An air-cooled turbogenerator wind path structure

A steam turbine generator and air path technology, applied in the magnetic circuit shape/style/structure, cooling/ventilation device, electromechanical device, etc., can solve the problem of excessive rotor temperature rise, brush carbon powder floating around, and pollution of the operating environment, etc. problem, to achieve the effect of uniform cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

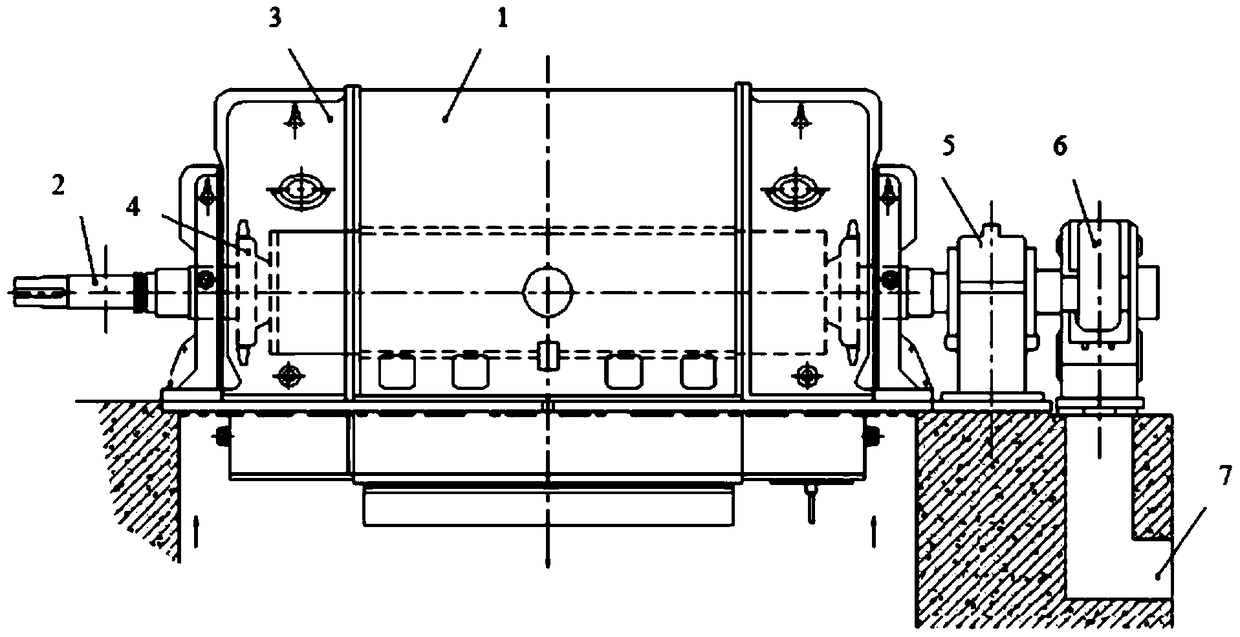

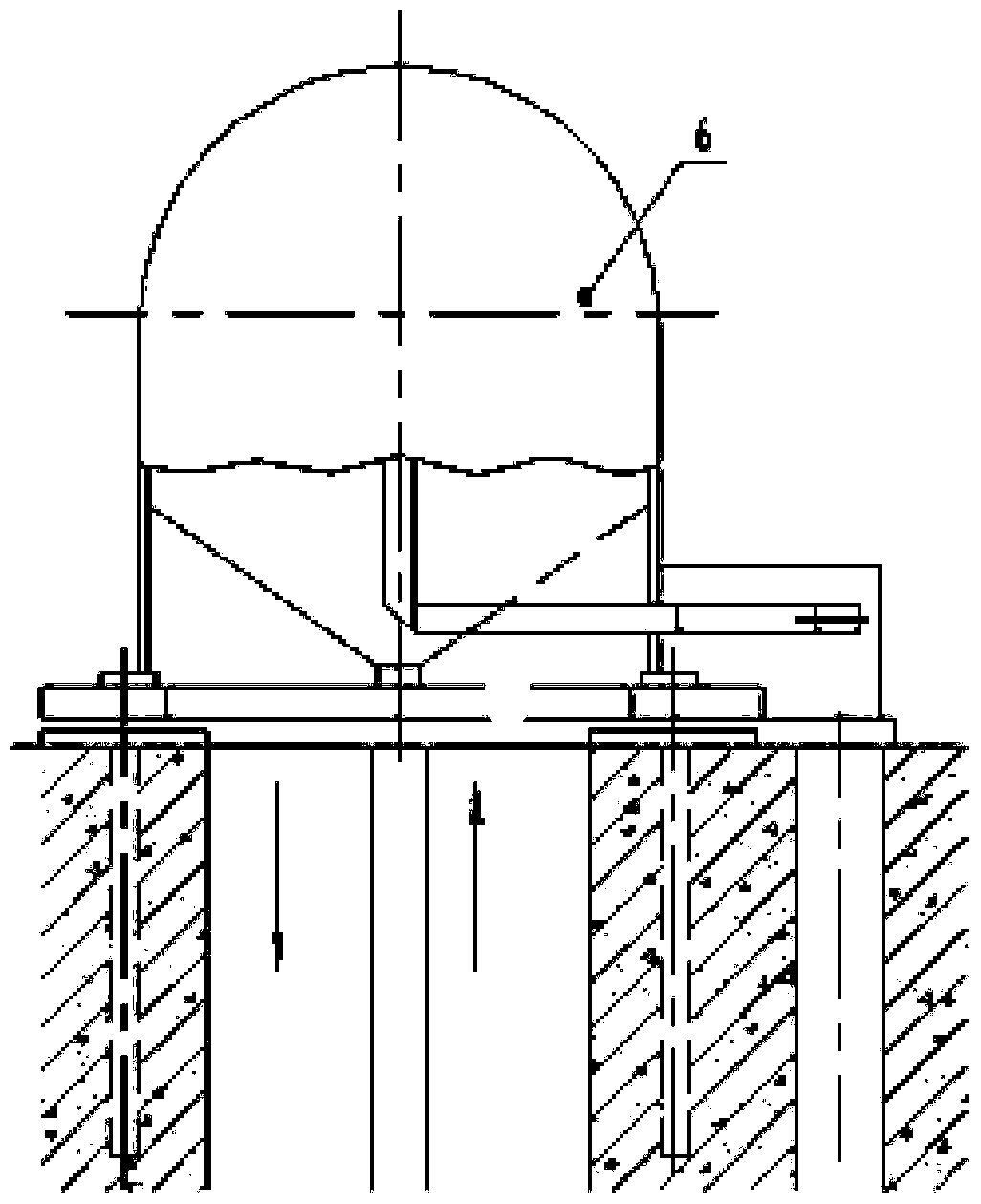

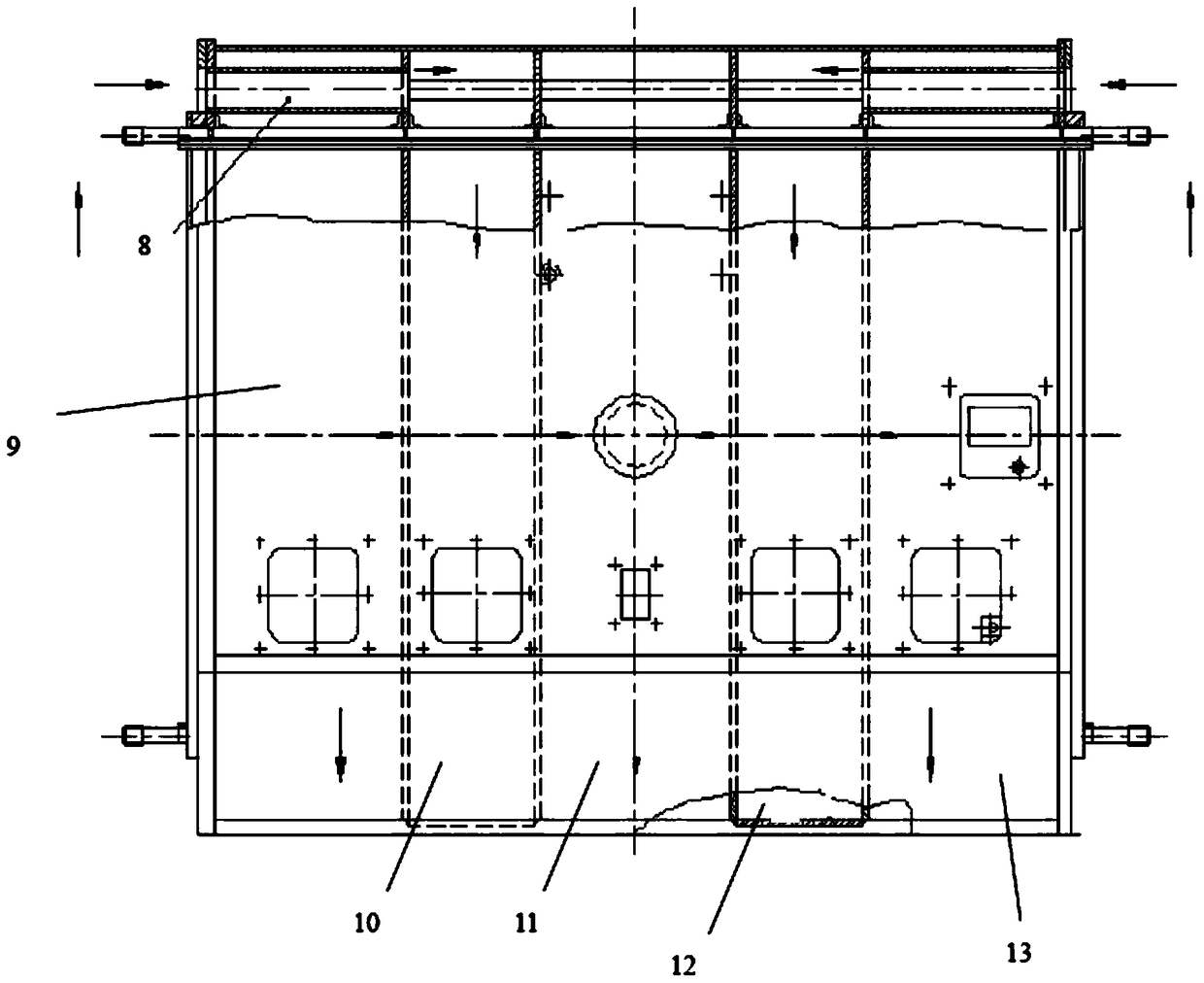

[0023] Such as image 3 and Figure 4 As shown, an air-cooled turbogenerator air path structure includes a stator frame air path, a rotor air path, a cold wind area and a hot air area arranged at the lower end of the stator frame, and a brush air path 7; the stator frame air path includes The stator ventilation pipe 8 located on the upper part of the stator frame 1, and the group of radial air passages distributed vertically and symmetrically inside the stator frame 1 with the center of the stator frame 1 as the center of symmetry, each radial air passage group of the radial air passage group The air ducts communicate with each other, the radial air duct group communicates with the stator ventilation pipe 8, the lower end of the radial air duct group communicates with the hot air area, and the left and right sides of the stator air duct 8 communicate with the cold air area;

[0024] The rotor air path includes an axial air duct, an air gap between the stator and rotor, and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com