Pneumatic power generating device

A technology of power generation device and air passage, which is applied to engine components, machines/engines, mechanical equipment, etc., can solve the problems of high production cost of driving wheels, unsatisfactory power generation, poor impact resistance, etc. The effect of improving processing and pressure resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

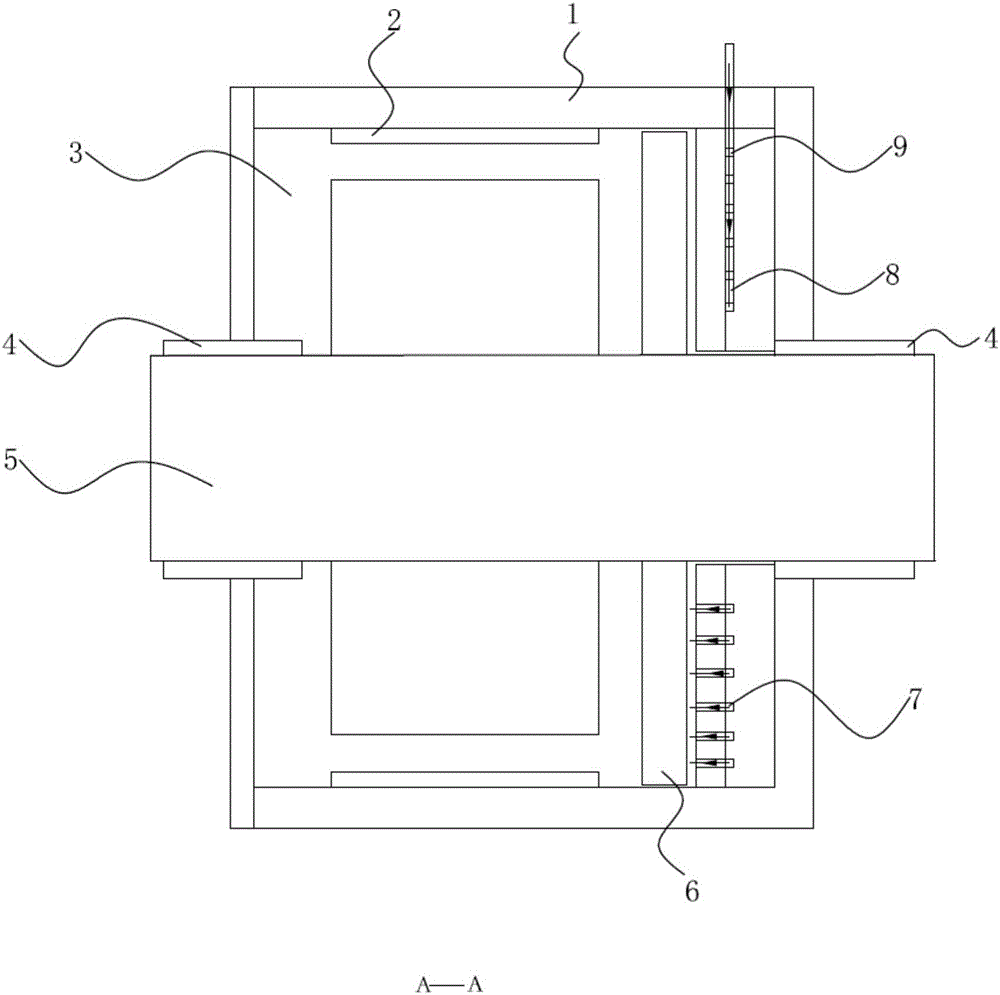

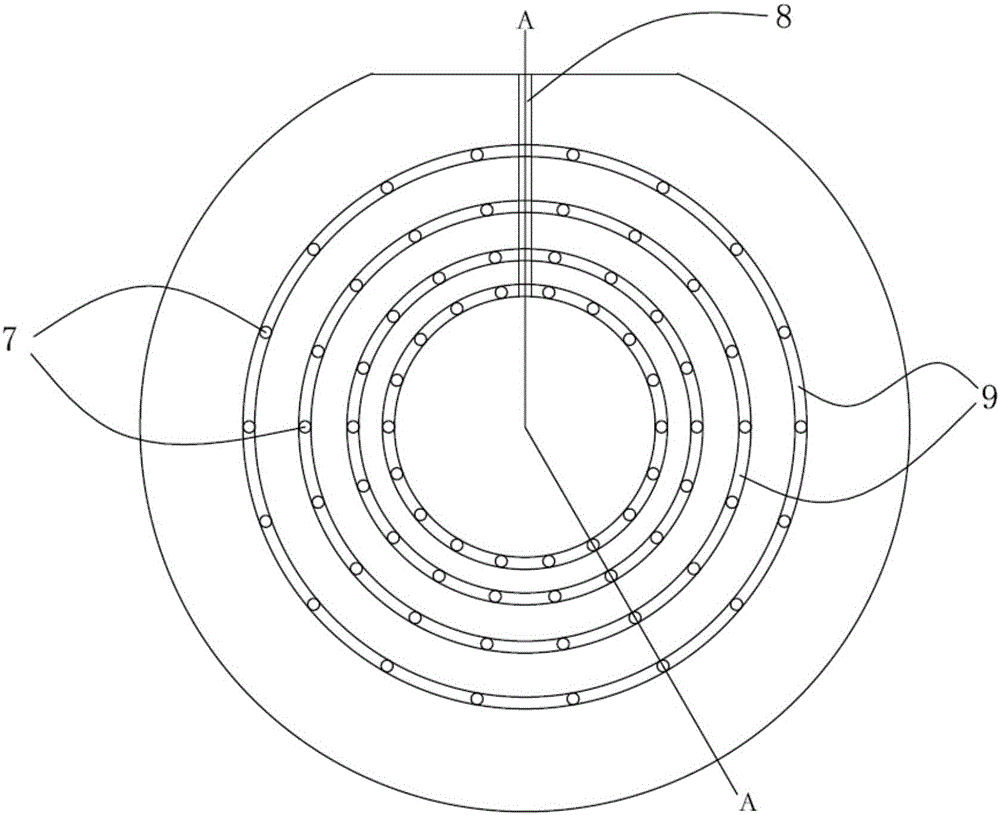

[0031] A pneumatic power generating device such as Figure 1-2 As shown, it includes a base 1, a stator 2 arranged on the base 1, a rotor 5 matched with the stator 2, a driving wheel 6 is arranged on the rotor 5, and the end surface of the driving wheel 6 is A drive hole for driving the drive wheel 6 to rotate is provided, the rotor 5 is set in the revolving cavity 3 of the base 1 through the air bearing 4, the base 1 is provided with an air passage, and the The air channel includes an air flotation air channel acting on the air flotation support 4, and a driving air channel acting on the driving hole, the rotor 5 shares the same air source with the air flotation support 4, and the air flotation The floating air channel communicates with the driving air channel through the rotary cavity 3 .

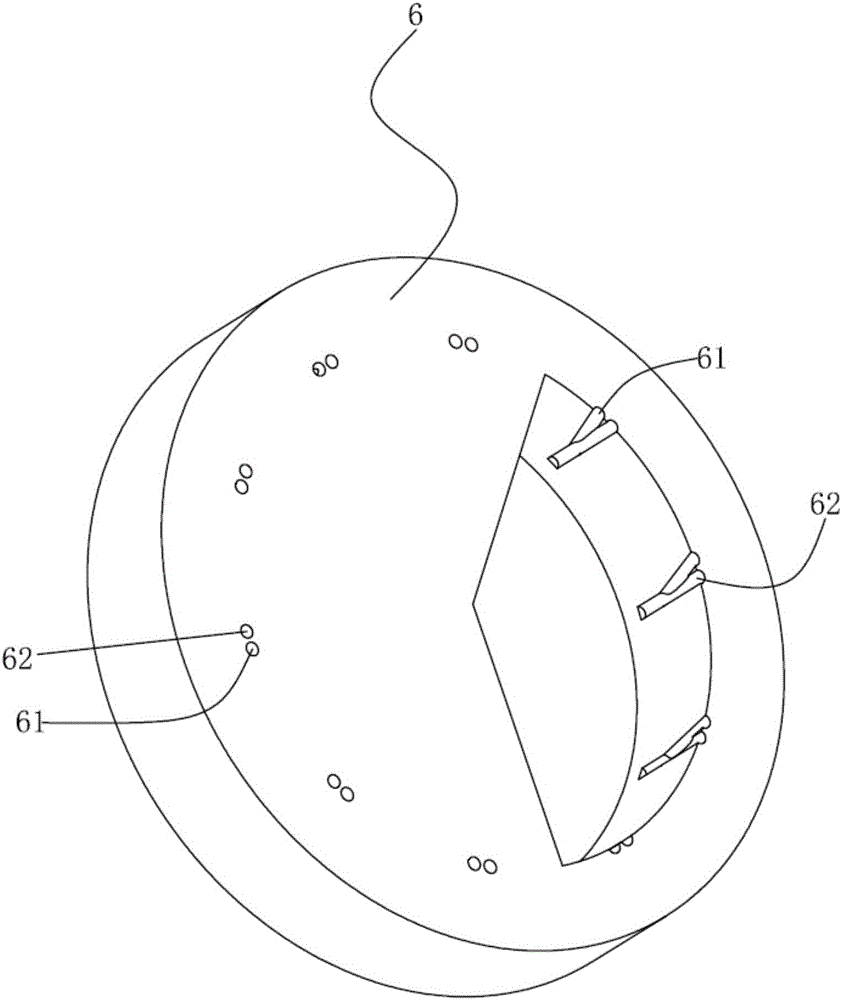

[0032] More specifically, such as image 3 As shown, the drive hole includes an exhaust hole 62 and an inclined counterbore 61, the exhaust hole 62 communicates with the inclined counte...

Embodiment 2

[0038]A pneumatic power generating device such as Figure 1-2 As shown, it includes a base 1, a stator 2 arranged on the base 1, a rotor 5 matched with the stator 2, a driving wheel 6 is arranged on the rotor 5, and the end surface of the driving wheel 6 is A drive hole for driving the drive wheel 6 to rotate is provided, the rotor 5 is set in the revolving cavity 3 of the base 1 through the air bearing 4, the base 1 is provided with an air passage, and the The air channel includes an air flotation air channel acting on the air flotation support 4, and a driving air channel acting on the driving hole, the rotor 5 shares the same air source with the air flotation support 4, and the air flotation The floating air channel communicates with the driving air channel through the rotary cavity 3 .

[0039] More specifically, such as Figure 4 As shown, the drive hole includes an exhaust hole 62 and an inclined counterbore 61, the exhaust hole 62 communicates with the inclined counte...

Embodiment 3

[0045] A pneumatic power generating device such as Figure 1-2 As shown, it includes a base 1, a stator 2 arranged on the base 1, a rotor 5 matched with the stator 2, a driving wheel 6 is arranged on the rotor 5, and the end surface of the driving wheel 6 is A drive hole for driving the drive wheel 6 to rotate is provided, the rotor 5 is set in the revolving cavity 3 of the base 1 through the air bearing 4, the base 1 is provided with an air passage, and the The air channel includes an air flotation air channel acting on the air flotation support 4, and a driving air channel acting on the driving hole, the rotor 5 shares the same air source with the air flotation support 4, and the air flotation The floating air channel communicates with the driving air channel through the rotary cavity 3 .

[0046] More specifically, such as Figure 5 As shown, the drive hole includes an exhaust hole 62 and an inclined counterbore 61, the exhaust hole 62 communicates with the inclined count...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com