A cable structure capable of high-speed rotation

A technology of cable structure and high-speed rotation, applied in the direction of insulated cables, cables, circuits, etc., can solve problems such as cable wear, large rotation radius, and wear or break of each layer of the cable structure, to prevent deformation, avoid stress concentration, and good durability abrasive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below in conjunction with the accompanying drawings of the description.

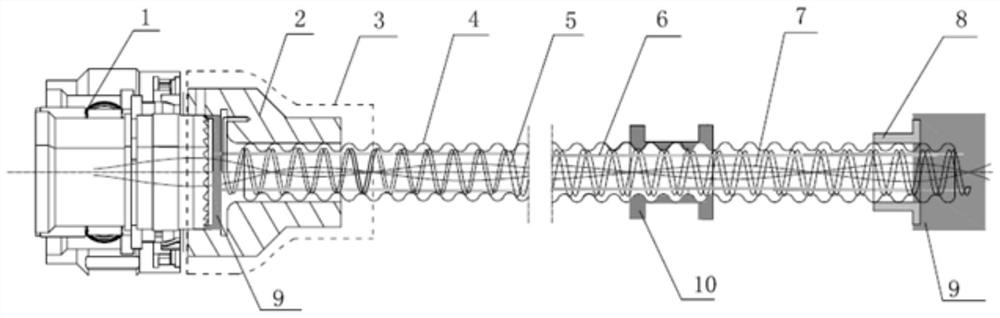

[0017] Such as figure 1 As shown, a high-speed rotating cable structure includes an outer sheath 4, a spring 5 located in the outer sheath 4, an aramid braided sheath 6, and a wire harness 7. One end of the cable is fixed inside the rotating part by a rubber ring 8, It is connected with the internal transmission line of the component, and the other end is fixed with the tail accessory 2 through a spring hook, and the plug 1 is connected with other components to transmit electric energy. Among them, both ends of the cable are fixed with adhesive 9 to fix the spring 5, aramid braided sleeve 6, and wire harness 7, and the tail part 2 is protected by a heat-shrinkable sleeve 3, and the middle position of the cable can be fixed with a heat-shrinkable coil 10.

[0018] The outer sheath 4 adopts a polytetrafluoroethylene spiral tube or a heat-shr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com