Assembled temporary pavement

A prefabricated, pavement technology, applied in the direction of roads, roads, pavement details, etc., can solve the problems of increasing the control difficulty of energy conservation and emission reduction targets, the method or structure is not ideal, and can not meet the use, etc., to improve economic and social benefits, High construction efficiency and the effect of reducing waste of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

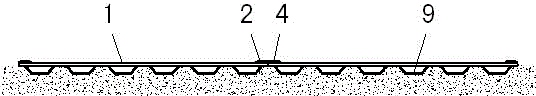

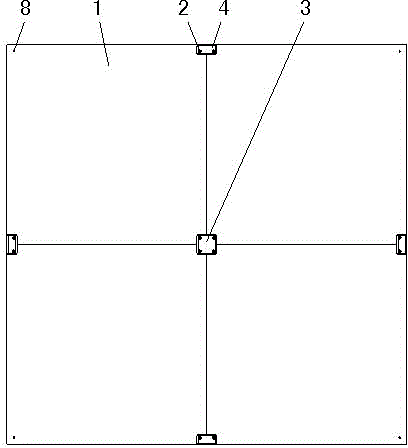

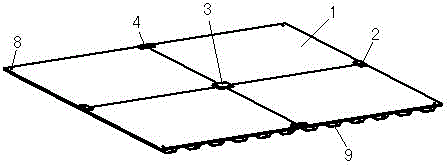

[0029] In this example, the detailed design is carried out through the mechanical analysis of the steel plate pavement, and a temporary steel plate pavement unit is designed according to the mechanical analysis. The pavement unit is composed of a group of parallel shock-absorbing and sound-absorbing strips welded to the bottom of a square steel plate with a thickness of 20mm and a side length of 2 meters. The shock-absorbing and noise-absorbing strip is a steel strip with a trapezoidal cross-section folded from a steel plate with a thickness of 6mm. A group of parallel shock-absorbing and noise-absorbing strips form a wave shape at the bottom of the steel plate. The elastic contact surface transmits the self-weight of the overpressure of the road surface and the load to the ground structure. On the one hand, it can prevent the deformation of the steel plate caused by the heavy pressure of the vehicle, and on the other hand, it can also control the displacement of the road sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com