Ascending type movable formwork box beam concrete pouring construction method

A technology of mobile formwork and construction methods, which is applied in the direction of erecting/assembling bridges, bridges, buildings, etc., which can solve the problems of difficulty in quality and safety control, low construction efficiency, and large pouring volume, and achieve quality assurance and construction of box girders. Good work efficiency and high mechanical utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

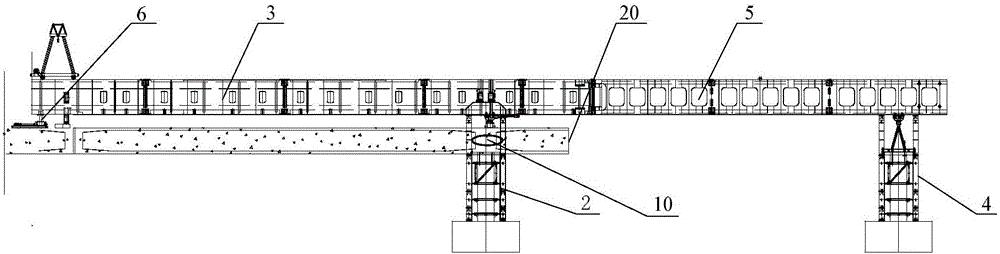

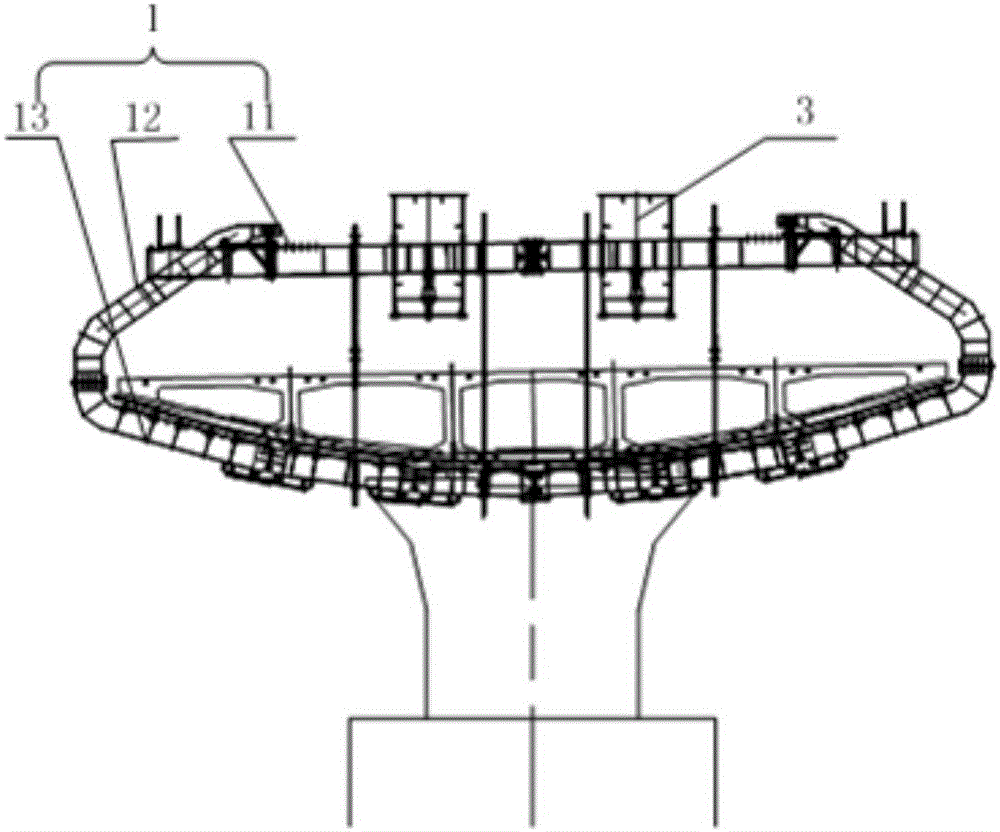

[0055] refer tofigure 1 , the preferred embodiment of the present invention provides a kind of upward mobile formwork box girder concrete pouring construction method, such as figure 2 and image 3 As shown, the upward mobile formwork includes a box girder main body construction mold 1 for unfolding from the bottom to remove the formwork of the box girder or closing from the bottom to pour the box girder, supported on the middle leg 2 of the box girder for carrying the box The beam main body construction mold 1 drives the box girder main body construction mold 1 to move the main girder 3 along the longitudinal direction of the box girder, and the nose bridge 5 supported on the front leg 4 of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com