Control method for aluminum electrolysis crown block stock bin material level online monitoring and fault alarm system

A technology of fault alarm and control method, which is applied in the field of aluminum electrolysis equipment, can solve the problems of affecting the discharge of the silo, the blockage of the discharge port, and the easy solidification into particles, etc., so as to achieve simple structure and operation steps, avoid operation errors, and improve work efficiency. efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

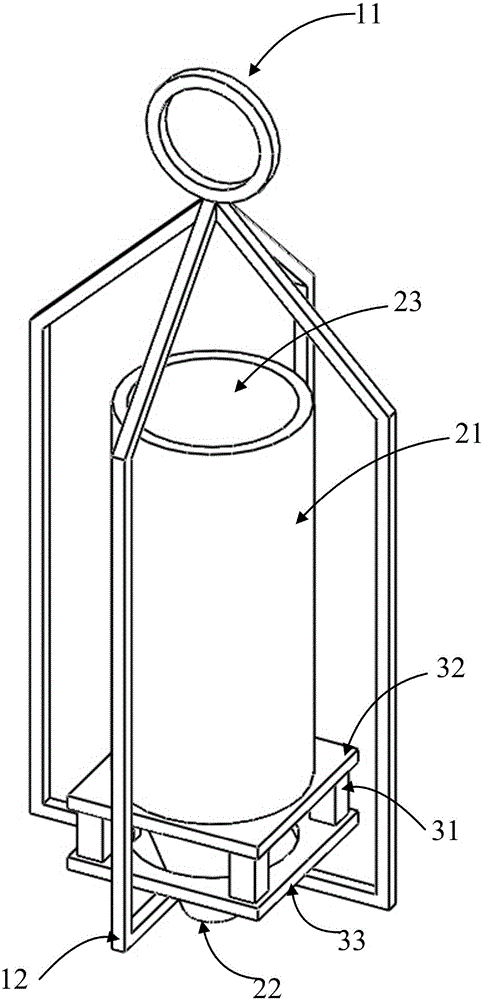

[0036] Such as Figure 1-2 As shown, in the first embodiment of the present invention, the crane silo failure alarm system includes: a silo 21 for holding raw materials, a crane for moving the silo, and an electronic control system for controlling the silo. module;

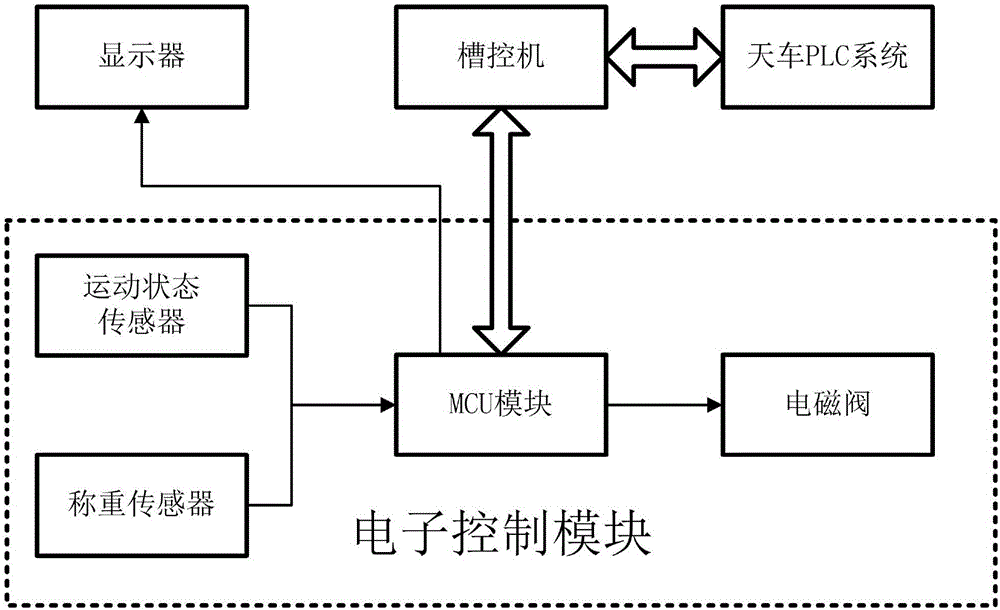

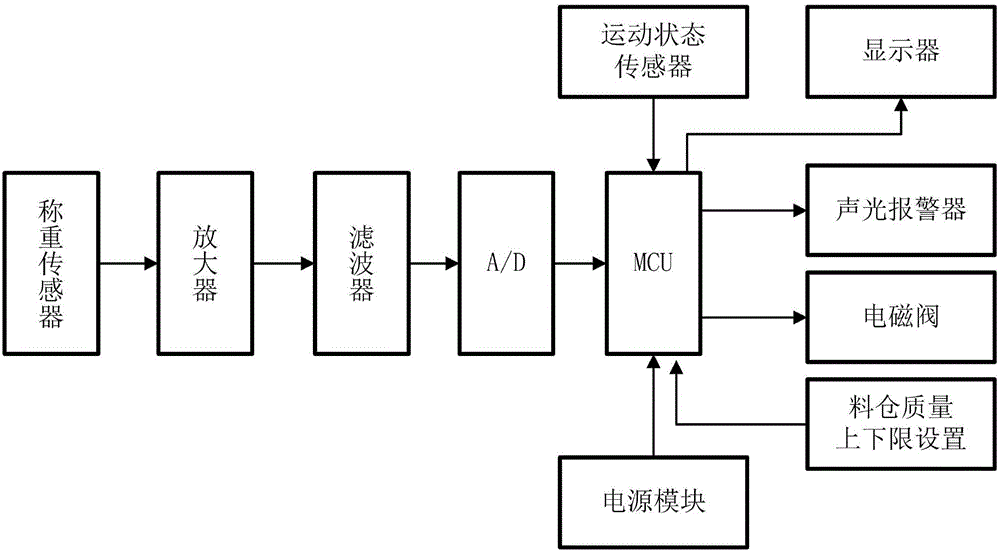

[0037] The electronic control module includes: an antimagnetic load cell, a motion state sensor, an MCU module, and a solenoid valve; the antimagnetic load cell is electrically connected to the MCU module; the motion state sensor is electrically connected to the MCU module; The solenoid valve is electrically connected to the MCU module; the MCU module is connected to the slot control machine in communication;

[0038]The crane is provided with a crane ring 11 and a support seat 12, and the antimagnetic load cell 31 is provided with an upper backing plate 32 and a lower backing plate 33, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com