Vibration isolator

A vibration isolator and vibration isolation technology, which is applied in the direction of vibration absorber, spring/shock absorber, vibration suppression adjustment, etc., can solve the problems of poor stability and poor vibration isolation effect, and achieve enhanced stability and enhanced vibration isolation effect , the effect of reducing the transmission rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the drawings.

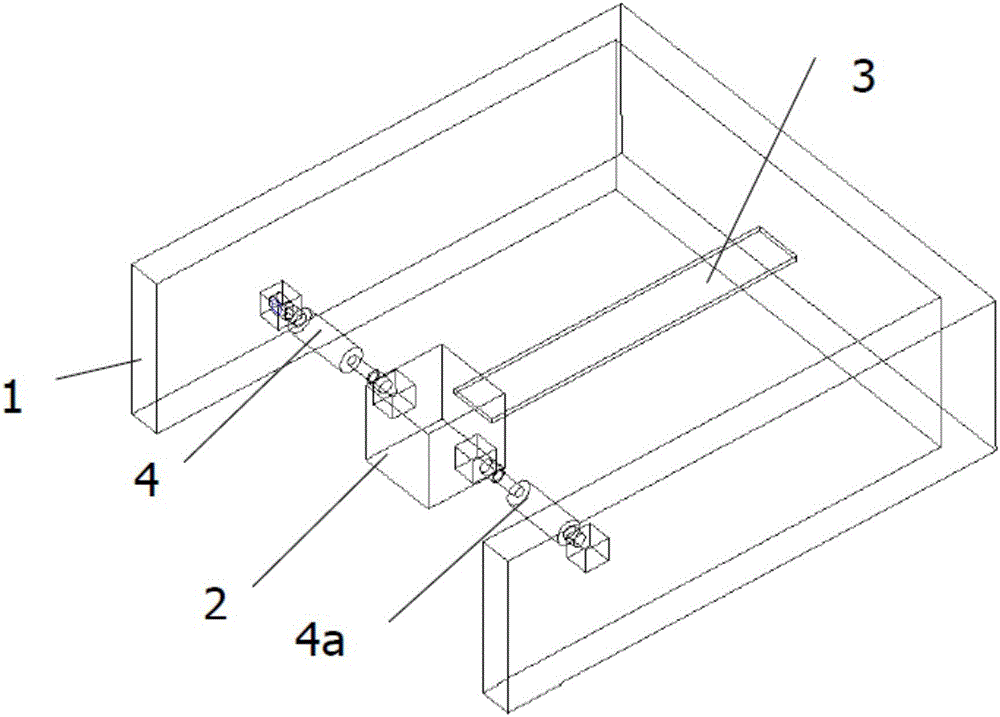

[0012] Such as figure 1 As shown, a vibration isolator includes a foundation 1, a device to be vibration-isolated 2, a leaf spring 3, and first and second air springs 4, 4a. The first air spring 4 is placed horizontally and is located on one side of the equipment to be isolated 2, and its two ends are respectively hinged with the foundation 1 and the equipment to be isolated 2 by bolts; the second air spring 4a is placed horizontally and located at On the other side of the equipment to be isolated 2, its two ends are hinged with the foundation 1 and the equipment to be isolated 2 by bolts. The symmetrical structure of the two air springs provides nonlinear restoring force and damping force for the equipment to be isolated 2, so that The resultant external force in the horizontal direction of the vibration isolation equipment 2 is zero, so as to ensure that the equipment to be isolate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com