Solution and method for evaluating corrosion resistance of water-based antirust layer on surface of steel plate

A technology of anti-rust layer and corrosion resistance, which is applied in the fields of weather resistance/light resistance/corrosion resistance, metal material coating technology, measuring devices, etc., and can solve problems that cannot reflect natural conditions and cannot fully reflect the protective effect of anti-rust layer , to achieve the effects of strong controllability, moderate test severity and moderate severity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-6

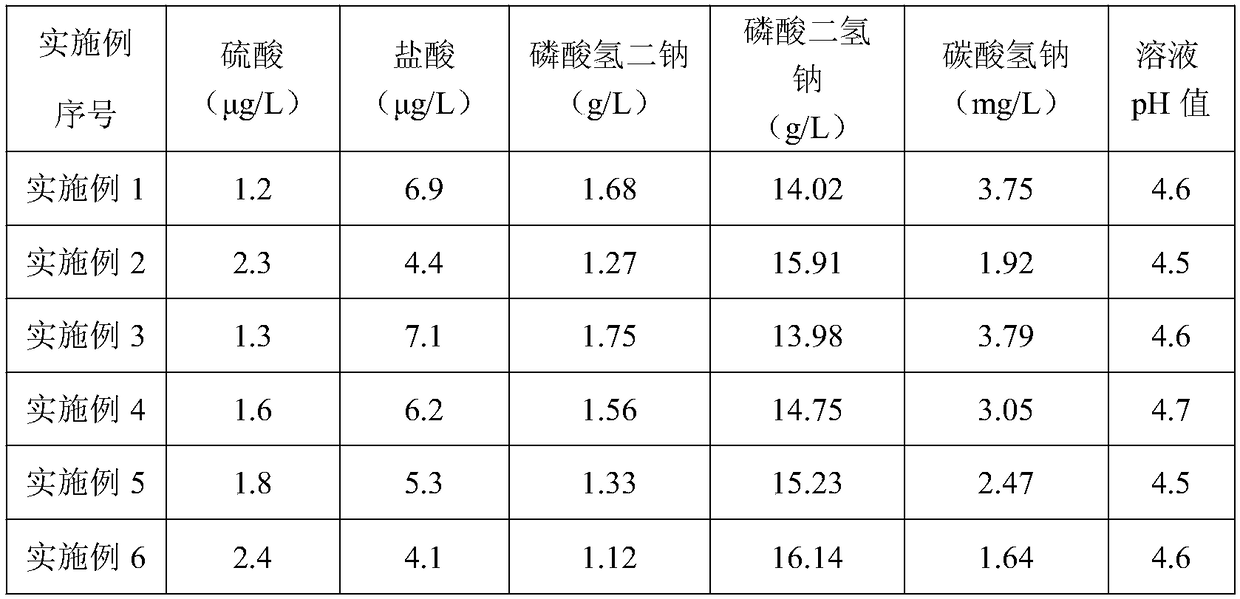

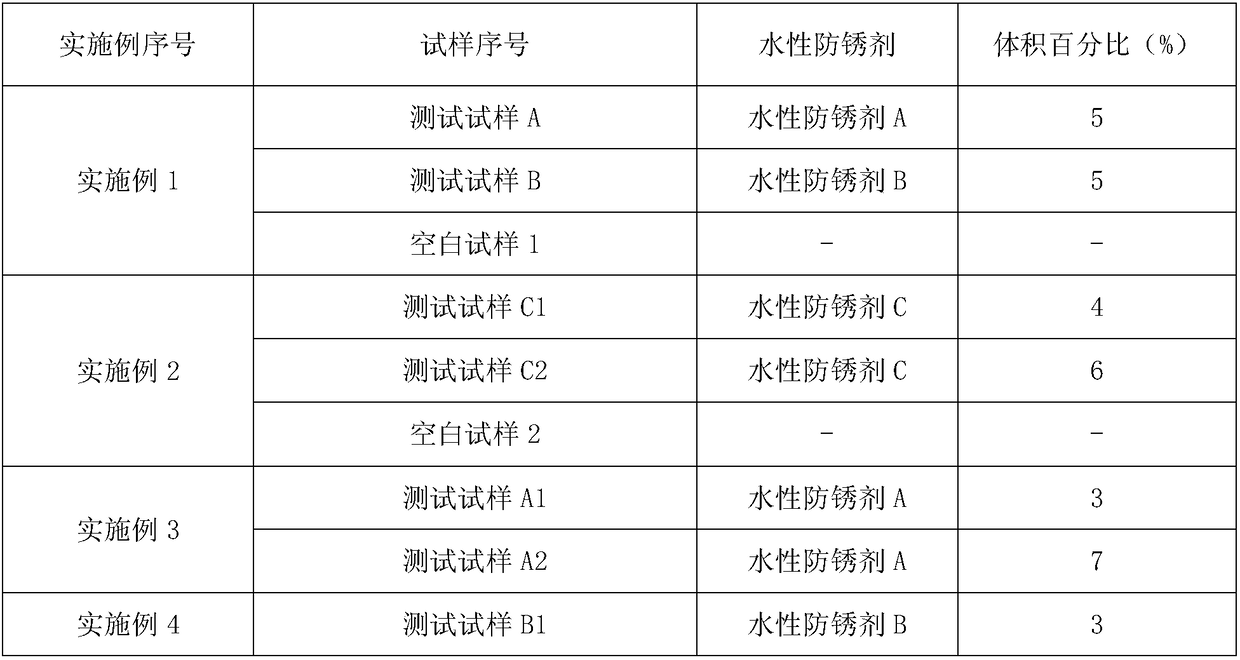

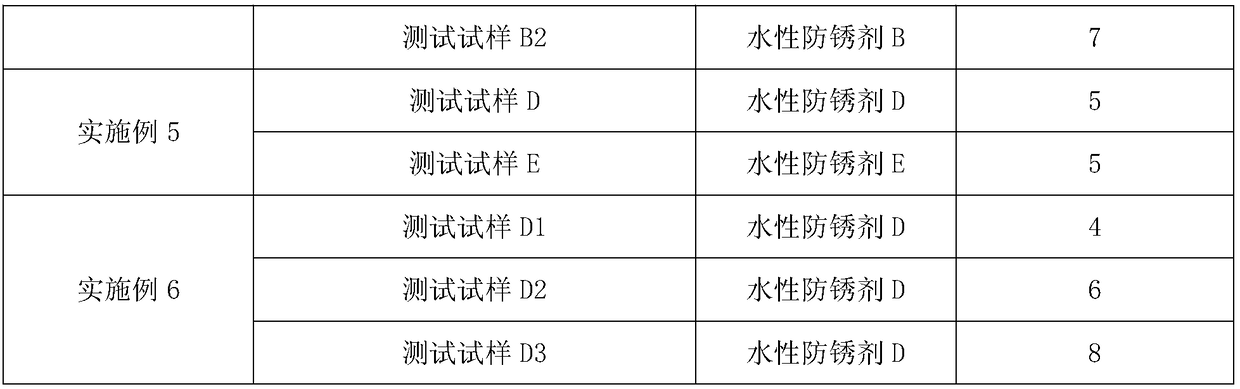

[0048] Embodiment 1-6 adopts following steps to test:

[0049] (1) Add the test solution into the test chamber, set the initial temperature in the test chamber to be 18-25°C, and set the initial relative humidity to 85-95%, keep the sample to be tested in the solution after 0.6-3h; wherein, The solution of embodiment 1-6 is according to the component distribution ratio listed in table 1, and the sample in embodiment 1-6 is made according to table 2, and every part of sample is prepared three pieces and tests;

[0050] (2) Set the temperature in the test chamber to be 18-25°C, and the relative humidity to be 85-95%, and keep it for 6-10h;

[0051] (3) Set the temperature in the test chamber to be 40-50°C, and the relative humidity to be 50-60%, and keep it for 3-5h;

[0052] (4) Set the temperature in the test chamber to be 40-50°C, and the relative humidity to be 70-80%, and keep it for 3-5h;

[0053] (5) Set the temperature in the test chamber to be 30-40°C, and the relativ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com