A transformer spiral winding cable arrangement

A spiral type and transformer technology, applied in the field of transformer manufacturing, can solve the problems of power supply company and user loss, endanger personal and property safety, impact on power supply network, etc., achieve the effect of reducing the probability of burning, simple structure, and free position adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

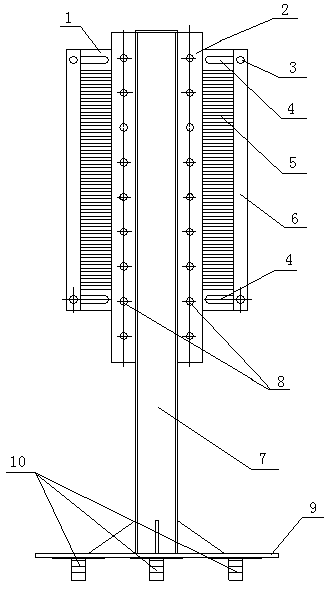

[0011] Such as figure 1 As shown, this embodiment includes a threading board 1 , a wire blocking board 6 , an adjusting board 2 and a bracket 7 . Both ends of the threading plate 1 are provided with 32 equidistant threading slots 5 and four retaining lines symmetrically distributed relative to the central vertical axis (48, 40, 24, etc. can also be set as required in multiples of 4) Plate installation elongated holes 4. The strip holes 4 are located on the upper and lower edges of the threading board 1 . The upper and lower ends of the left and right middle positions of the threading plate 1 are provided with four mounting holes of the regulating plate. The adjusting plate 2 is welded and fixed on the support 7, on which two rows of vertical fixing holes 8 are opened. The threading plate 1 is fixed on the adjusting plate 2 by screws to adju...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com