Flush toilet

A toilet and flushing technology, applied in flushing toilets, water supply devices, flushing equipment with water tanks, etc., can solve the problems of water flying out of the toilet, forming an inner edge, and lowering the height of the inner edge, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

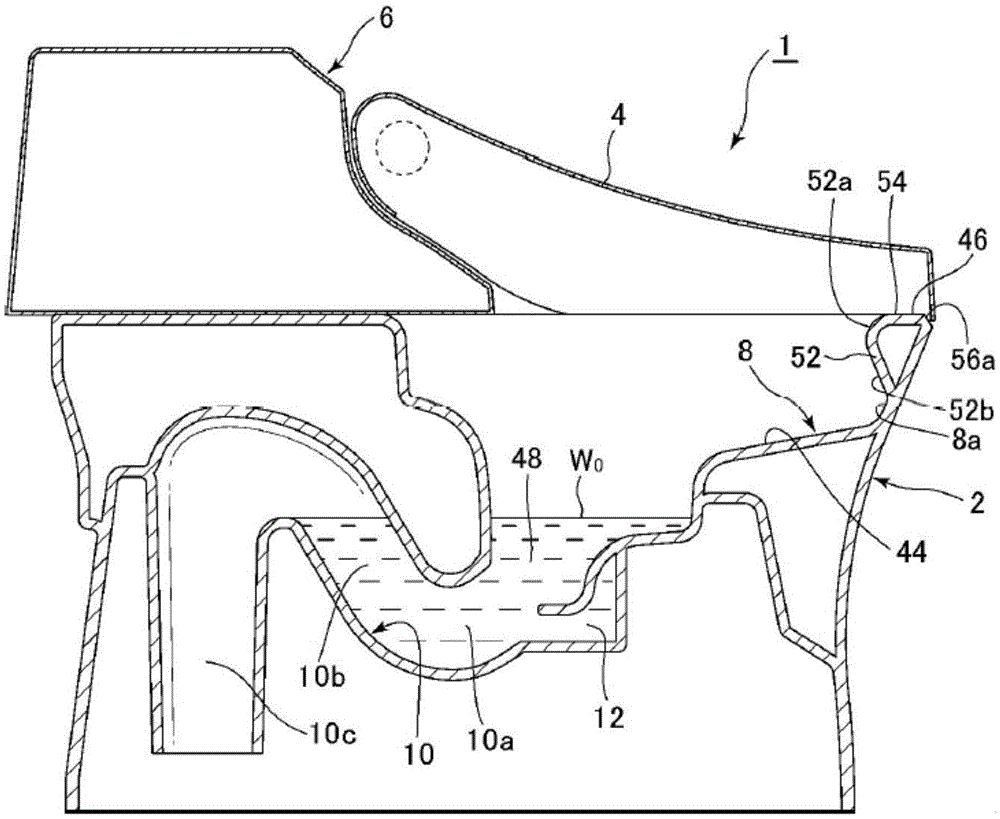

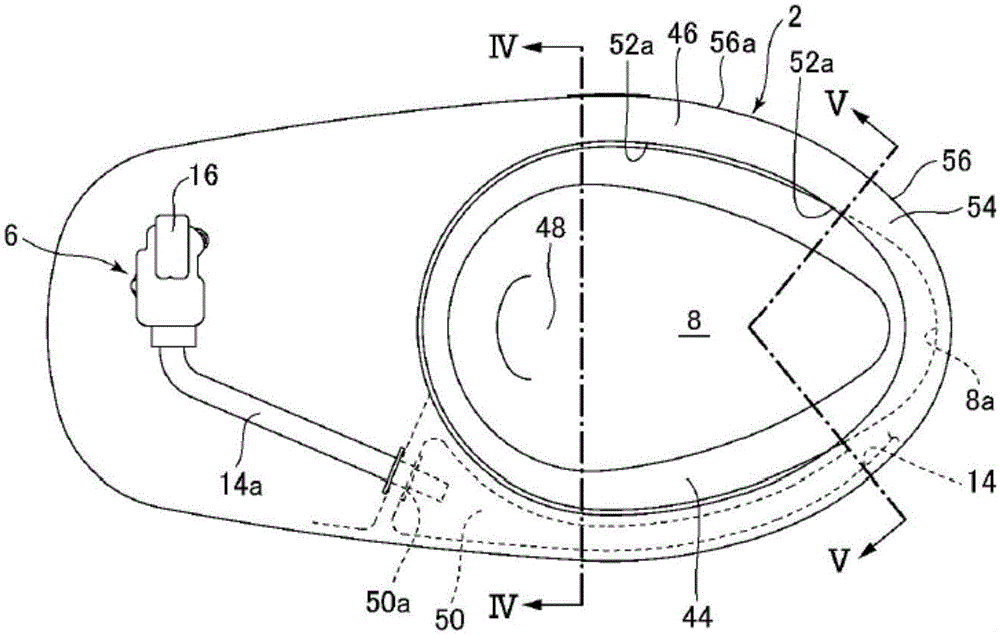

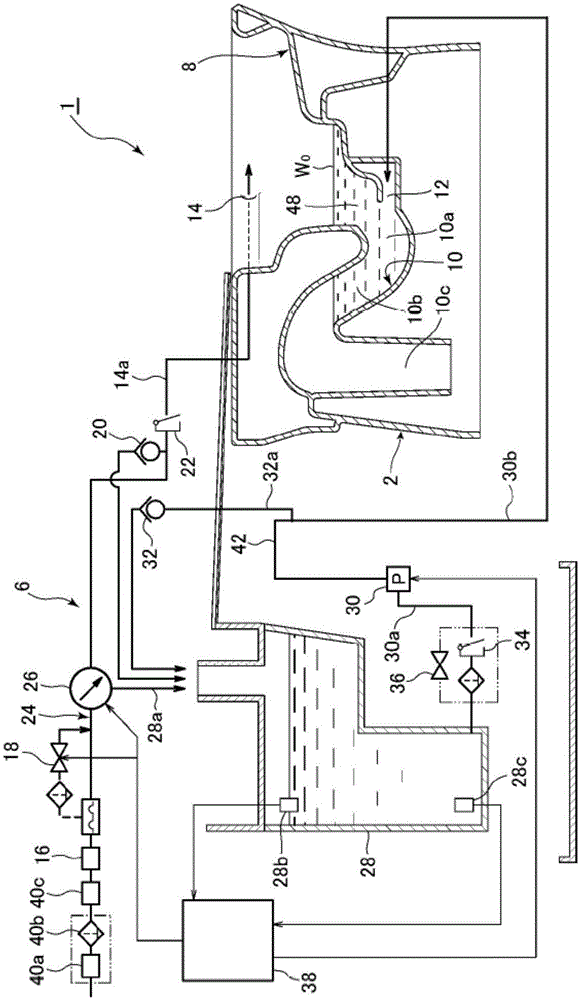

[0045] Next, a flush toilet according to an embodiment of the present invention will be described with reference to the drawings.

[0046] First, through Figure 1 to Figure 3 The structure of the flush toilet according to the first embodiment of the present invention will be described. here, figure 1 It shows the state of the water supply device and the lid of the flush toilet according to the first embodiment of the present invention viewed from the side, and is a partial cross-sectional view showing the inside of the toilet body along the central section, figure 2 It is a schematic plan view showing a state where a cover and a part of the water supply device are removed from the flush toilet according to the first embodiment of the present invention, image 3 It is an overall configuration diagram showing the flush toilet according to the first embodiment of the present invention.

[0047] Such as figure 1 and figure 2 As shown, the flush toilet 1 according to the fi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap