A prefabricated thin thermal insulation composite exterior wall, structural system and construction method thereof

A technology of thermal insulation composite and composite wall panels, which is applied in the direction of walls, building components, building structures, etc., can solve the problems of surface thickness and durability, achieve the effects of reducing thickness, small hoisting load, and improving integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

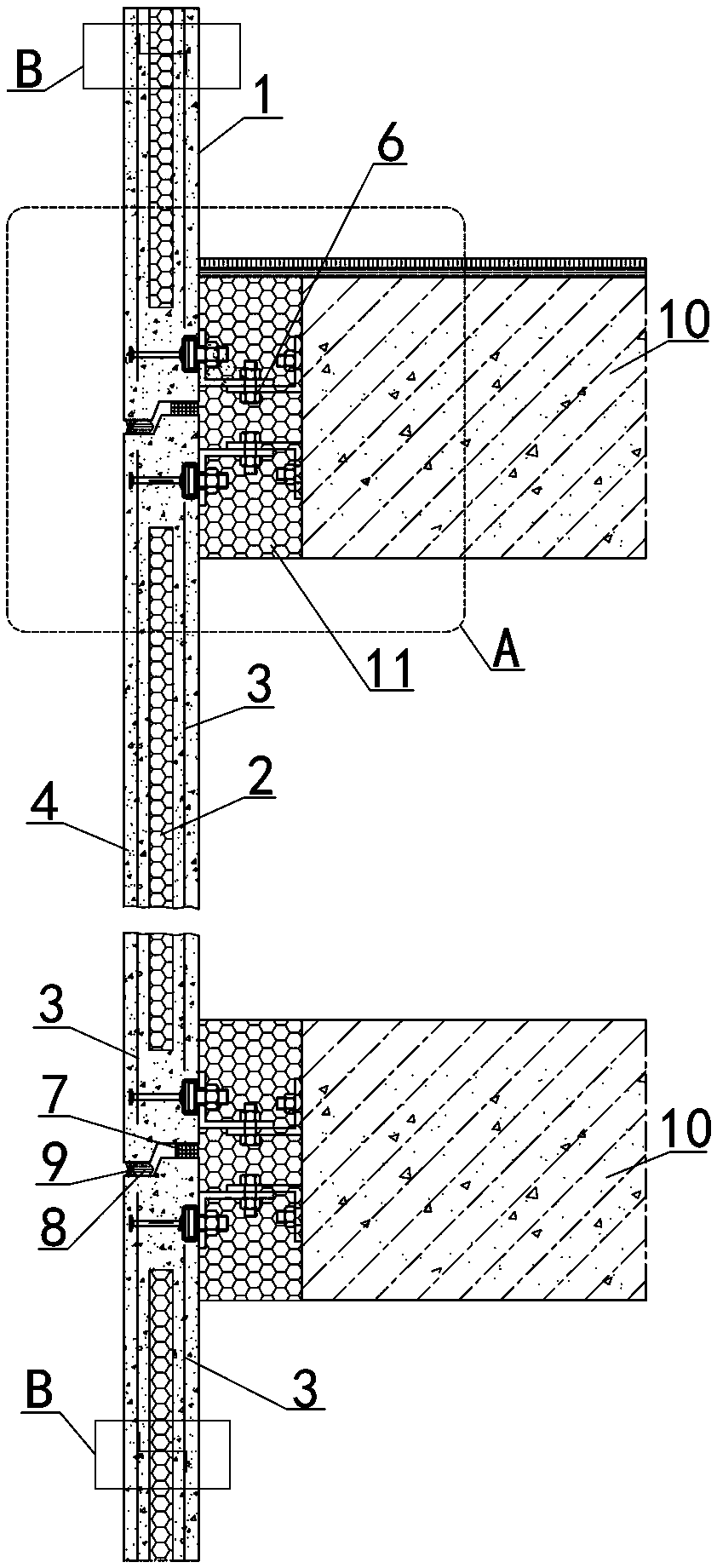

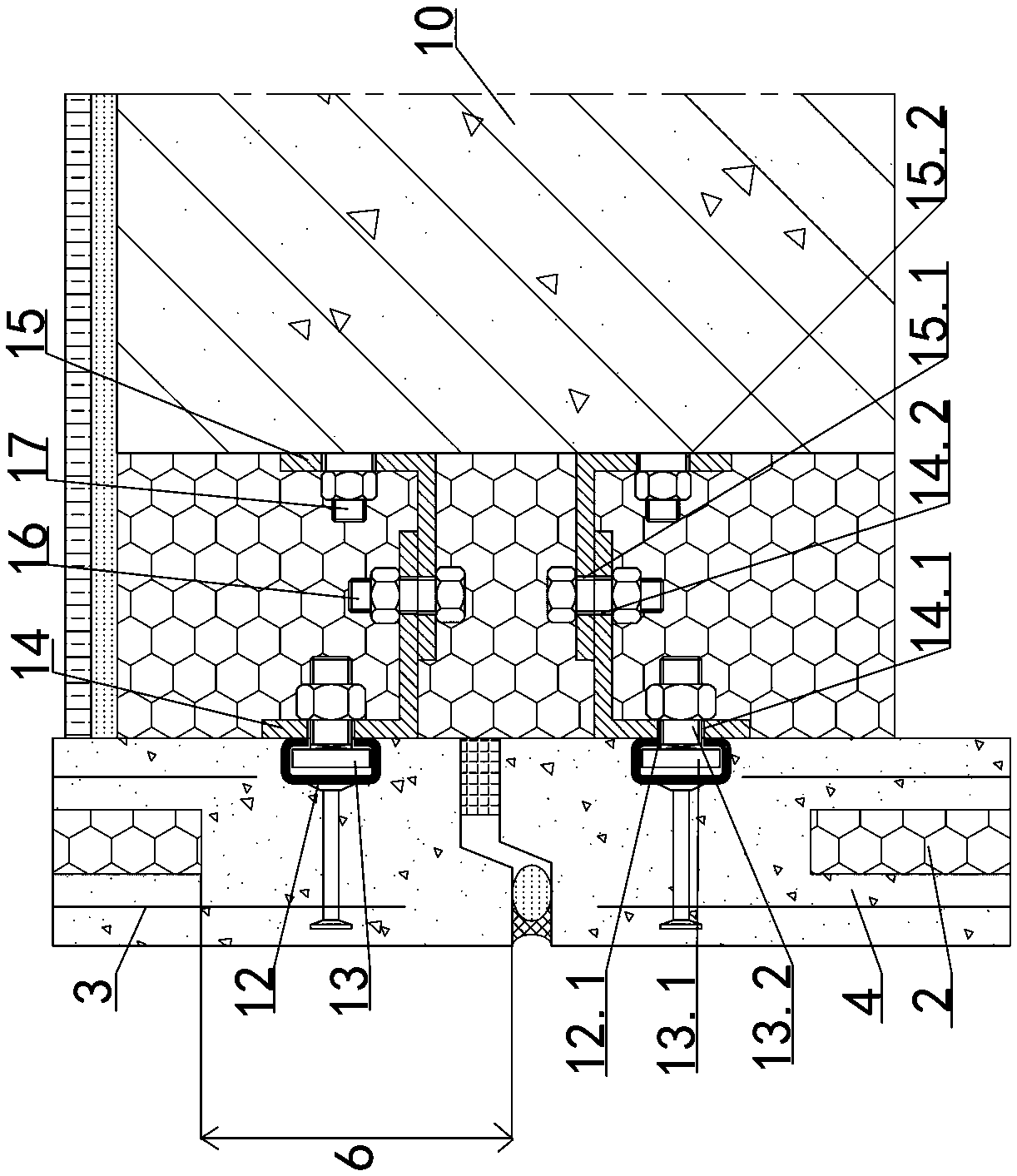

[0047] Embodiment one sees Figure 1-2 As shown in , 4, the prefabricated thin thermal insulation composite exterior wall is arranged on the outside of the upper and lower two-story structural beams. The joint is located on the outside of the structural beam, and the sandwich composite wallboard should include panel 1, insulation layer 2, steel wire mesh 3, concrete 4 and wallboard tensile flexible connector 5;

[0048] The heat insulation layer 2 is a vacuum heat insulation core board, and the vacuum heat insulation core board is disconnected at least one place inside the sandwich composite wallboard and is discontinuously arranged; in this example, the discontinuously arranged area 6 is arranged in the middle of the sandwich composite wallboard upper end and lower end. This arrangement locally limits the relative sliding of the concrete layers. The discontinuous setting area 6 is set at the upper end and the lower end of the sandwich composite wallboard, that is, the part ...

Embodiment 2

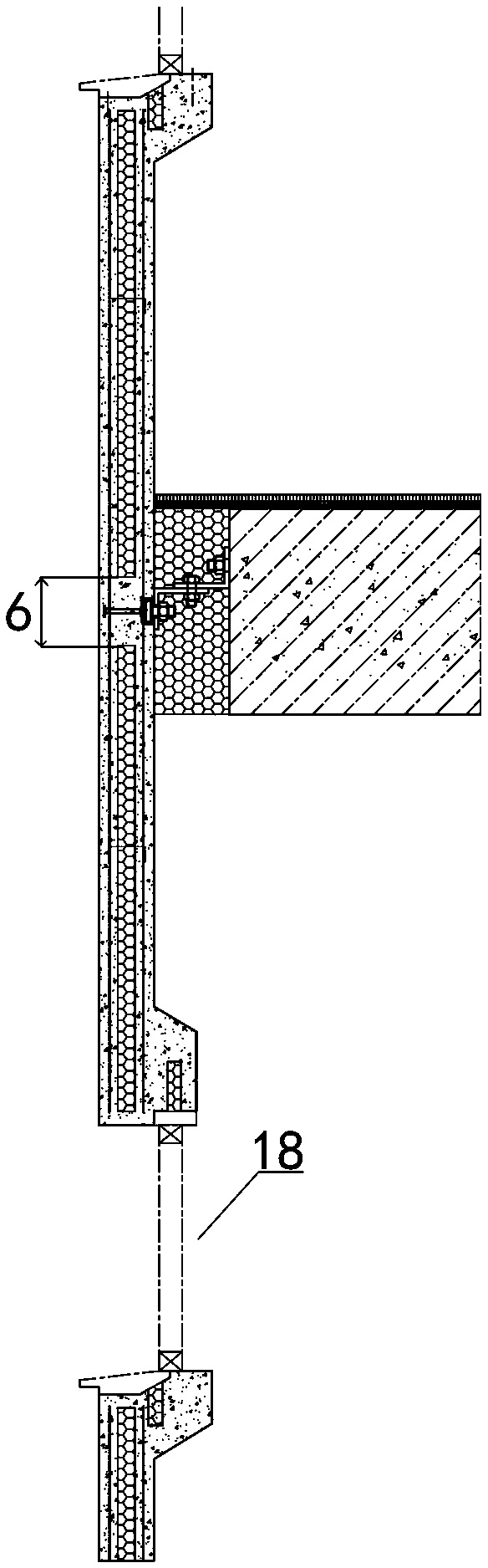

[0067] Embodiment two see image 3 As shown, the difference from the first embodiment is that the non-continuous setting area 6 is set in the middle of the sandwich composite wall panels, and door and window openings 18 are set between the upper and lower adjacent sandwich composite wall panels.

[0068] Construction method step of the present invention is as follows:

[0069] Step 1. Prefabricate the prefabricated thin thermal insulation composite exterior wall in the factory, pre-embed the groove type embedded parts 12 in the wall, and at the same time fix the first connecting angle steel 14 and the prefabricated thin thermal insulation composite exterior wall through the pre-embedded supporting bolts 13;

[0070] Step 2. If the horizontal structural member 10 is a concrete member, the second connecting bolt 17 needs to be pre-embedded in the designated position of the horizontal structural member 10 during pouring or factory prefabrication. After the concrete of the horizon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com