High-speed motor rotor based on segmented magnetic steel and variable cross-section shaft

A high-speed motor with variable cross-section technology, which is applied to the rotating parts of the magnetic circuit, the shape/style/structure of the magnetic circuit, etc., can solve the problem of the difficulty of ensuring the coaxiality of the rotor runout accuracy, the deformation of the permanent magnet, the fracture, and the extreme requirements of the assembly tooling. Advanced problems, to achieve the effect of good rigidity, high positioning accuracy and convenient assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

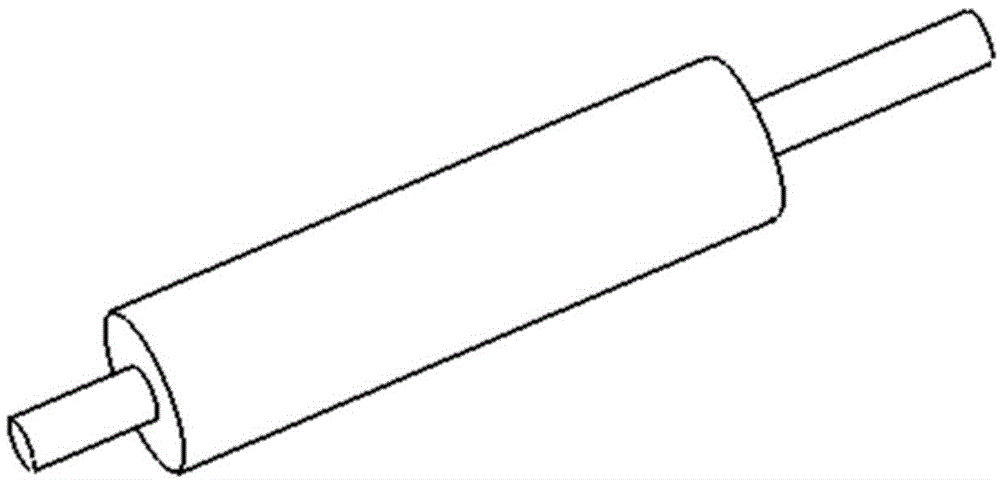

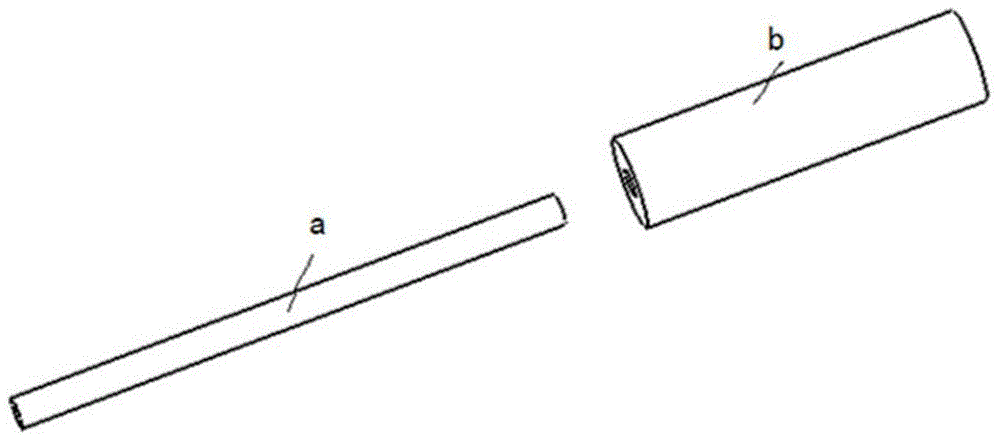

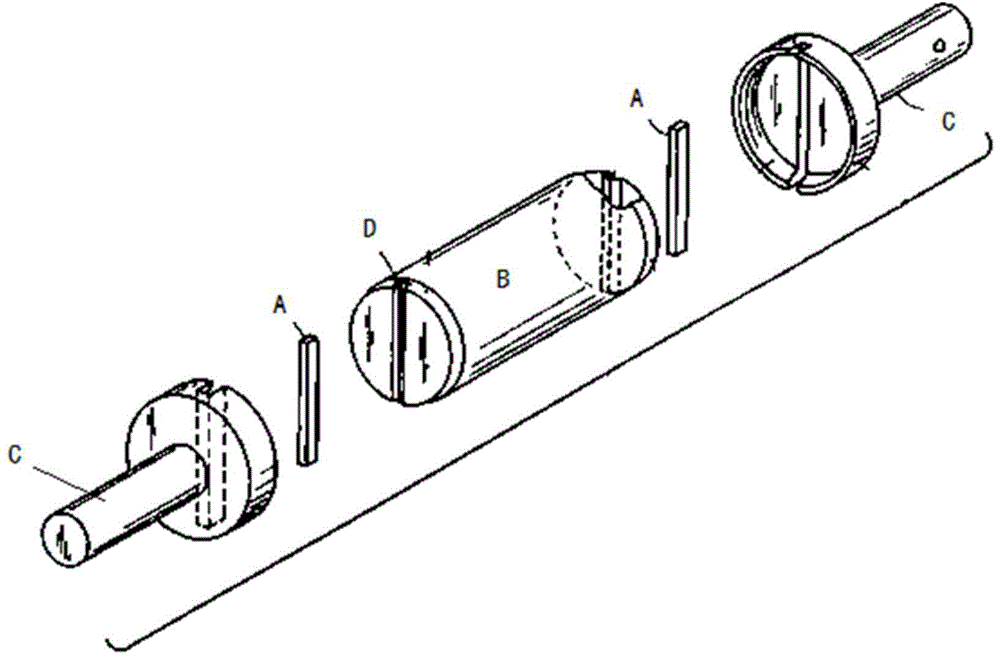

[0030] Such as Figure 4 and 5 As shown, the high-speed motor rotor based on segmented magnets and variable-section shafts includes three segments of magnets 1, 3, and 4 and a stepped shaft 2. The stepped shaft 2 is inserted into each segment of magnets 1, 3, and 4 in sequence, and each segment of magnets The steel is provided with a matching shaft hole corresponding to the stepped shaft 2, and the thick end of the stepped shaft 2 is used as the output shaft end. The stepped shaft 2 is fixed to each section of magnetic steel by glue, and the adjacent magnetic steels are not adhered to each other.

[0031] From Figure 7 It can be seen that the through-shaft structure adopts a piece of magnetic steel, and the shaft section of the shaft section mated with the optical shaft is subjected to the same torque and load T, and the shaft diameter of the entire shaft section is required to be the same as the place where the bending moment is the largest (the bearing support of the dang...

Embodiment 2

[0034] Such as Figure 8 As shown, the rotor of the present invention includes a section of magnetic steel and a stepped shaft, and the rest are the same as in Embodiment 1.

Embodiment 3

[0036] Such as Figure 9 As shown, the rotor of the present invention includes two sections of magnetic steel and a stepped shaft, and the rest are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com