Temperature and humidity regulation and control system for box-type transformer station

A box-type substation and control system technology, applied in control/regulation system, non-electric variable control, simultaneous control of multiple variables, etc. Problems such as the normal operation of the line, to avoid the aging of the line, the structure is simple, and the effect of ventilation and heat dissipation is achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

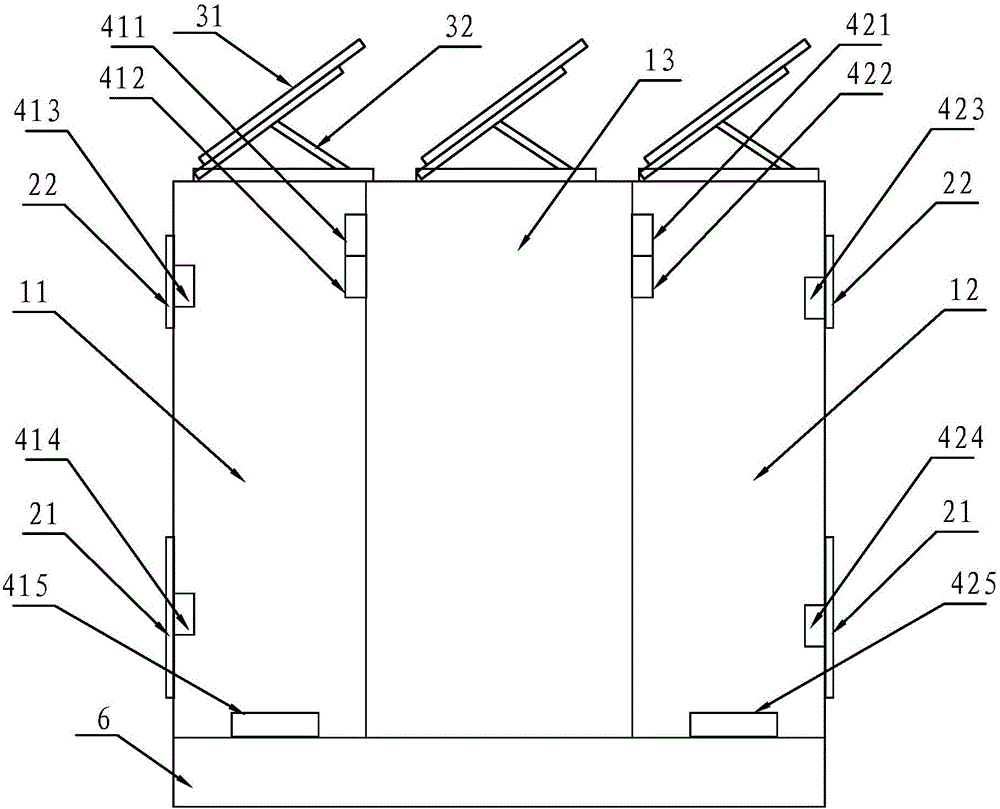

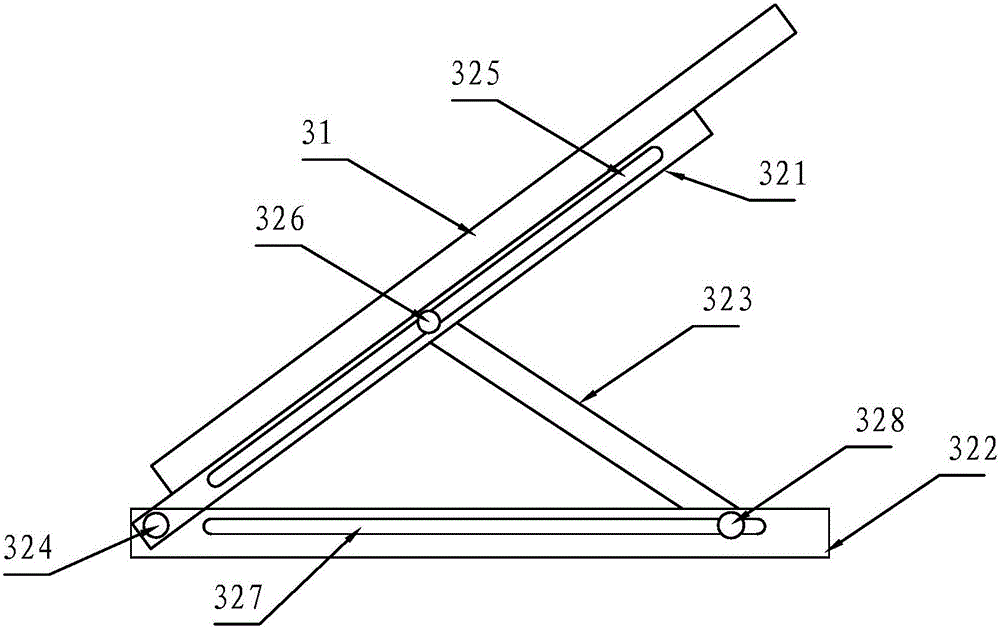

[0032] Such as figure 1 ,to Figure 4 As shown, a box-type substation temperature and humidity control system of the present invention, the box-type substation includes a high-voltage room 11, a low-voltage room 12 and a transformer room 13, the side walls of the high-voltage room 11 and low-voltage room 12 are respectively provided with Heat dissipation and ventilation structure; the temperature and humidity control system includes a temperature and humidity detection device, a controller, a cooling and dehumidification device and a power module, and the temperature and humidity detection device is arranged in the high pressure chamber 11 and the low pressure chamber 12 and is connected to the controller. The controller is connected with the cooling and dehumidifying device, and the cooling and dehumidifying device is set in the high-voltage chamber 11 and the low-voltage chamber 12, and the power module is a DC power supply, which provides working power for the humidity dete...

Embodiment 2

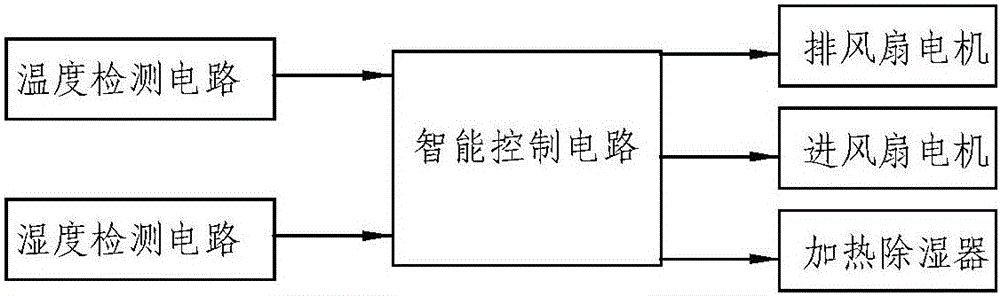

[0047] Such as figure 2 , Figure 5 , Figure 6 and Figure 7 As shown, the difference between Embodiment 2 and Embodiment 1 is that the temperature and humidity detection device includes a first temperature and humidity sensor 511 and a second temperature and humidity sensor 521, and the controller includes a processor installed in a high pressure chamber or a low pressure chamber and GPRS communication module, the cooling and dehumidification device includes a first exhaust fan 512, a second exhaust fan 522, a first heating dehumidifier 513 and a second heating dehumidifier 523, the first temperature and humidity sensor 511 is arranged in the high-pressure chamber, and the The second temperature and humidity sensor 521 is arranged in the low-pressure chamber, the first row fan 512 is arranged at the top plate 22 where the air in the high-pressure chamber flows out, and the second row fan 522 is arranged at the air flow out of the top plate 22 in the low-pressure chamber. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com