Composite material for solar component, solar component frame, preparation method of frame and application of frame

A technology of solar modules and composite materials, applied in the fields of solar module frames and their preparation, and composite materials for solar modules, can solve the problems of strong PID effect, poor performance of polymer materials, PID effect, etc., to reduce the PID effect and meet the structural requirements Strength, effects of reducing component mass

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

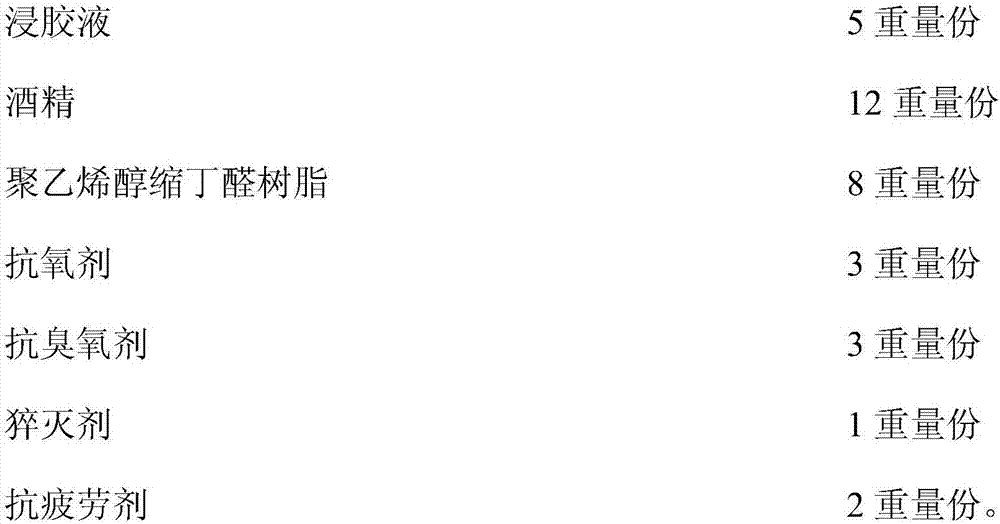

[0075] In this embodiment, the weight ratio of each component in the preparation raw materials of the composite material is as follows:

[0076]

[0077]

[0078] Its preparation method comprises the following steps:

[0079] (1) SMC sheet molding compound, short glass fibers, calcium carbonate powder, quenching agent and dipping liquid are physically mixed in a kneader at a rotating speed of 30r / min, and then dried;

[0080] (2) The mixture obtained in step (1) was subjected to a crosslinking reaction at a temperature of 130° C. for 10 minutes to obtain a crosslinked product;

[0081] (3) Add polyvinyl butyral resin and alcohol to the cross-linked product obtained in step (2), and perform a preheating treatment at 80° C. for 8 minutes;

[0082] (4) Add antioxidant, antiozonant, antifatigue agent to the preheating treatment product that step (3) obtains, mix homogeneously to obtain described composite material for solar modules.

Embodiment 2

[0084] In this embodiment, the weight ratio of each component in the preparation raw materials of the composite material is as follows:

[0085]

[0086]

[0087] Its preparation method comprises the following steps:

[0088] (1) SMC sheet molding compound, short glass fibers, calcium carbonate powder, quenching agent and dipping liquid are physically mixed in a kneader at a rotating speed of 20r / min, and then dried;

[0089] (2) The mixture obtained in step (1) was subjected to a crosslinking reaction at a temperature of 120° C. for 12 minutes to obtain a crosslinked product;

[0090] (3) Add polyvinyl butyral resin and alcohol to the cross-linked product obtained in step (2), and perform a preheating treatment at 90° C. for 10 minutes;

[0091] (4) Add antioxidant, antiozonant, antifatigue agent to the preheating treatment product that step (3) obtains, mix homogeneously to obtain described composite material for solar modules.

Embodiment 3

[0093] In this embodiment, the weight ratio of each component in the preparation raw materials of the composite material is as follows:

[0094]

[0095]

[0096] Its preparation method comprises the following steps:

[0097] (1) SMC sheet molding compound, short glass fibers, calcium carbonate powder, quenching agent and dipping liquid are physically mixed in a kneader at a rotating speed of 40r / min, and then dried;

[0098] (2) The mixture obtained in step (1) was subjected to a crosslinking reaction at a temperature of 125° C. for 15 minutes to obtain a crosslinked product;

[0099] (3) Add polyvinyl butyral resin and alcohol to the cross-linked product obtained in step (2), and perform a preheating treatment at 85° C. for 5 minutes;

[0100] (4) Add antioxidant, antiozonant, antifatigue agent to the preheating treatment product that step (3) obtains, mix homogeneously to obtain described composite material for solar modules.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Heat distortion temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com