Method for manufacturing OLED module having heat dissipation function, and heat dissipation structure

A manufacturing method and heat dissipation structure technology, applied in the field of OLED modules, can solve the problems of affecting heat conduction, lack of thermal conductivity, unfavorable heat dispersion, etc., and achieve the effect of rapid and uniform dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

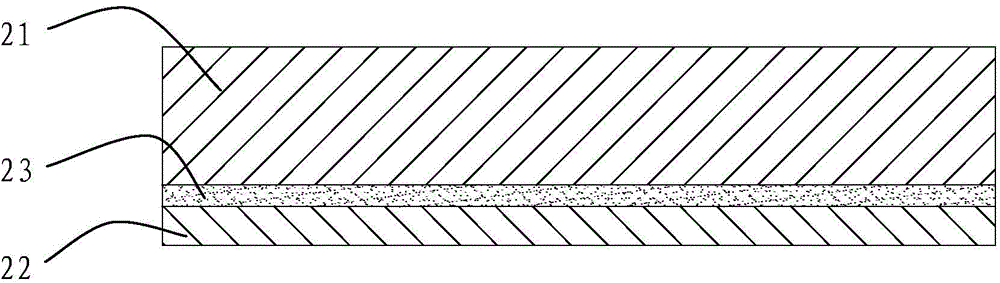

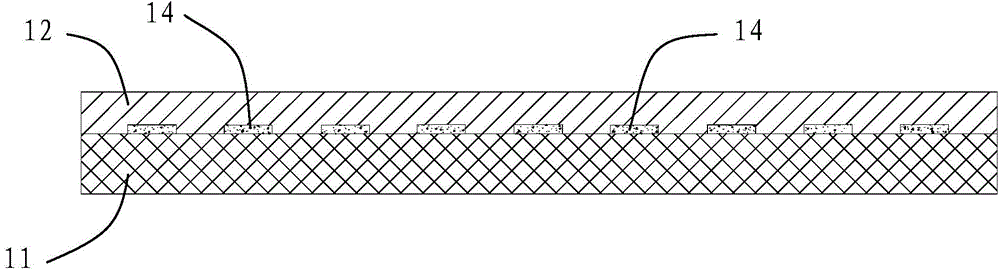

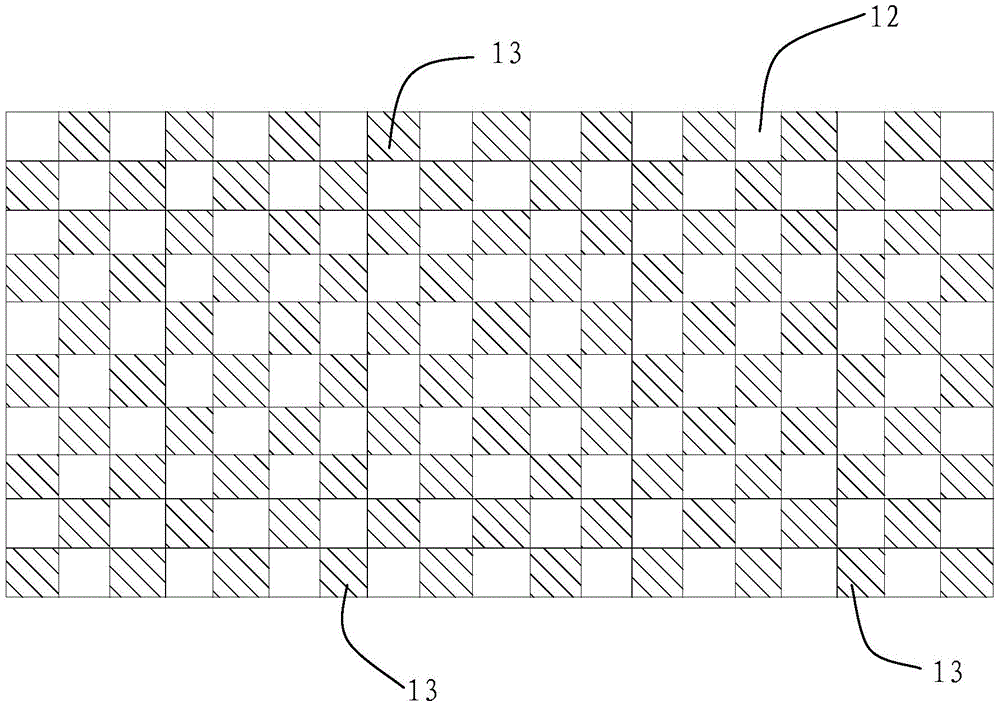

[0026] The organic light emitting device (Organic Light Emitting Diode, referred to as OLED) module generates more heat, so it is necessary to attach a heat dissipation material on the back of the OLED module to distribute the heat evenly across the entire back of the OLED module. Avoid many defects such as abnormal display of OLED modules caused by excessive local aging. At present, considering the heat dissipation performance and cost, it is generally adopted to attach a heat dissipation film on the back of the OLED module. Since the heat dissipation film itself is not sticky, the heat dissipation film must be attached to the OLED module through an adhesive. On the back, however, the adhesive does not have thermal conductivity and is a heat-resistant material, so the presence of the adhesive will adversely affect the heat conduction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com