A bottomless steel casing cast-in-place concrete diversion cofferdam and its construction method

A construction method and concrete pouring technology, which is applied in water conservancy projects, water conservancy engineering equipment, infrastructure engineering, etc., can solve the problems of easy collapse and difficult construction of earth-rock cofferdams, etc., to enhance the ability to resist water impact and stabilize the cofferdam structure , High construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the drawings and specific embodiments.

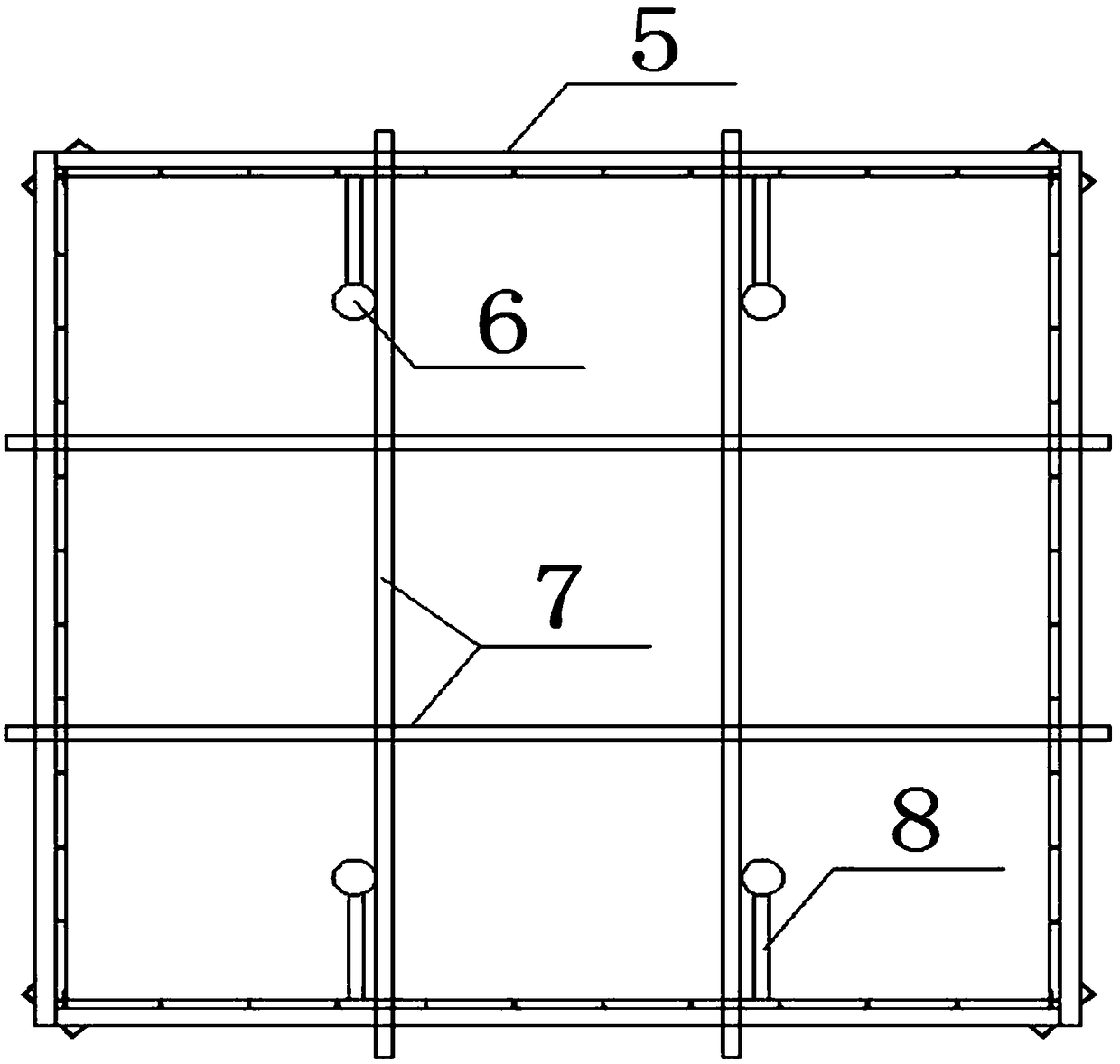

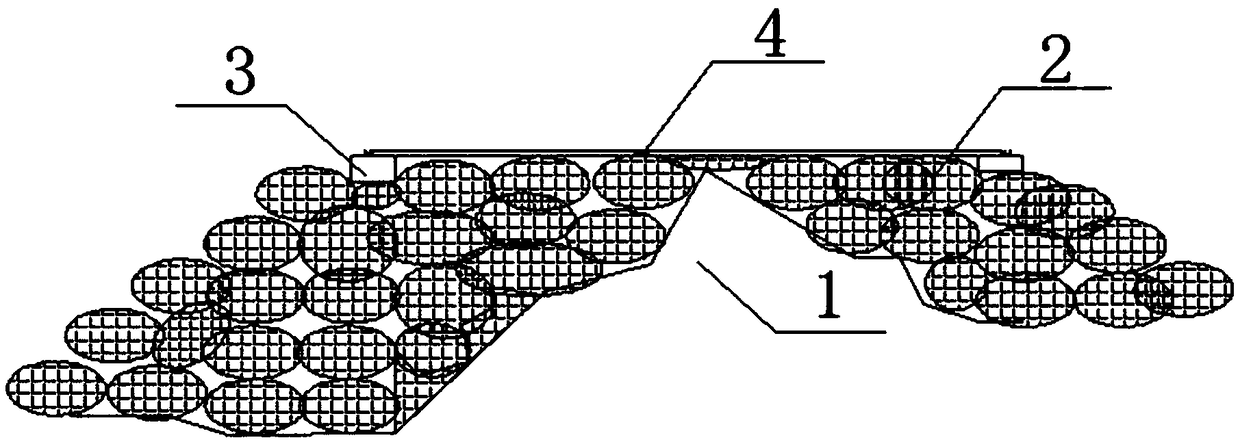

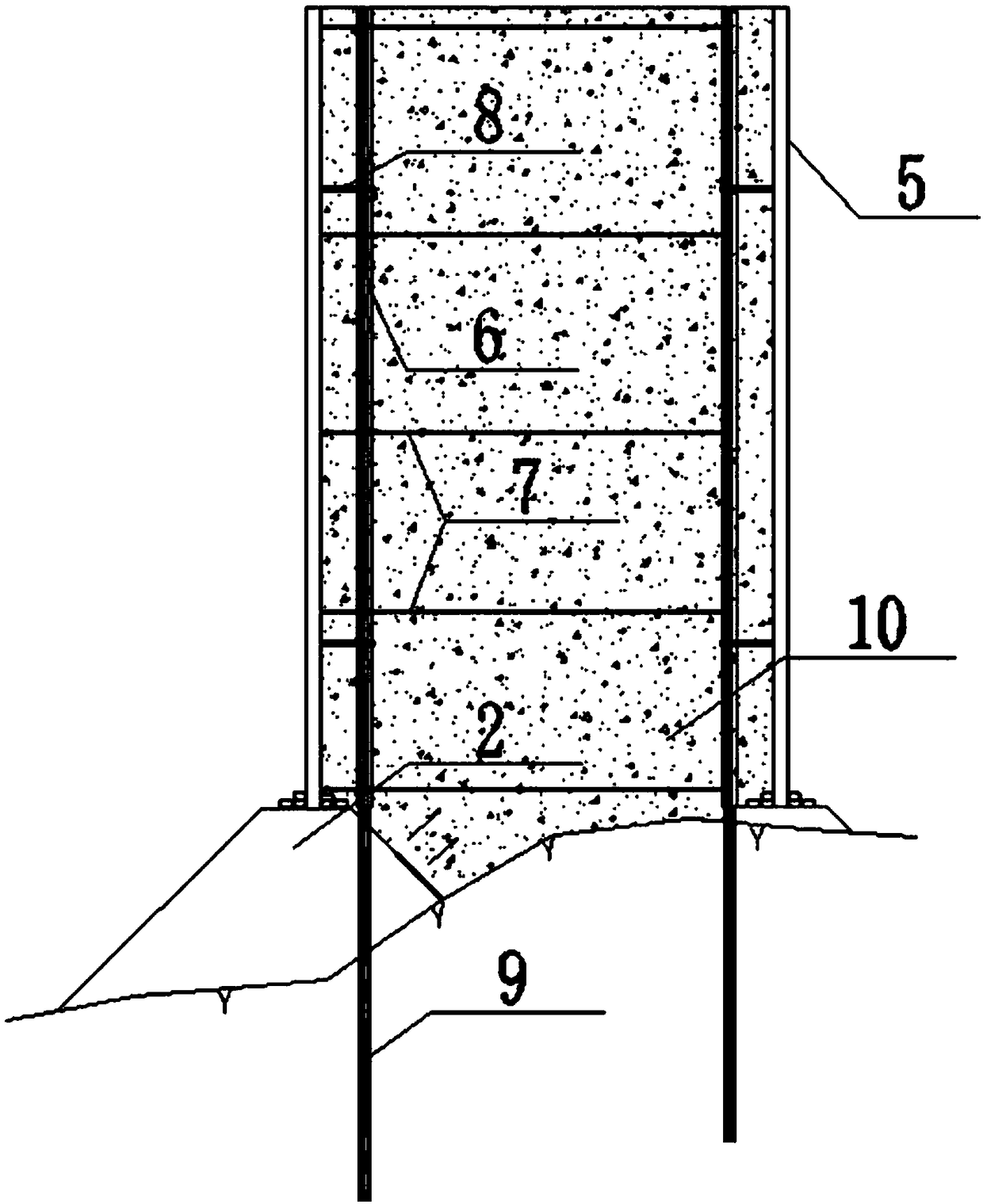

[0029] Such as Figure 1~3 , A bottomless steel box cast-in-place concrete diversion cofferdam. The diversion cofferdam of this embodiment is used in turbulent waters. The diversion cofferdam mainly uses the steel shell casing 5 as the main structure. The steel shell box 5 is a ring structure with open upper and lower ends. Before the steel shell box 5 is lowered onto the river bed 1, several sections of the steel shell box 5 can be welded together end to end. The steel shell box 5 is according to Design the height of the diversion cofferdam.

[0030] The steel shell box 5 is provided with an internal support structure, which includes a plurality of tie rods 7 arranged in the steel shell box 5, one end of the tie rod 7 is fixed on one side wall of the steel shell box 5, and the other end Fixed on the side wall on the opposite side, a plurality of tie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com