A Low Noise Switched Reluctance Motor

A switched reluctance motor, low-noise technology, applied in the direction of electric components, electrical components, electromechanical devices, etc., can solve the problems of poor rotor mass balance, high noise of brushed motors, and large vibration during high-speed operation, so as not to be easily displaced , improve the connection strength, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

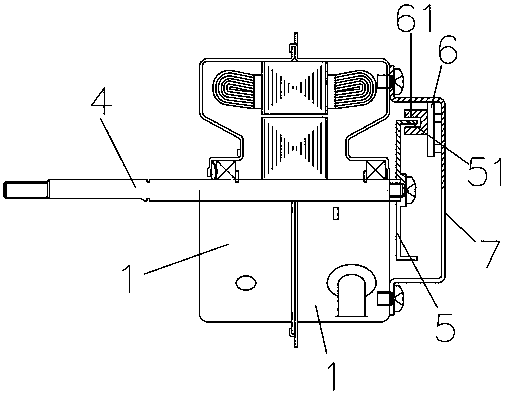

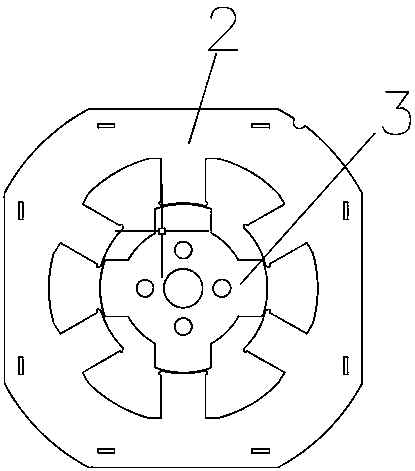

[0032] A low-noise switched reluctance motor includes an end cover 1, a stator 2 and a rotor 3 arranged in the end cover; the rotor is provided with a rotating shaft 4 connected to the end cover through a bearing, and one end of the rotating shaft protrudes from the end cover. The end cover forms an output shaft; the rotor includes a rotor body 32 and a number of teeth 31 surrounding the rotor body, and anti-vibration noise reduction blocks 81 are filled between adjacent teeth, and the anti-vibration noise reduction blocks pass through The connecting pieces located on the two end surfaces of the rotor are fixedly connected, and a reinforced engagement structure is arranged between the rotor and the anti-vibration noise reduction block.

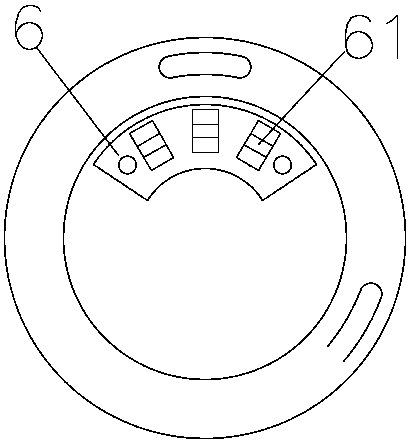

[0033] A sensing device is provided on the part protruding from the end cover at the other end of the rotating shaft; the sensing device includes a code disc having a code bar 5 detachably fixed on the rotating shaft, and a sensor 6 for sensing...

Embodiment 2

[0039] The difference from the above embodiment is that the rotor is provided with 8 teeth, and the code bars are corresponding 8 bars.

[0040]The rotor includes a tooth slot 33 surrounded by the adjacent teeth and the rotor body. The side of the groove and the bottom of the groove are respectively provided with an occlusal groove, the anti-vibration noise reduction block is provided with an occlusal rib 82 that fills the occlusion groove, and the outer side of the anti-vibration and noise reduction block and the outer side of the teeth are coaxial A circular arc surface with the same diameter, the connecting piece is a connecting plate 83 coaxially arranged with the rotor.

[0041] The occlusal slot is a closing slot with a slot width smaller than the inner width of the slot, and a plurality of anti-twist through holes 35 filled with anti-twist ribs 84 are formed on the upper edge of the rotor body perpendicular to the connecting plate. The two ends are respectively fixedly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com