Machining clamp for work piece having taper hole and used in numerically-controlled machine tool

A technology of CNC machine tools and taper holes, which is used in manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve the problems of inconvenient clamping and unloading, cannot effectively improve production efficiency, etc. The effect of locating stress points and reducing wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

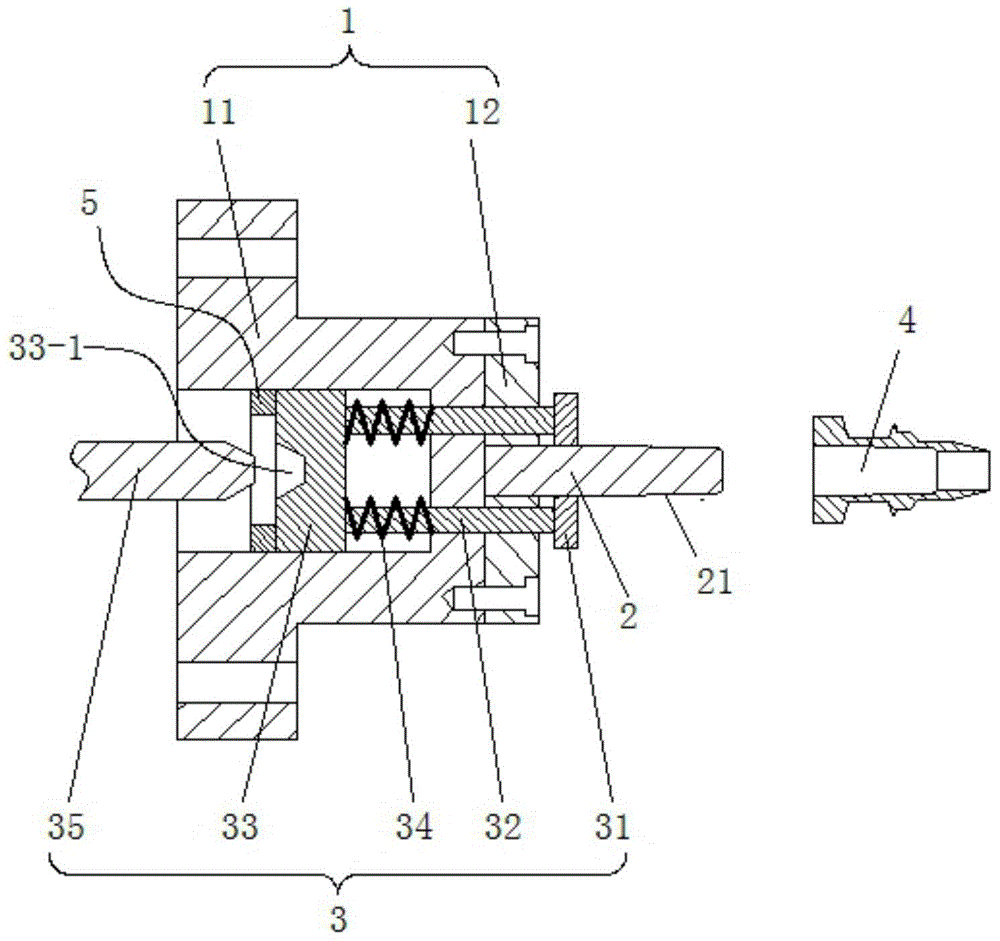

[0012] See figure 1 , the present invention has a clamp body 1, a clamping shaft 2 and an unloading device 3; the clamp body 1 includes a body 11 and a positioning mandrel 12, one end of the body 11 is provided with a connecting portion connected to the spindle of a CNC machine tool, and the other end is fixed A positioning mandrel 12 is installed, and the positioning mandrel 12 is coaxial with the CNC machine tool spindle; the center of the positioning mandrel 12 is provided with a connecting hole coaxial with it, and one end of the clamping shaft 2 is fixedly installed in the connecting hole and aligned with the positioning The mandrel 12 is coaxial, and the other end is provided with a self-locking tapered surface 21 matched with the tapered hole of the workpiece 4; the unloading device 3 includes a cylinder, an unloading plate 31, a push rod 32, a force block 33 and a return spring 34 The inside of the clamp body 1 is provided with a chute, and the force block 33 is slidab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com