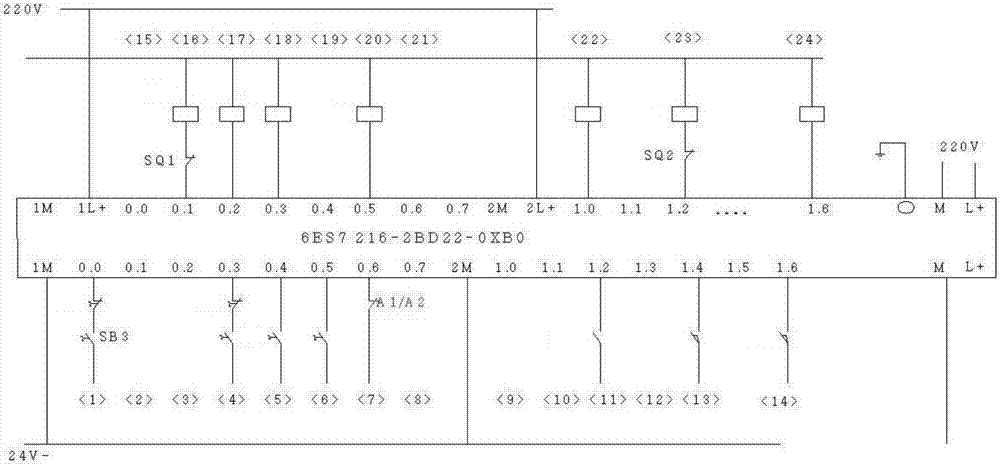

[0021] Such as figure 1 and 5 As shown, a heating furnace hydraulic pushing steel emergency stop device includes a PLC controller, an intermediate relay for controlling the on-off of the solenoid valve, a steel pushing machine hydraulic pump motor control circuit and an emergency stop button 1, and the emergency stop button 1 There is a button cap 5, a button push rod 6, an emergency stop button base 7, a first emergency stop normally closed contact 2, a second emergency stop normally closed contact 3 and a third emergency stop normally closed contact 4. The button cap 5 is fixedly connected to the top of the button push rod 6, the emergency stop button base 7 is arranged on the bottom of the button push rod 6, the first emergency stop normally closed contact 2, the second em...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com