Steel plate rubber track attached to the surface

A rubber crawler and steel plate technology, applied in crawler vehicles, motor vehicles, transportation and packaging, etc., can solve the problems of inferior steel crawler lifespan, low driving comfort, and crawler damage, and achieve low vibration and high driving comfort. , light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

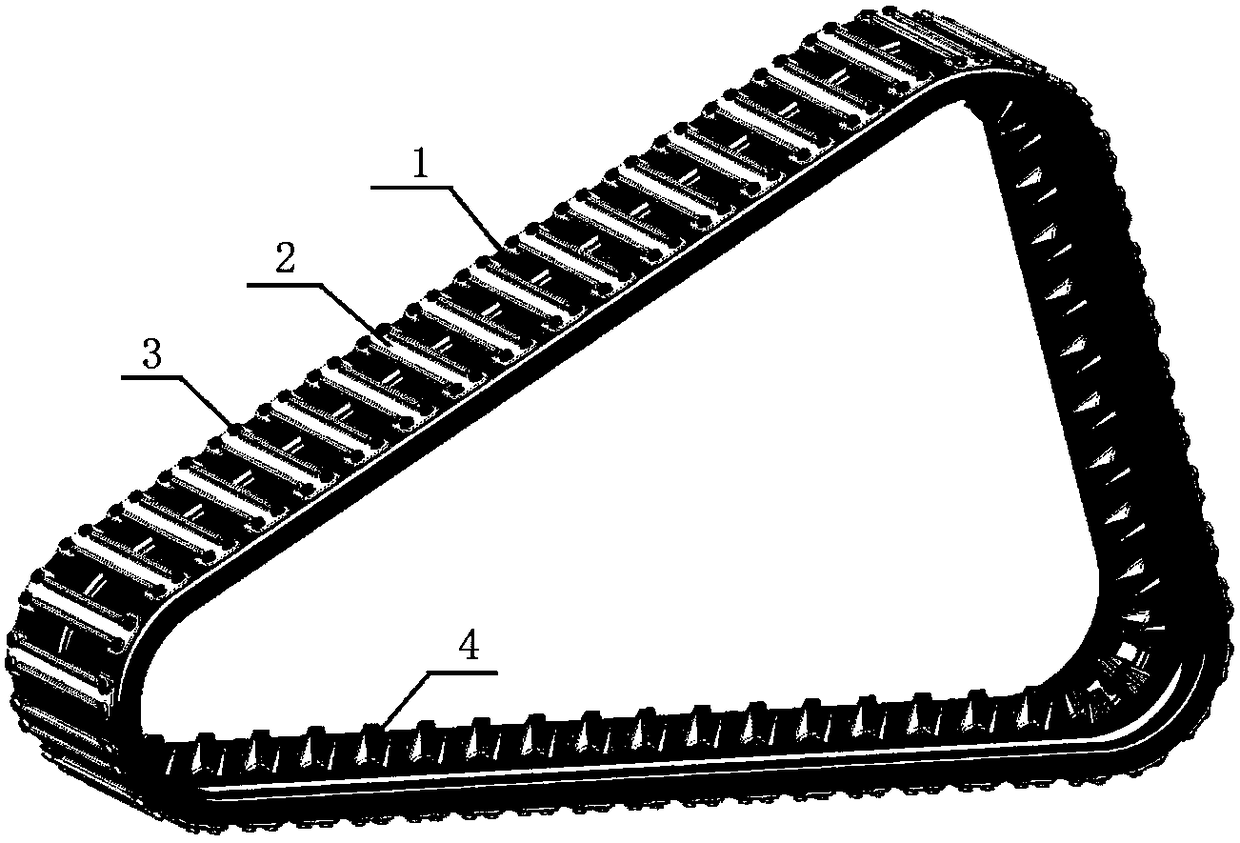

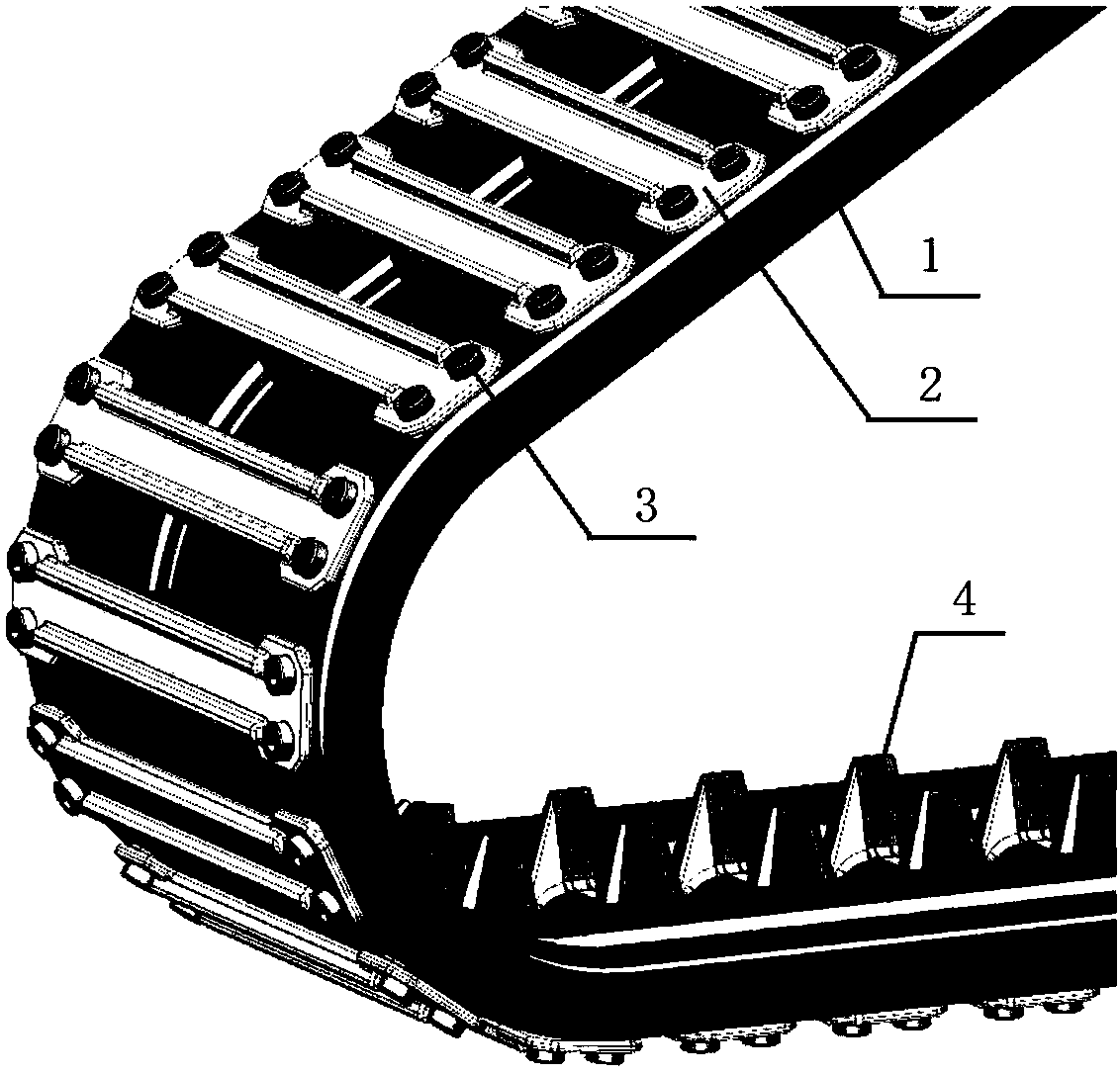

[0022] Embodiment 1: as attached figure 1 As shown, there are iron teeth 4 inside the rubber crawler 1, and a steel plate 2 is attached to the outer peripheral surface of the rubber crawler 1, and the steel plate 2 and the iron teeth 4 are connected and fixed through the fastener 3 from the front direction.

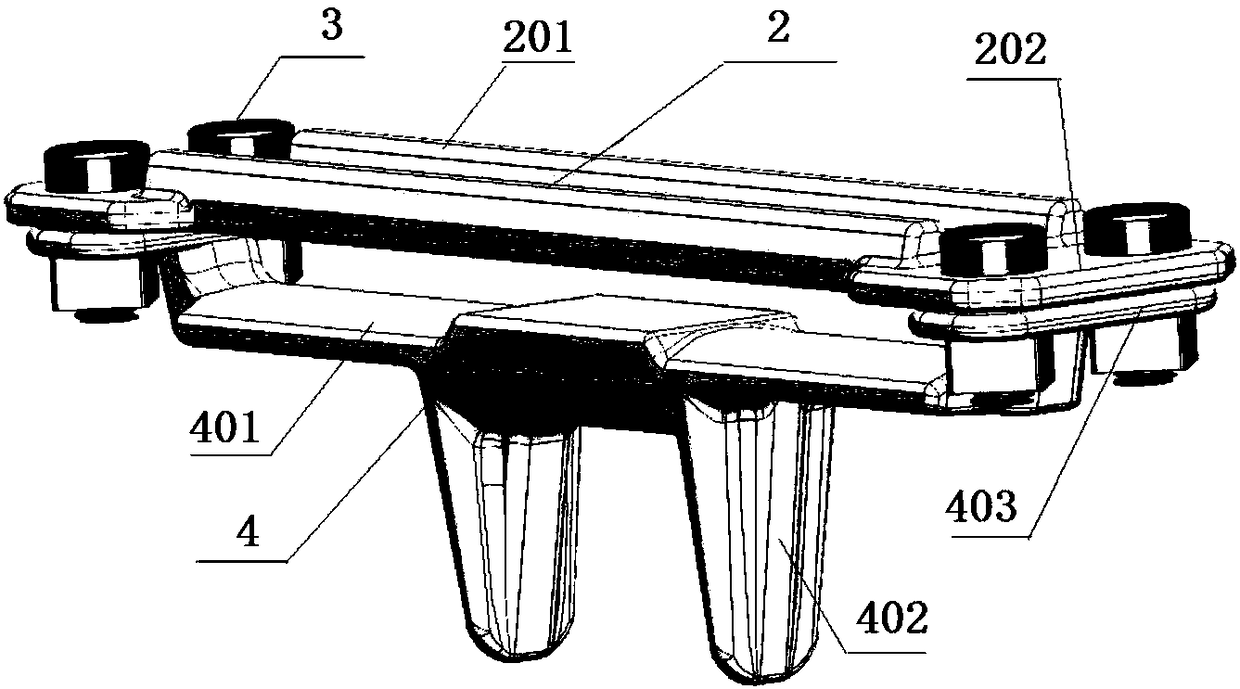

[0023] In the foregoing, as attached figure 2 As shown, the iron teeth 4 have elongated tooth plates 401 arranged transversely, and the steel plate 2 and the tooth plates 401 are connected and fixed by fasteners 3 from both ends.

[0024] In the foregoing, as attached figure 2 As shown, the outer surface of the steel plate 2 has reinforcing ribs 201, the two outer ends of the steel plate 2 have end hole plates 202 respectively, and fixing holes are arranged on the end hole plates 202, and the fastener 3 is on the upper end surface protruding from the outer surface of the steel plate 2 Not higher than the top surface of the rib 201.

[0025] In the above, there are pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com