A full-circle LED light tube

A technology of LED lamps and lamps, which is applied in the direction of light sources, light source fixation, semiconductor devices of light-emitting elements, etc., can solve problems such as high temperature, reduced LED light efficiency, and greatly compressed heat dissipation space, etc., to achieve normal work extension, Avoid long-term heating and facilitate line maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

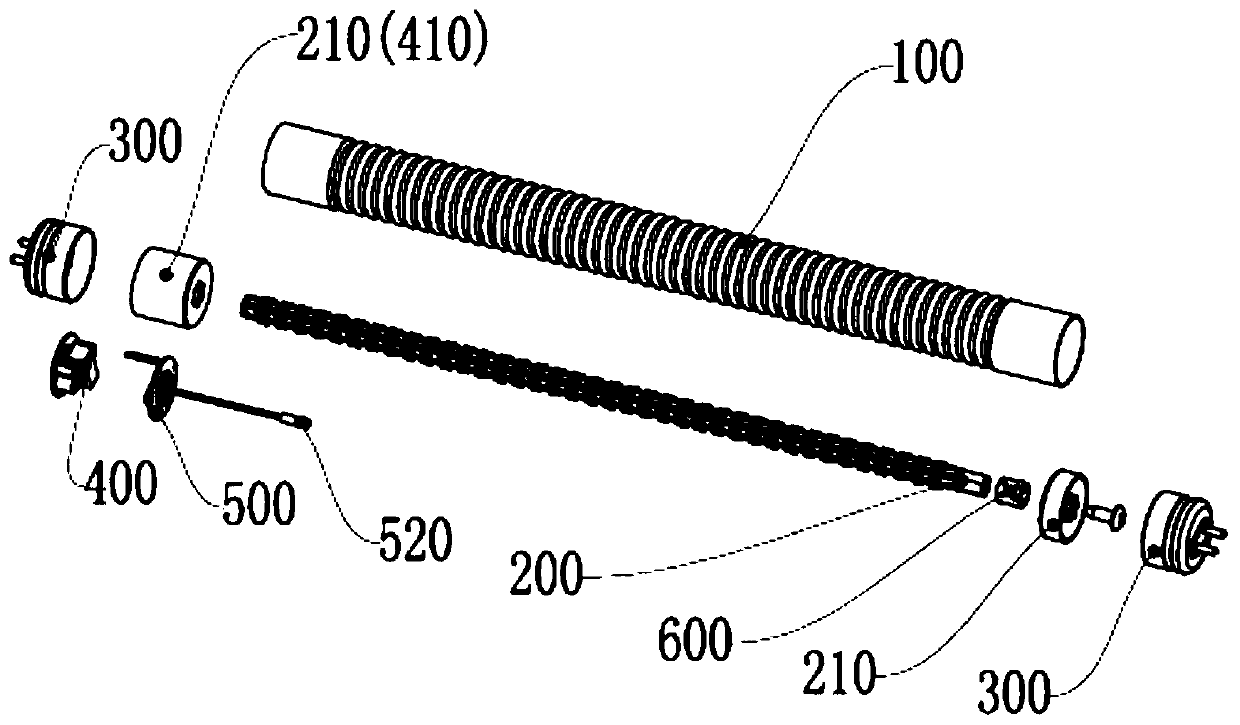

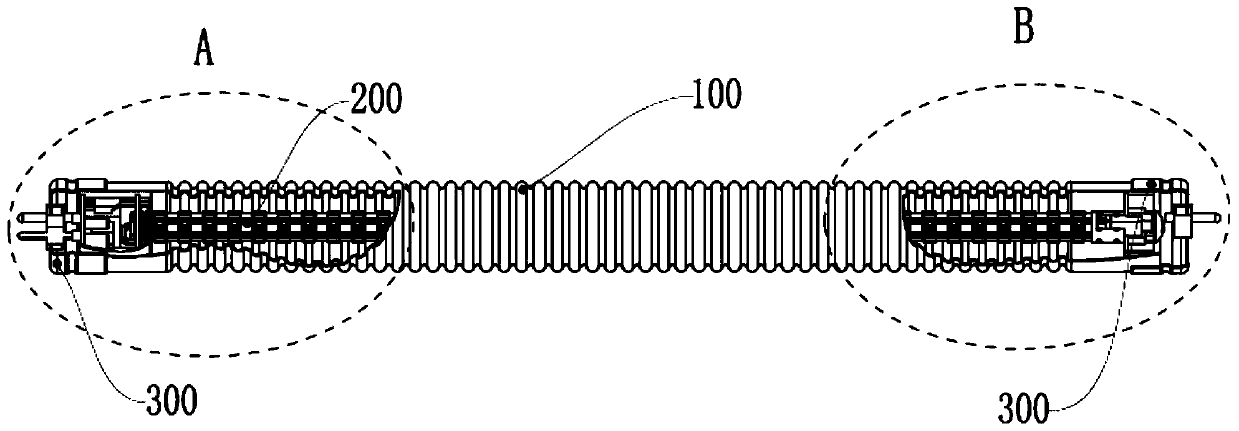

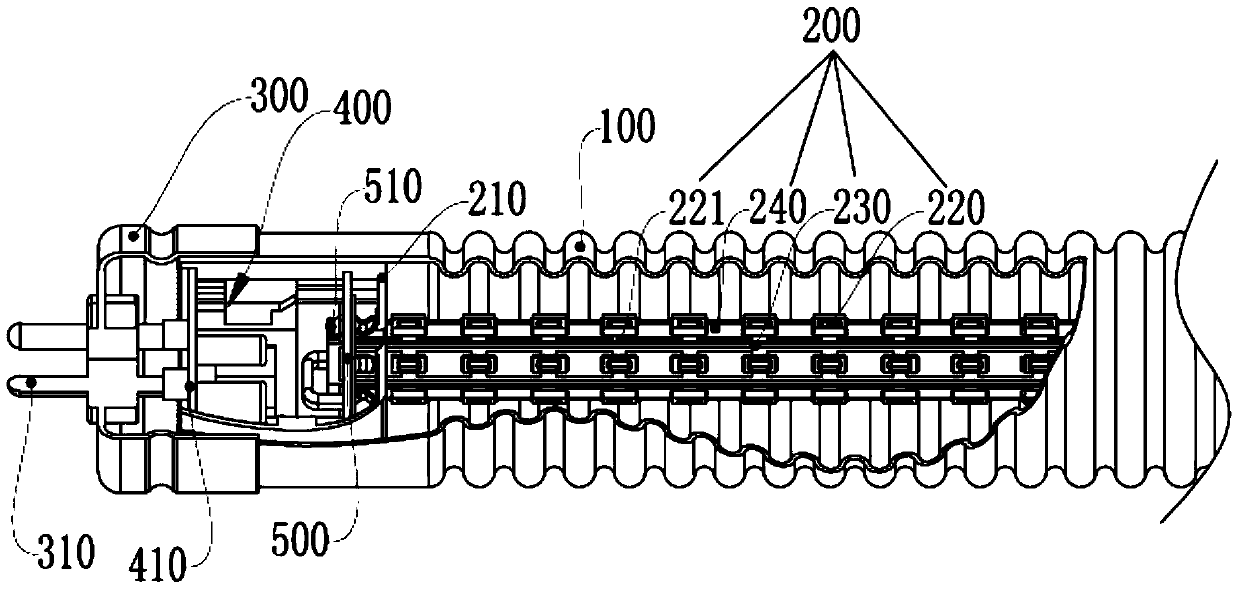

[0028] Such as Figure 1-7 As shown, a full-circle light LED lamp, the full-circle light lamp tube is composed of a lamp tube shell 100, a wick 200 installed inside the lamp tube shell 100, and end caps 300 connected to both ends of the lamp tube shell 100; The shell 100 is in the shape of a circular tube with both ends connected. The lamp shell 100 is a corrugated tube. The two ends of the lamp shell 100 are provided with a wick holder 210 for fixing the wick 200, and one end is provided with a driving circuit assembly 400. The drive circuit assembly 400 is connected to one end of the wick 200, the wick 200 is in the shape of a polygonal column, and a number of LED chips 220 are uniformly arranged on the surface of the prism, and the two ends of the wick 200 are fixed on the wick holder 210 so that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com