Connection structure of large-diameter enhanced pipes

A technology for connecting structures and reinforcing pipes, applied in non-removable pipe connections, pipe/pipe joints/pipe fittings, passing elements, etc., can solve the problems of insufficient connection strength and complicated process, and achieve fast installation speed and low operation requirements. , the effect of high structural safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail with reference to the accompanying drawings and embodiments.

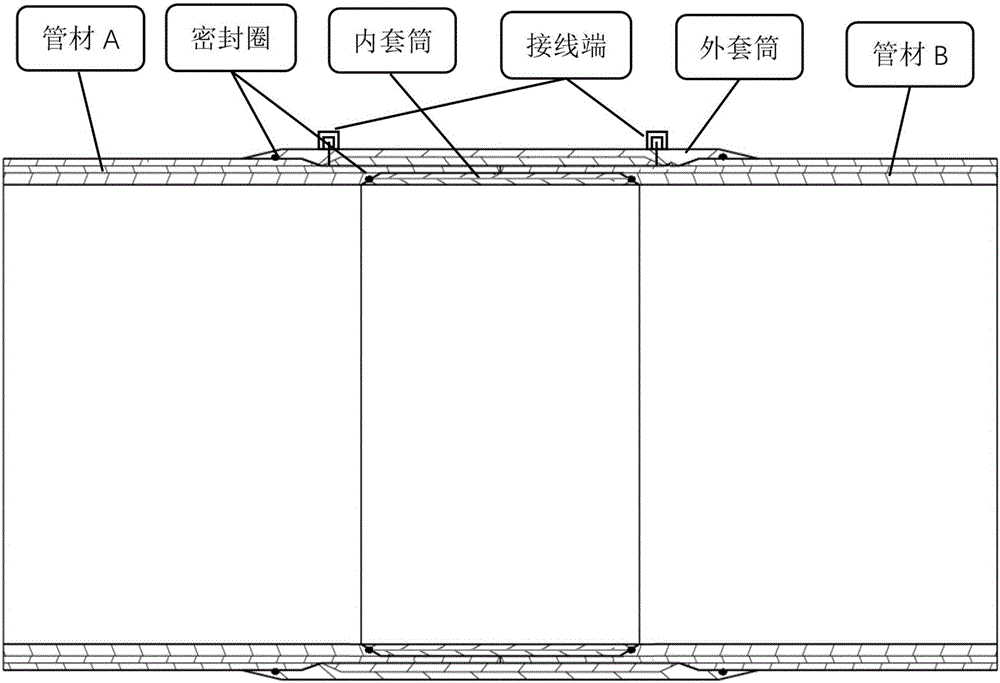

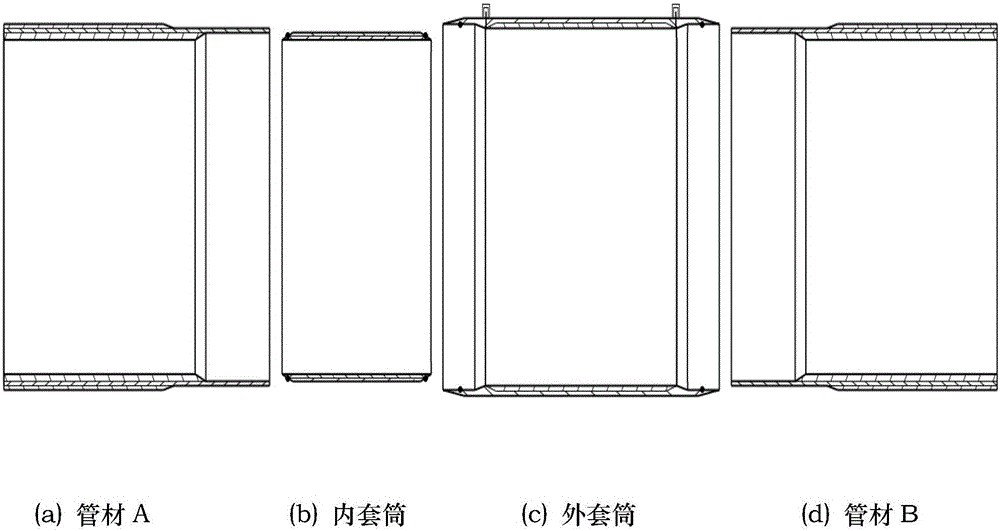

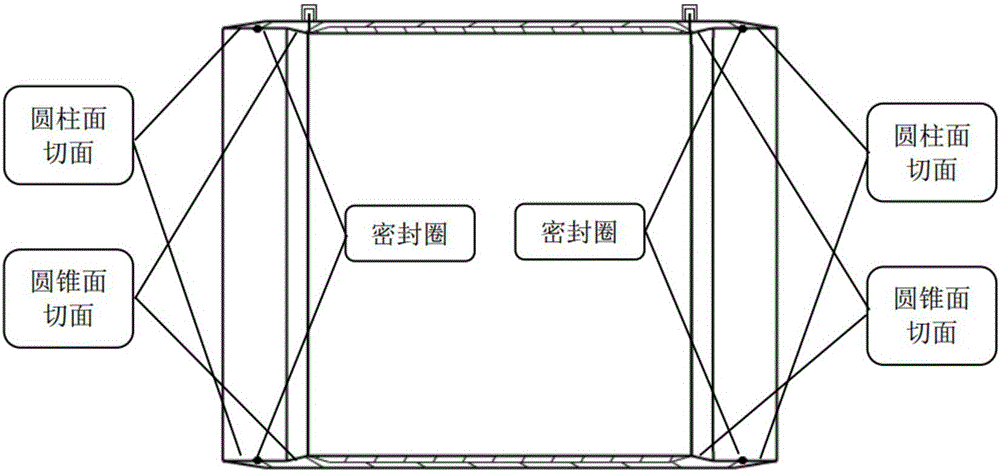

[0022] The reinforced pipe is made of three layers of material inside and outside, the middle layer is the reinforced layer to bear the load, and the inner and outer two layers are the functional layer to maintain the function. The inner wall of the reinforced layer is provided with an inner functional layer, and the outer wall is provided with an outer functional layer. Reinforced pipe B joints are processed, the inner functional layer and the outer functional layer are removed, so that the cut surface of the inner functional layer and the outer functional layer is a conical surface, and the cut surface of the reinforced layer is a plane. The present invention is applied to the above-mentioned reinforced pipes that need to be connected connection structure, such as figure 1 As shown, including inner sleeve, outer sleeve and sealing ring;

[0023] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com