Greenhouse used for planting tomatoes

A greenhouse and tomato technology, applied in the field of greenhouses, can solve the problems of increased self-weight load, low land utilization rate, poor natural ventilation capacity, etc., and achieve the effect of enhanced bearing capacity, increased greenhouse space, and improved bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

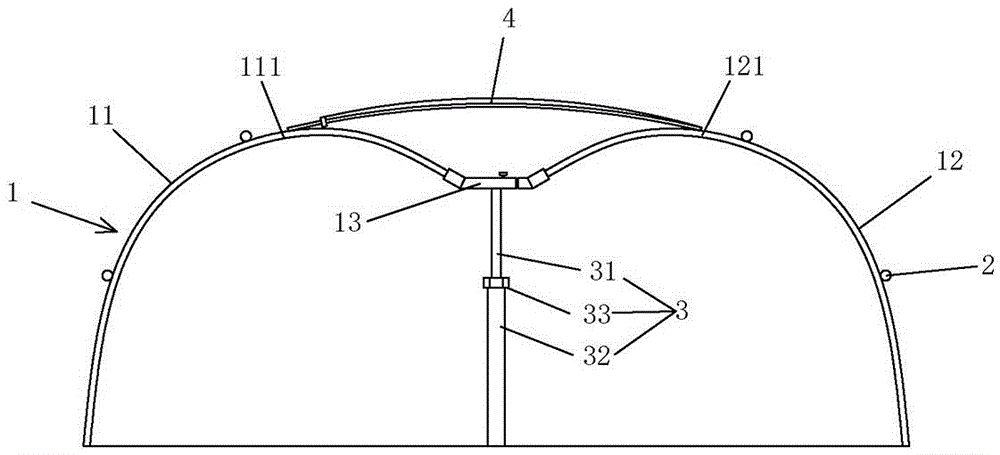

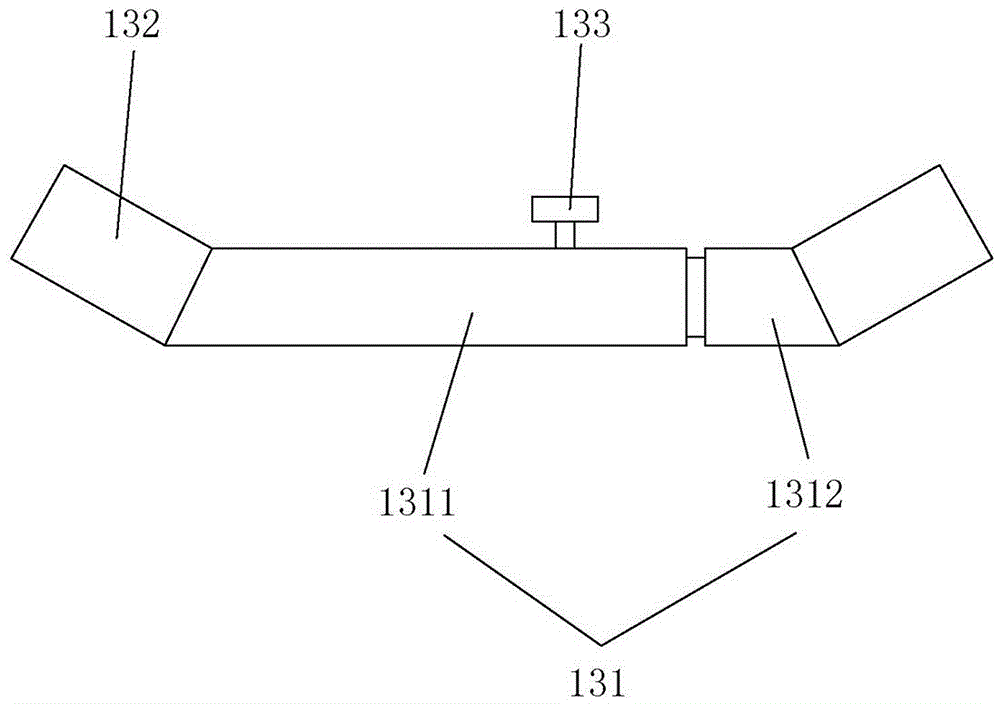

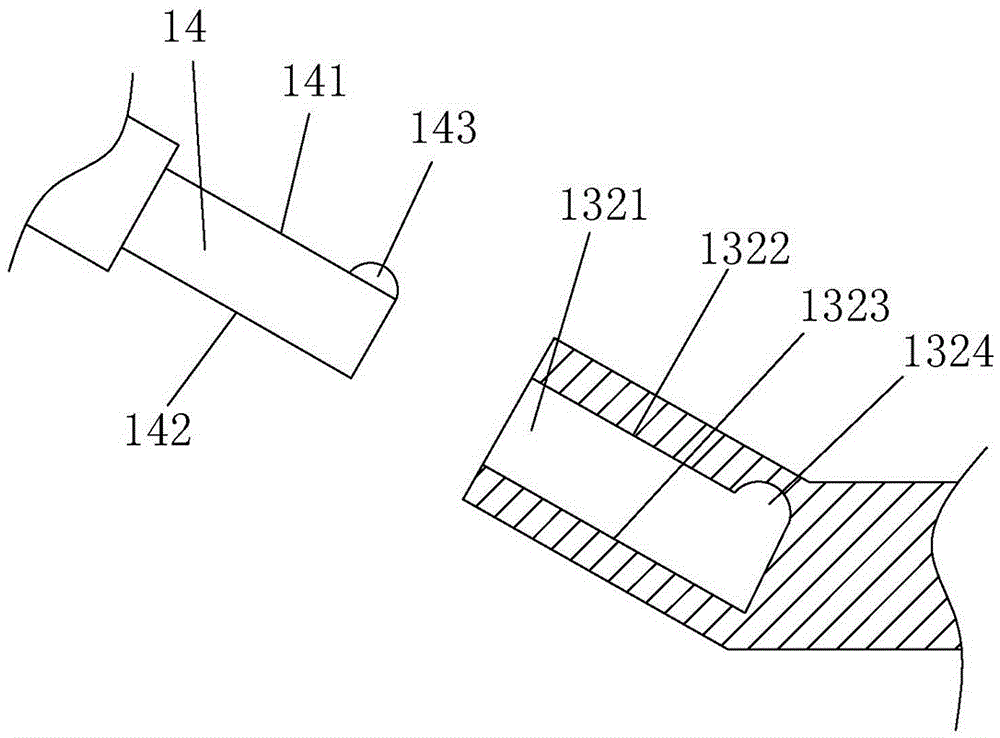

[0025] Embodiment 1: as figure 1 As shown, a greenhouse for growing tomatoes includes a film, an arched support 1 for supporting the film and a tie rod 2 for connecting two adjacent arched supports 1, and the arched support 1 includes a connector 13 and the first strut 11 and the second strut 12 connected to the two ends of the connector 13, the first strut 11 is bent to form a first arched portion 111, and the second strut 12 is bent to form a second The arched portion 121 forms a concave portion between the first arched portion 111 and the second arched portion 121 at the position of the connecting piece 13 . A support rod 3 for supporting the lower recess is provided below the connecting piece 13, and the support rod 3 is a telescopic structure. The film is covered on the first pole 11 and the second pole 12, and a vent is formed at the lower recess, and a shield for covering the vent is provided above the vent. Rain plate 4.

[0026] The support rod 3 includes an upper ...

Embodiment 2

[0031] Embodiment 2: The difference from Embodiment 1 is that the length of the second strut is greater than the length of the first strut, and the length of the second strut is 1.2 of the length of the first strut. -1.5 times, the height of the first arched portion is lower than the height of the second arched portion.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com