Engineering tire tread rubber composition and use thereof

A technology of rubber composition and engineering tire, which is applied in the field of engineering tire tread rubber composition and the formulation field of engineering tire tread rubber, which can solve the problems of reduced tire performance, poor rubber dispersion, and reduced tear resistance. Achieve the effects of reduced hysteresis loss, improved aging resistance, and good tear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

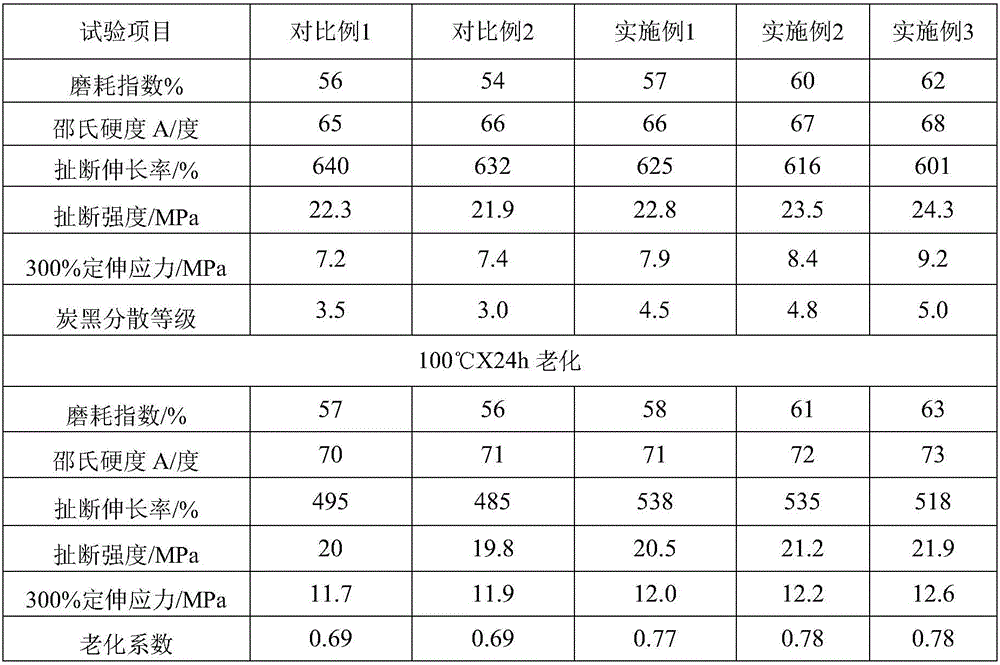

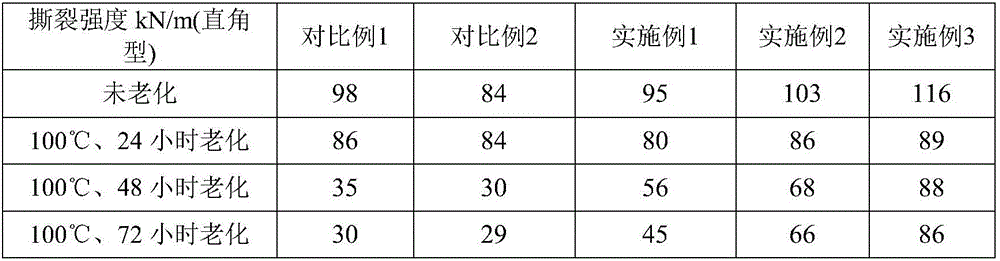

[0037] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with specific examples. It should be pointed out that all similar substitutions and modifications are obvious to those skilled in the art, and they are all deemed to be included in the present invention.

[0038] Other components and source in embodiment and comparative example rubber composition are as follows:

[0039] Natural rubber, SMR20, product from Malaysia, Qingdao Qunce International Trade Co., Ltd.;

[0040] Styrene butadiene rubber, 1502, Shenhua Chemical Industry Co., Ltd.;

[0041] Carbon black N234, Cabot (China) Investment Co., Ltd.;

[0042] Silica, VN3, Qingdao Degussa Chemical Co., Ltd.;

[0043] White carbon black dispersant, prepared in laboratory (prepared by the method of embodiment 2 in CN201310461727.5);

[0044] Zinc Oxide, Dalian Zinc Oxide Factory;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap