Vertical axis wind power generation device

A wind power generation device, vertical axis technology, applied in wind turbines, wind turbine combinations, wind turbines at right angles to the wind direction, etc., can solve the problems of low blade performance, shortened service life, deformation of blades or blade frames, etc. Achieve the effect of improving power generation efficiency, increasing work capacity, and high wind energy utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] The present invention will be further described with reference to the accompanying drawings.

[0008] The contribution of the invention lies in slowing down the speed of the blade frame rotation, increasing the time for the wind to act on the curved surface of the blade, and solving the long-standing problem that the power generation efficiency decreases when the wind speed is high.

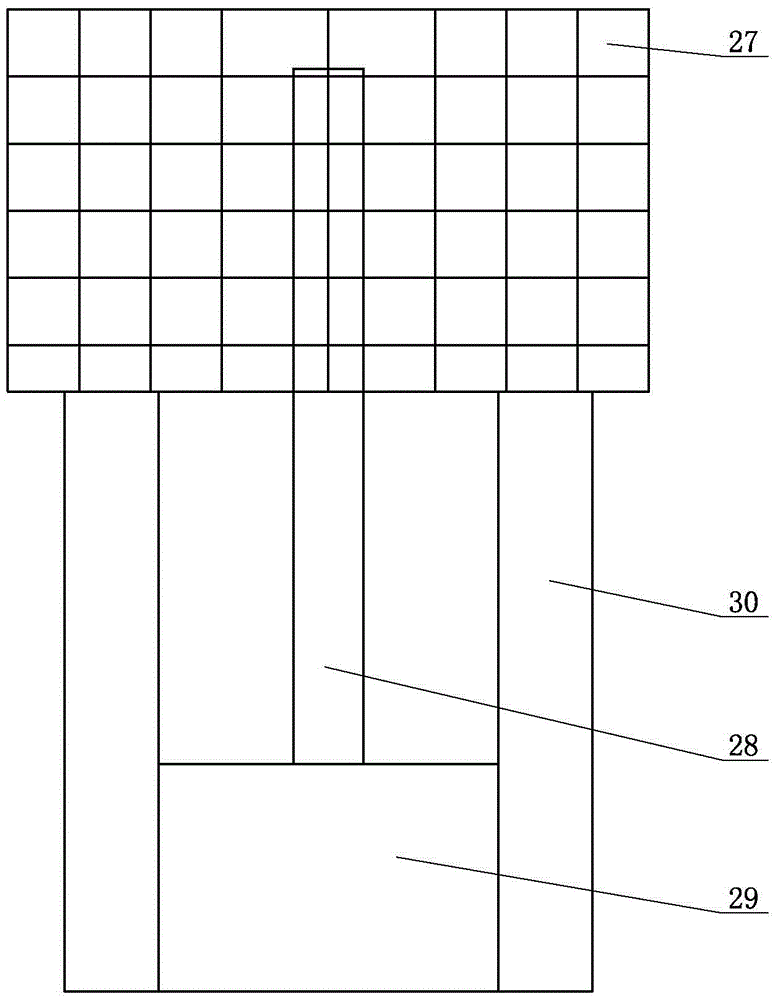

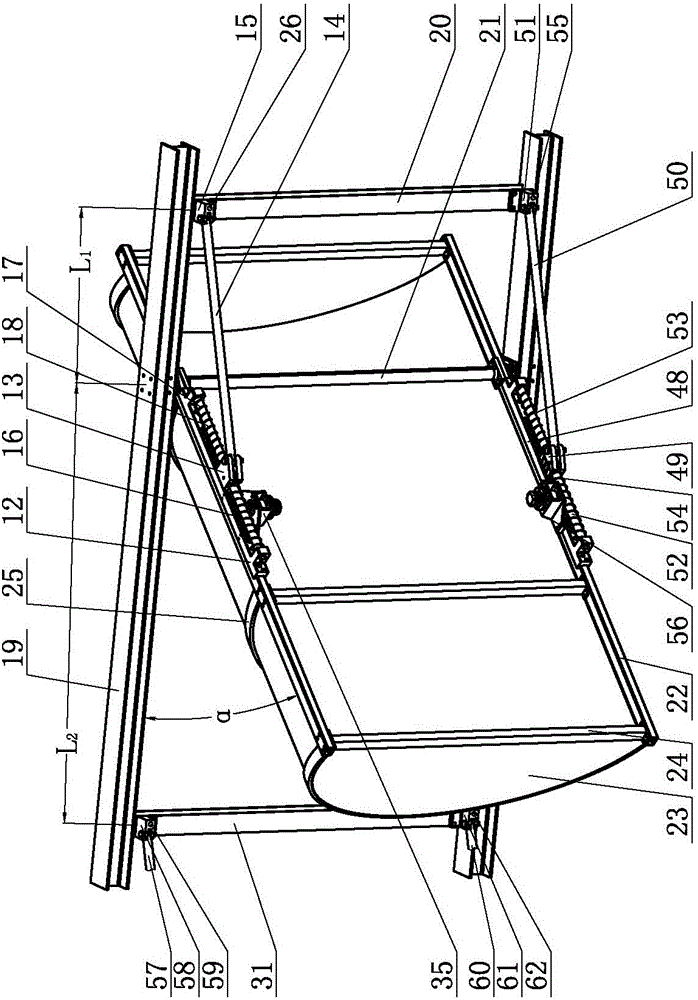

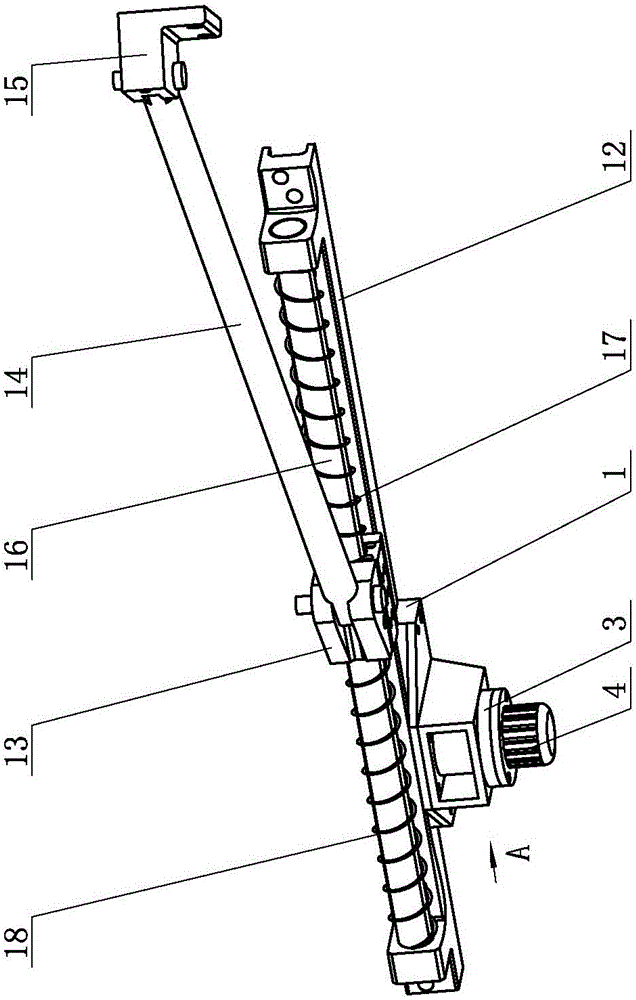

[0009] The technical solution provided by the present invention is: a vertical axis wind power generation device, including a tower frame 30, the tower frame 30 is connected with the rotating shaft 28 through a fixing piece, the lower part of the rotating shaft 28 is connected with the generating mechanism 29, and several rotating shafts are installed on the rotating shaft 28. Leaf frames 19, corresponding leaf frames 22 are respectively installed on each leaf frame 19, the leaf frames 22 are connected with the blades 23, the first support plate 20 is located at the right end of the leaf fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com