Anion formaldehyde scavenging machine

A technology for the generation of negative ions and negative ions, applied in separation methods, dispersed particle separation, gas treatment, etc., can solve the problems of formaldehyde pollution, small contact area between carbon packets and air, and unsatisfactory adsorption effect, and achieve the effect of fresh indoor air.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

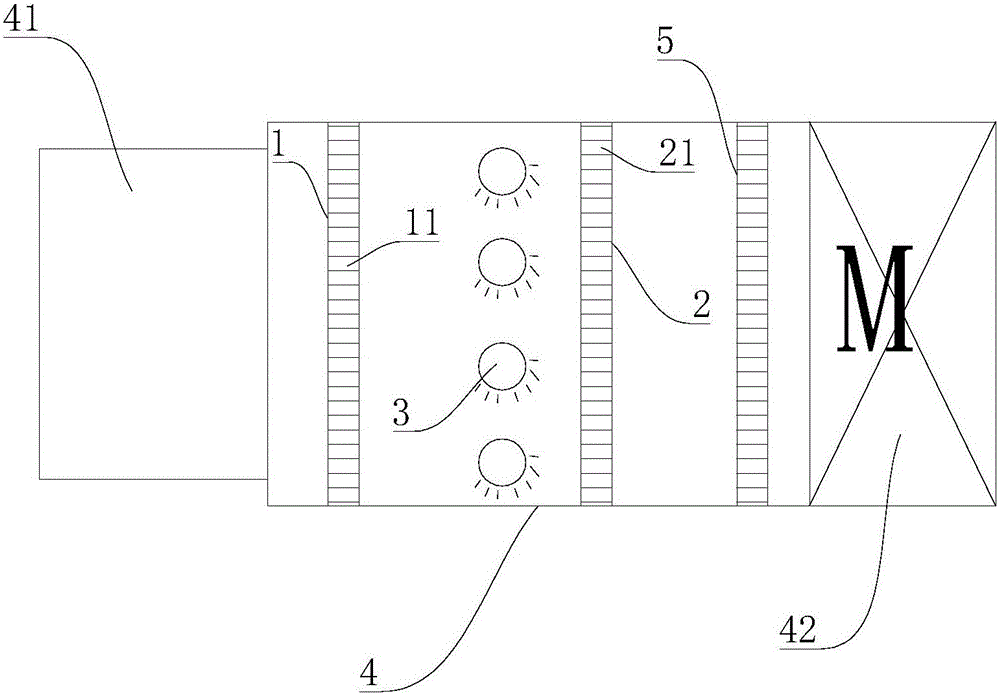

[0014] The negative ion formaldehyde removal machine includes a housing 4, one end of the housing 4 is provided with an air inlet 41, and the other end is provided with an exhaust fan 42, and the housing 4 is provided with a coated filter plate 1, a metal filter plate 2, an ultraviolet Lamp 3 and negative ion generating plate 5; described coating filter plate 1, metal filter plate 2 and negative ion generating plate 5 are all provided with a plurality of fine through holes, and the surface coating of described coating filter plate 1 and its fine through holes There is a formaldehyde adsorption layer, and the formaldehyde adsorption layer contains water-soluble polymer compounds containing hydroxyl groups, amino-containing compounds, cyanamide compounds and nano-scale titanium dioxide; the surface of the metal filter plate 2 and its fine through-holes are provided w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com