Bottom oven

A bottom plate and furnace shell technology is applied in the field of metallurgical melting and casting aluminum furnaces, which can solve problems such as waste of electric energy, and achieve the effects of reducing power consumption, uniform thermal deformation, and uniform stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

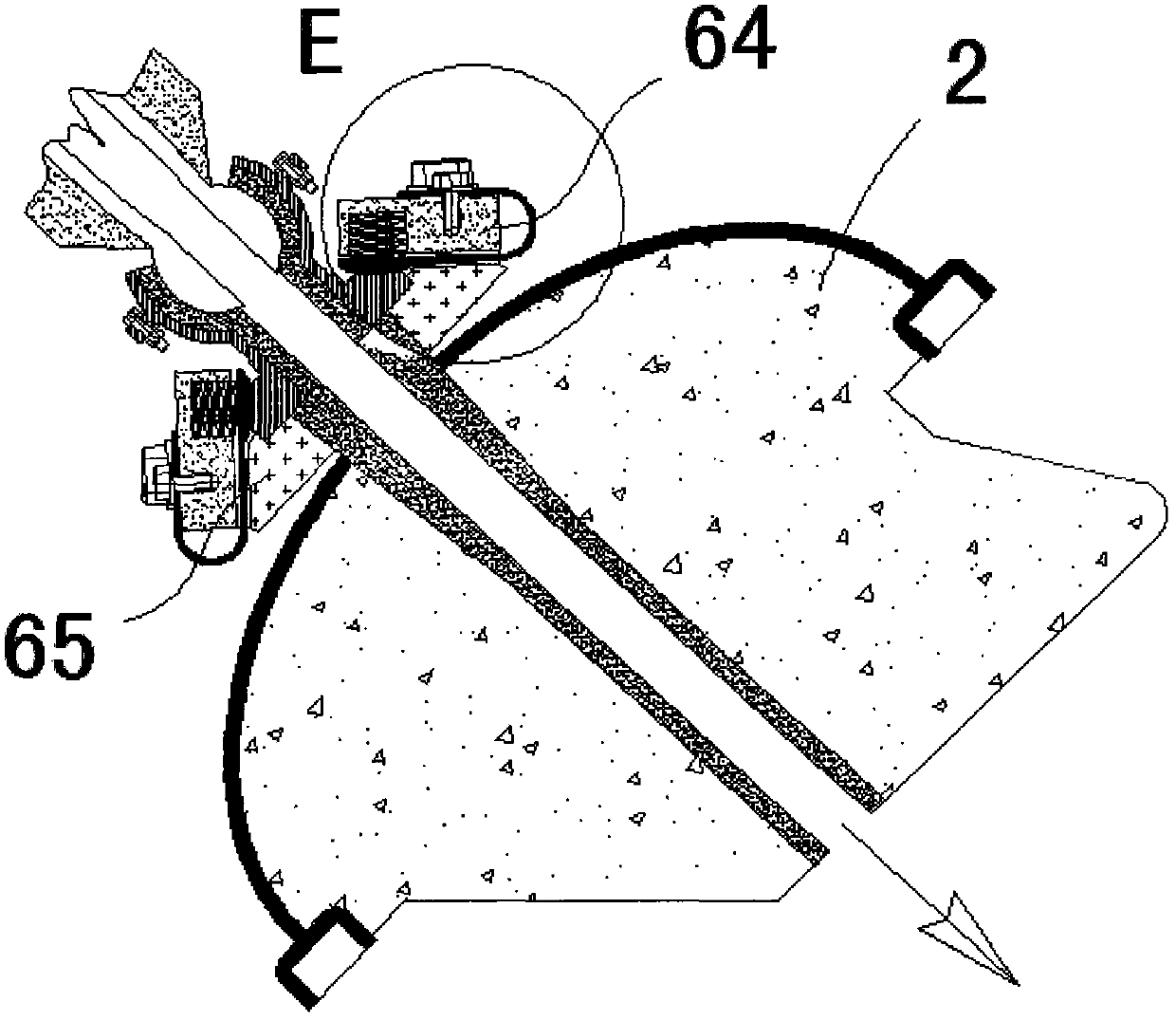

[0047] attached figure 1 Shown is the general configuration of the invention.

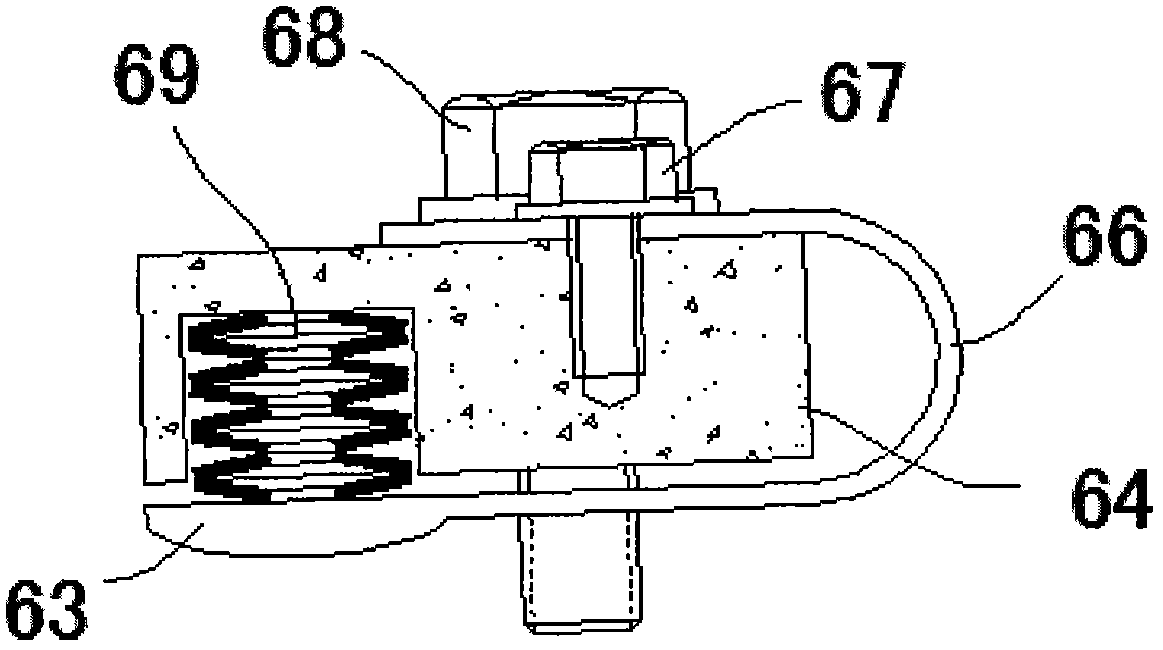

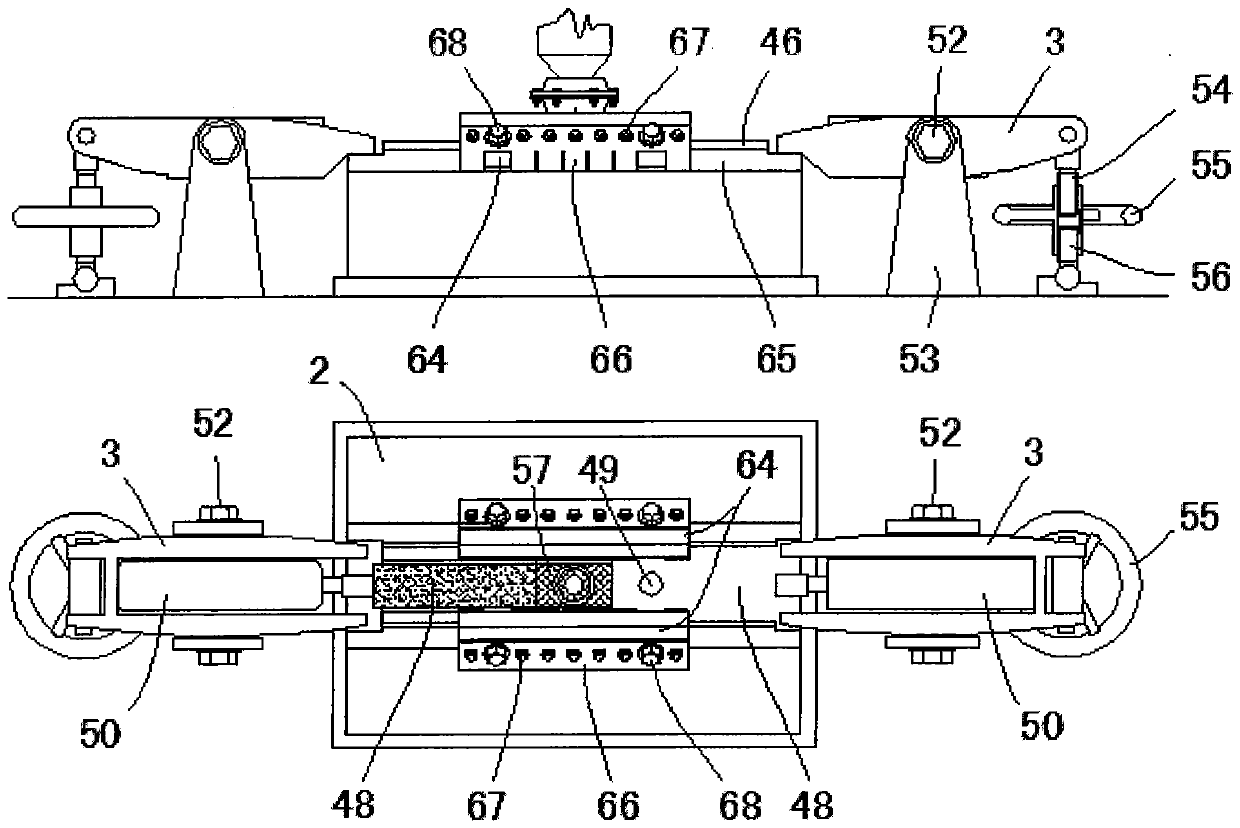

[0048] attached Figure 2-4 Shown is the gate valve configuration.

[0049] In the furnace, insert or pull out the joint slide plate 57 in the slideway 46 of the gate valve 1, the joint slide plate 57 is provided with a ball head socket, and the ball head part connected to the door pipe 51 is movably installed in the ball head socket, and the ball head is mounted on the ball head The door pipe 51 in the nest has a section connected to the aluminum liquid level 37 installed in the transfer tank 7; the two ends of the slideway 46 of the door valve 1 are respectively equipped with oil cylinders 50, and the two oil cylinders 50 push the blind plate 48 in opposite directions, and the blind plate 48 indirectly Push joint slide plate 57, push joint slide plate...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap