Labeling machine

A labeling machine and labeling technology, applied in the direction of labeling machines, labels, conveyor objects, etc., can solve the problems of slow running speed, non-adjustable height of label printers, and easy noise generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0085] The present invention will be further described below in conjunction with the examples, but it should not be interpreted as a limitation of the present invention. The protection scope of the present invention is based on the contents recorded in the claims. protection scope of the present invention.

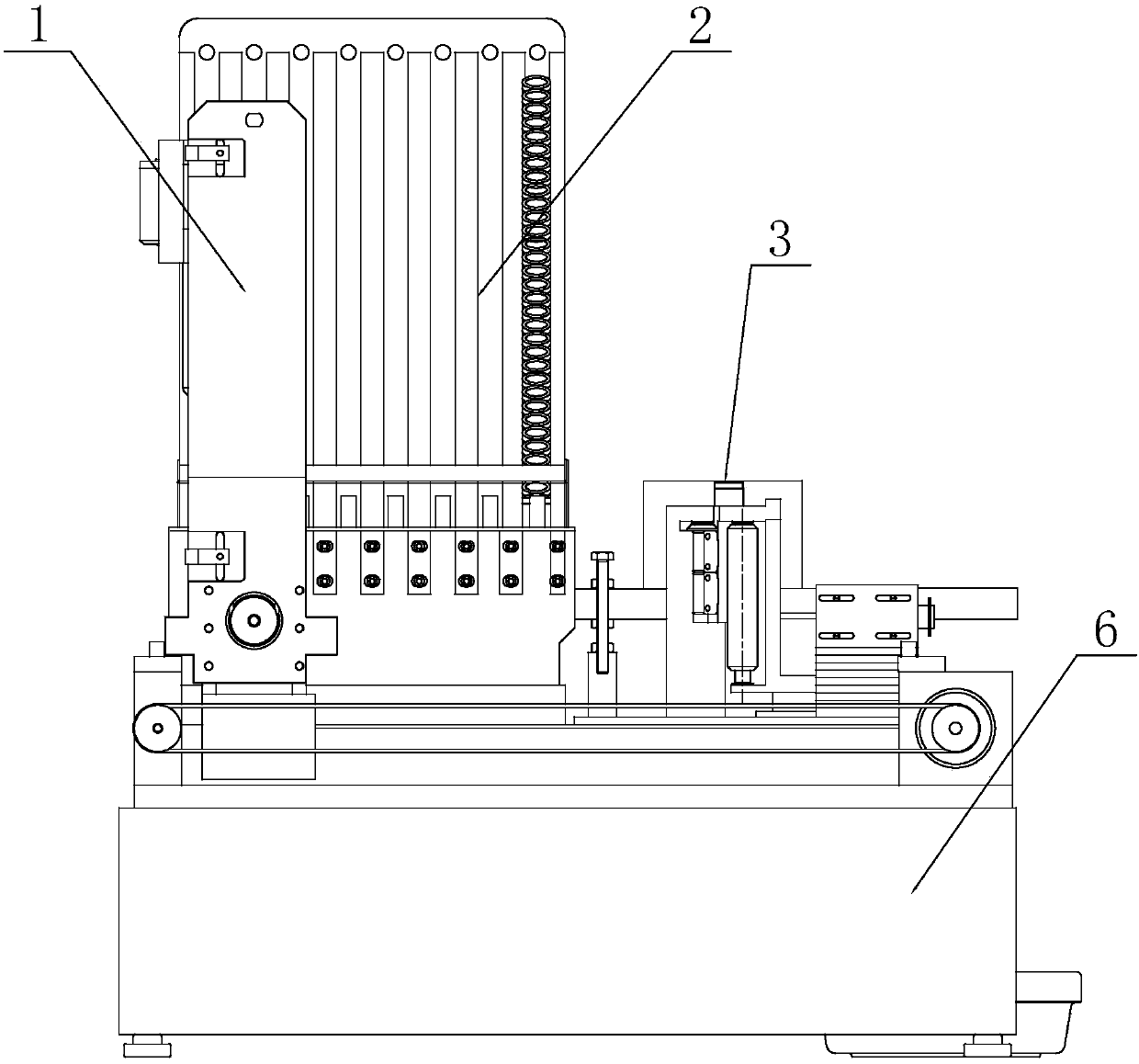

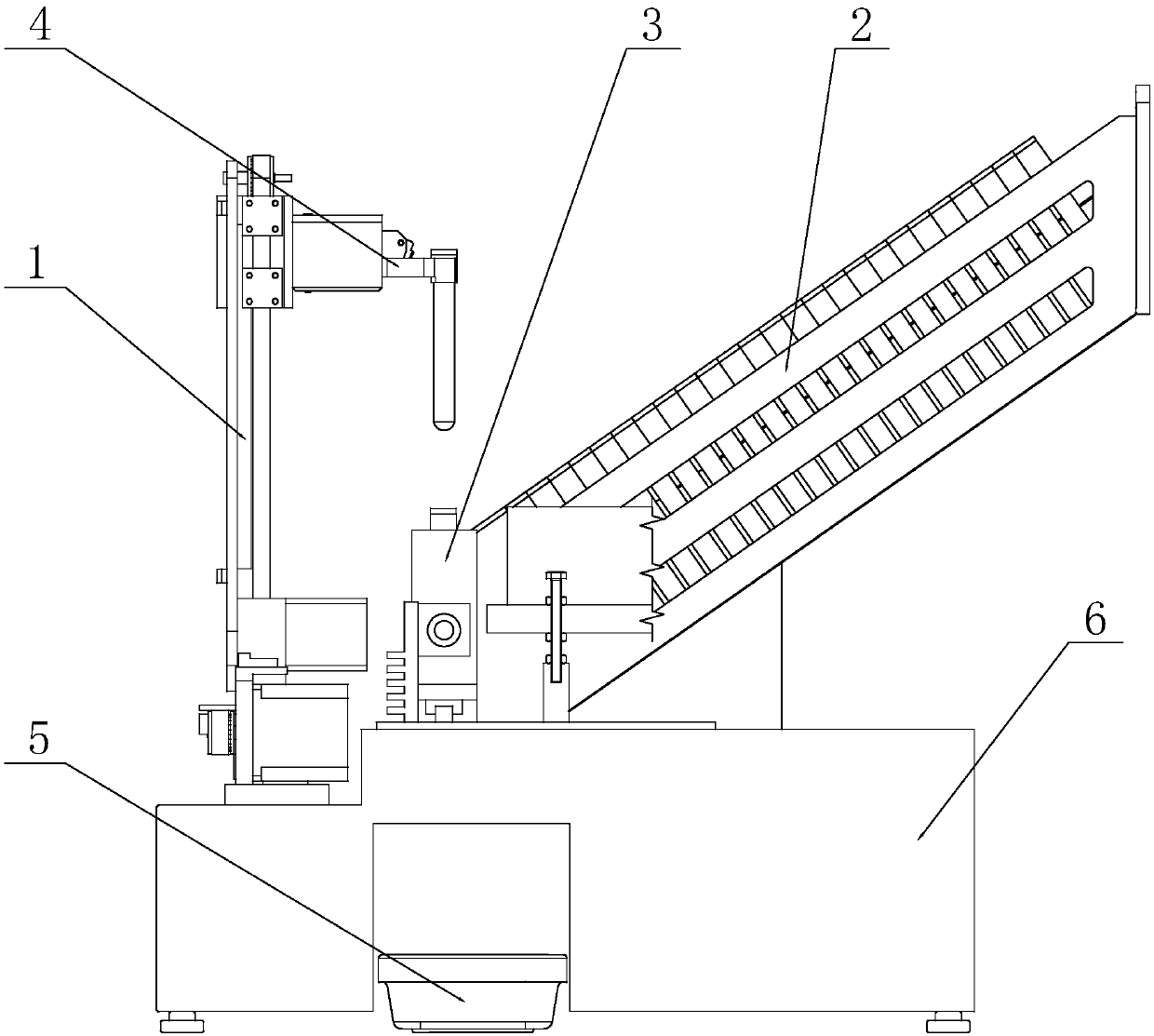

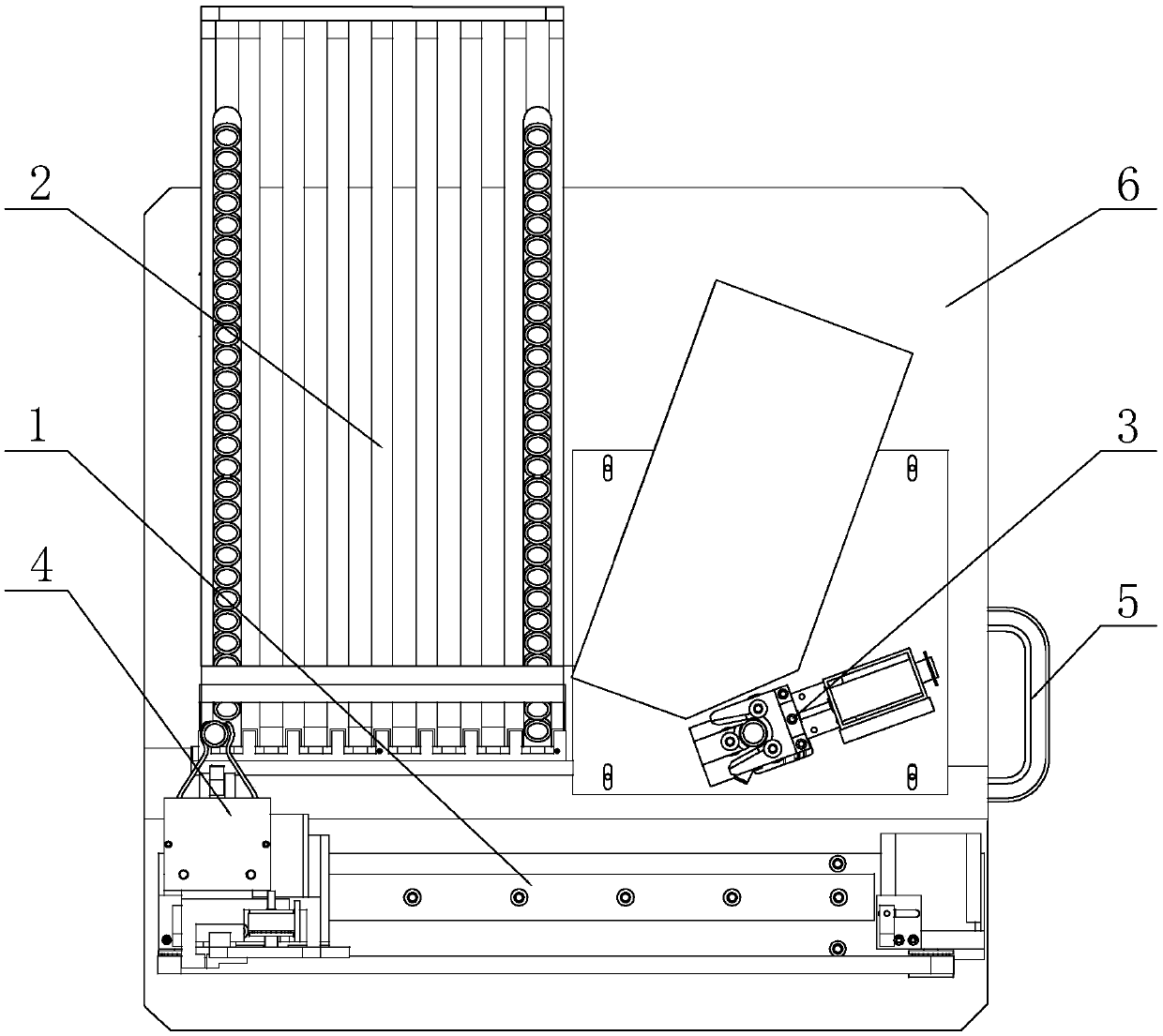

[0086] The overall structure of this embodiment and the structure of each corresponding mechanism are as shown in the figure, including a cross slide 1, a silo mechanism 2, a labeling mechanism 3, a manipulator and a receiving box 5, and the manipulator grabs blood under the control of the central control device After the test tube is transported to the labeling mechanism 3 through the cross slide 1, the blood collection test tube after labeling falls into the material receiving box 5; the manipulator is an electromagnetic manipulator 4, which includes two oppositely arranged mechanical grippers 4a , the grasping parts of the front ends of the two mechanical grippers 4a ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com