Helicopter rotor wing compound motion parallel driving device

A helicopter rotor and compound motion technology, which is applied in the field of helicopters, can solve the problems of low load-bearing tensile capacity of the ball pair, complex rotor motion drive device, and low speed, and achieve the effects of good force bearing, simple structure and improved service life of the ball pair

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

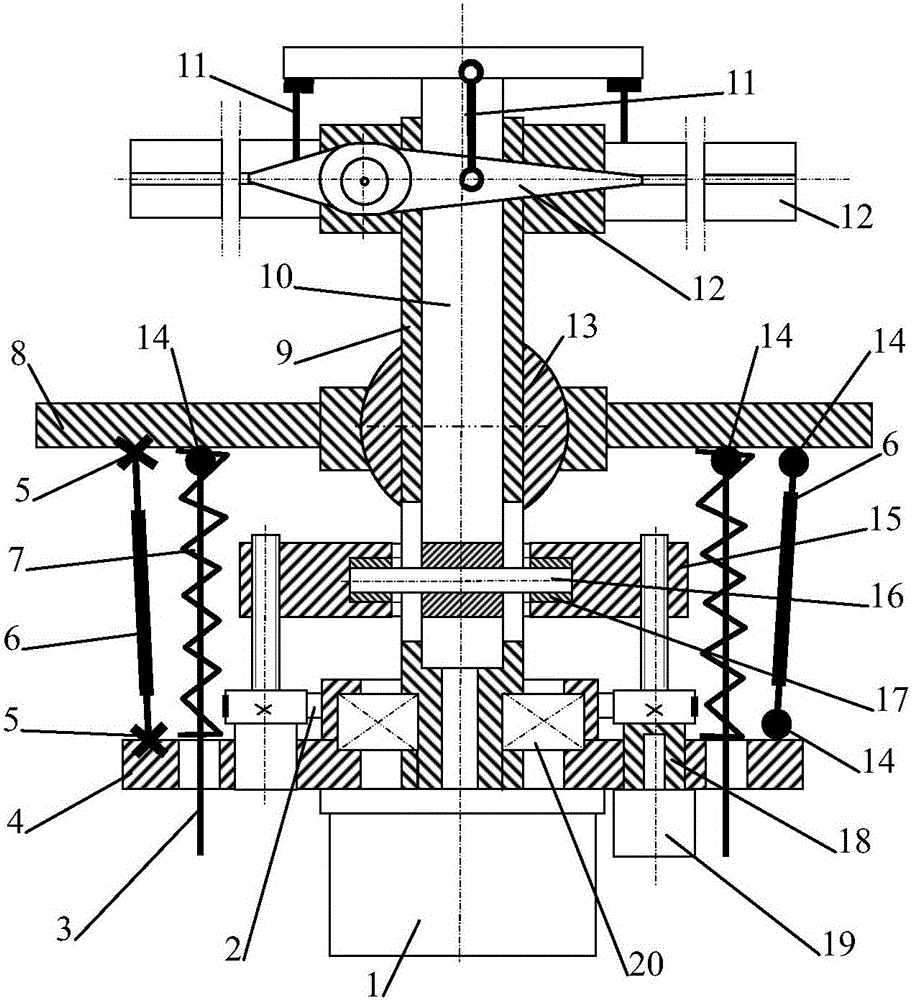

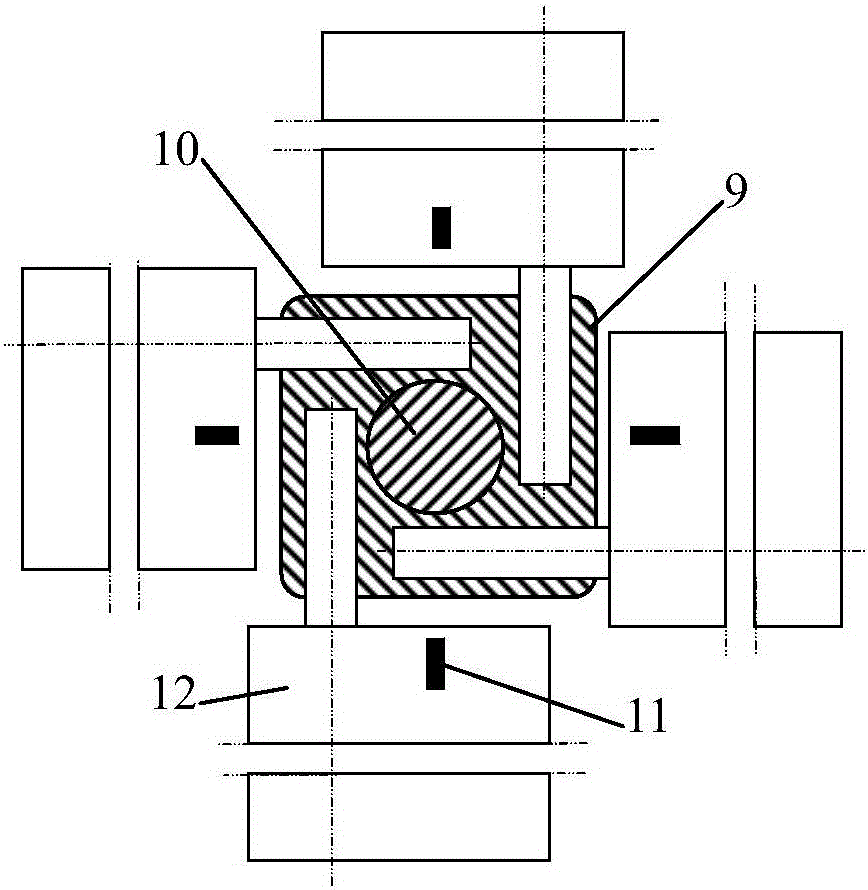

[0016] exist figure 1 and figure 2 In the schematic diagram of the helicopter rotor compound motion parallel driving device shown, the parallel mechanism includes the base, the moving table, the middle SP-type passive restraint branch, the UPU-type driving branch connecting the base and the moving table, and two SPS-type driving branches with the same structure , to realize the axial movement of the main shaft of the rotor and the three-dimensional rotation around the center ball pair of the base; the center of the base 8 is provided with a concave spherical surface hole; Three through holes evenly distributed and three through holes evenly distributed on the large circumference; the middle SP-type passive restraint branch includes a main shaft 9, a large bearing 20 and a ball sleeve 13, and the ball sleeve is provided with an outer spherical surface and a ball center The main shaft with the central through hole is connected with the through-hole cylindrical pair of the ball...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com