Rotary shaft automatic locking mechanism

An automatic locking and rotating shaft technology, applied in the direction of brake actuators, gear transmission mechanisms, mechanical equipment, etc., can solve the problems of incomplete electromagnetic screen, unreliable unlocking of the locking mechanism, and large space occupied by the locking mechanism. Achieve good application value and promotion prospects, convenient and quick locking and unlocking conversion, and solve the effect of poor work reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

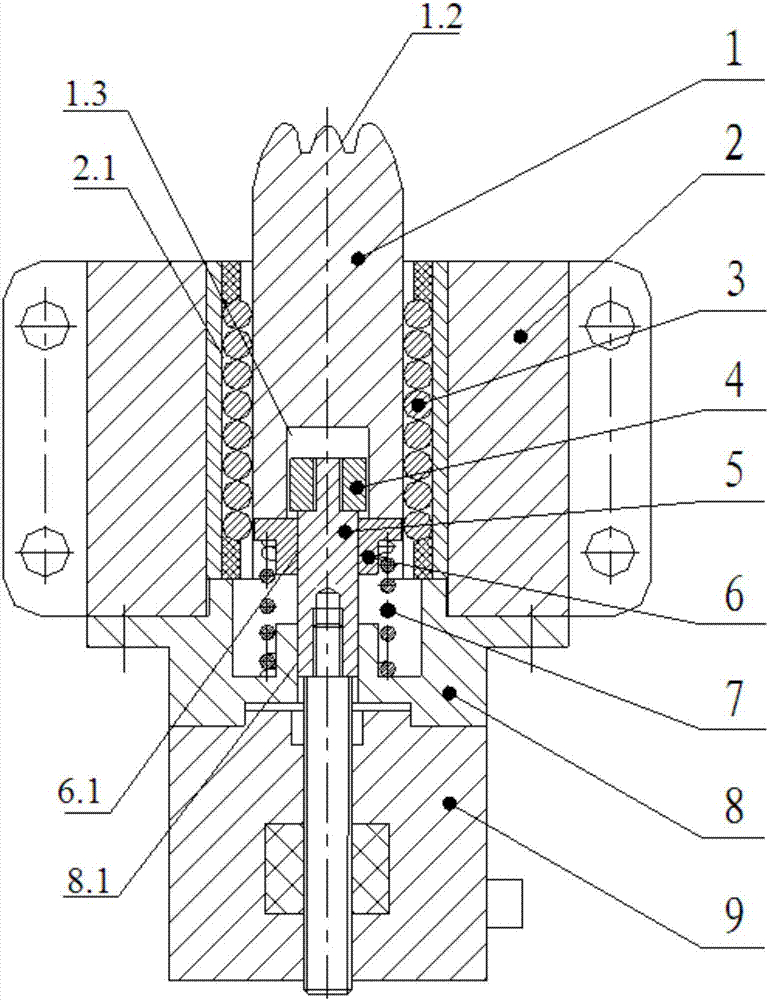

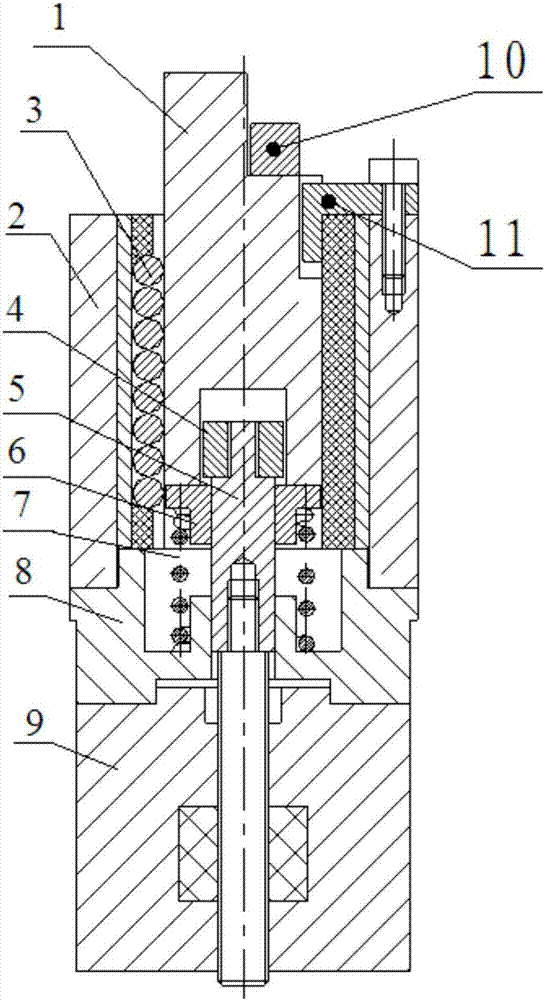

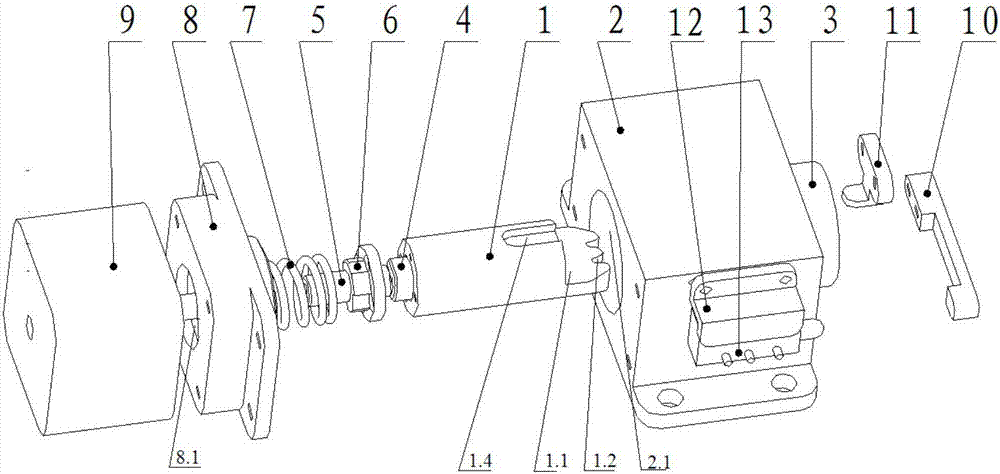

[0019] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0020] Such as Figure 1~6 The automatic locking mechanism of the rotating shaft shown includes a toothed cylindrical slider 1 (the diameter of the outer circle is 20mm), a locking bracket 2, a linear bearing 3 (model LM20UU), a limit nut 4, a guide stud 5, a push Rod seat 6, spring 7, motor mounting seat 8, linear motor 9 (type 43000 linear stepper motor), potentiometer sensing sheet 10, potentiometer pressing plate 12 and potentiometer 13, wherein the inside of the locking bracket 2 A cylindrical hole 2.1 is provided at the middle position, and the toothed cylindrical slider 1 is set in the cylindrical hole 2.1 through a linear bearing 3. The front end of the toothed cylindrical slider 1 is provided with a notch 1.1, and a potentiometer sensing piece 10 is installed on the notch 1.1. The front end of the toothed cylindrical slider 1 is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com