Rotation type waterway three-way switching device

A switching device, rotary technology, applied in valve devices, multi-port valves, engine components, etc., can solve the problems of small total water output, reduce water flow velocity, increase water flow resistance, etc., to achieve higher adjustment sensitivity and reduce flow. Resistance, the effect of increasing water output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

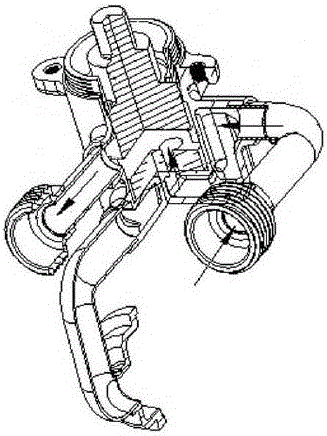

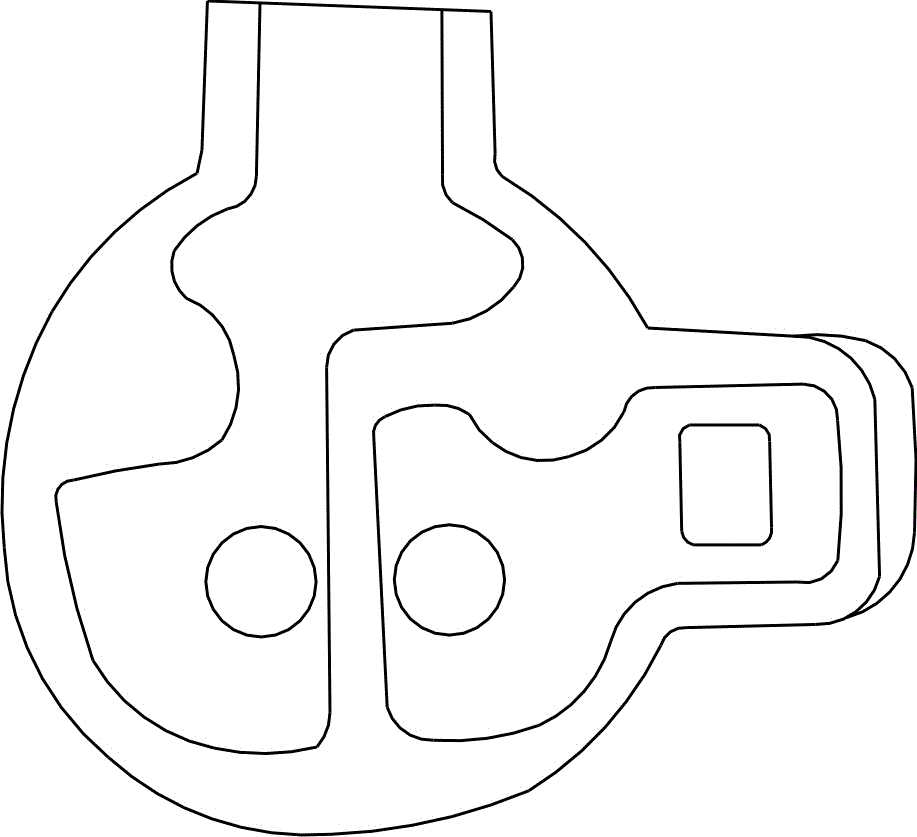

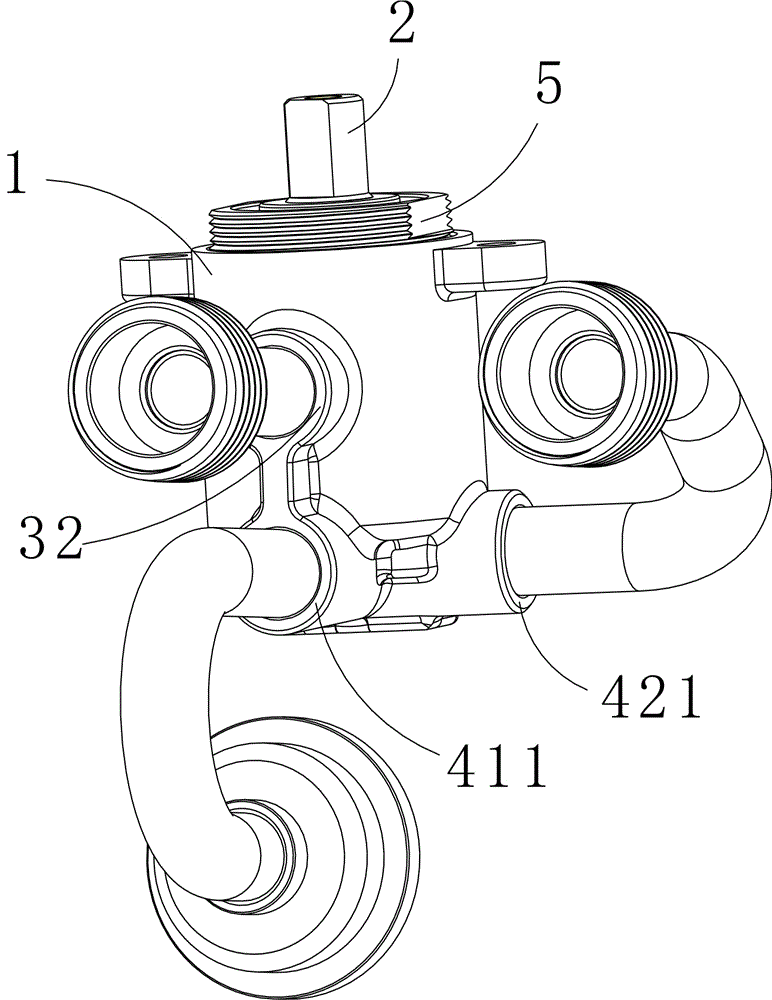

[0031] Embodiment 1, the valve body 1 is integrally formed by a forging process, wherein the water inlet channel includes a first water inlet channel 41 and a second water inlet channel 42, both of which are straight channels . The first water inlet channel 41 includes a first water inlet port 411 and a first water outlet port 412 , and the second water inlet channel 42 includes a second water inlet port 421 and a second water outlet port 422 . The first water inlet port 411 of the first water inlet channel 41 is located directly below the water outlet 32 , and the first water inlet port 411 is at a right angle to the second water inlet port 421 of the second water inlet channel 42 .

[0032] When the switching mechanism 2 is placed in the valve body 1, it can be rotated so that a passage is formed between the first water inlet port 411, the first water outlet port 412 and the water outlet 32, and at the same time the second water inlet channel 42 is closed; or the second wa...

Embodiment 2

[0033] Embodiment 2, in order to reduce the flow resistance of water flow, both the first water inlet channel 41 and the second water inlet channel 42 are L-shaped channels, wherein the transverse diameter of the first water inlet channel 41 is the same as that of the second water inlet channel 42 The transverse diameters are the same, and the longitudinal diameter of the first water inlet channel 41 is the same as that of the second water inlet channel 42 .

[0034] Meanwhile, the first water inlet port 411 and the second water inlet port 421 are located at the same level. Others are the same as in Embodiment 1.

Embodiment 3

[0035] Embodiment 3, in order to solve the problem that the water needs to be squeezed out of the valve body, the switching mechanism 2 includes a housing 21, a rotating shaft 22, a locking member 23 and a bottom plate 24. The top of the housing 21 is provided with a through hole 211, and the housing 21 A plurality of windows 212 are defined on the side wall, and the rotating shaft 22 is inserted into the through hole 211 of the housing 21 to be rotatably connected with the housing 21 . The lower part of the rotating shaft 22 is connected with a locking piece 23 and a bottom plate 24 , both of which are placed in the casing 21 , and the bottom plate 24 is close to the bottom surface of the water outlet area 3 of the valve body 1 . Wherein, there is a gap between the bottom plate 24 and the locking member 23 .

[0036] The bottom plate 24 is provided with a circular notch 241 matching the diameter of the water outlet port. The bottom plate 24 can make the circular notch 241 be lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com