Novel backpack optimization type home elevator

A home elevator and knapsack technology, applied in the field of new knapsack-optimized home elevators, can solve problems such as poor corrosion resistance, reduced strength and flexibility of wire ropes, and noise generation, and achieve long service life, simplify installation engineering, and reduce friction noise. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

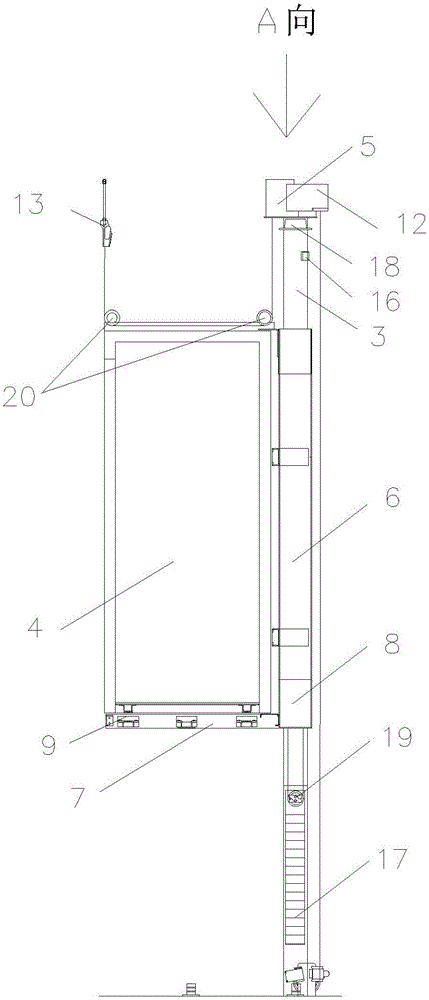

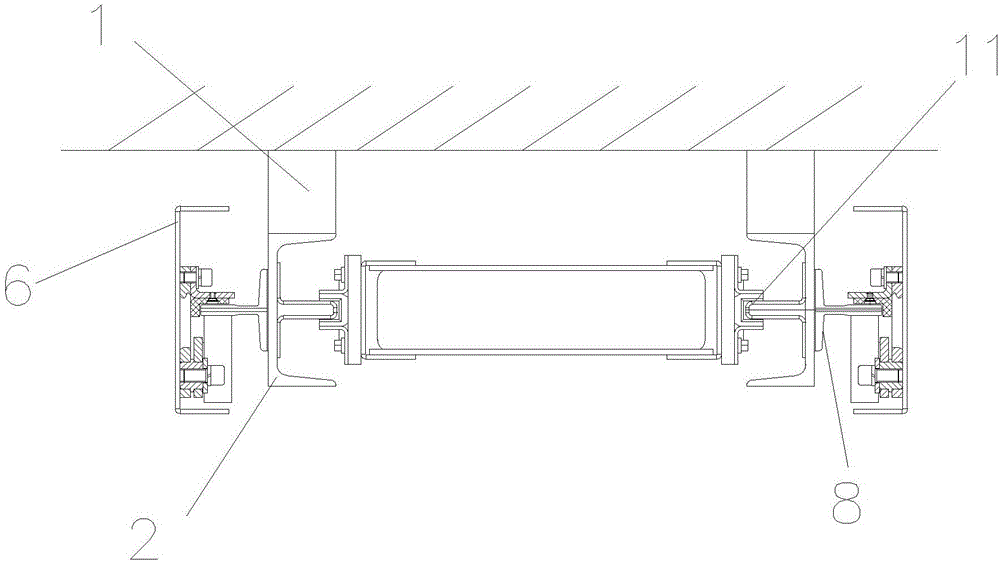

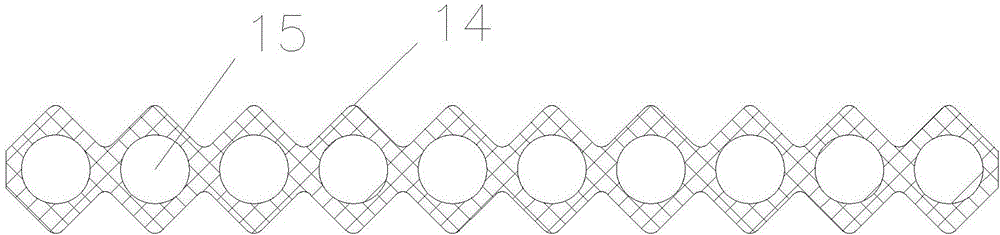

[0036] Figures 1 to 3 As shown, a novel backpack-optimized home elevator includes a pair of support frames 1 , the support frames 1 are fixed on the wall, and a channel steel 2 is connected to the surface of each support frame 1 . Also be provided with an L-shaped car frame, on which the car 4 is fixed; The L-shaped car frame includes two vertical beams 6 that are arranged on one side of the channel steel 2 and are parallel to each other as vertical ends, and one as a horizontal end. A bracket 7 perpendicular to the vertical beam 6, the car 4 is placed above the bracket 7; the main rail 3 is arranged on the vertical beam 6, and the main rail 3 is located on the Same side of car 4. The main rail 3 is provided with a main rail guide shoe 8, the main rail guide shoe 8 is conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com