External oil type metal corrugated expansion oil conservator

An oil conservator and metal technology, applied in the field of compensation devices, can solve the problems of oil pollution, inability to complete synchronization, stuck, etc., to avoid stuck, easy installation and disassembly, and easy monitoring.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings.

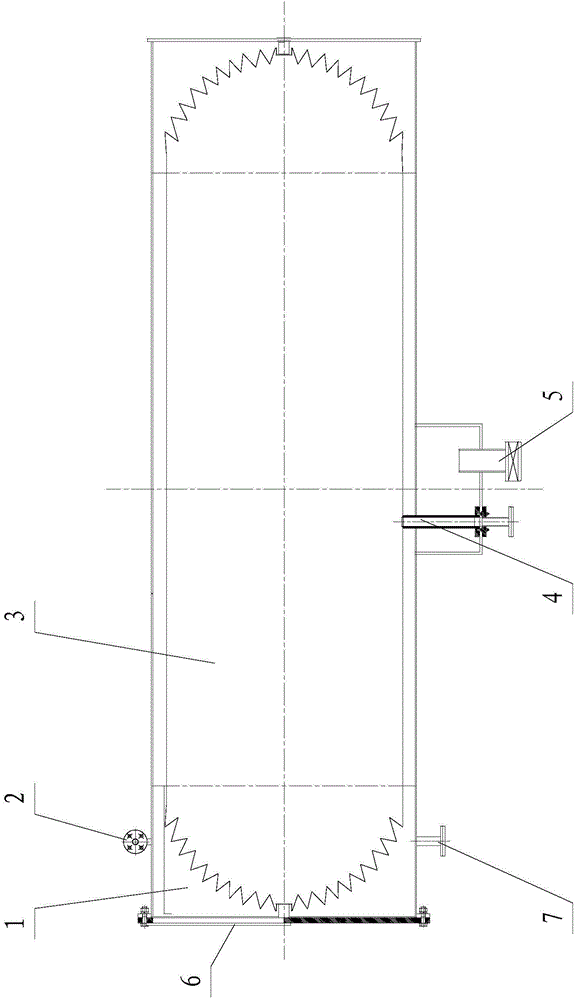

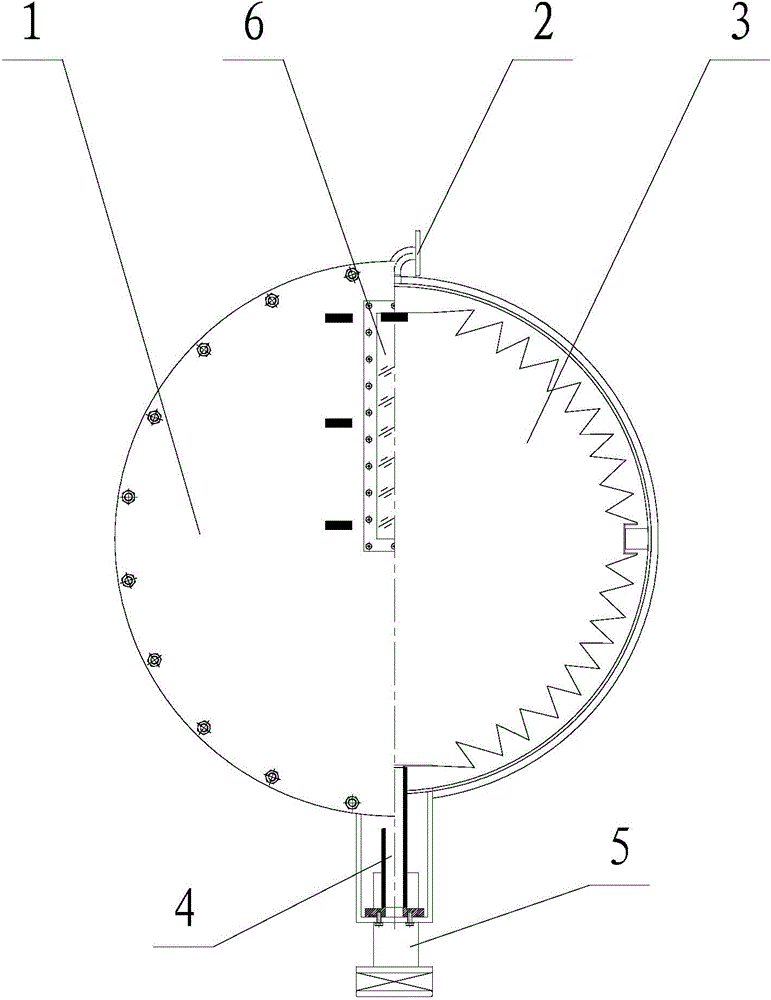

[0018] Such as figure 1 , figure 2 As shown, the present invention includes a cabinet body 1 and a metal corrugated expansion body 3 installed in the cabinet body 1, wherein the middle diameter of the metal corrugated expansion body 3 is greater than the diameters at both ends, that is, the diameter of the metal corrugated expansion body 2 is along the axial direction Indent from the middle to both ends.

[0019] In order to facilitate disassembly and assembly, the metal corrugated expansion body 3 in this embodiment is divided into two upper and lower parts with the same shape, and each metal corrugated expansion body 3 is a diameter-reducing structure, that is, the diameter shrinks from one end to the other end; The two metal corrugated expansion bodies 3 are arranged up and down, and the metal corrugated expansion body 3 located at the bottom is set ups...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com