Pedal-controlled electric apparatus, electric vehicle, and method of driving, braking and range extending of the same

A technology of electric devices and electric vehicles, applied in electromechanical devices, electric vehicles, control systems, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

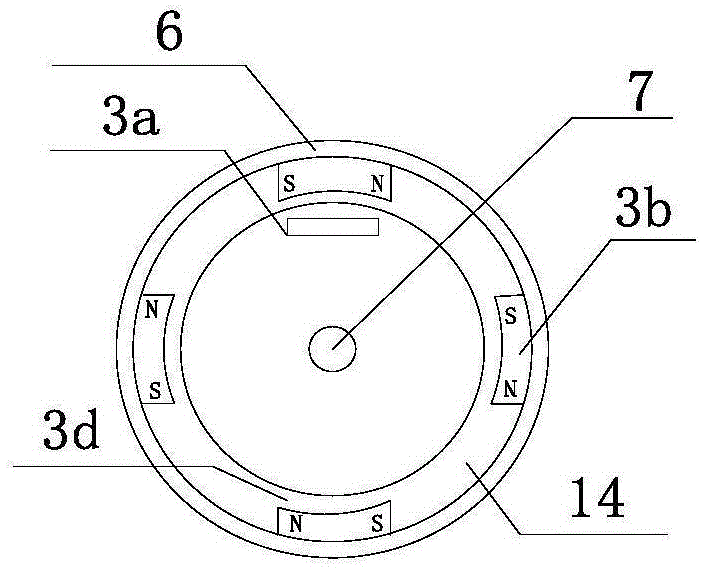

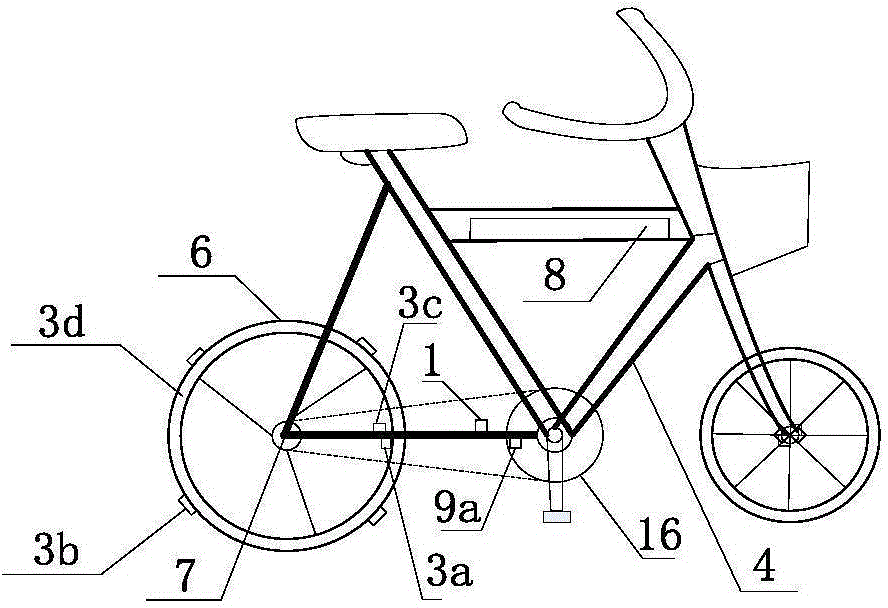

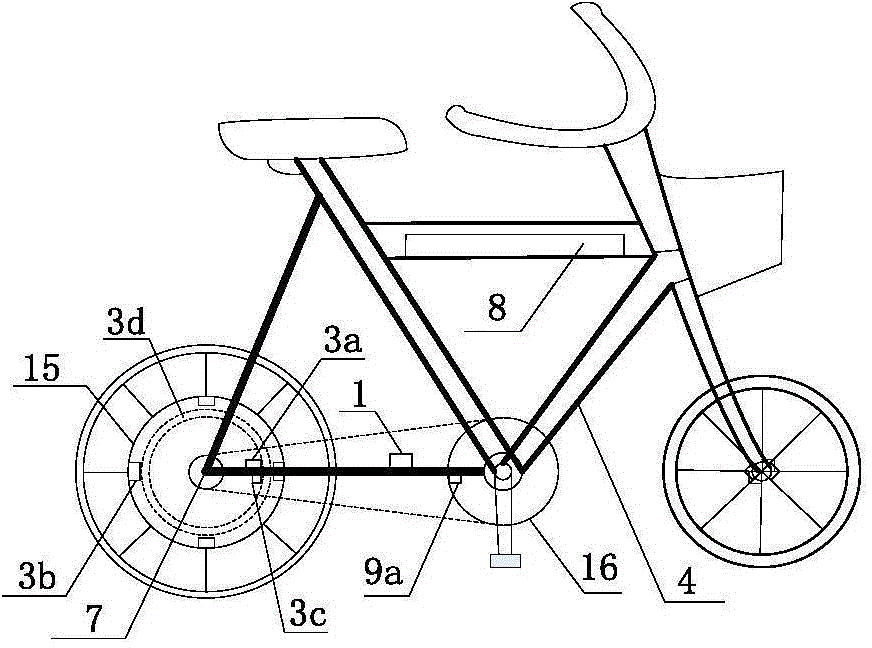

[0094] An electric device and a two-wheeled vehicle containing the device, the local structure of the supporting vehicle frame 4 is as follows: Figure 1c As shown, the circumference of the wheel is 1000mm, and the battery pack 8b is a 24V12Ah lithium iron phosphate battery installed inside the frame. The rotating body of the electric device adopts a double-annular titanium-aluminum alloy hub 15 with a rotation axis and a circumference of 100mm, which is arranged on the rear wheel. A disc with a fixed shaft is set on the coaxial 7 inside the hub, and the outer fixed shaft of the disc is The mechanical parameters are designed with reference to the data of the supporting two-wheeled vehicle, and are used to replace the fixed axle of the conventional two-wheeled vehicle for installation. A stator unit 3a is installed on the disc; 8 rotor units made of NdFeB are arranged on the inner edge of the hub.

[0095] The rotor unit is processed into a small arc-shaped box-shaped unit with...

Embodiment 2

[0103]The materials for setting 8 rotor units on the inner edge of the hub 15 described in Example 1 are transformed into 4 NdFeB and 4 conventional magnetizers, and the NdFeB rotor units and the magnetizer rotor units are evenly arranged one by one.

[0104] The pulse digital technical solution adopted by the power supply modulator is similar to that of Embodiment 1, and the working logic is adjusted as follows: when the winding of the stator unit is energized, within 4s, the corresponding wheel rotation cycle is automatically increased in each next cycle based on 6A The current sequence of 10% output intensity, waits for the next work command of the drive control device from the 5th second: if the drive control device 9a has no input command, the power modulator 1 sleeps; if the command given by the drive control device is to accelerate, then At the moment when the power modulator starts to energize in the next cycle, it executes T 1 with (T 2 +T 0 ) ratio of 1:6 current s...

Embodiment 3

[0107] The hub 15 of the electric device described in Embodiment 1 is changed to a rotating body 6 in the form of a single annular titanium-aluminum alloy ring with a rotating shaft and a circumference of 100 mm, and a disc with a fixed shaft is set on the coaxial 7 in the rotating body. The external mechanical parameters of the fixed shaft of the disc are also designed with reference to the data of the supporting two-wheeled vehicle, and are installed to replace the fixed wheel shaft of the conventional two-wheeled vehicle. A stator unit 3a is installed on the disc; The combined deceleration / torque conversion device 2 is installed coaxially with the rotating body, and the deceleration ratio is 10:1; the deceleration / torque conversion device is provided with a number of mechanical holes, one end of the spokes is perforated and fixed, and the other end is fixed. Even the inner edge of the hub (wheel rim) makes the electric device realize the transmission of the wheel 5, such as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com