Environment-friendly type reversible mobile belt conveyor

A belt conveyor and mobile technology, applied in the field of transportation, can solve problems such as long maintenance time, loud noise, and large dust, and achieve the effect of light weight and strong strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention is described in further detail below in conjunction with accompanying drawing:

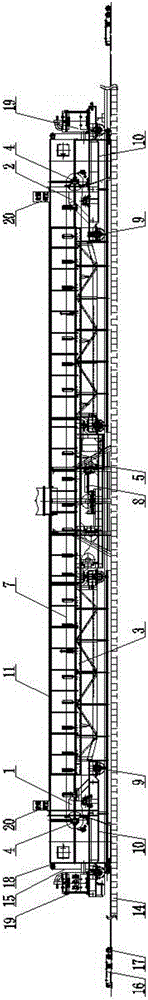

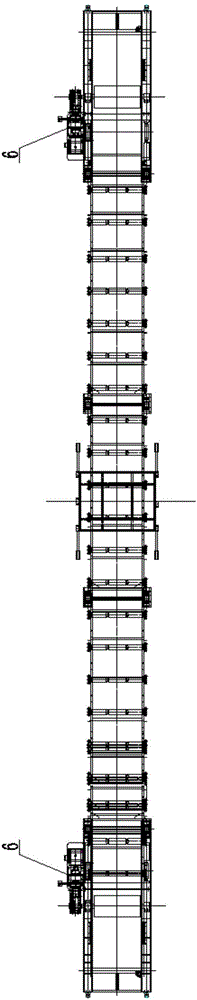

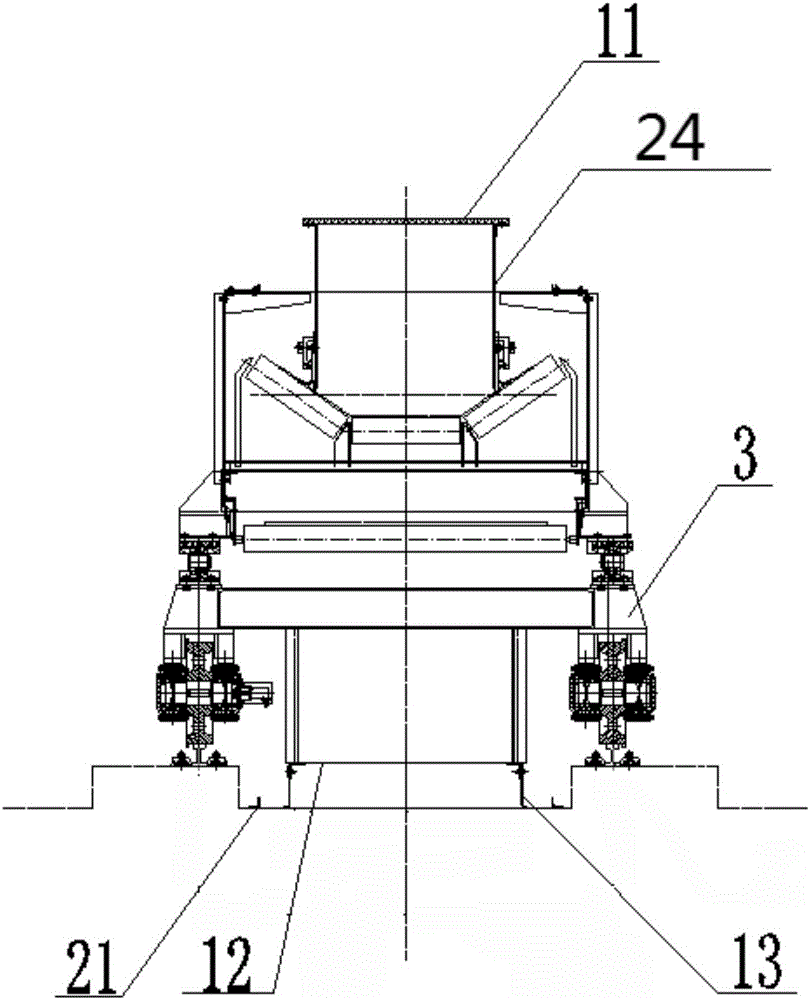

[0032] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown in the figure, an environment-friendly reversible warehouse allocation mobile belt conveyor includes a conveying mechanism and a dust-proof mechanism arranged outside the conveying mechanism;

[0033] The dust-proof mechanism includes an upper cover plate of the material guide trough, a sealing plate 12 and a sealing curtain 13; The outside of the discharge port 14 at both ends of the mechanism; the upper part of the discharge port 14 is provided with a sealing tape 15; both ends of the machine head are provided with a tensioning device 16 and a tensioning guide roller 17 for tensioning the sealing tape 15, The discharge funnels 10 at both ends of the conveying mechanism are provided with sealing tapes and fixed rollers 18 respectively; the outside of the discharge funnels 10 are provided with nega...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com