Light-transmitting concrete slab with wire drawing effect and manufacturing method thereof

A light-transmitting concrete and drawing effect technology, which is applied in the manufacture of tools, building components, building materials, etc., can solve problems such as low compressive strength, low production efficiency, and single light-transmitting visual effects, so as to improve strength and reduce labor costs , enhance the effect of aesthetics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

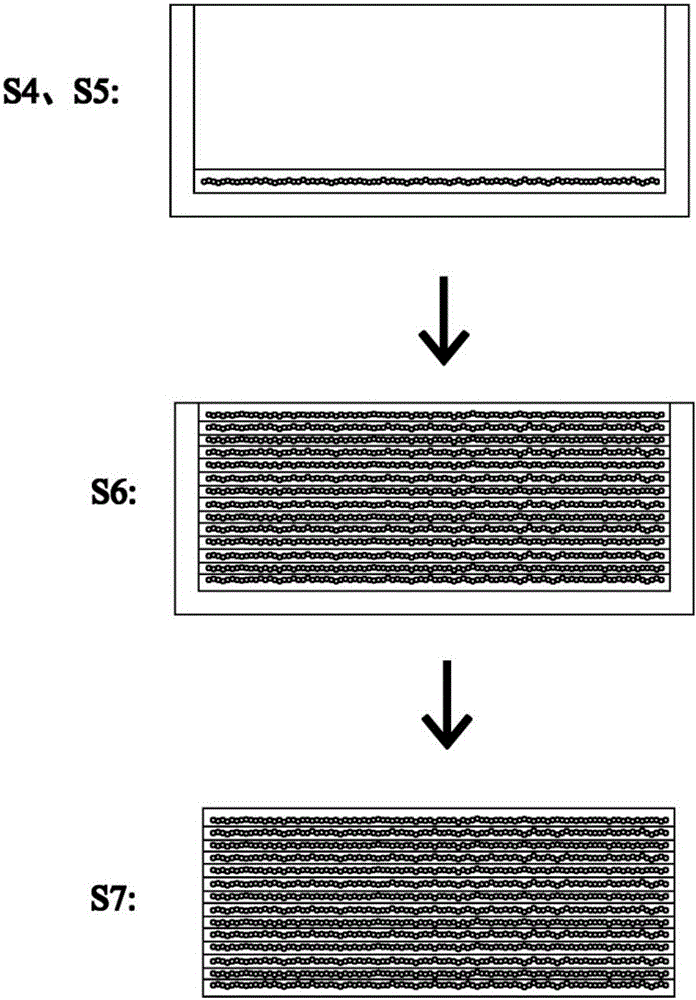

[0027] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

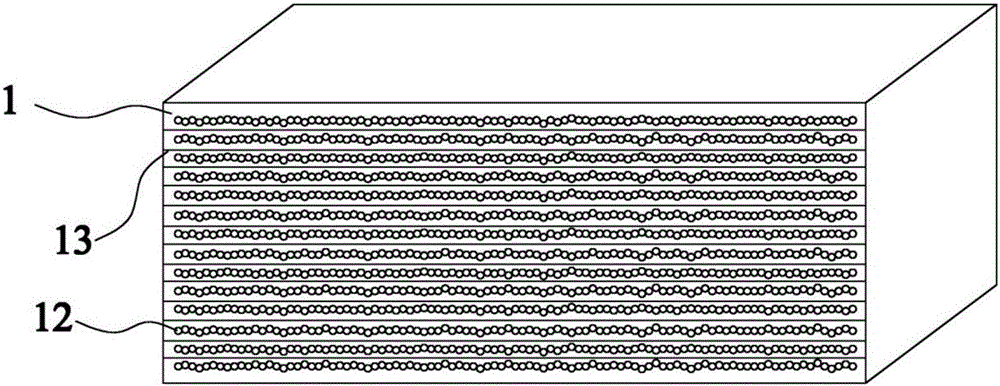

[0028] like figure 1 As shown, a light-transmitting concrete slab with a wire drawing effect provided by the present invention includes a cement mortar cementitious material 1 and an optical fiber cloth layer 12 and a glass fiber mesh cloth layer 13 wrapped and fixed in the cement mortar cementitious material 1 , the optical fiber cloth layer 12 and the glass fiber mesh cloth layer 13 have multiple layers, the optical fiber cloth layer 12 and the glass fiber mesh cloth layer 13 are alternately stacked and arranged in the cement mortar cementitious material 1, and each adjacent two optical fiber cloth layers A glass fiber mesh cloth layer 13 is arranged between the fiber cloth layers 12 .

[0029] Specifically, the optical fiber cloth layer 12 includes a plurality of optical fibers arranged in sequence on the same p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com