Main piston rod, air control valve and lubricating method for slide valve pair

A main piston rod and air control technology, applied in the direction of engine lubrication, valve operation/release device, valve details, etc., can solve problems such as poor lubrication of slide valve pairs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

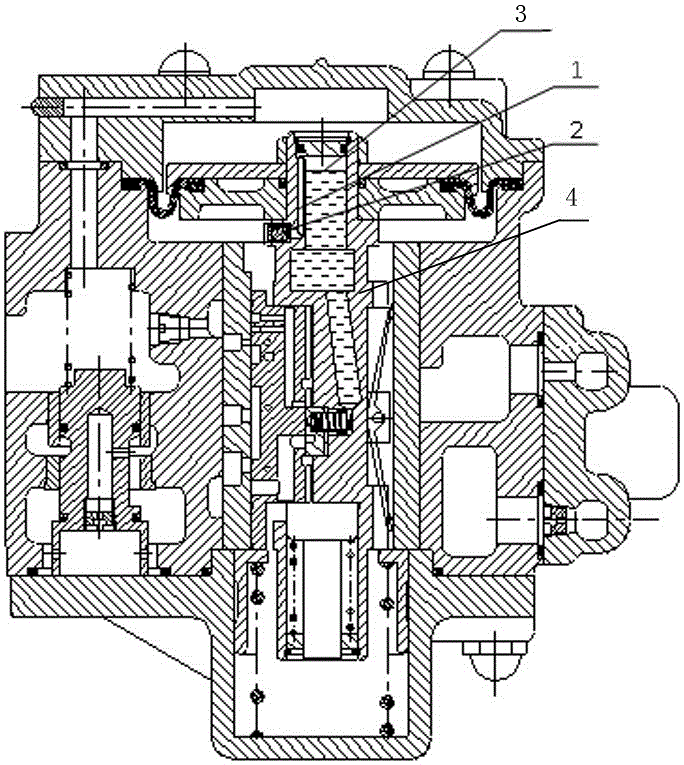

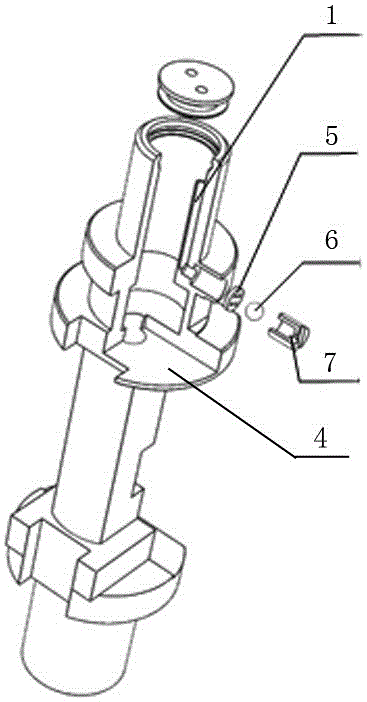

[0043] like figure 1 and figure 2 As shown, a main piston rod includes a main piston rod body 4, an oil storage chamber 3 is arranged on the main piston rod body 4, and a balance valve 2 and a balance pipe 1 are also included;

[0044] The balance valve 2 includes a valve seat 7 and a sliding body 6, the valve seat 7 is cylindrical, the sliding body 6 is located in the hollow area of the valve seat 7, and the sliding body 6 can move along the length of the valve seat 7 direction movement;

[0045] Both ends of the valve seat 7 are provided with sealing plates, the two sealing plates are respectively the sealing plate A5 and the sealing plate B, and the two sealing plates are all provided with through holes for the fluid to enter and exit the hollow area, and the sliding body 6 is in the When moving to contact with the sealing plate A5, the sliding body 6 does not affect the medium flow capacity of the through hole on the sealing plate A5, and when the sliding body 6 moves...

Embodiment 2

[0053] like figure 1 and figure 2 As shown, this embodiment is further limited on the basis of Embodiment 1: a circular blind hole is provided on the outside of the main piston rod body 4, an internal thread is provided on the circular blind hole, and the valve seat 7 To be provided with a cylinder with external threads, the sealing plate A5 is in the shape of a disc, and a plurality of through holes are arranged on the sealing plate A5, and the valve seat 7 is threadedly connected with the circular blind hole, and the sealing plate A5 is penetrated into the circle by the valve seat 7. One end of the shaped blind hole is pressed on the bottom of the circular blind hole, the sealing plate B is disc-shaped, the through hole on the sealing plate B is located at the center of the sealing plate B, and the sealing plate B is fixed on the end of the valve seat 7;

[0054] The balance pipe 1 is a hole provided on the main piston rod body 4, and one end of the hole is located on the ...

Embodiment 3

[0065] This embodiment further defines this case on the basis of any one of the technical solutions provided by any one of the above embodiments, such as figure 1 and figure 2 As shown, this embodiment also discloses an air control valve, the air control valve includes a control valve body, a slide valve sleeve fixed on the control valve body, a slide valve that forms a slide valve pair with the slide valve sleeve, The throttle valve matched with the spool valve also includes the main piston rod provided by any of the above schemes, the main piston rod is used to drive the spool valve to slide, the through hole on the sealing plate B on the balance valve 2 and the spool valve chamber The air cavity is connected. Since the air control valve adopts the main piston rod provided above, the balance valve 2 on the main piston rod produces a lubrication method different from that of the prior art, which not only enables the slide valve pair of the air control valve to be forced to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com