A 24-slot 2-pole three-phase AC motor single-layer stator winding

A phase winding, single-layer and double-layer technology, applied in the shape/style/structure of winding conductors, electrical components, electromechanical devices, etc., can solve the problems of limiting motor efficiency and long copper wire length, etc., to improve motor performance, The effect of increasing the fundamental winding coefficient and reducing the harmonic winding coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

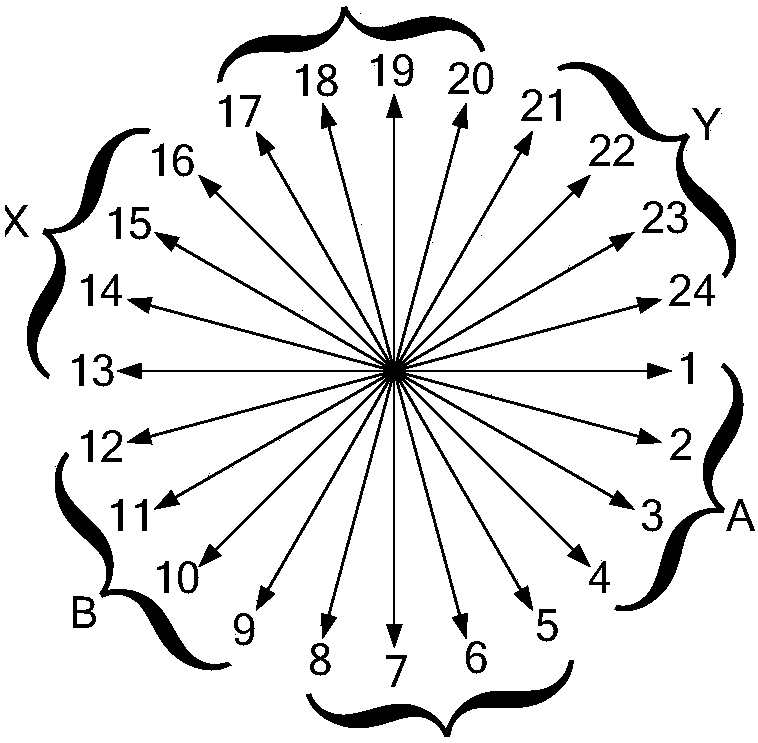

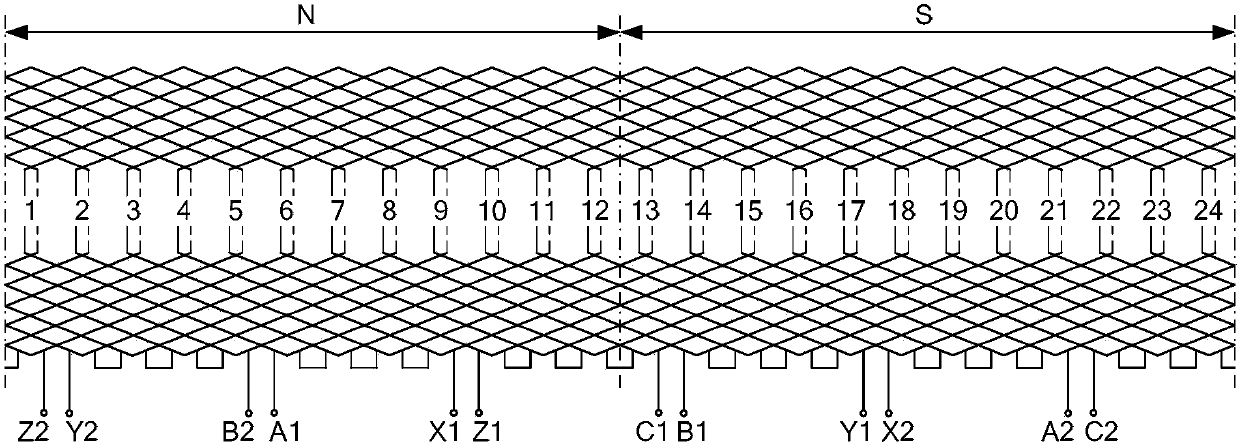

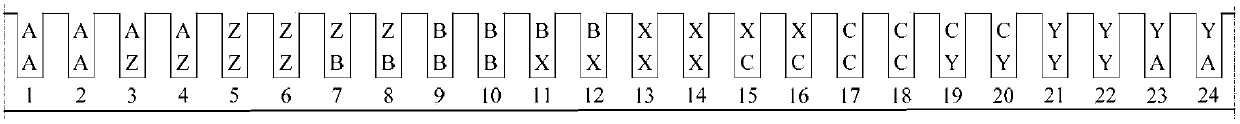

[0015] Such as Figure 5 As shown, the present invention proposes a 24-slot 2-pole three-phase AC motor stator winding with shorter winding ends, which can be applied to three-phase induction motors and three-phase AC synchronous motors.

[0016] The design idea of the stator winding of the 24-slot 2-pole three-phase AC motor of the present invention is evolved from the three-phase double-layer short-distance distributed stacked winding with a 24-slot 2-pole coil and an equal span of 10 slots. There are 4 coils each, and there are 2 adjacent slots in the positive and negative phase belts of each phase. The upper and lower coil sides of the coils in the 2 slots belong to the phase. While moving to the large slot number and shortening the end length, the lower coil in the large slot number is moving to the small slot number and shortening the end length. The coil span after moving 4 coils per phase is 9 slots, respectively Together with the unmoved coils of the 4 coil sides, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com