Heating body and production process

A heating body and process technology, applied to tobacco and other directions, can solve the problems of poor assembly, poor atomization effect, easy fragmentation, etc., and achieve the effect of solving fragmentation, good oil guiding effect, and satisfying structural strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

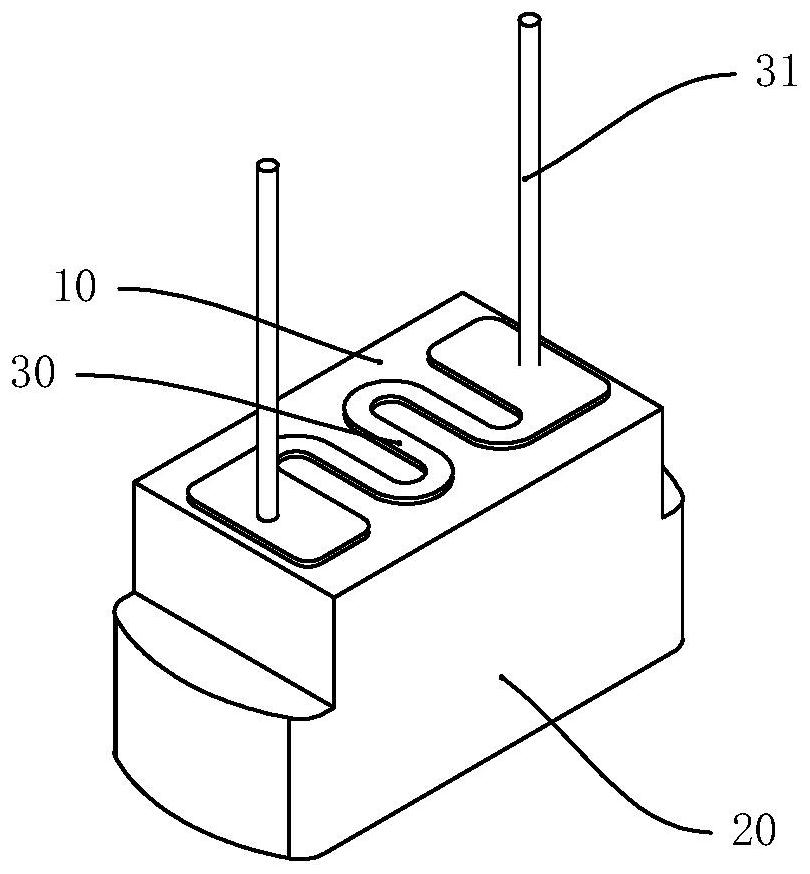

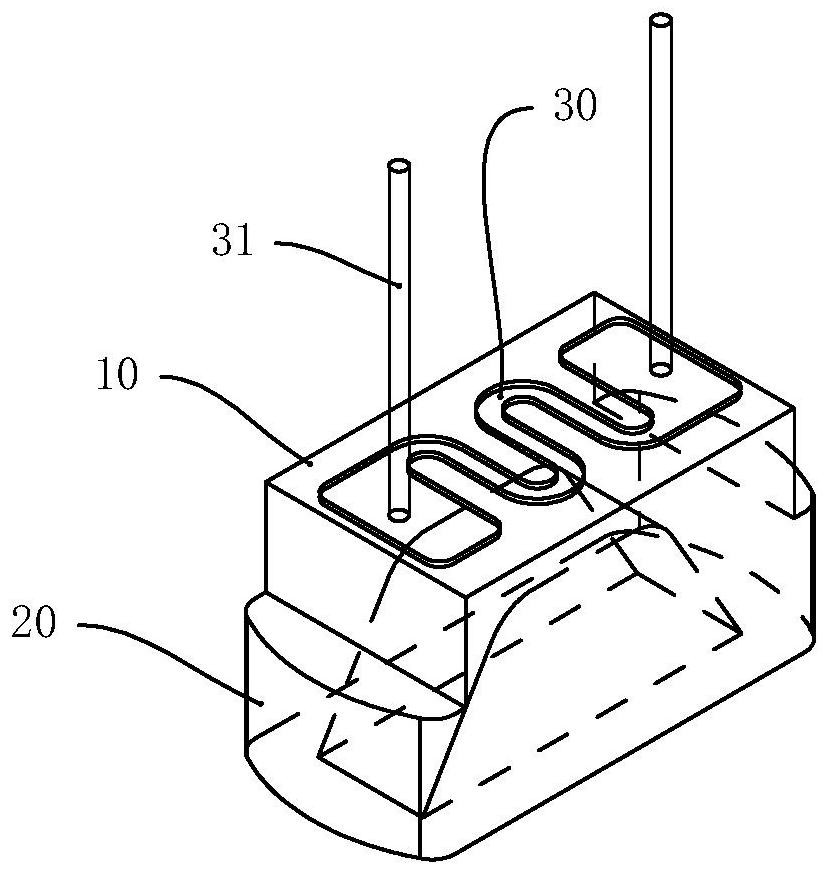

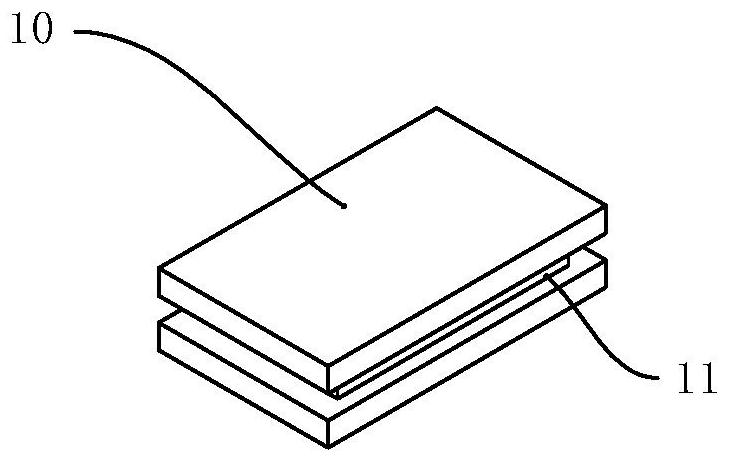

[0031] The first embodiment, such as Figure 1 to Figure 9 As shown, a heating body includes a high-porosity ceramic body 10 and a low-porosity ceramic body 20, the low-porosity ceramic body 20 runs through a cavity 21, and the high-porosity ceramic body 10 is embedded in the cavity 21 The interior and surroundings of the high-porosity ceramic body 10 are sealed and connected with the cavity 21 . The outer surface of the high-porosity ceramic body 10 is printed with a heating circuit 30 , and the heating circuit 30 is connected with a lead wire 31 .

[0032] Such as Figure 1 to Figure 9 As shown, the high-porosity ceramic body 10 has a relatively good oil-guiding effect, which can ensure the passage of e-liquid. The strength of the high-porosity ceramic body 10 is relatively low, and the strength of the low-porosity ceramic body 20 is relatively high, and the e-liquid can penetrate from the cavity 21 In the high-porosity ceramic body 10, the e-liquid cannot penetrate into th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com