Method for Simultaneous Determination of Yield Strength and Fracture Toughness of Low Alloy High Strength Steel

A low-alloy high-strength, yield strength technology, applied in the direction of applying stable tension/pressure to test material strength, strength characteristics, measuring devices, etc., can solve low-cost testing, high-strength steel strength and fracture toughness testing problems, and workload Reduce problems such as easy to judge the rationality of the results, simplify the processing of test pieces and test loading equipment, and reduce the difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

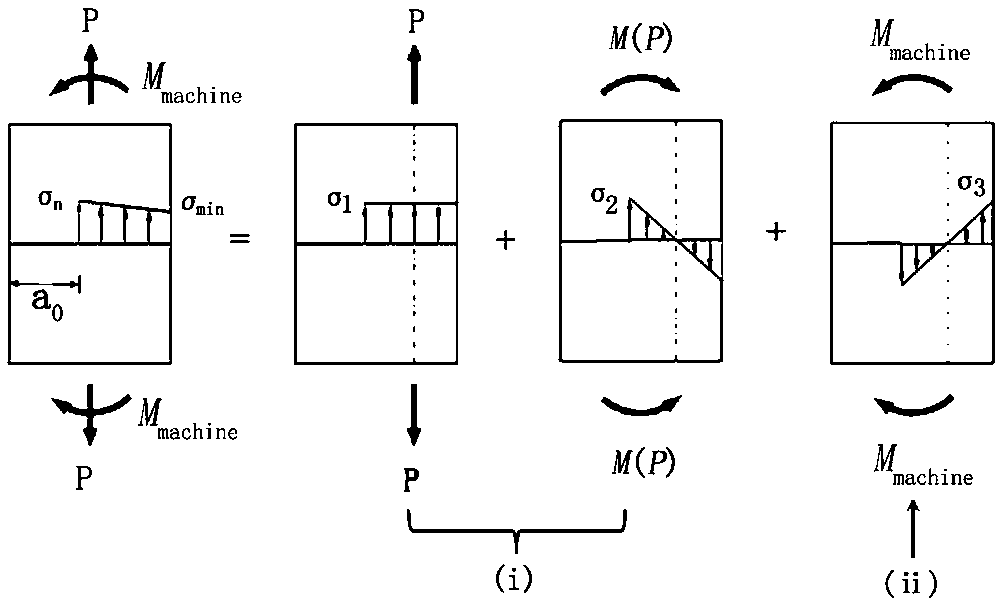

Method used

Image

Examples

Embodiment 1

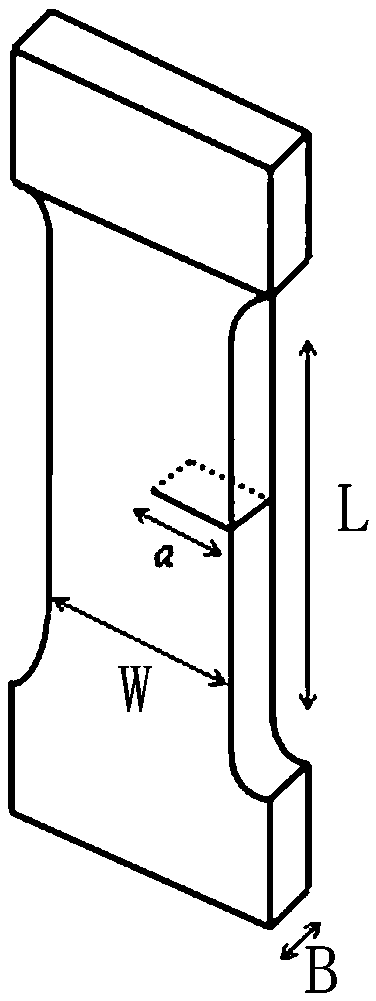

[0044] Example 1: Using low-alloy high-strength steel to make a unilateral tensile test piece, the size of the test piece is W=40mm, B=10mm, L=60mm, the height of the arc segment is 20mm, and the size of the rectangular clamping end is: 70mm× 80mm. Make the seam height ratio as a 0 / W=0.1, 0.2, 0.3, 0.4, 0.5, 0.6, 0.7 7 groups of test pieces, each group made 5 test pieces, a total of 35 test pieces.

[0045]Carry out uniform loading at the rate specified in the "Tensile Test of Metal Materials Part 1: Test Method at Room Temperature" (GB / T 228.1-2010) and other specifications, until the specimen breaks and fails. The yield load of each specimen shall be recorded during the test. Before yielding of the test specimen of the embodiment, continuous pictures can be taken with a camera to capture the length of the yield zone at the tip of the crack. In this embodiment, the length of the yield zone of the specimen is 1mm-2mm.

[0046] For tensile testing machines or universal tes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com