Method for improving copper slag level in zinc hydrometallurgy process

A technology for hydro-smelting zinc and copper slag, applied in the field of smelting, can solve the problems of increasing the production cost of the purification process of hydro-zinc smelting, limiting the improvement of the economic benefits of copper slag, and low grade of copper slag, and achieving good economic benefits and production. Low cost and the effect of improving copper content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

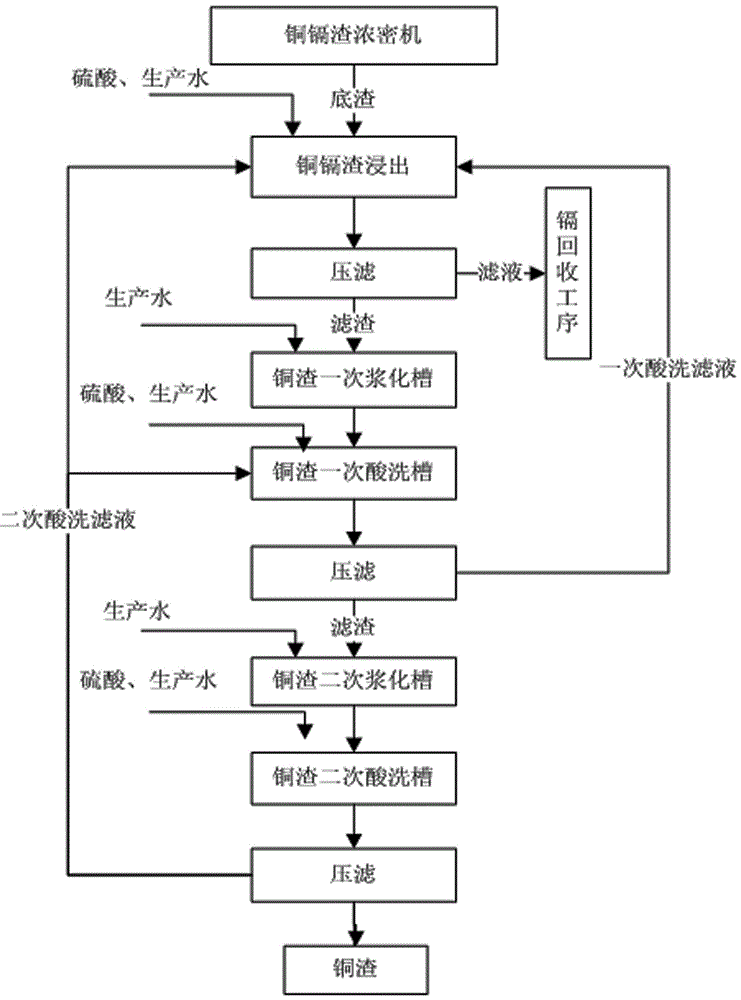

Image

Examples

Embodiment 1

[0015] A method for improving the grade of copper slag in a zinc hydrometallurgy process, specifically comprising the following steps:

[0016] A. Copper-cadmium slag high-temperature high-acid leaching: Purify the copper-cadmium slag produced in the process of removing copper and cadmium once, add water to the copper-cadmium slag at a solid-to-liquid ratio of 1:2, mix it into a wet overflow ball mill for ball milling to obtain a pulp, and After ball milling, the slurry is pumped to the copper cadmium slag thickener for sedimentation to obtain supernatant and bottom slag, and the supernatant is returned to the leaching system. The copper content in the bottom slag is 20%; slag Pump to the copper cadmium slag leaching tank, add production water to the bottom slag, control the liquid-solid ratio to 4:1, then slowly add concentrated sulfuric acid with a mass concentration of 98% to the leaching tank while raising the temperature of the pulp, and control the stirring speed to 76 ...

Embodiment 2

[0023] A method for improving the grade of copper slag in a zinc hydrometallurgy process, specifically comprising the following steps:

[0024] A. Copper-cadmium slag high-temperature high-acid leaching: Purify the copper-cadmium slag produced in the process of removing copper and cadmium once, add water to the copper-cadmium slag at a solid-to-liquid ratio of 1:2, mix it into a wet overflow ball mill for ball milling to obtain a pulp, and After ball milling, the slurry is pumped to the copper cadmium slag thickener for sedimentation to obtain the supernatant and bottom slag, and the supernatant is returned to the leaching system. The copper content in the bottom slag is 20%; the bottom slag is pumped to the copper cadmium slag leaching tank, where Add production water to the bottom slag, control the liquid-solid ratio to 4:1, then slowly add concentrated sulfuric acid with a mass concentration of 98% to the leaching tank while raising the temperature of the pulp, control the s...

Embodiment 3

[0031] A method for improving the grade of copper slag in a zinc hydrometallurgy process, specifically comprising the following steps:

[0032] A. Copper-cadmium slag high-temperature high-acid leaching: Purify the copper-cadmium slag produced in the process of removing copper and cadmium once, add water to the copper-cadmium slag at a solid-to-liquid ratio of 1:3, mix it into a wet overflow ball mill for ball milling to obtain a pulp, and After ball milling, the slurry is pumped to the copper-cadmium slag thickener for sedimentation to obtain the supernatant and bottom slag, and the supernatant is returned to the leaching system. The copper content in the bottom slag is 25%; the bottom slag is pumped to the copper-cadmium slag leaching tank, where Add production water to the bottom slag, control the liquid-solid ratio to 5:1, then slowly add concentrated sulfuric acid with a mass concentration of 98% to the leaching tank while raising the temperature of the pulp, control the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com