Oil-proof and dragging-resistant coiled control cable

A control cable and anti-drag technology, applied in the direction of insulated cables, communication cables, bendable cables, etc., can solve the problems of insufficient tightness of the cable insulation core structure, affecting the normal use of the cable, and the breakage of the central insulation core, etc., to achieve The structure is tight, ensuring stability, and has the effect of tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

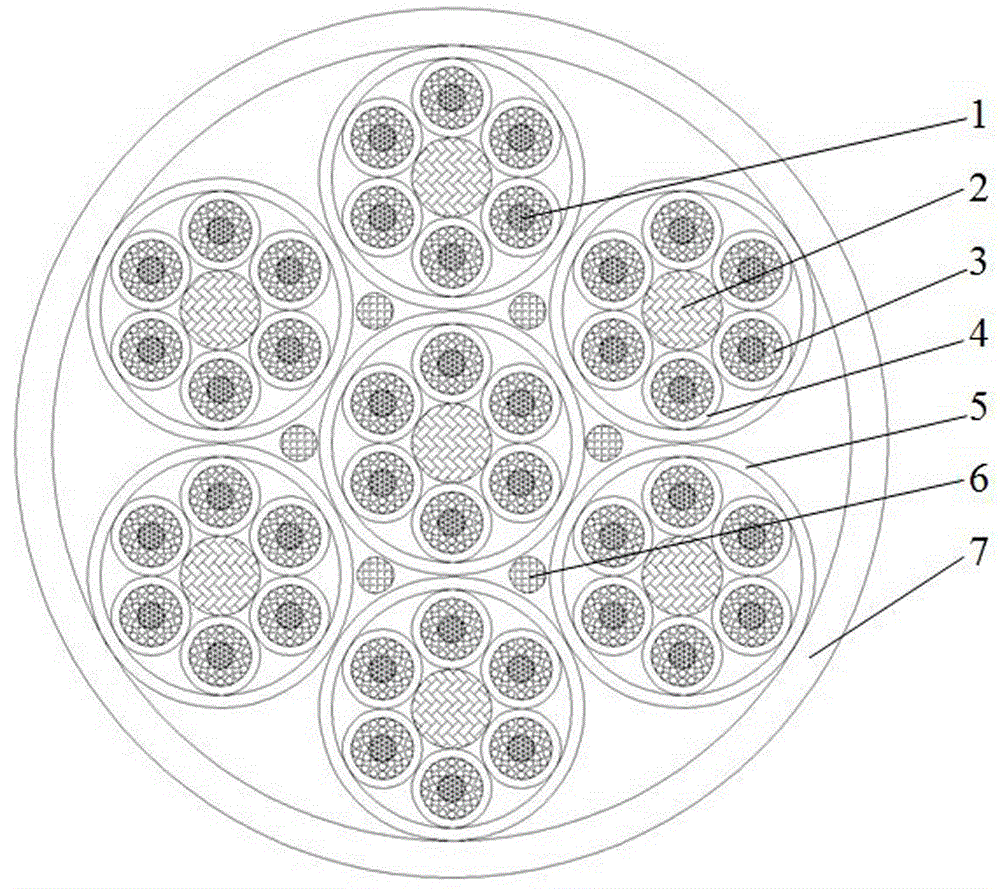

[0026] refer to figure 1 , is a specific structure of the oil-resistant and drag-resistant reel control cable of the present invention. specific:

[0027] Firstly, first use the tinned copper single wire 3 of no more than 0.3 mm to be wound on the cotton support rope 1 to make a tinned copper wire conductor; extrude the insulating layer 4 around the tinned copper wire conductor to make a tinned copper wire conductor. Copper wire insulated core.

[0028] Then, a cotton load-bearing rope 2 and 6 tinned copper wire insulated wire cores are twisted to form a control wire core group, in which the cotton load-bearing rope 2 is located in the center; and a layer of inner sheath is tightly extruded outside the control wire core group 5. Make the cable core.

[0029] Then, a total of 7 cable core groups are arranged in two layers according to the arrangement of 1+6. Among them, 6 cotton-filled ropes 6 are braided outside the cable core placed in the center; and the cotton-filled rop...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com