Patents

Literature

50results about How to "Avoid running errors" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

TV software update method, device and system

InactiveCN102289382AAvoid running errorsNot missingTelevision system detailsColor television detailsSoftware updateDowntime

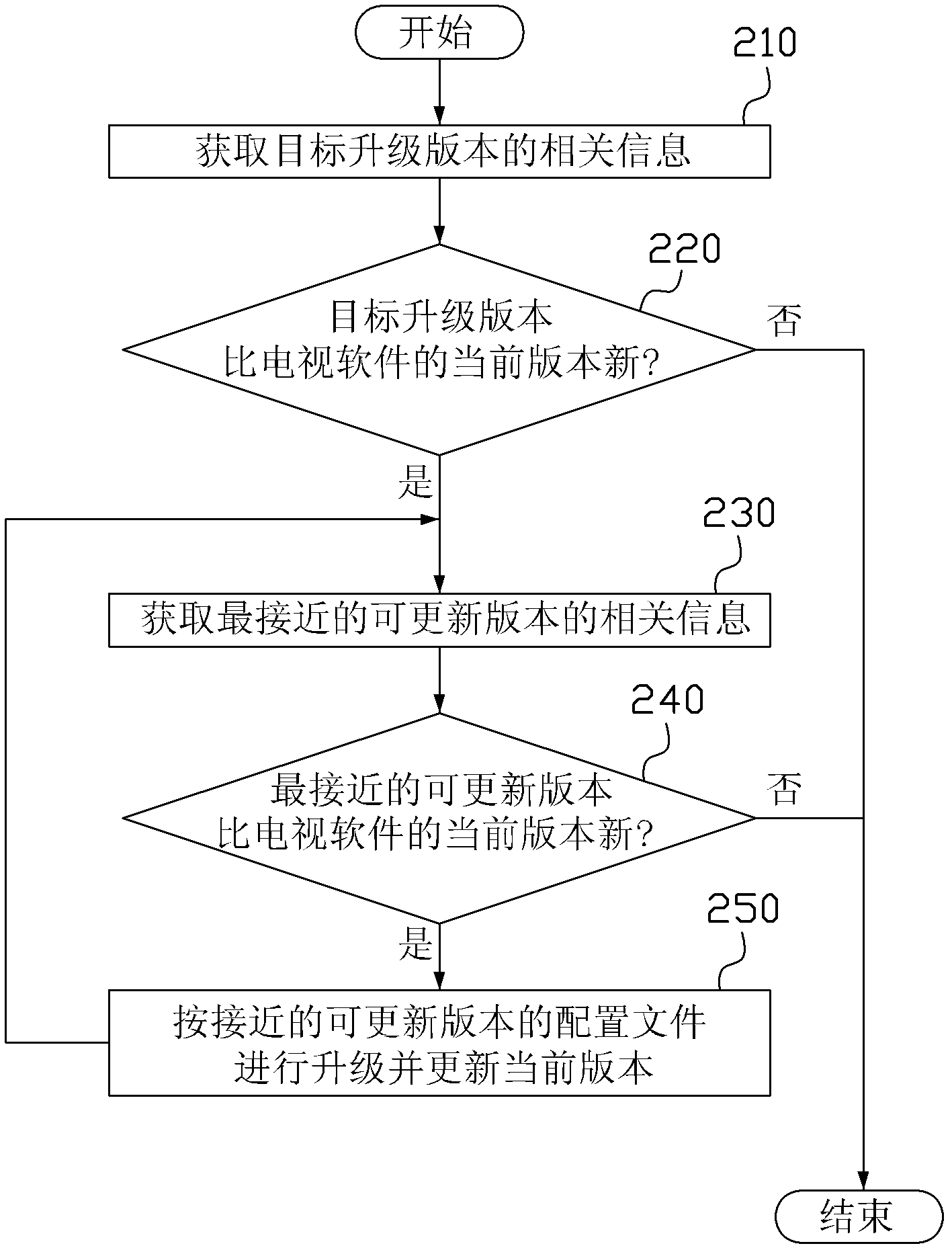

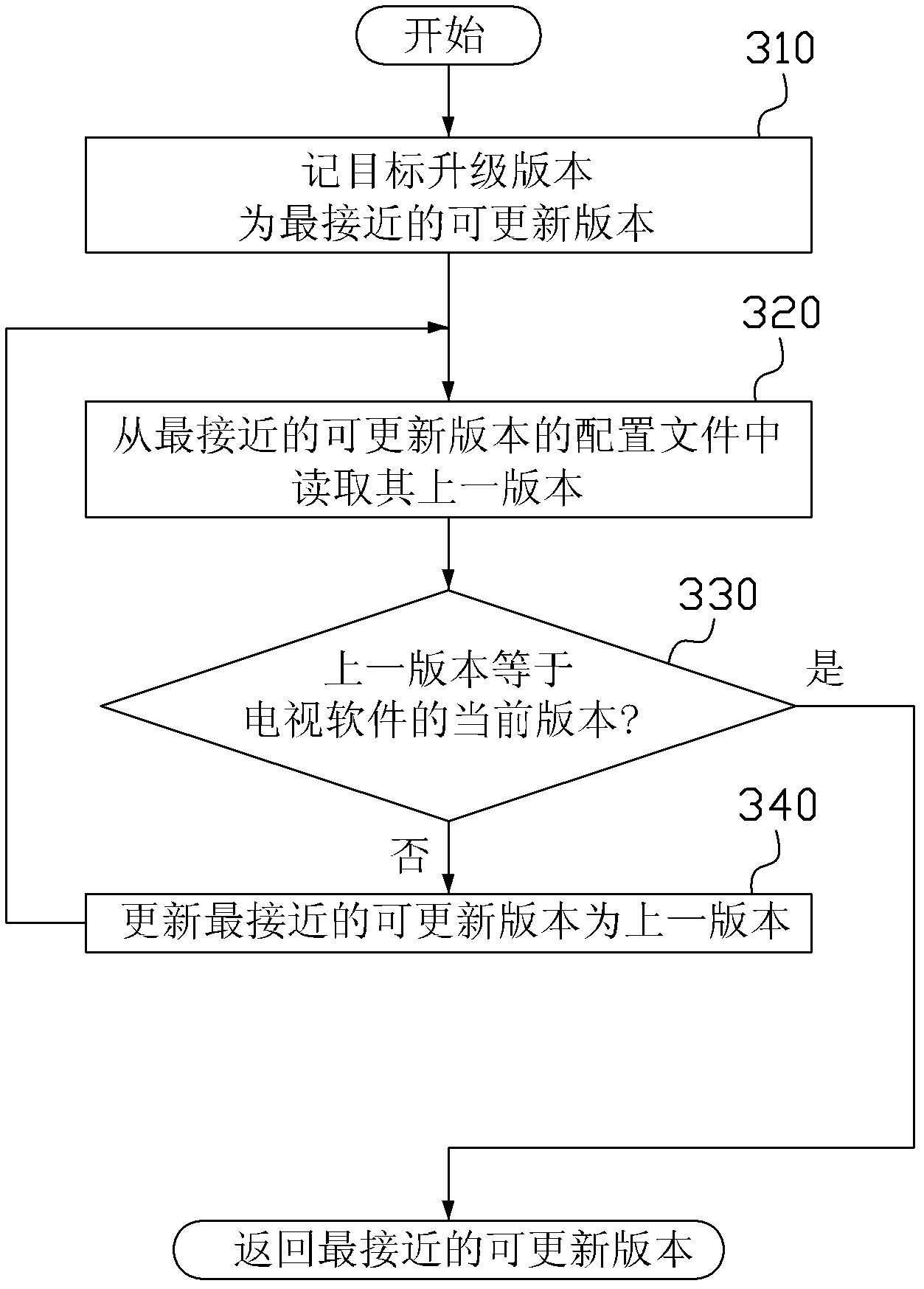

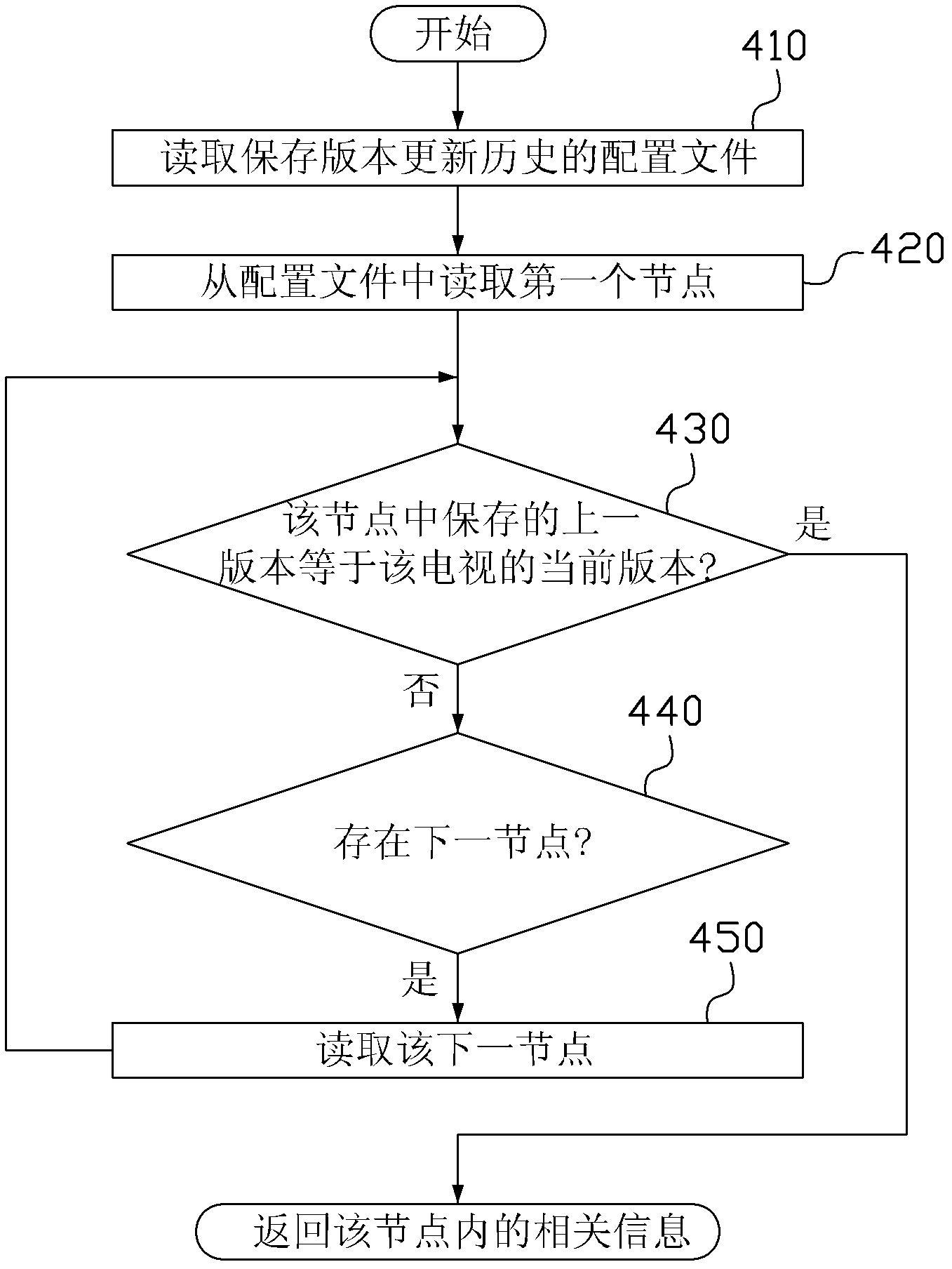

The invention relates to a method for updating television software. The television software has the current version. This update method includes: obtaining information of a target upgrade version of the TV software from a server, this information at least includes version information and a list of upgrade or update files; if the target upgrade version is newer than the current version of the TV software, then: the steps 1: Obtain the information of the updateable version closest to the current version of the TV software; Step 2: update the TV software according to the information of the closest updateable version and update the current version of the TV software accordingly; and repeat Step 1 and Step 2 until the current version of the TV software is the same as the target upgrade version. The above TV software update method can avoid software operation error, inoperability and possible system downtime caused by file loss or data error. In addition, the invention also provides a TV software updating device and system.

Owner:HISENSE VISUAL TECH CO LTD

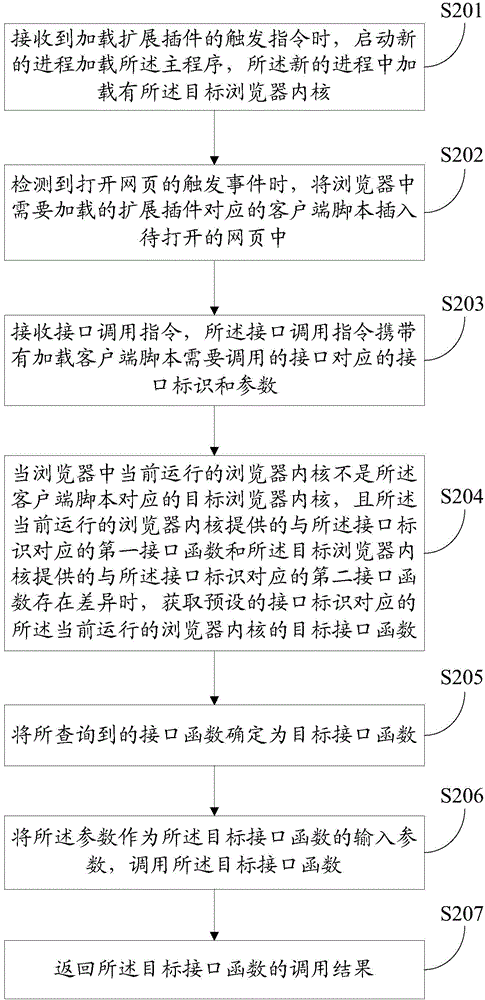

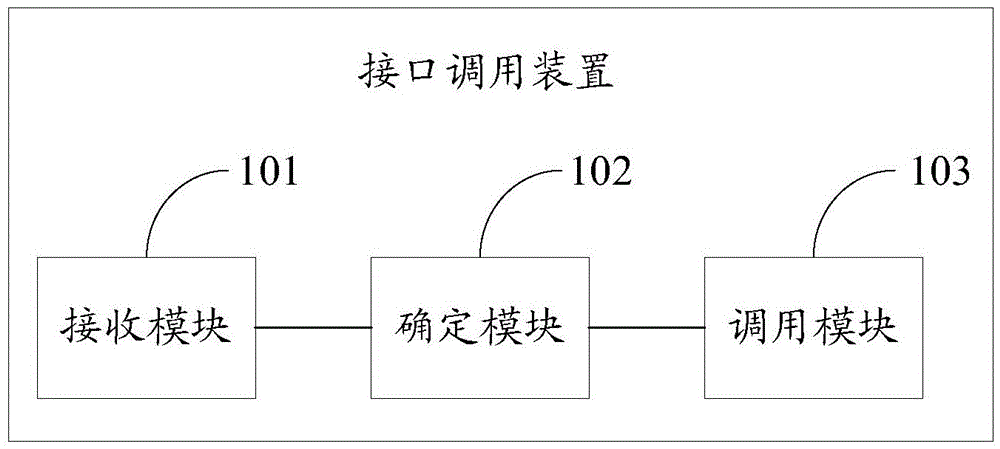

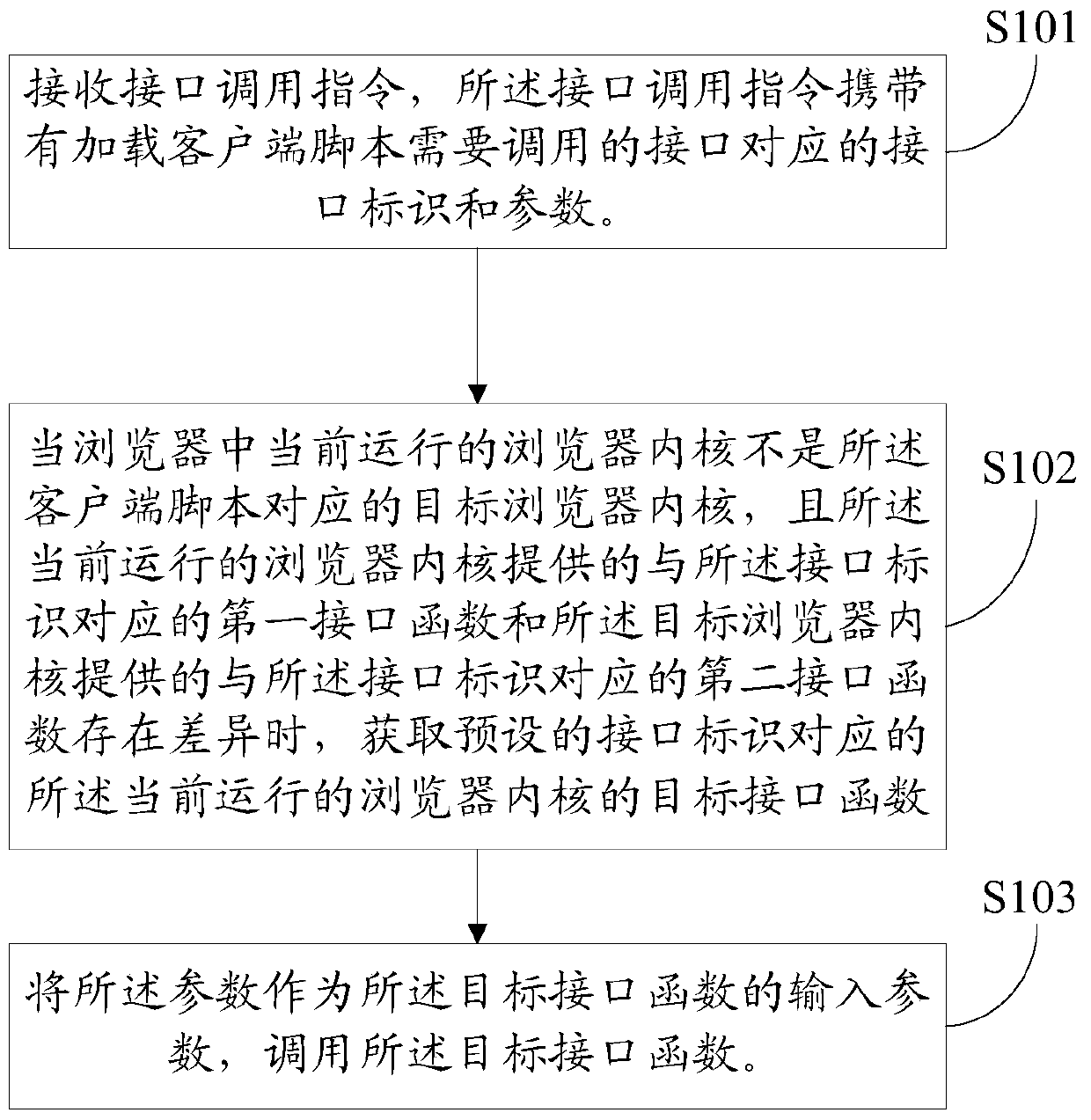

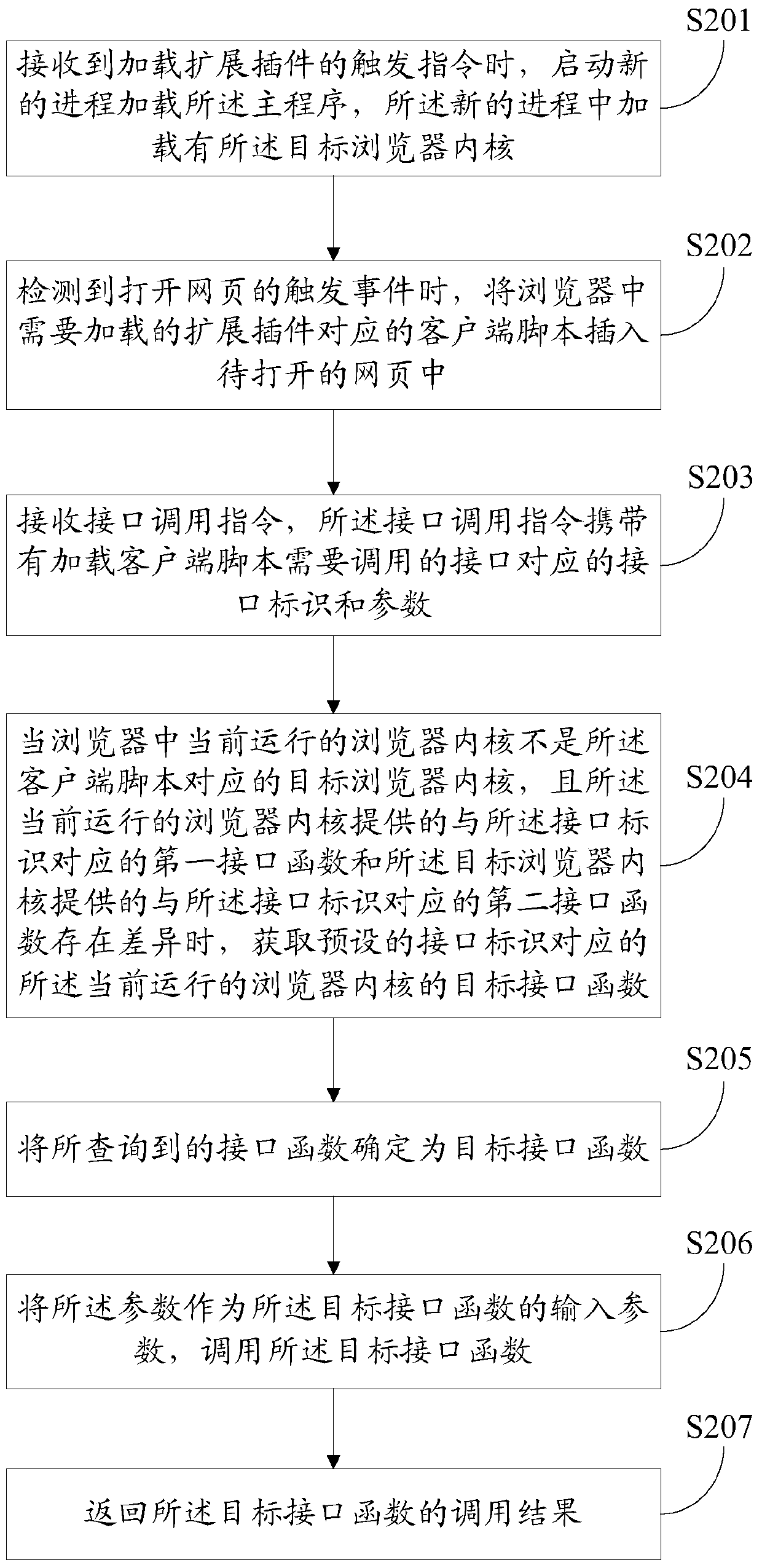

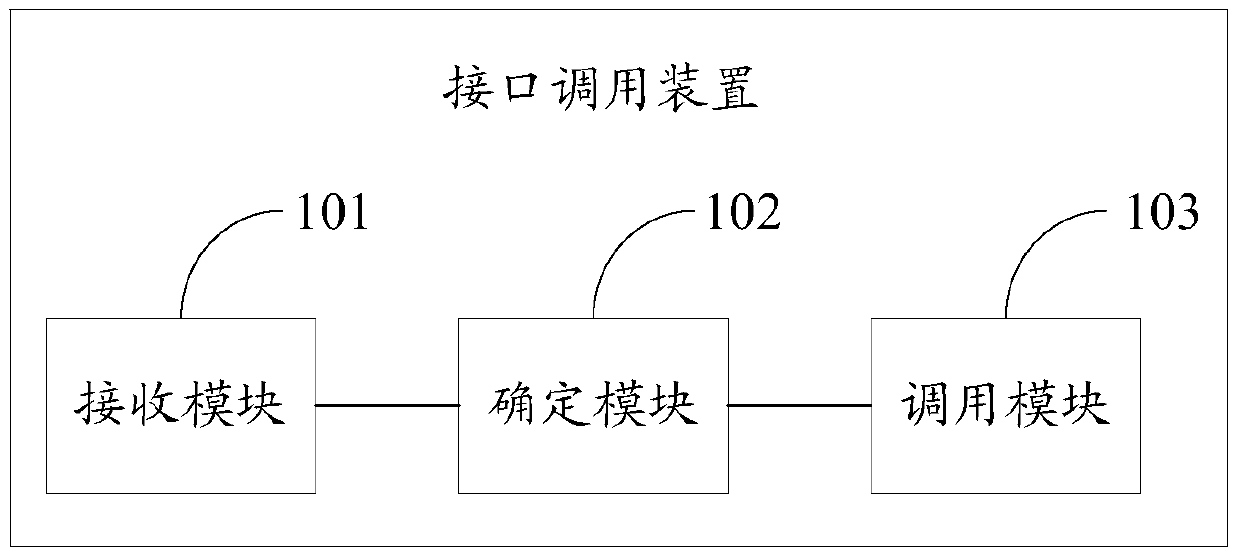

Interface calling method, apparatus and terminal

ActiveCN104881318AAvoid running errorsImprove compatibilityMultiprogramming arrangementsProgram loading/initiatingClient-side scriptingSoftware engineering

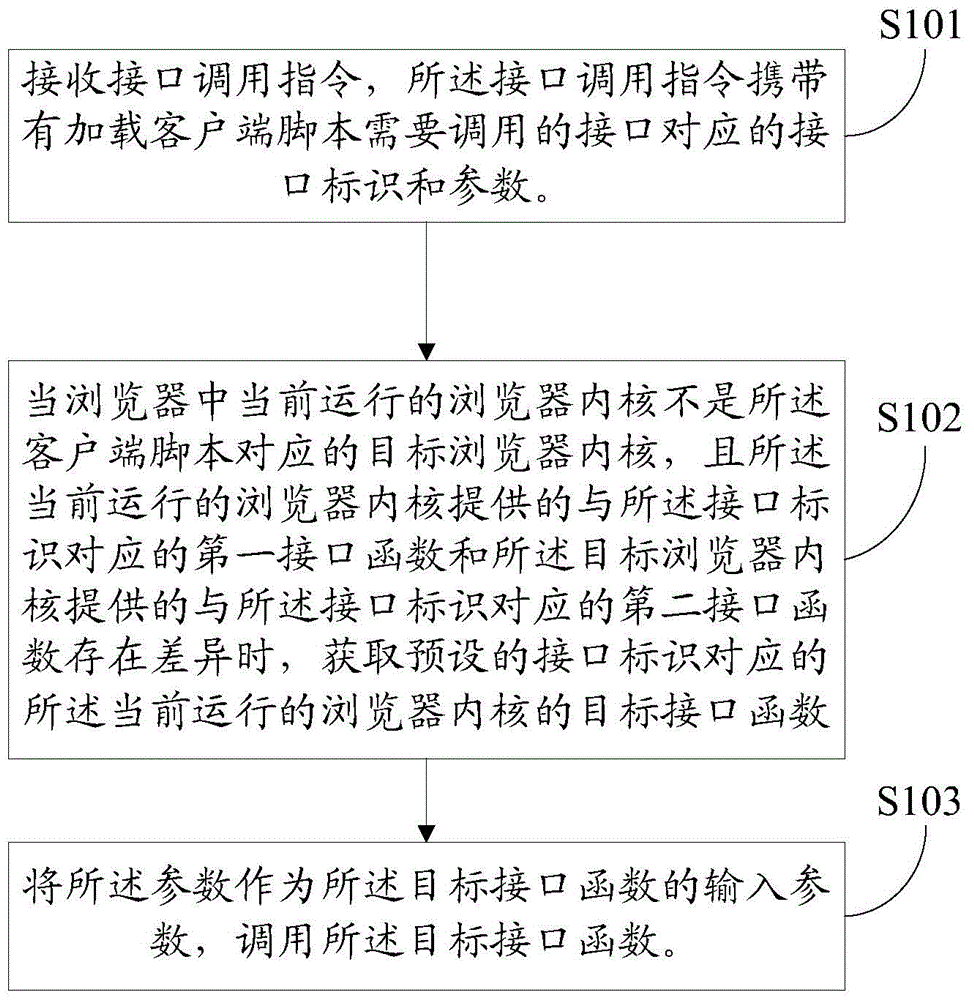

The embodiments of the present invention disclose an interface calling method, comprising: receiving an interface calling instruction with an interface identifier and parameter corresponding to an interface required to be called for loading a client script; obtaining a target interface function of a currently operating browser core corresponding to a preset interface identifier when the currently operating browser core in a browser is not a target browser core corresponding to the client script and a first interface function, corresponding to the interface identifier, provided by the currently operating browser core is different from a second interface function, corresponding to the interface identifier, provided by the target browser core; and using the parameter as an input parameter of the target interface function to call the target interface function. The embodiments of the present invention also disclose an interface calling apparatus and terminal. By utilization of the embodiments of the present invention, compatibility of the browser can be improved.

Owner:ZHUHAI BAOQU TECH CO LTD

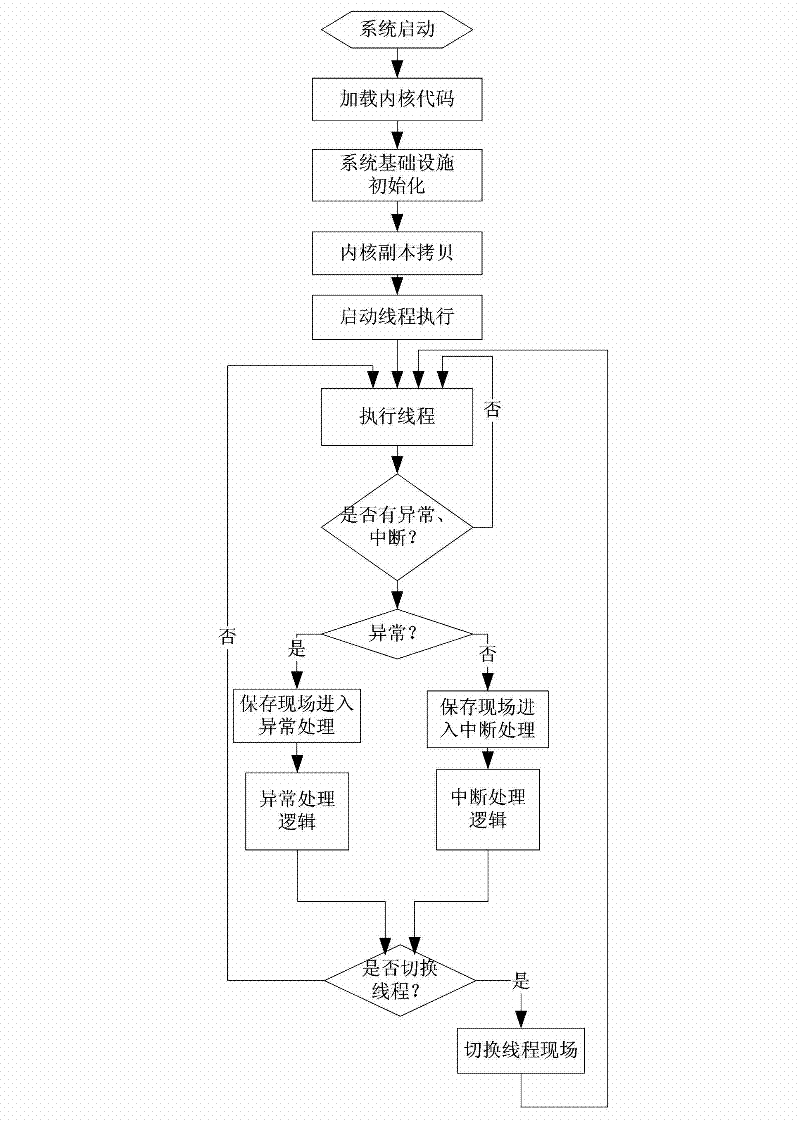

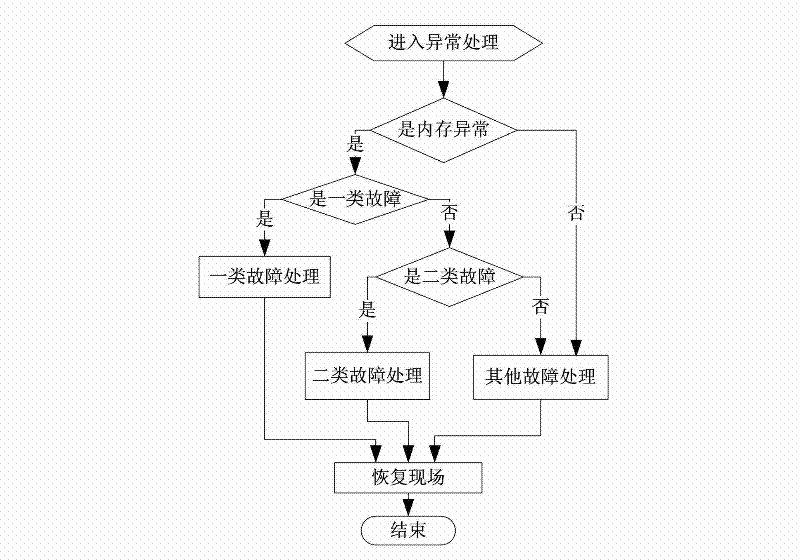

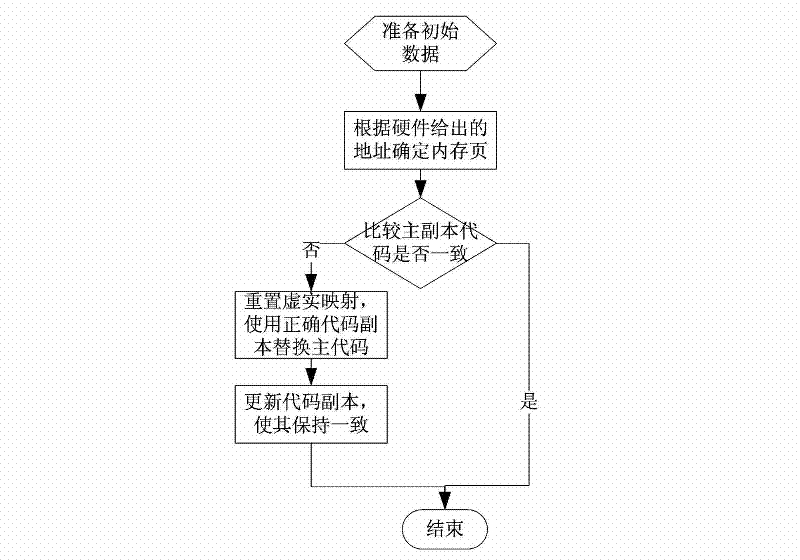

Kernel code soft fault tolerance method for hardware unrecoverable memory faults

ActiveCN102508742AImprove stabilityImprove reliabilityRedundant operation error correctionPage tableDependability

The invention discloses a kernel code soft fault tolerance method for hardware unrecoverable memory faults. The method comprises the following implementation steps of: 1) when an operating system loads the kernel codes to a physical memory, marking the kernel codes as main codes, setting multiple code copies for each segment of kernel codes, and loading the copies into the physical memory; 2) when the operating system runs, if the memory of the kernel codes is in memory exceptions, locating an error kernel page of the current main codes, comparing the error kernel page codes with the code copies, if errors of the codes of the error kernel page is determined, suspending the running of a computer, modifying a kernel code page table of the error kernel page, selecting a regular code copy from the code copies corresponding to the current main codes to substitute the current main codes, and then, keeping on running the computer. The method can improve the running stability of the operating system, enhance the reliability of a kernel module, reducing the possibility of error in the memory and reducing the interference of memory fault on the running of the operating system.

Owner:KYLIN CORP

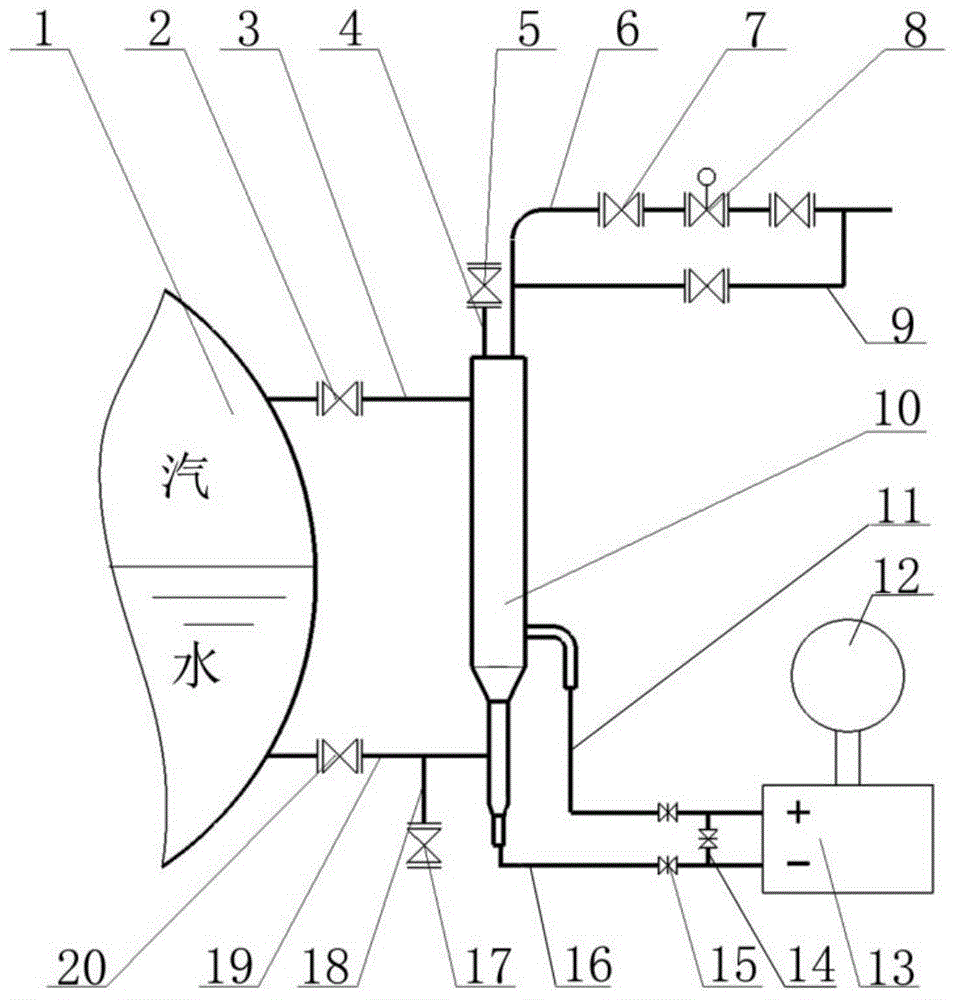

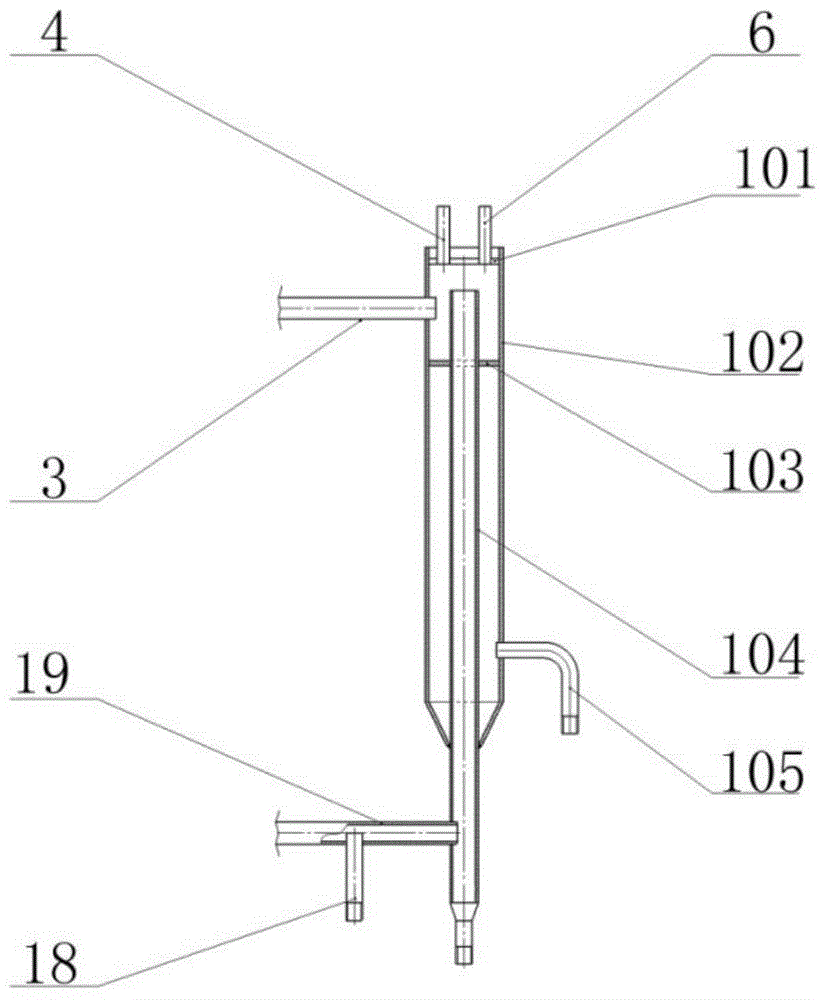

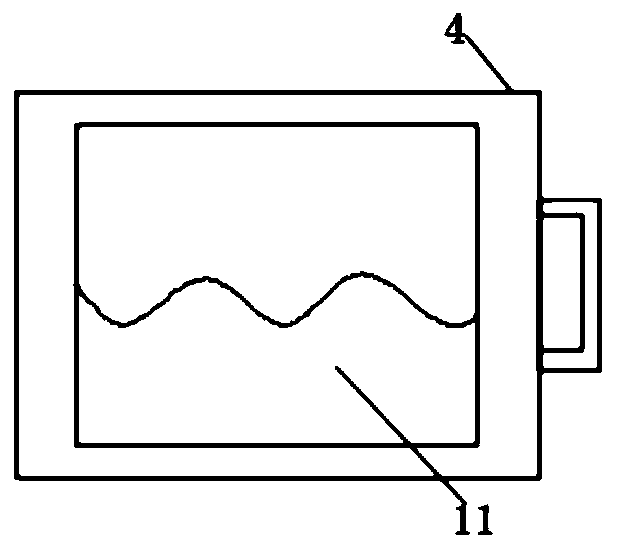

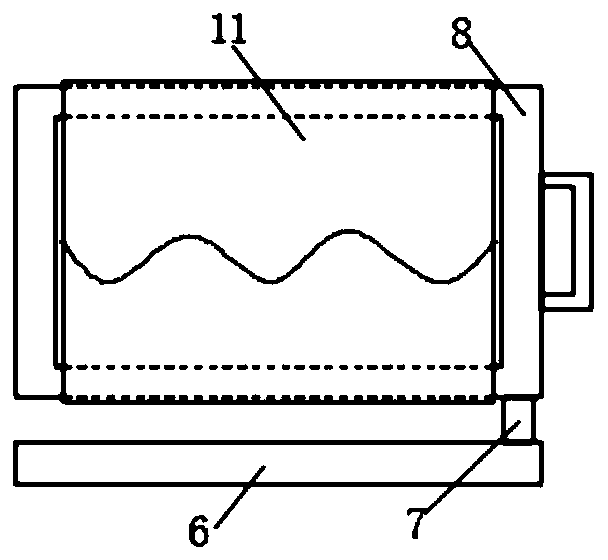

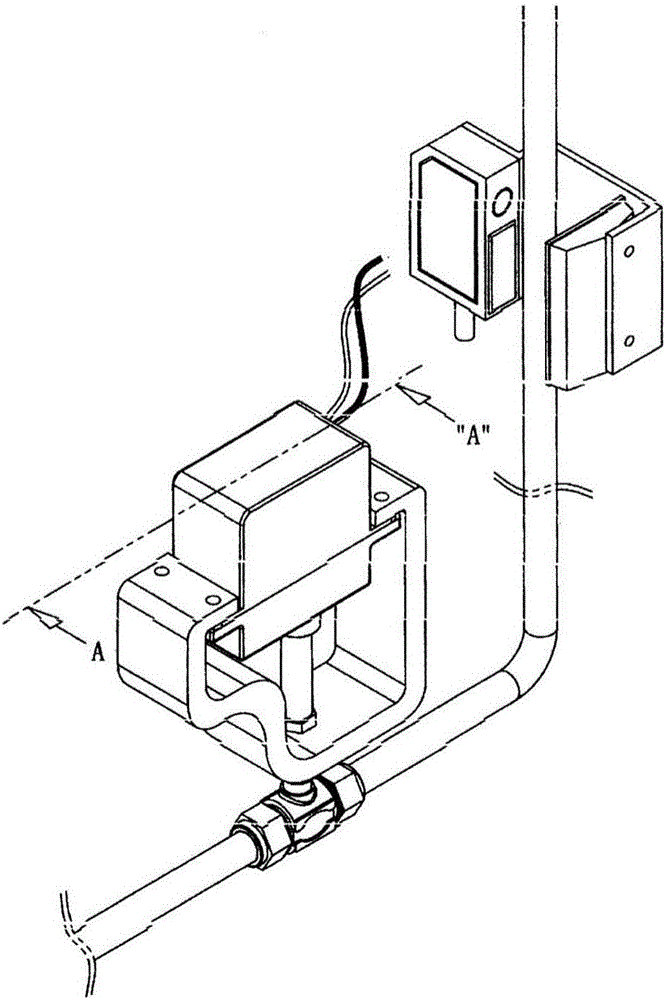

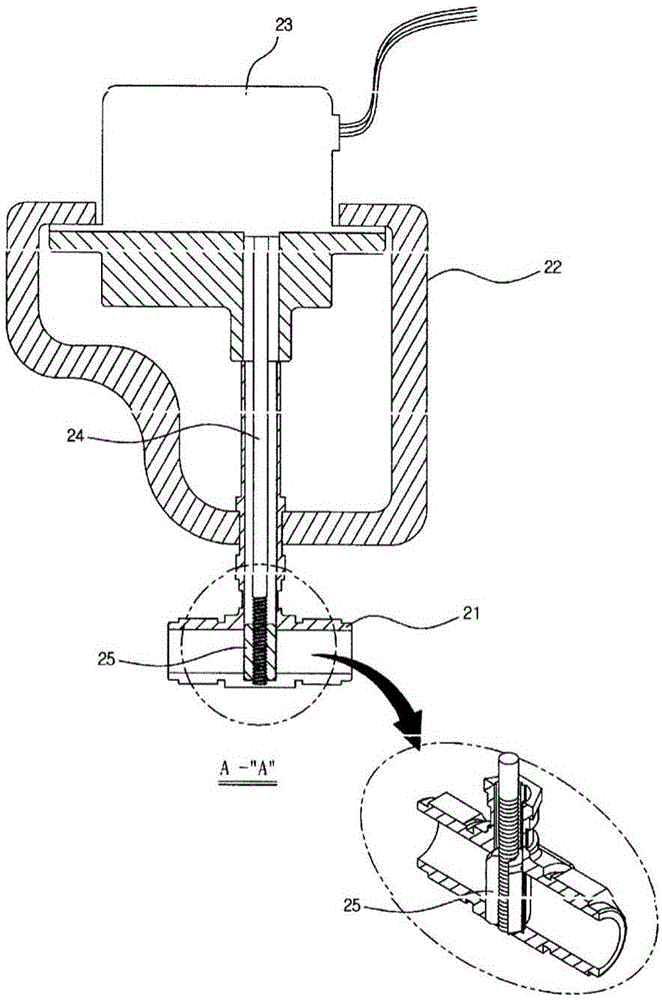

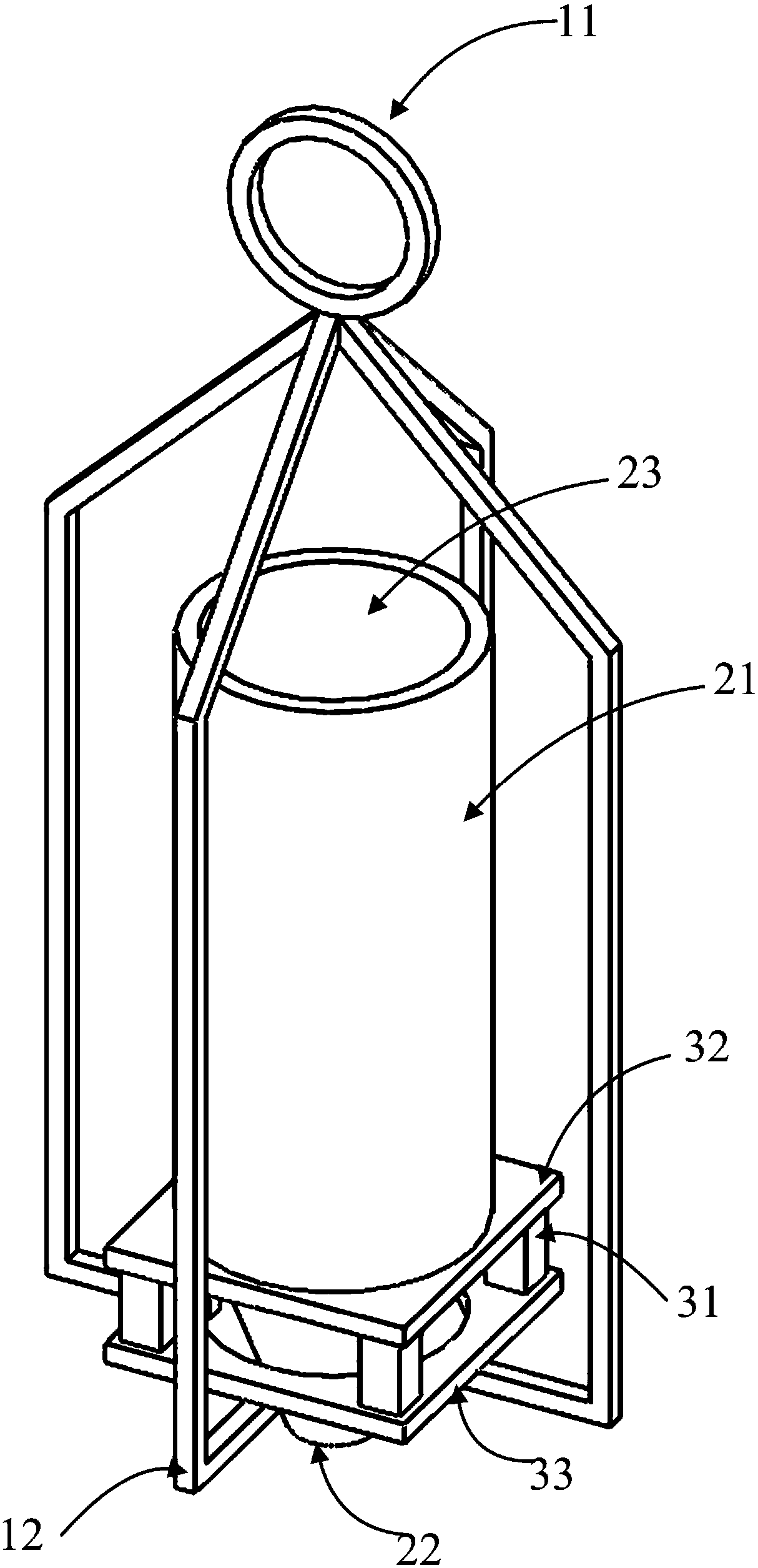

Balance container system capable of performing online setting check and online setting check method based on balance container system

ActiveCN104879739ARealize disassembly-free online setting and verificationReliable performanceBoiler indication operationsSteam boilersLower limitDifferential pressure

The invention relates to a balance container system capable of performing online setting check and an online setting check method based on the balance container system. The system comprises a balance container and a differential pressure transmitter connected with the balance container, wherein the balance container is connected with steam space and water space of a steam dome through a steam connection pipe and a water connection pipe respectively, and the differential pressure transmitter is connected with a boiler control system; a water supplementing pipe and an emptying pipe are vertically arranged at the upper part of a balance container barrel, the water connection pipe is vertically downwards provided with a water check pipe through a tee joint, the lower end surface of the water supplementing pipe is set as high as the water level detection upper limit position, and the upper end surface of the water check pipe is set as high as the water level detection lower limit position. The system is simple in structure and convenient to use and adjust, and can realize non-dismantling online setting check of the balance container; the online setting check method based on the balance container system comprises three adjusting modes including manual setting during initial assembly of a boiler, manual compensation setting during operation and automatic compensation setting, the setting is rapid and effective, stable and reliable working performance of the balance container can be guaranteed, and the time for setting check of the balance container can be greatly saved.

Owner:SINOSTEEL ANSHAN RES INST OF THERMO ENERGY CO LTD

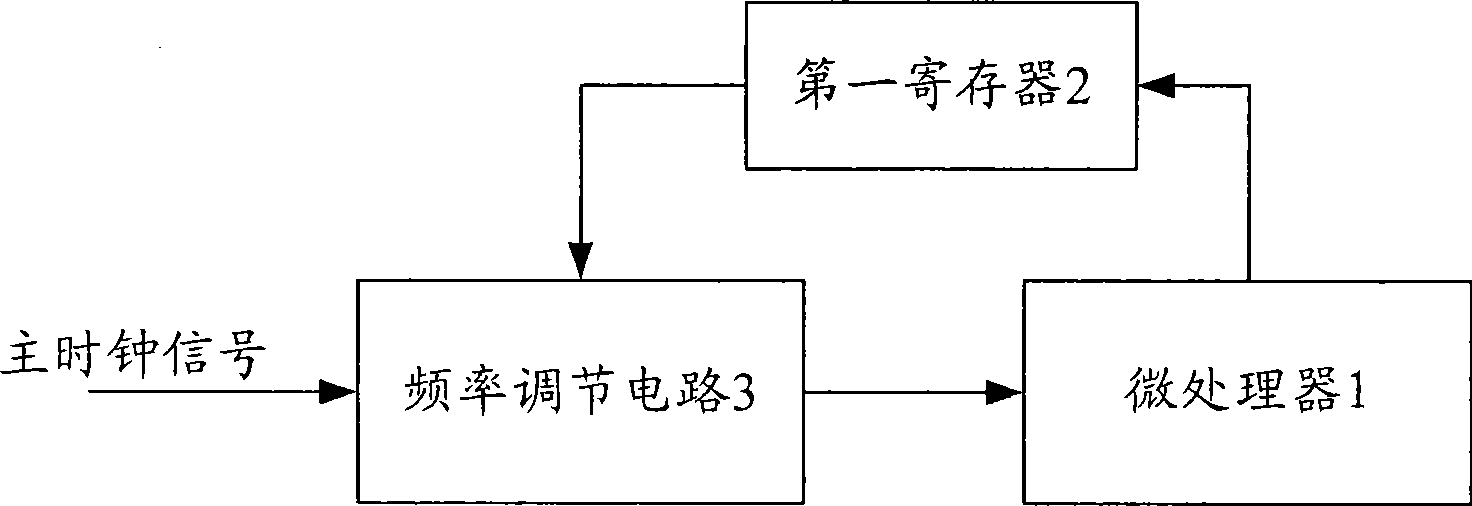

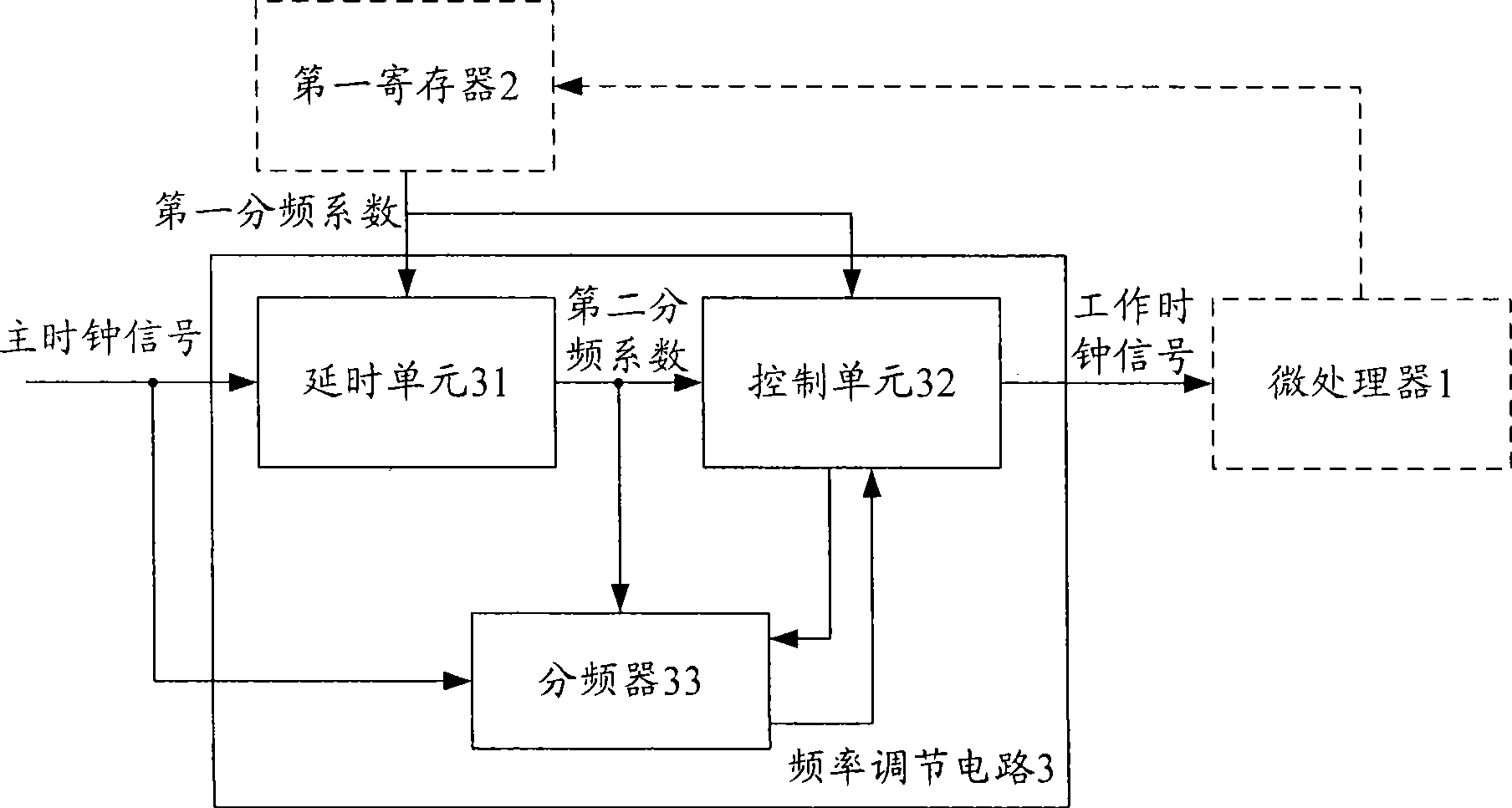

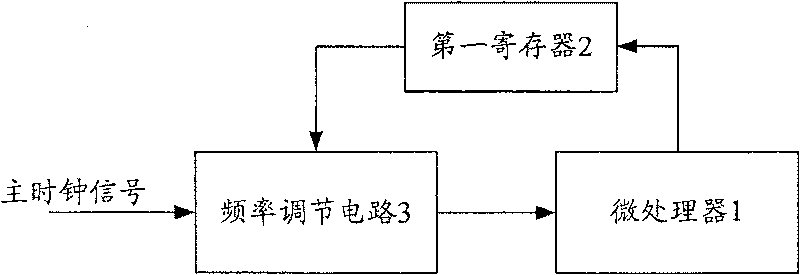

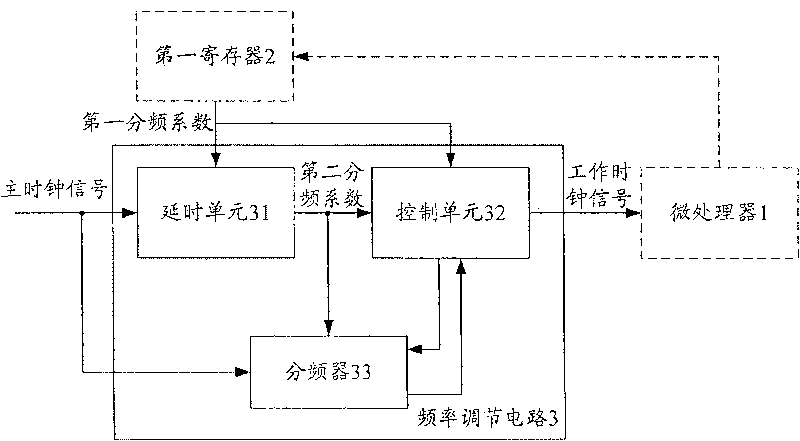

Frequency-adjusting device

ActiveCN101446845AAvoid running errorsSolve the problem of sudden change in duty cycleGenerating/distributing signalsElectronic informationInformation system

Owner:RDA MICROELECTRONICS SHANGHAICO LTD

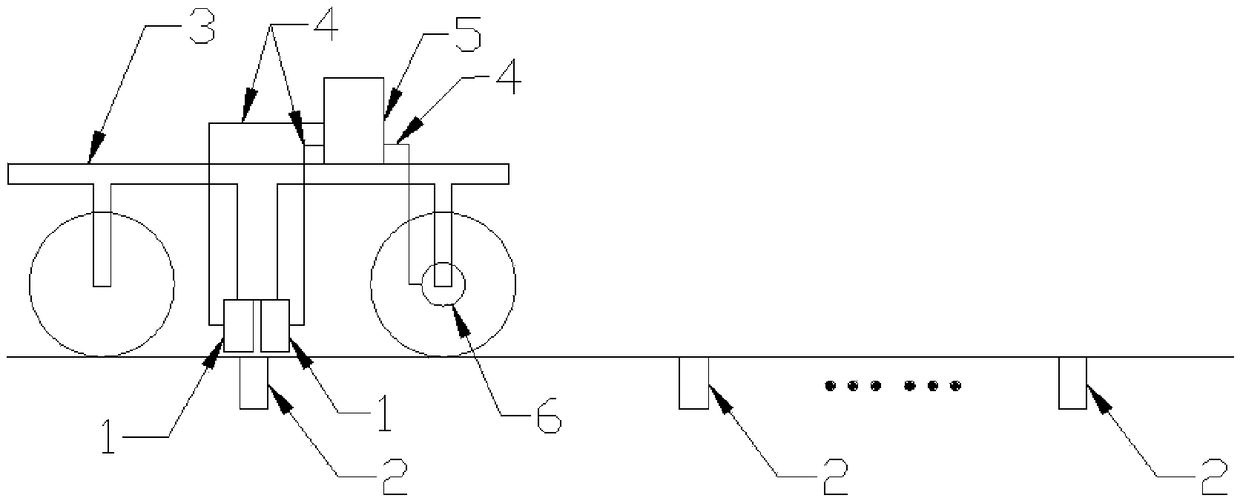

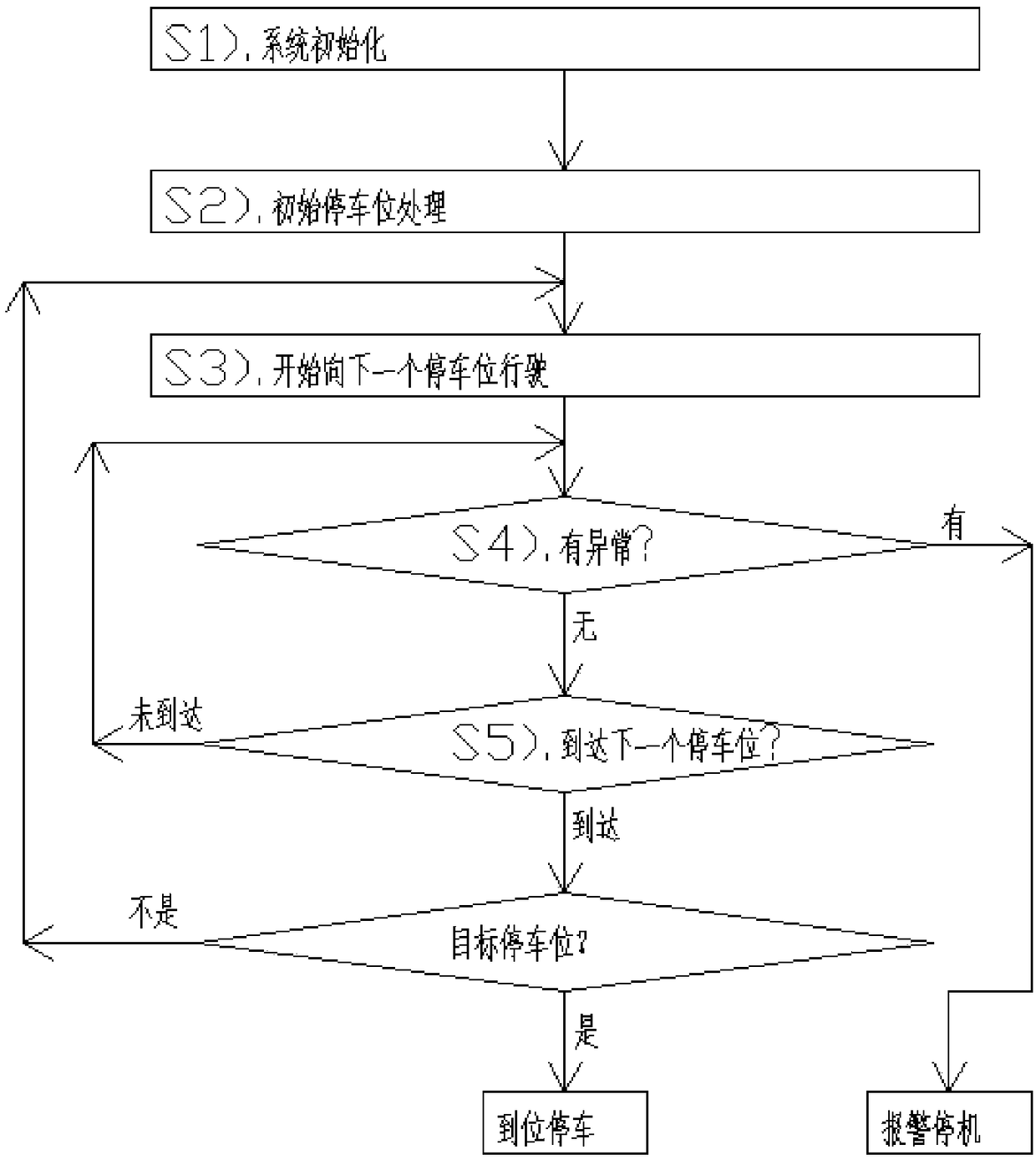

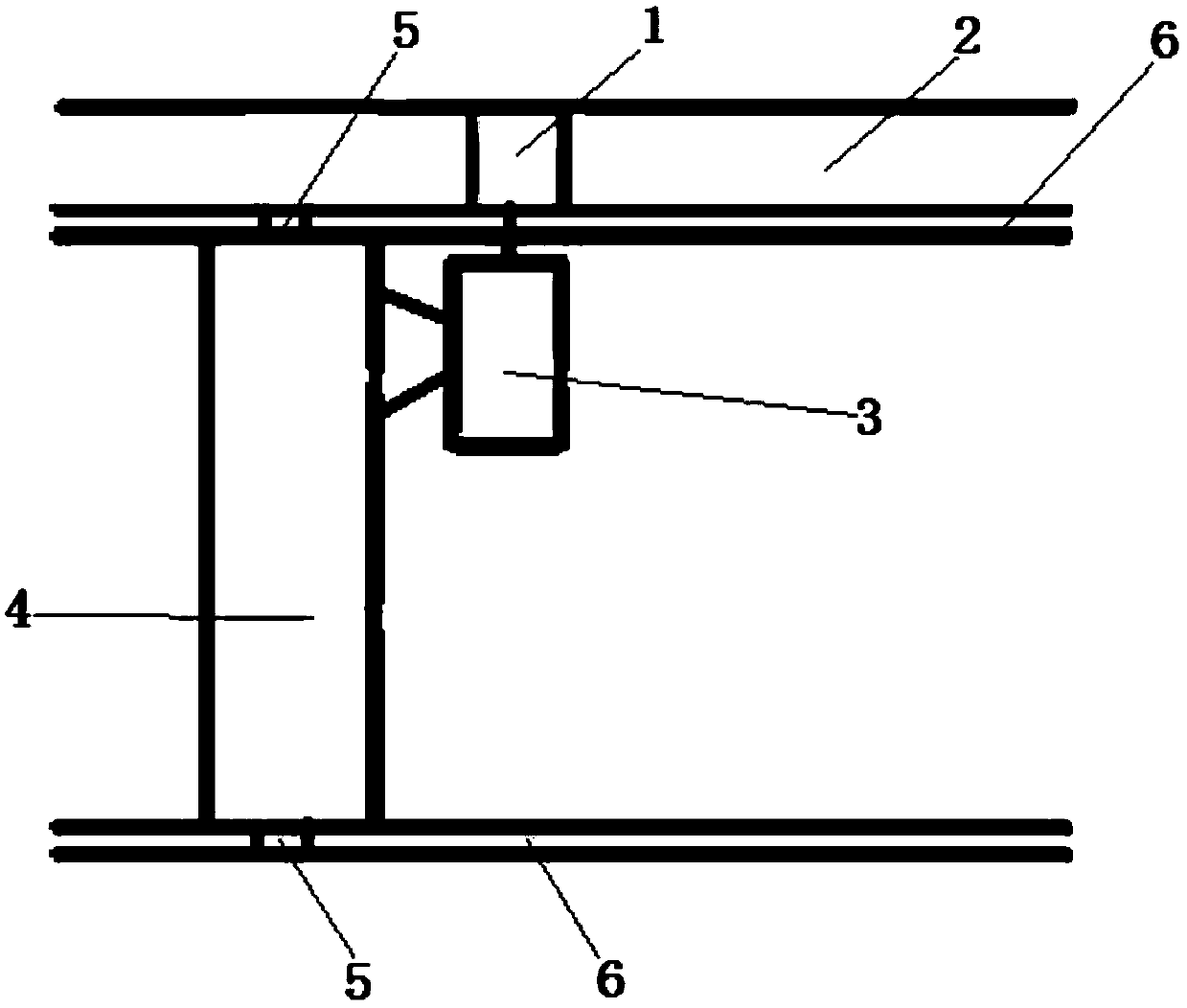

High-reliability moving positioning control method, device and system

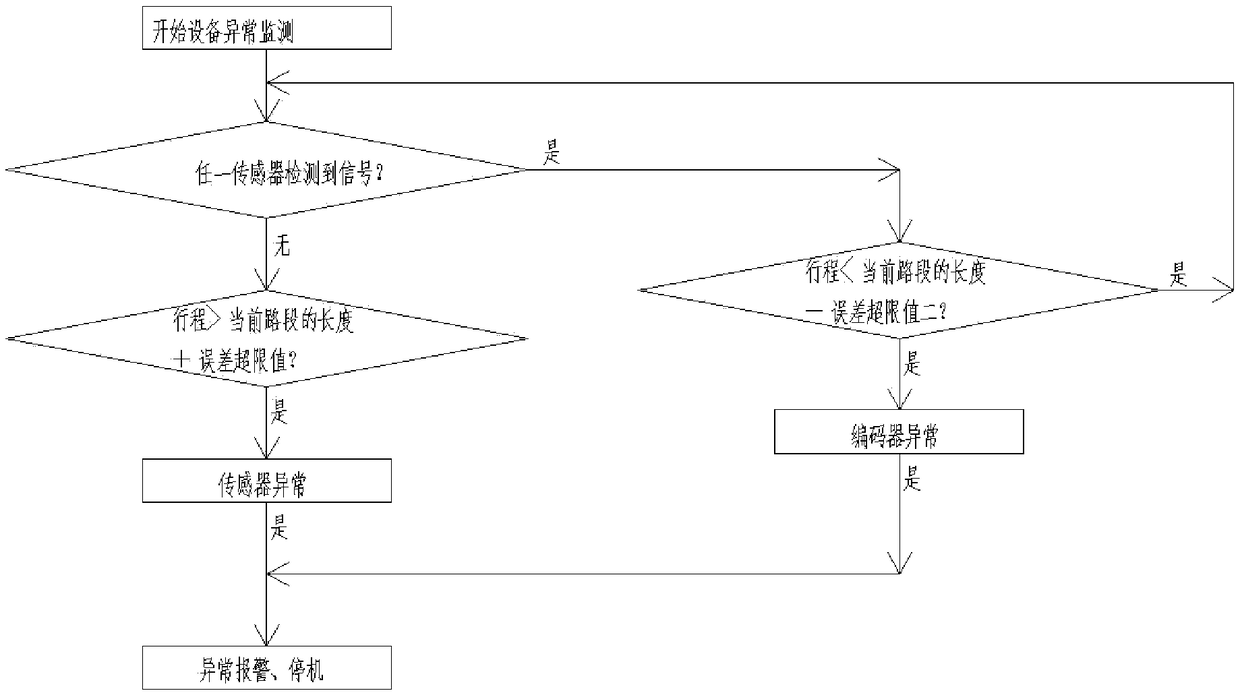

PendingCN108919817AAvoid work mistakesAvoid running errorsPosition/course control in two dimensionsParking spacePositioning equipment

The invention relates to a high-reliability moving positioning control system. The high-reliability moving positioning control system comprises a high-reliability moving positioning control device andan induction block, wherein the high-reliability moving positioning control device comprises a controller, an encoder and two sensors, the controller is a computer controller, the encoder and the twosensors are connected with the controller in a matching way, the encoder, the two sensors and the controller are fixed on a trolley in a matching way, the two sensors are arranged in a travelling direction of the trolley and are adjacent to each other in a forward and backward direction, the two sensors are matched with the induction block arranged at a parking position, and the encoder is installed with the trolley in a matching way and is used for detecting the range of the trolley. The two sensors, the induction block and the encoder are integrally used, a fault of key positioning equipment can be detected in real time, and a system working error caused by positioning mistake is prevented.

Owner:郑州鼎源自动化科技有限公司

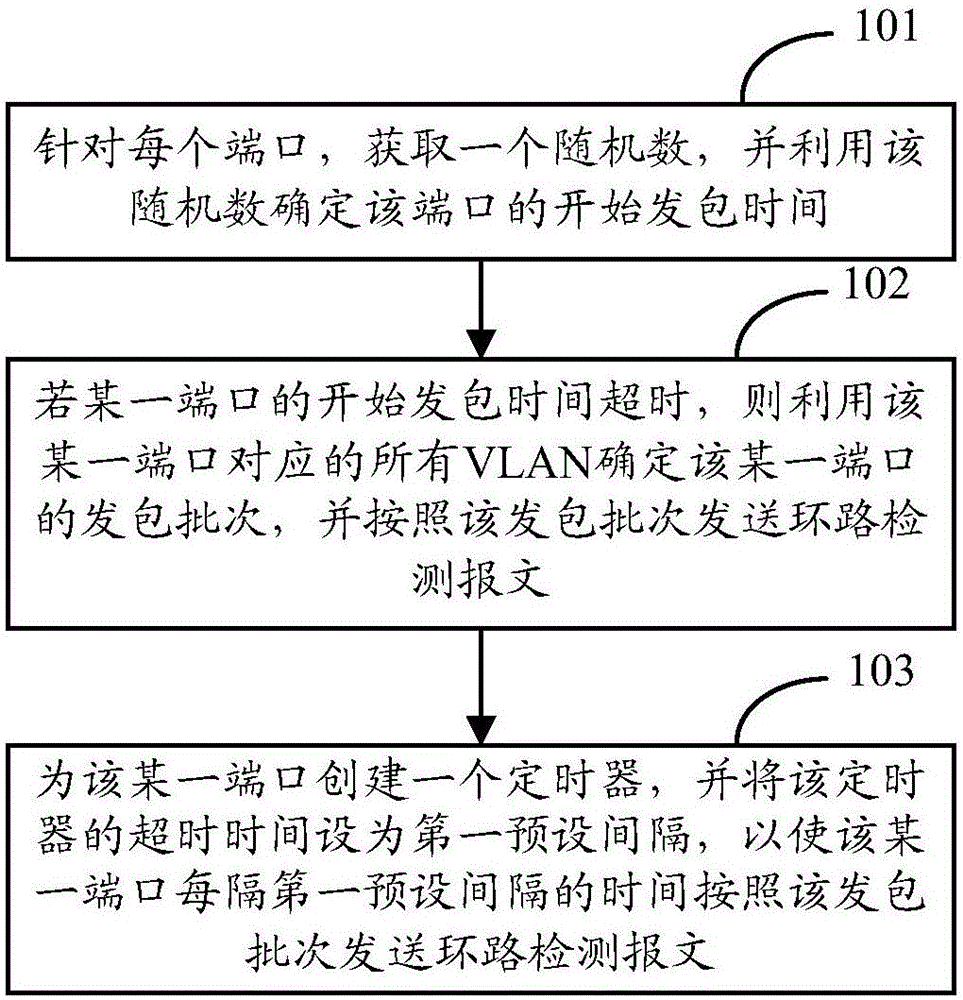

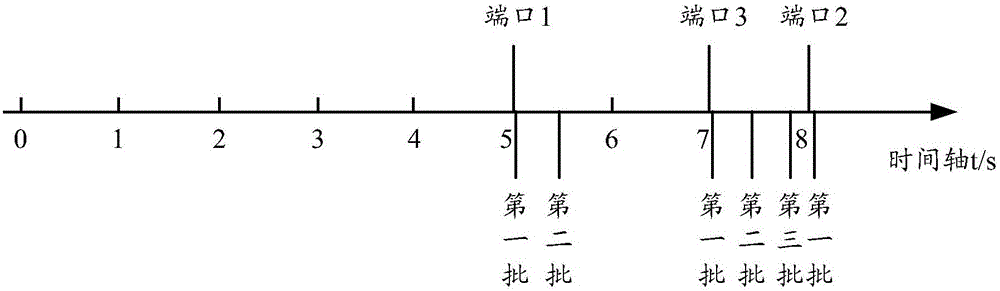

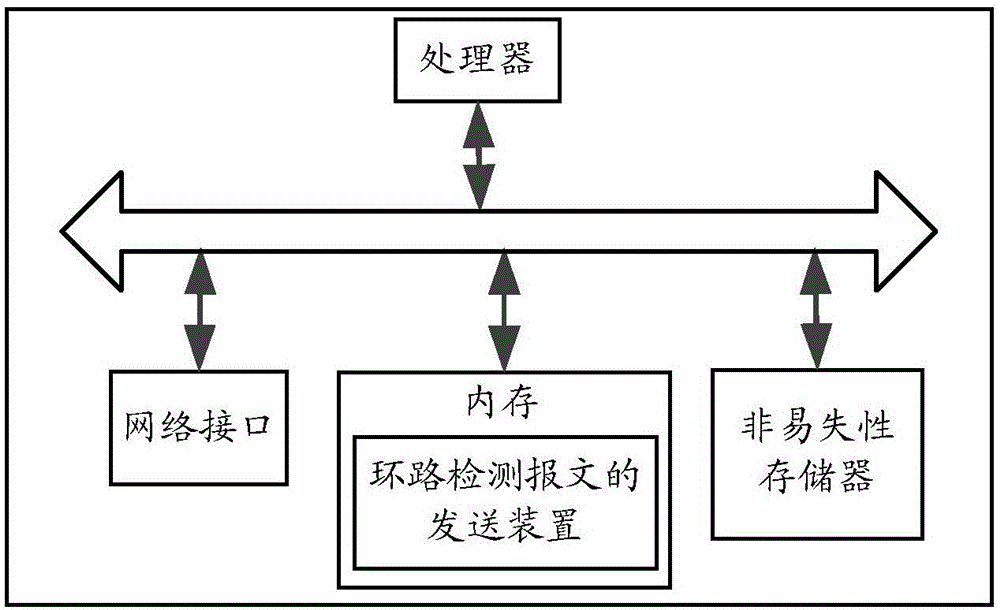

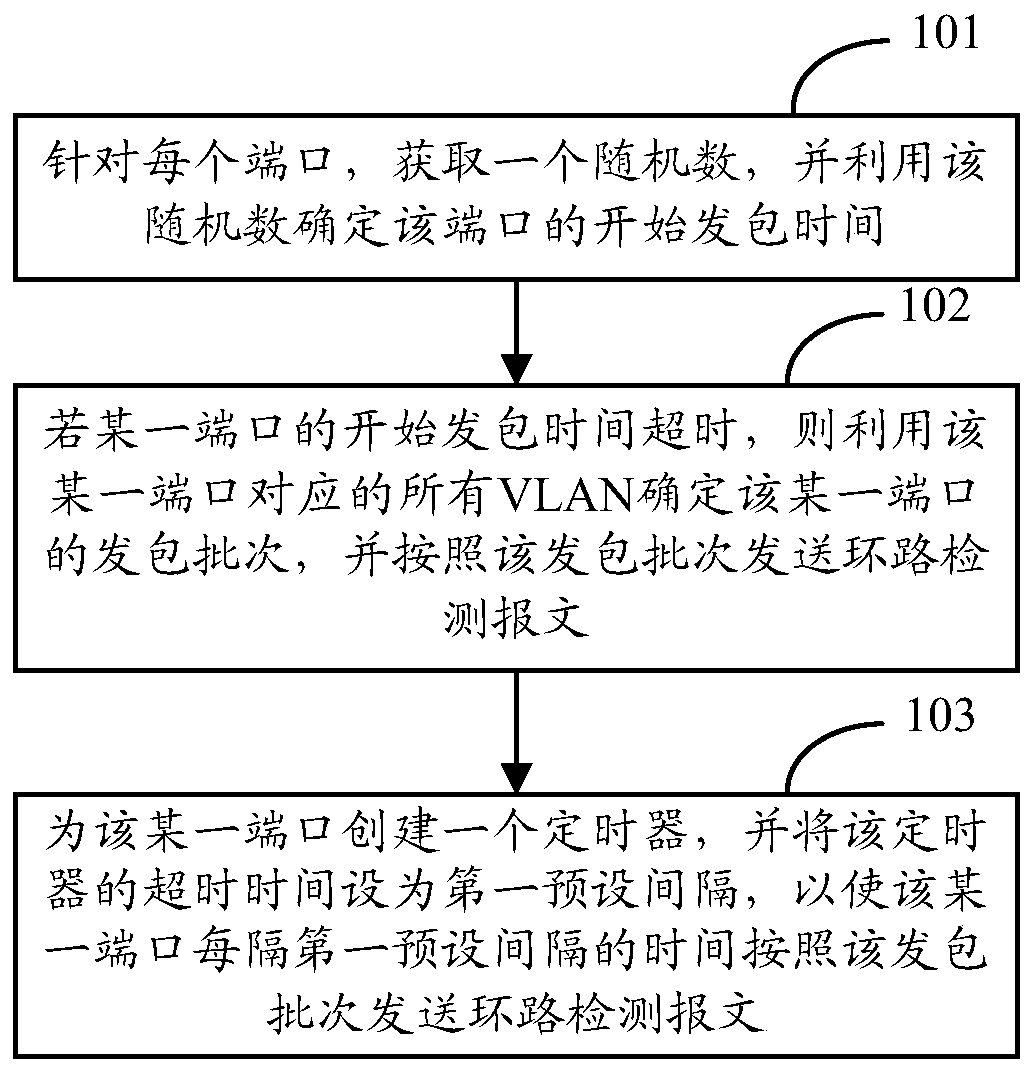

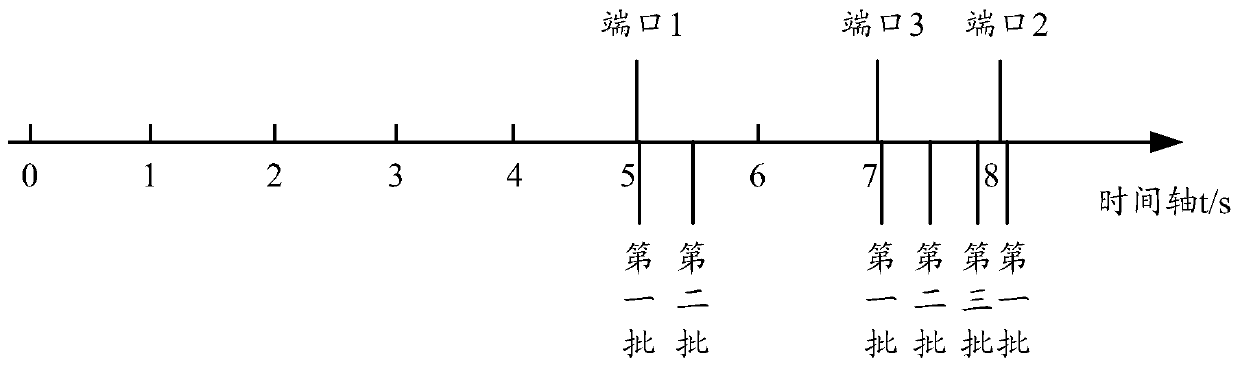

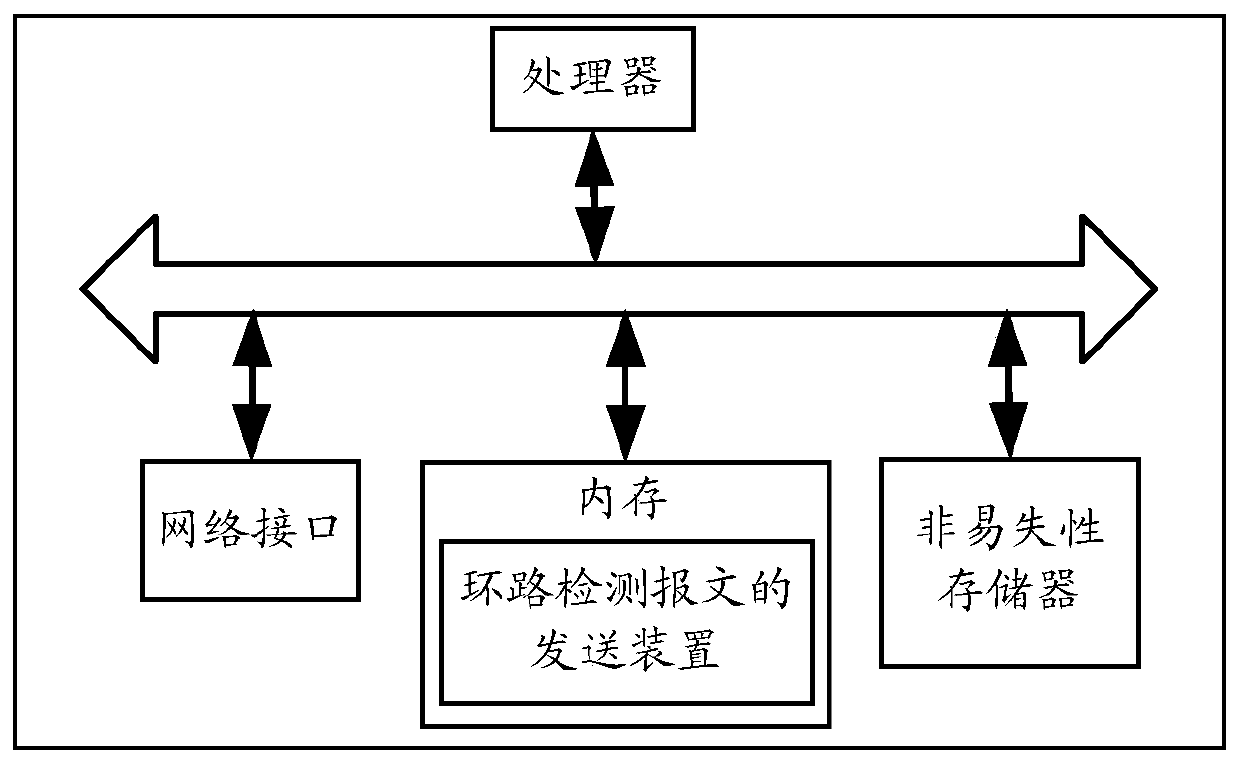

Method and apparatus for sending loop detection messages

ActiveCN106209561AImprove the efficiency of sending and receiving messagesImprove efficiencyNetworks interconnectionStart timeTimer

The application provides a method and an apparatus for sending loop detection messages. The method comprises the steps of aiming at each port, acquiring a random number, and determining message sending start time of each port by utilizing the random number; if the message sending start time of a certain port is out, determining a message sending batch of the certain port by utilizing all VLANs (Virtual Local Area Networks) corresponding to the certain port, and sending a loop detection message according to the message sending batch; and creating a timer for the certain port, setting timeout of the timer as a first preset interval, so that the certain port sends the loop detection message at a time interval equal to the first preset interval according to the message sending batch. According to the application, different message sending start time is obtained by different random numbers, so that time when each port sends the loop detection message is dispersed, and the number of the loop detection messages sent at the same time is reduced. Moreover, network equipment sends out the loop detection message of each port according to the batch, so that the number of sending the loop detection messages at the same time is further reduced.

Owner:HANGZHOU DPTECH TECH

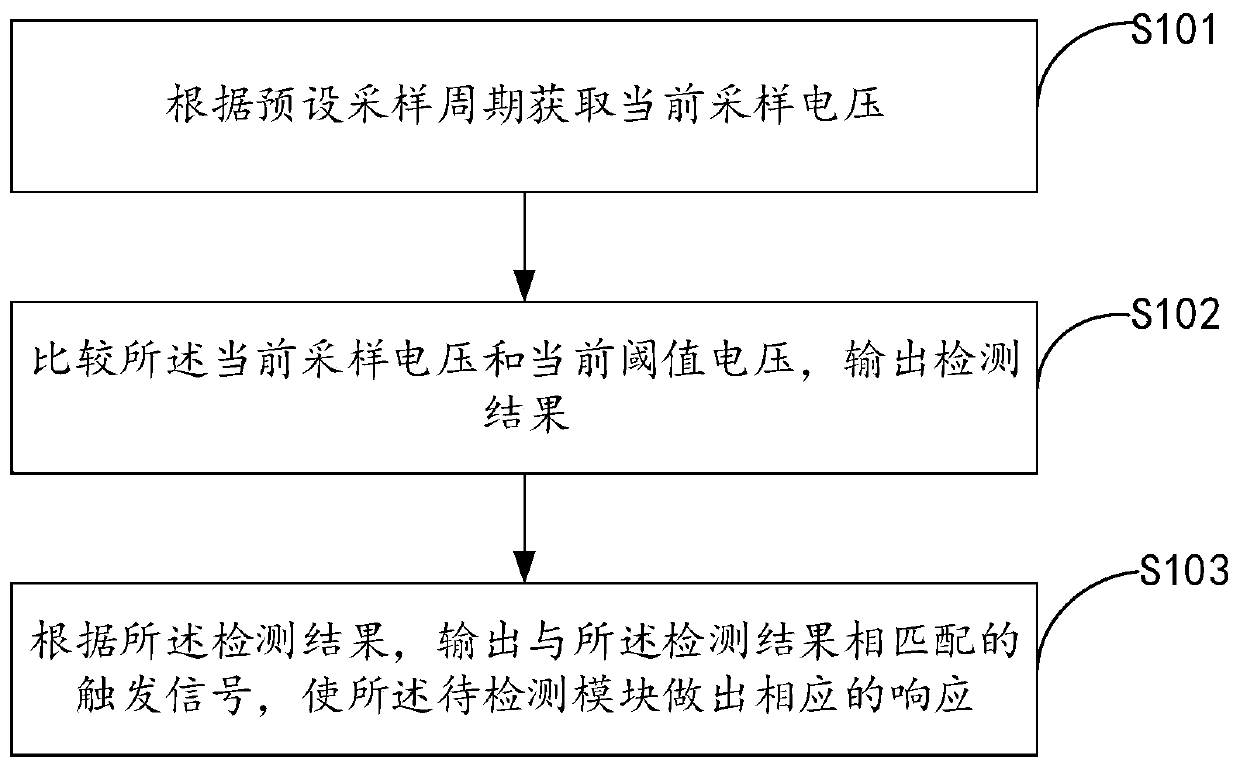

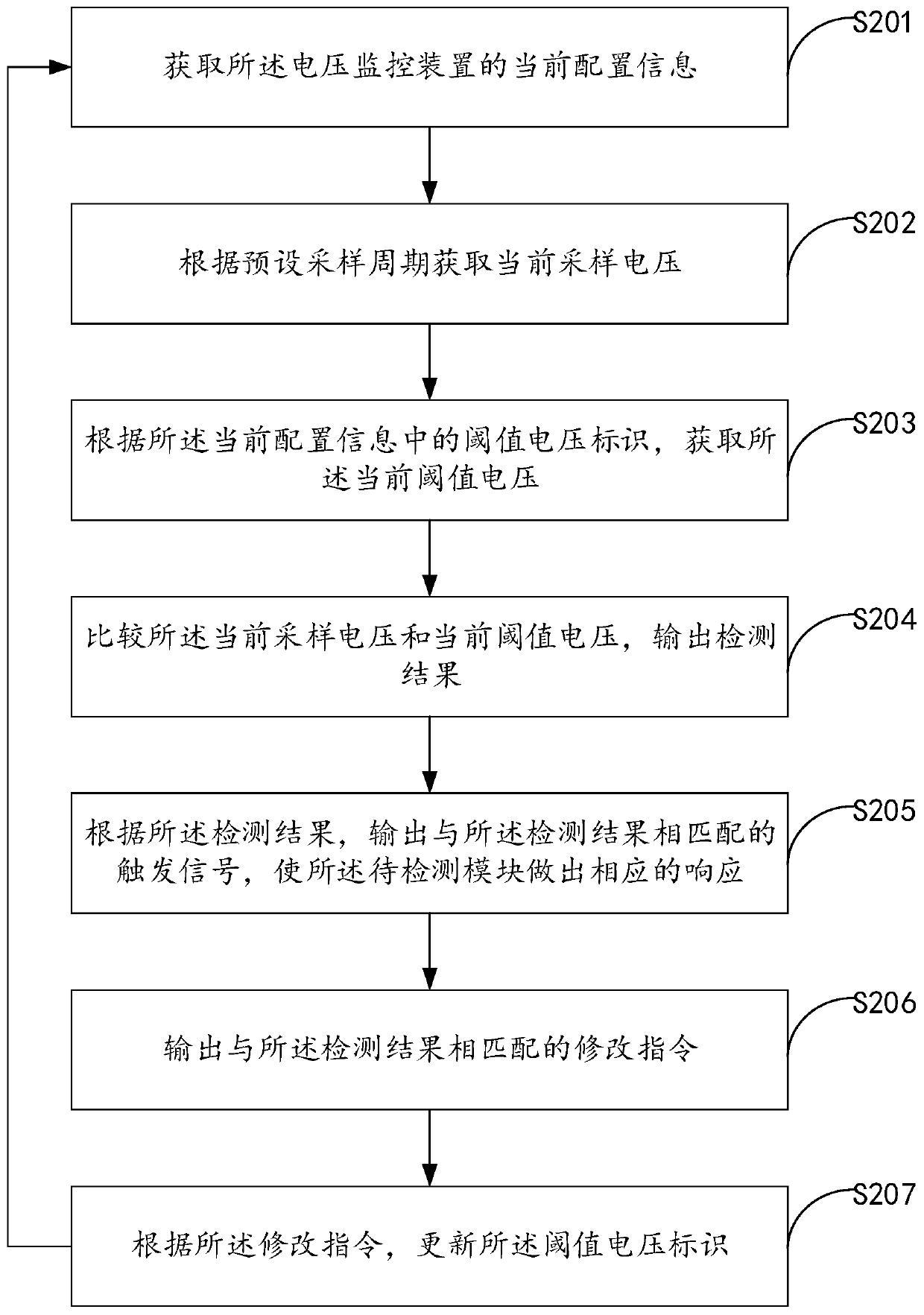

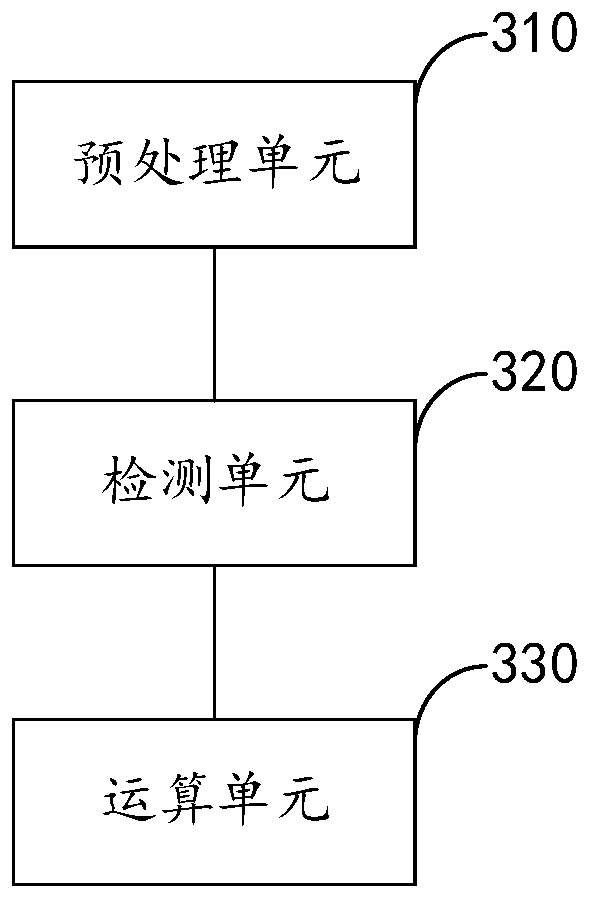

Voltage monitoring method and device

ActiveCN110954843ATimely responseAvoid running errorsPower supply testingVoltage measurements onlyCurrent thresholdEngineering

The invention provides a voltage monitoring method and device, and the method comprises the steps of obtaining a current sampling voltage according to a preset sampling period, wherein the current sampling voltage is the input voltage of a to-be-detected module; comparing the current sampling voltage with a current threshold voltage, and outputting a detection result; and outputting a trigger signal matched with the detection result according to the detection result, so that the to-be-detected module makes a corresponding response. According to the voltage monitoring method provided by the invention, the input voltage can be compared with the threshold voltage, and the trigger signal corresponding to the comparison result is sent out, so that the to-be-detected module can respond in time under different startup and shutdown interval durations, and the problem of operation errors can be avoided in time.

Owner:GREE ELECTRIC APPLIANCES INC

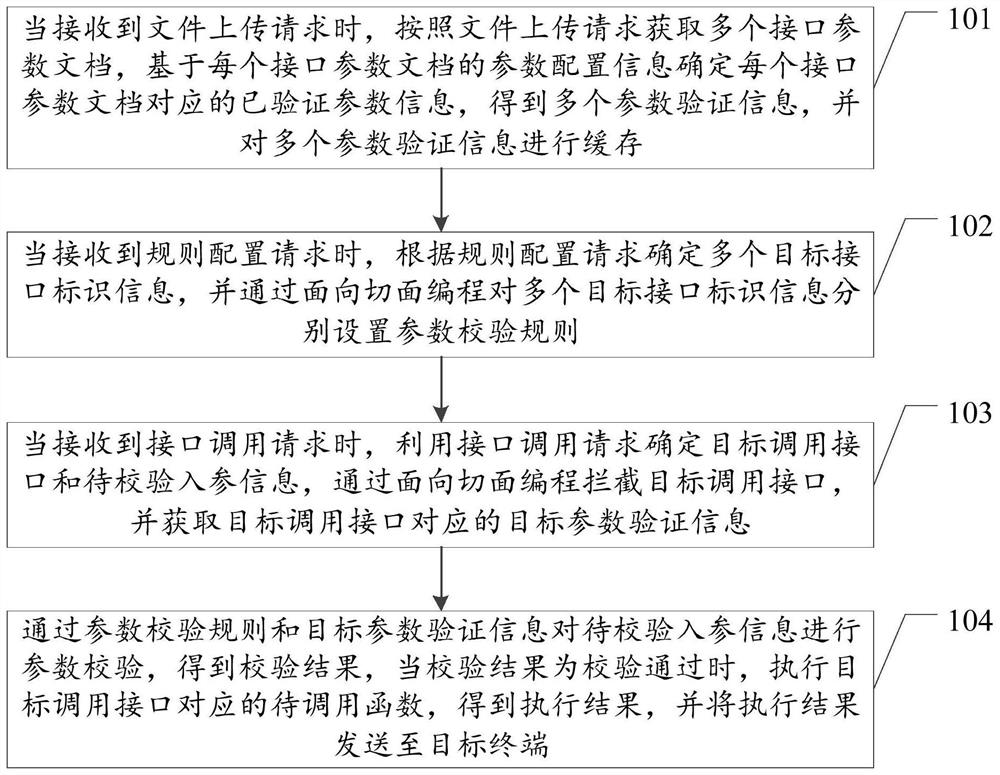

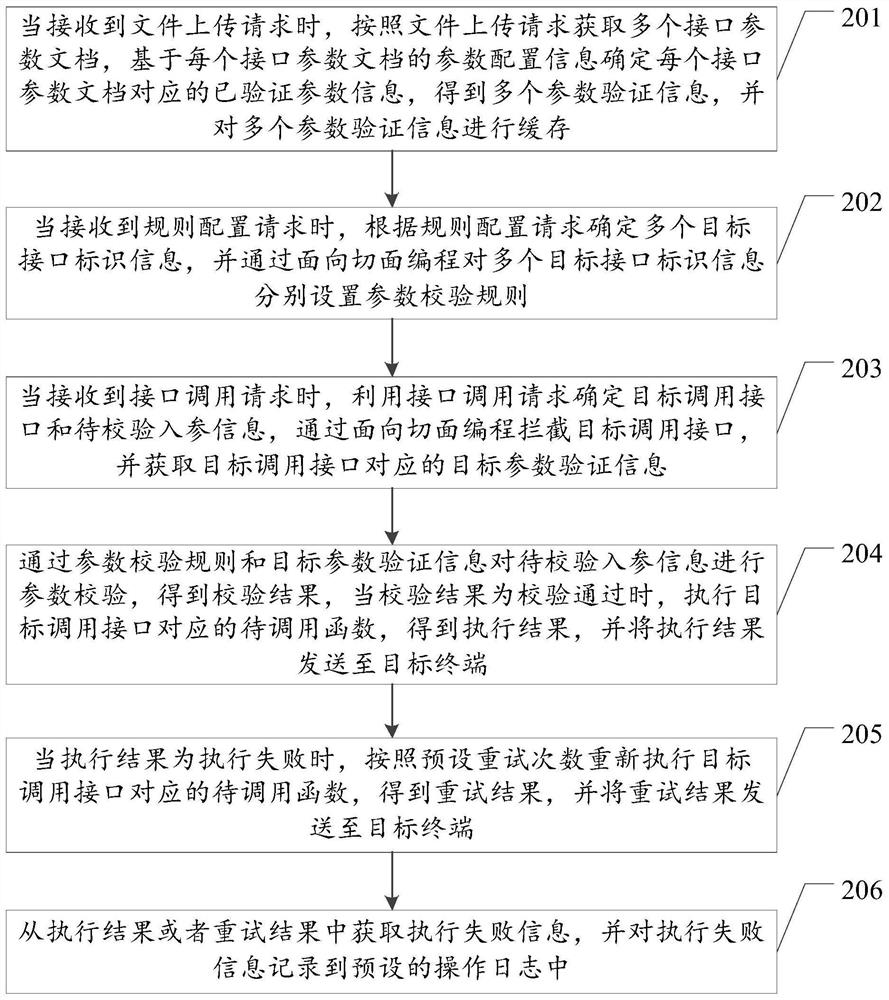

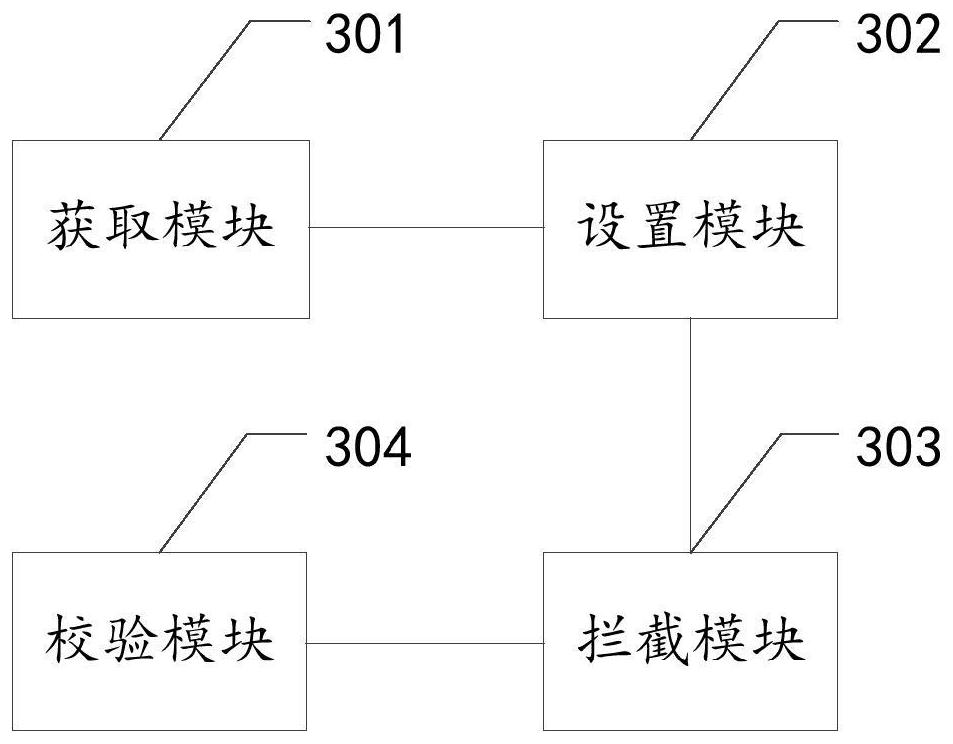

Interface parameter verification method, device and equipment and storage medium

PendingCN112306879AEasy maintenanceEasy to manageDatabase management systemsSoftware testing/debuggingComputer hardwareVerification

The invention relates to the technical field of big data, and discloses an interface parameter verification method, device and equipment and a storage medium, which are used for improving the verification efficiency of interface parameters. The interface parameter verification method comprises the steps of obtaining a plurality of interface parameter documents, determining corresponding verified parameter information based on each interface parameter document, and obtaining a plurality of parameter verification information; determining a plurality of pieces of target interface identification information, and respectively setting parameter verification rules for the plurality of pieces of target interface identification information; determining a target calling interface and to-be-verifiedinput parameter information, intercepting the target calling interface through aspect-oriented programming, and obtaining corresponding target parameter verification information; and performing parameter verification on the to-be-verified parameter information through the parameter verification rule and the target parameter verification information, and when the verification result is that the verification is passed, executing a to-be-called function corresponding to the target calling interface to obtain an execution result. In addition, the invention also relates to a blockchain technology,and a plurality of parameter verification information can be stored in the blockchain node.

Owner:PINGAN PUHUI ENTERPRISE MANAGEMENT CO LTD

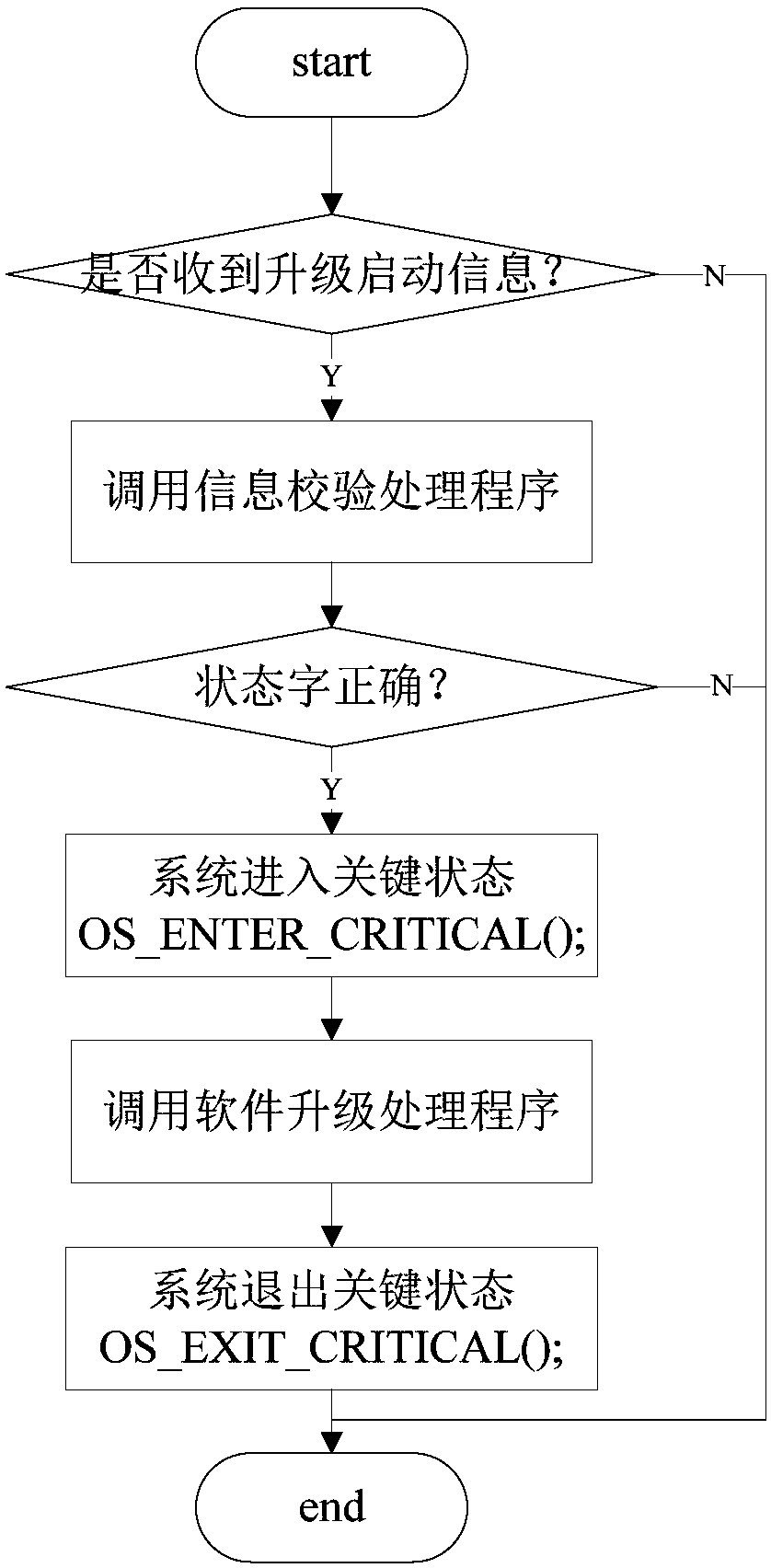

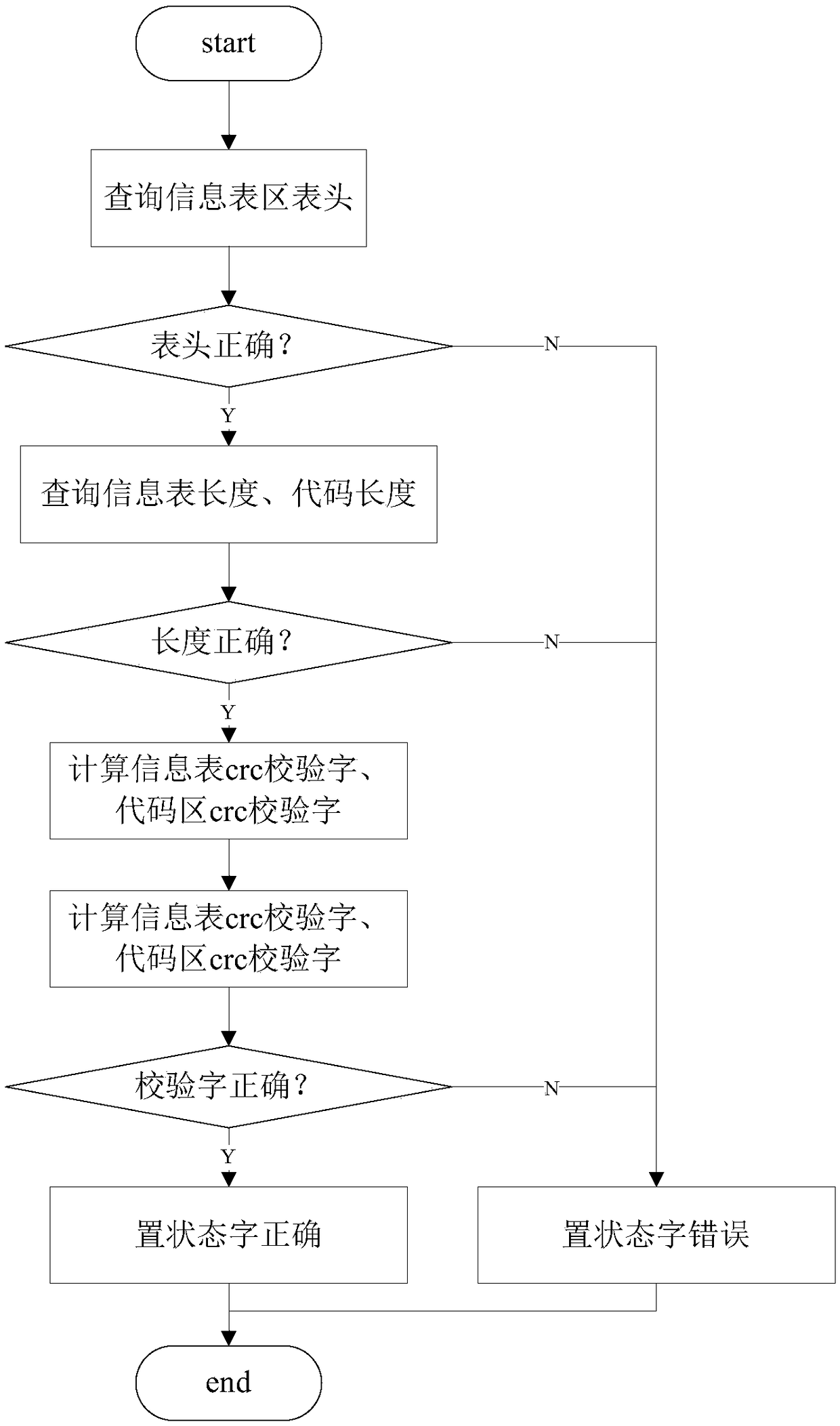

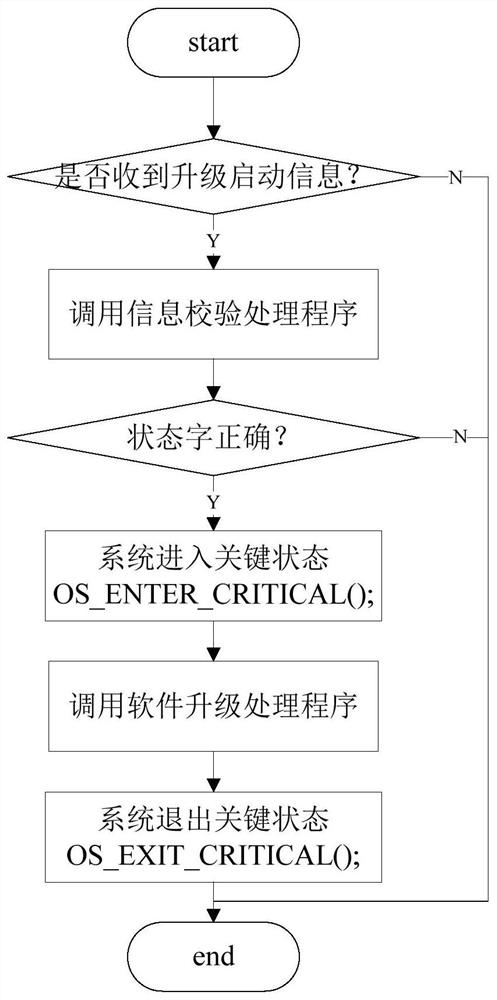

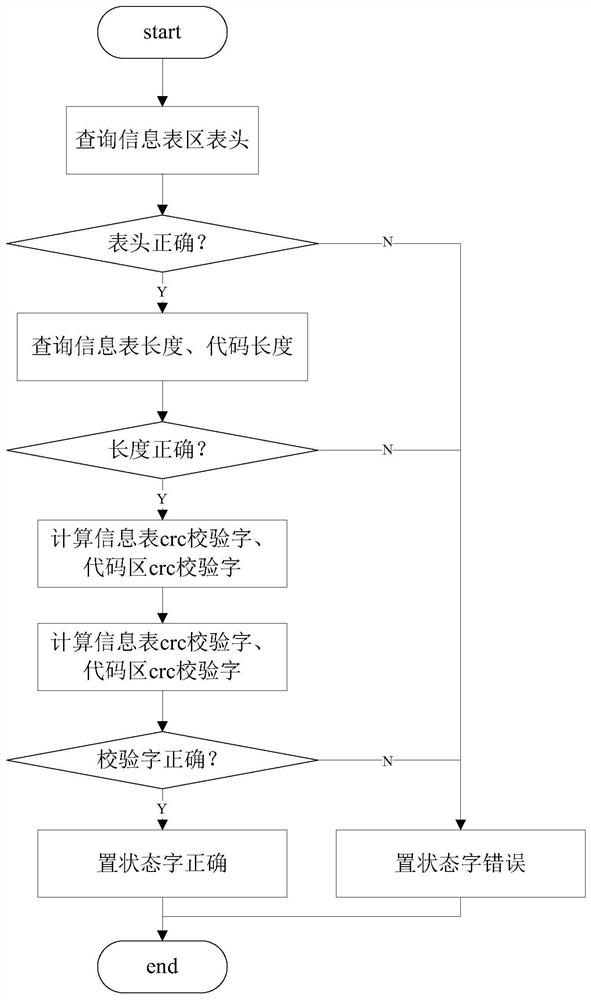

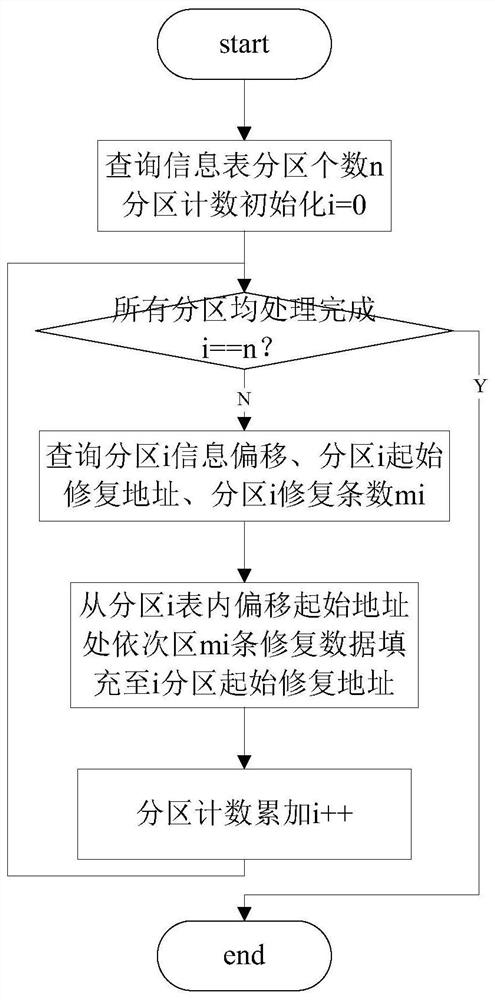

Remote dynamic upgrading method and method for embedded software of power system

ActiveCN108196873ASecurity upgradeReliable upgradeSoftware engineeringElectric power systemSoftware engineering

The invention discloses a remote dynamic upgrading method and method for embedded software of a power system. The method comprises the steps of remotely loading a software upgrade information table and a software upgrade code to the power system's equipment node to be upgraded; when an 'idle' task runs in the equipment node (all system tasks are idle), performing information check on the softwareupgrade information table, and executing dynamic software upgrading if the information check shows a positive result. Through information check and interruption control, a software upgrading process of good safety and reliable is guaranteed.

Owner:SHANDONG UNIV OF SCI & TECH

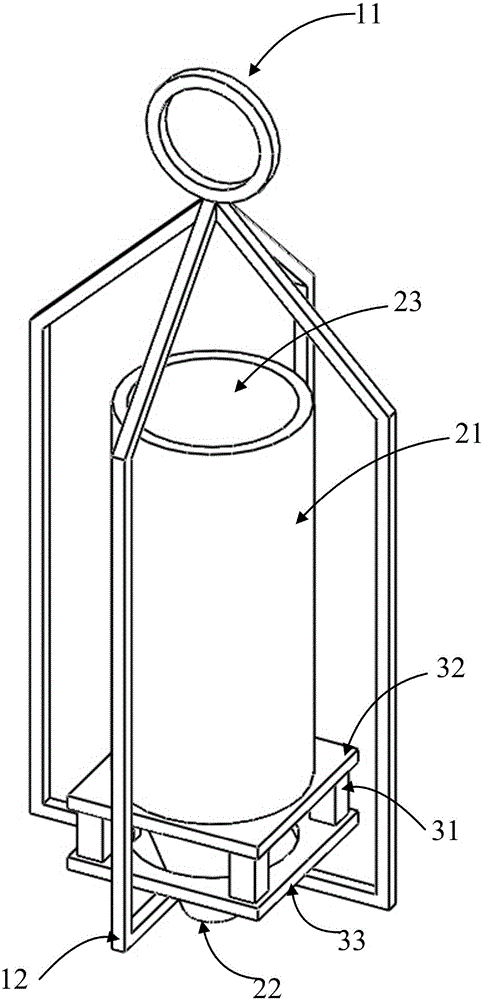

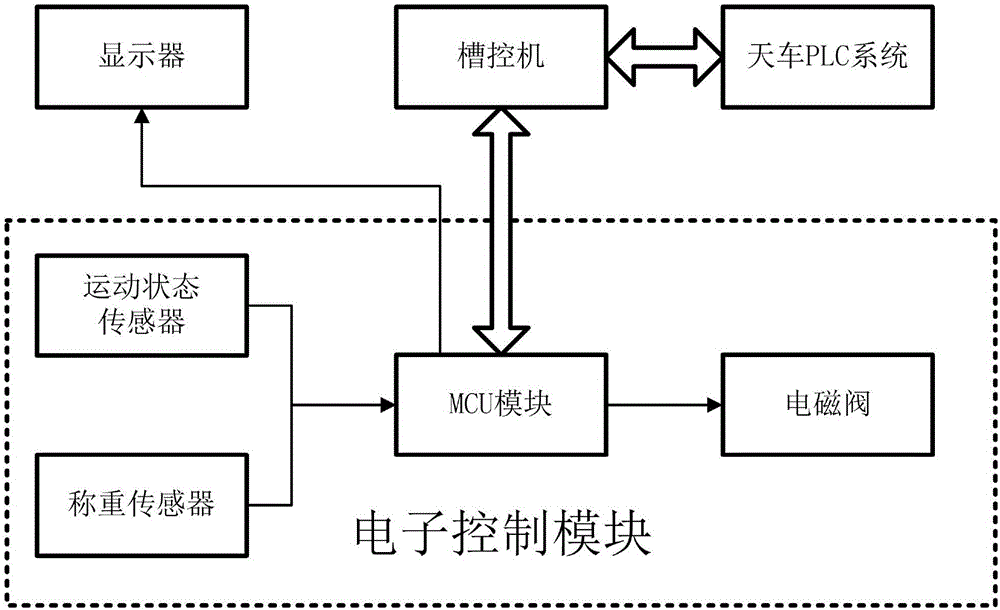

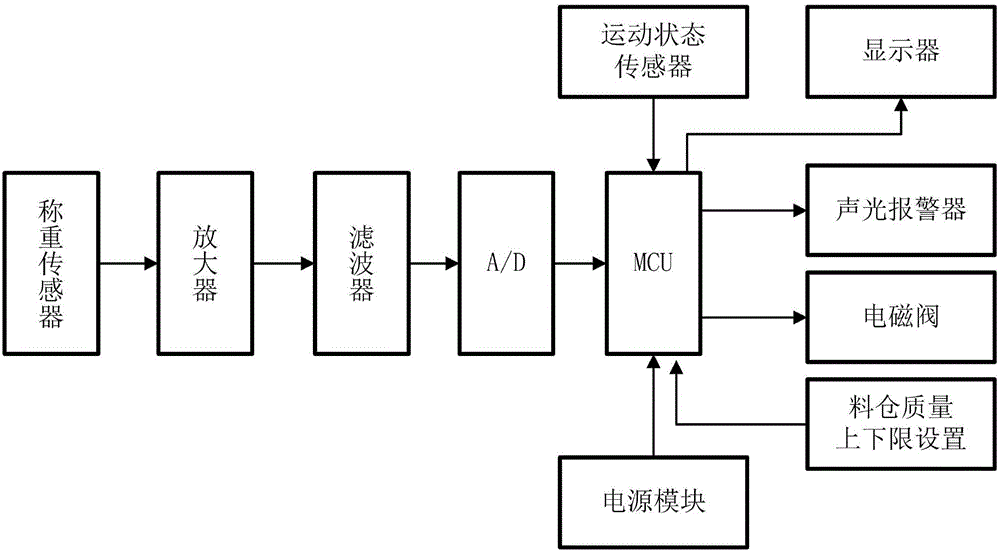

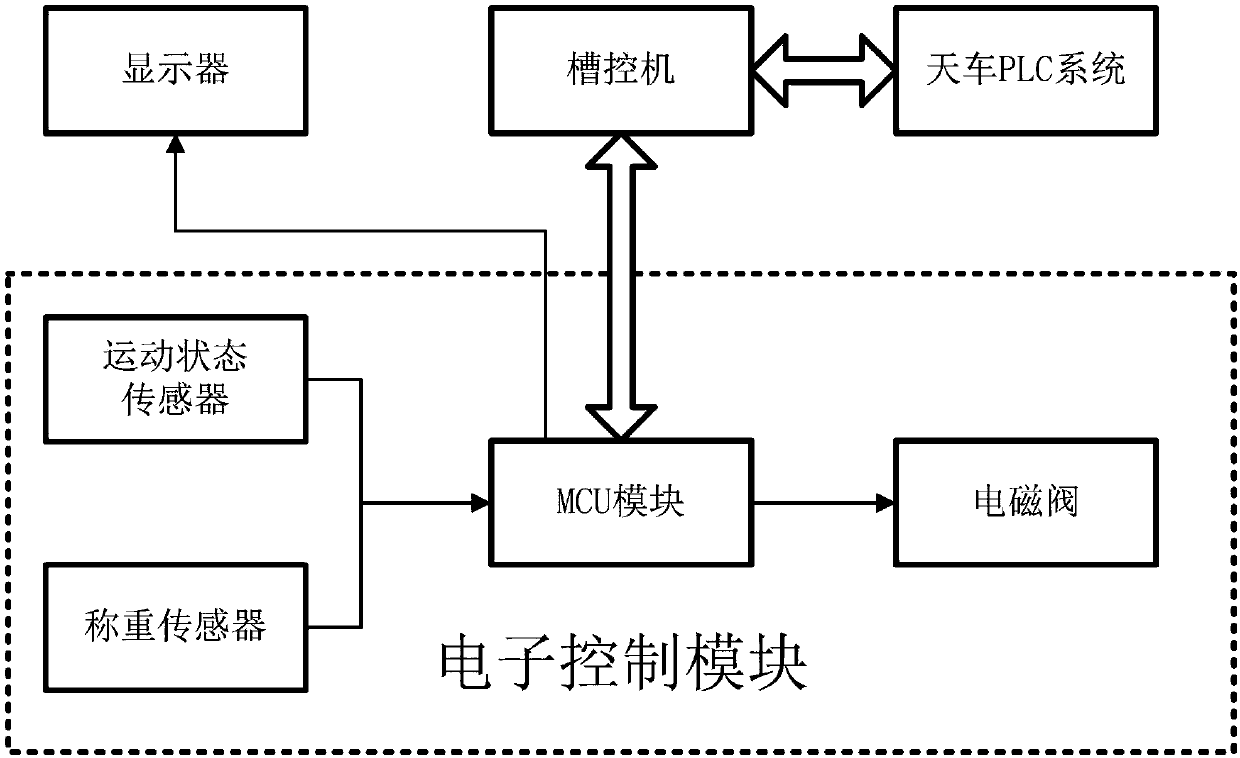

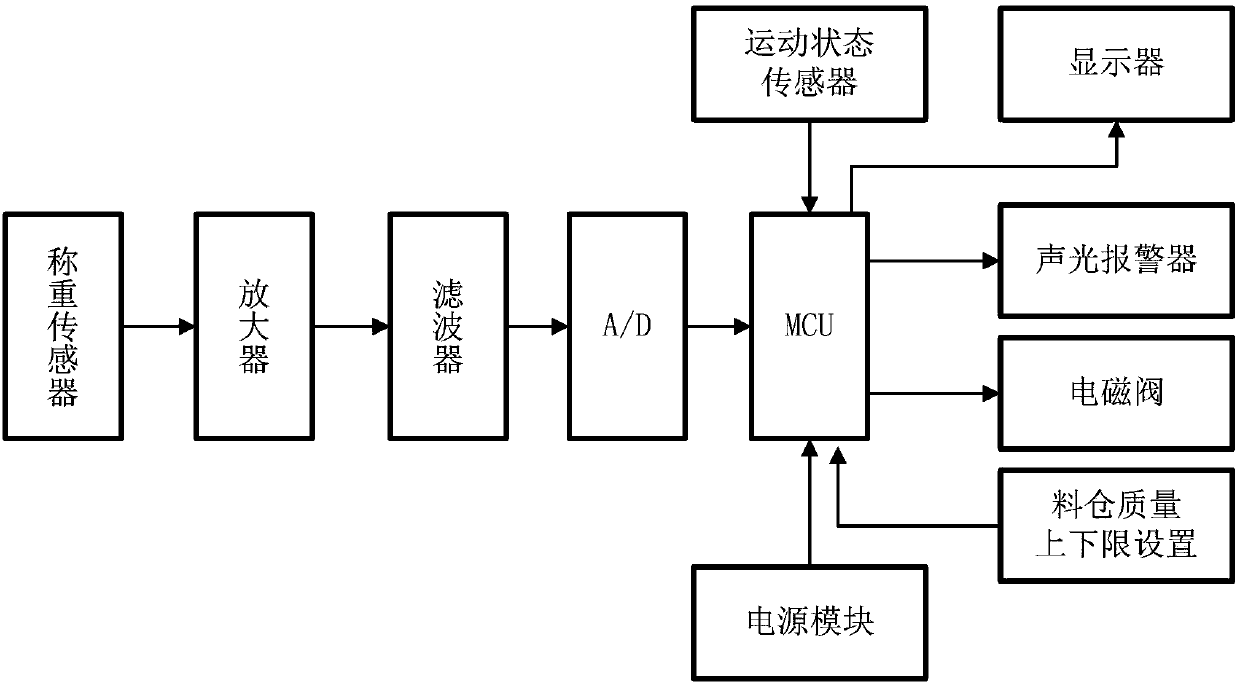

Control method for aluminum electrolysis crown block stock bin material level online monitoring and fault alarm system

Relating to the field of aluminum electrolysis equipment, the invention discloses a control method for an aluminum electrolysis crown block stock bin material level online monitoring and fault alarm system. The method consist of: judging the stock bin charging and motion state, if no charging behavior occur and the stock bin is at a stationary state, letting an MCU module communicate with a slot control machine to obtain the information that whether an aluminum electrolysis cell needs charging; if the aluminum electrolysis cell needs charging at the moment, carrying out charging and calculating the charging speed; and if the charging speed is normal, the stock bin is fault-free, if the charging speed is too slow, blocking can occur to the stock bin or fault can occur to the equipment, starting an audible and visual alarm. The method provided by the invention utilizes a weighing sensor to collect the stock bin quality data and calculates the raw material charging speed, then judges whether a discharge port is blocked, and gives an audible and visual alarm and requires overhauling. The method provided by the invention can achieve real-time online monitoring and control of the stock bin material level, at the same time detects stock bin blocking information in the first time so as to avoid blocking worsening. According to the invention, the structure and operation steps are simple, thus being easy to implement.

Owner:CHONGQING UNIV

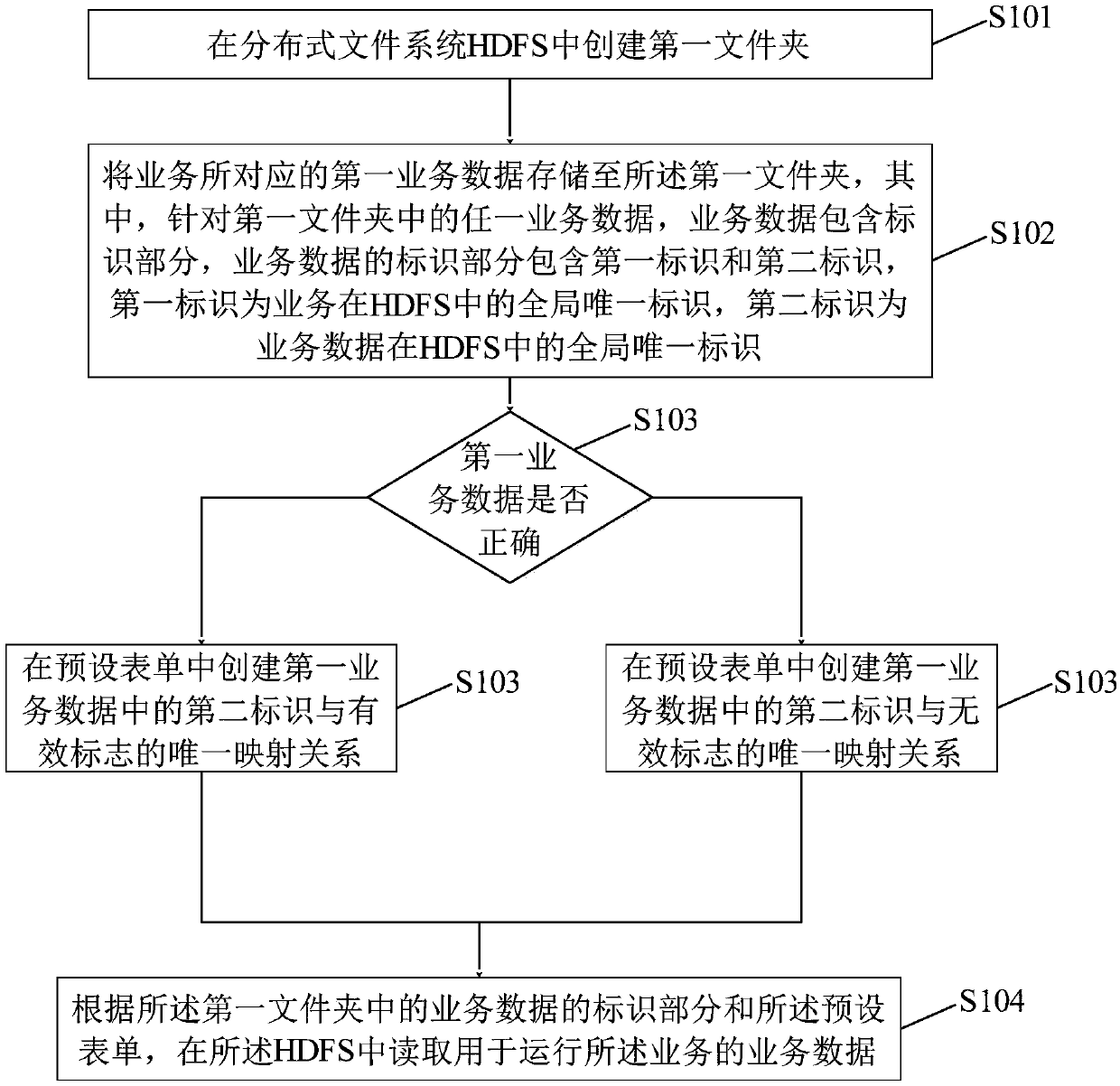

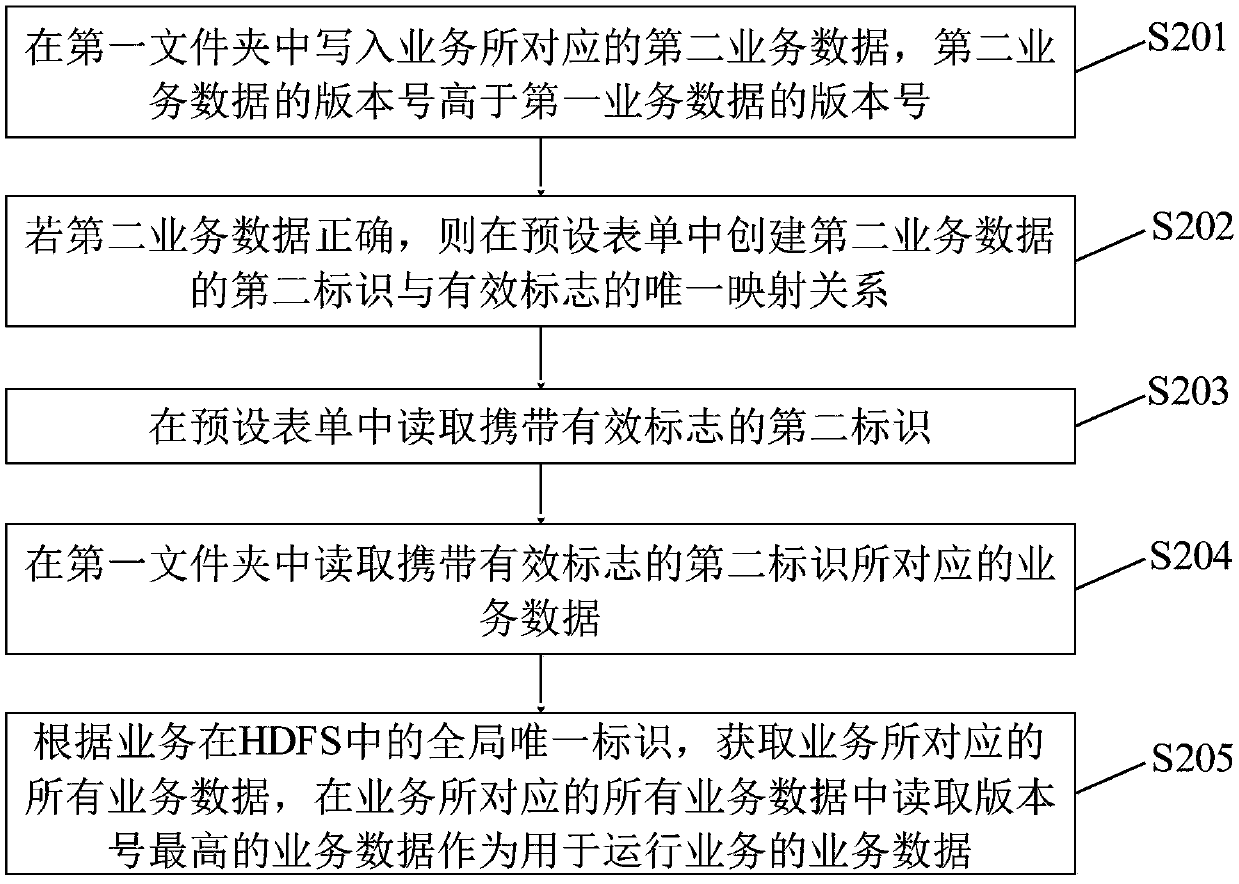

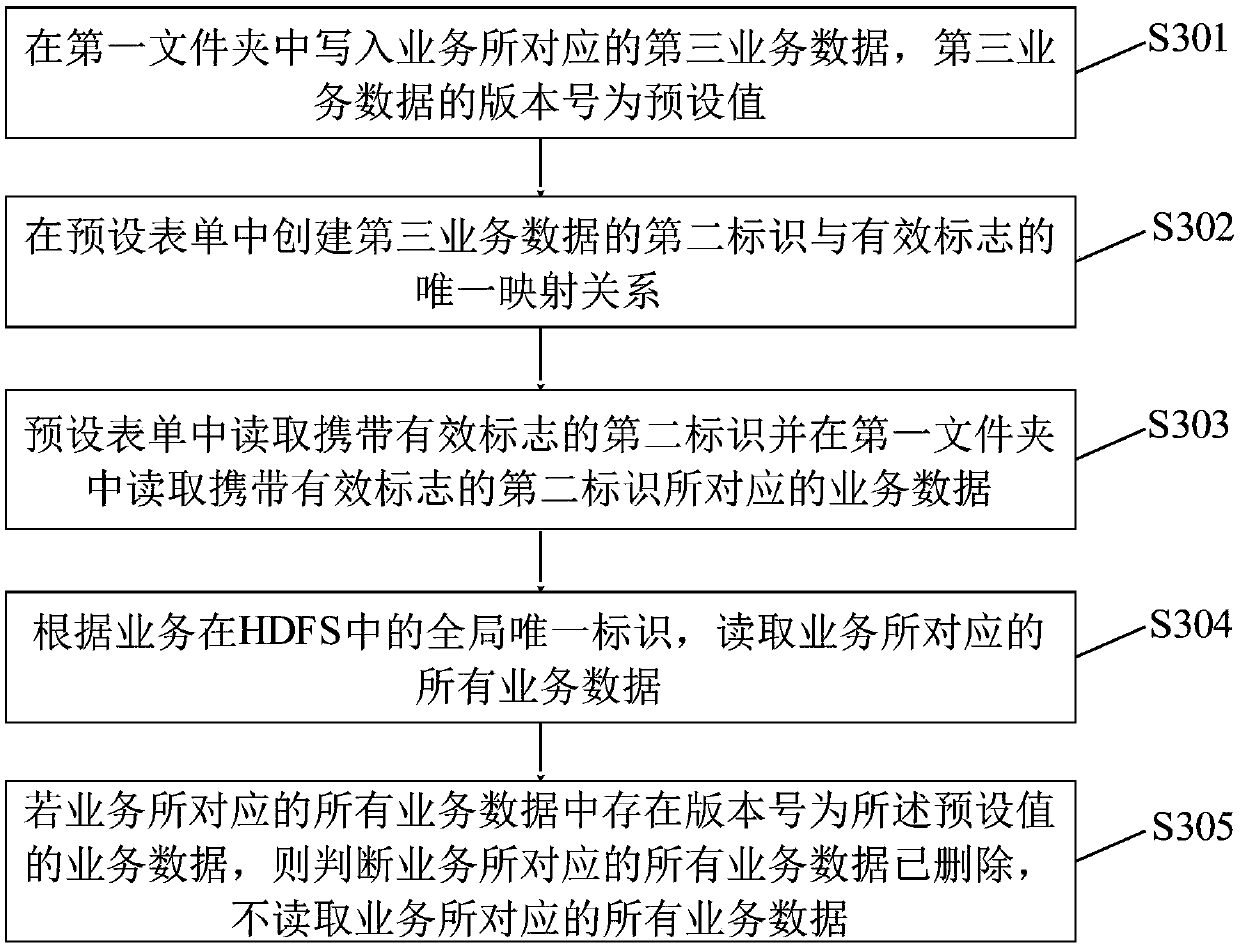

Service data management method based on HDFS, terminal device

ActiveCN109542860AAvoid running errorsFile access structuresFile/folder operationsTerminal equipmentData management

The invention provides a service data management method based on HDFS and a terminal device. The method includes; creating a first folder in the HDFS; storing the first service data corresponding to the service into the first folder, wherein the identification part of the service data comprises a first identification and a second identification, the first identification is a globally unique identification of the service in the HDFS, and the second identification is a globally unique identification of the service data in the HDFS; If the first service data is correct, a unique mapping relationship between the second identifier and the valid flag in the first service data is created in the preset form, and if the first service data is incorrect, a unique mapping relationship between the second identifier and the invalid flag in the first service data is created in the preset form; According to the identification part of the service data in the first folder and the preset form, the service data for running the service is read in the HDFS. Through the identification part of the business data and the preset form, the correct business data can be read, and the system operation error caused by the wrong business data can be avoided.

Owner:PING AN TECH (SHENZHEN) CO LTD

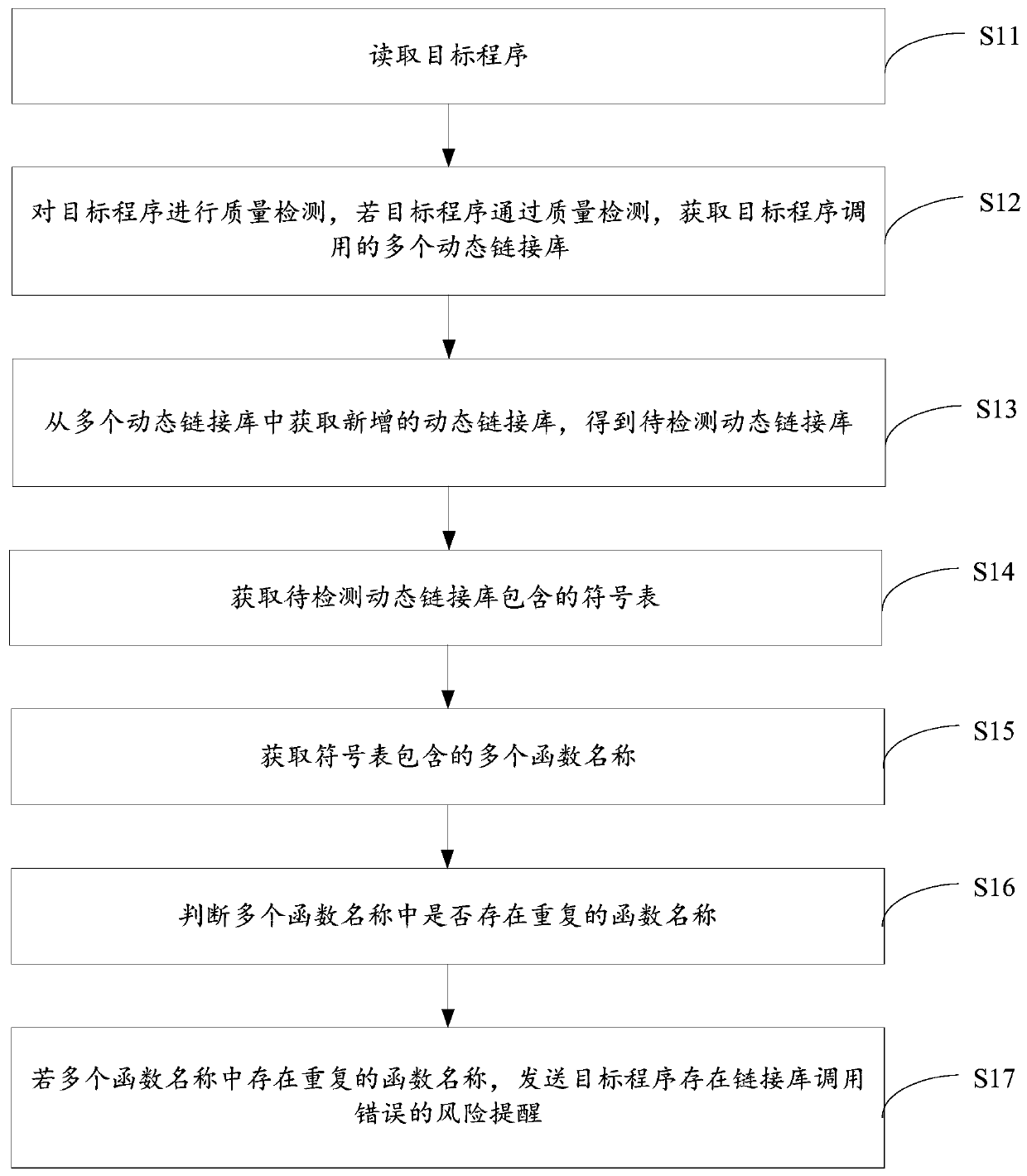

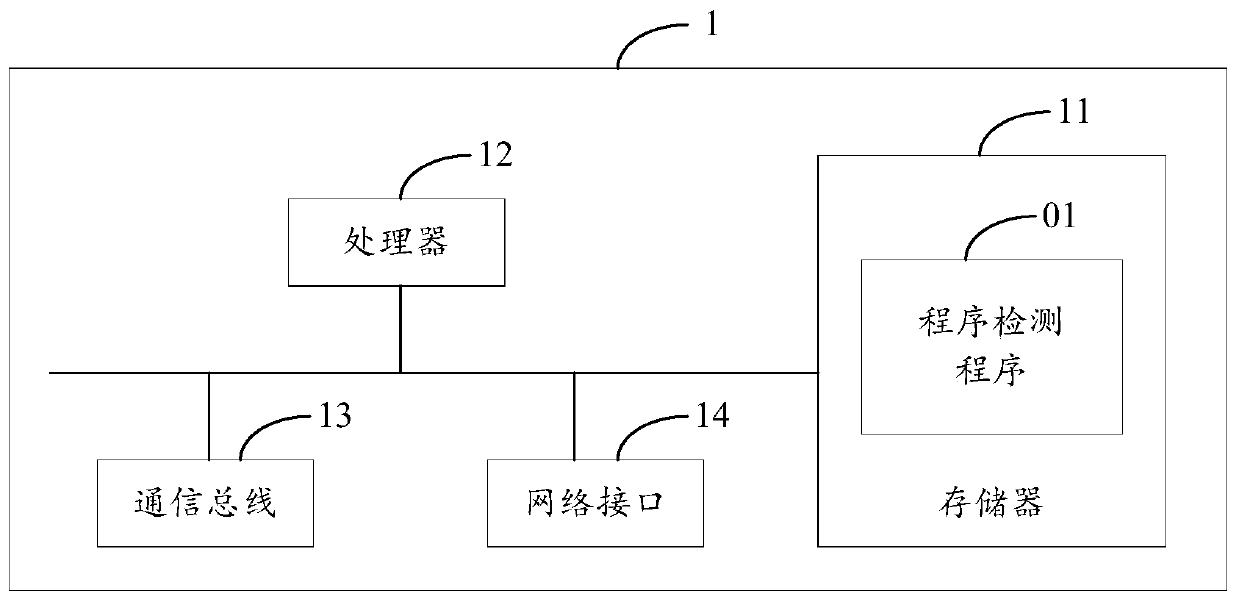

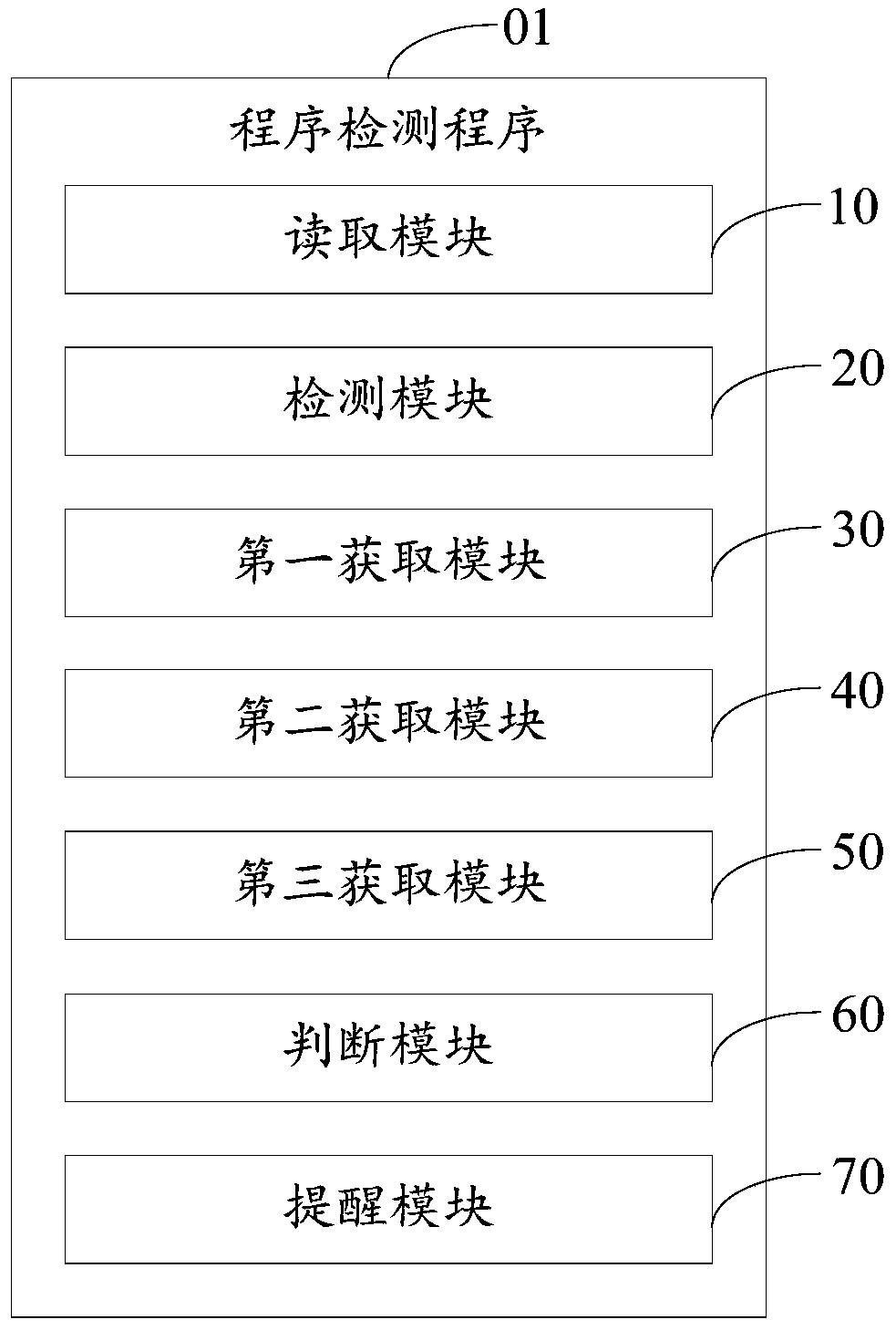

Program detection method and device and computer readable storage medium

PendingCN110471837AImprove stabilityAvoid running errorsSoftware testing/debuggingComputer engineeringData processing

The invention relates to the technical field of data processing, and discloses a program detection method which comprises the following steps: reading a target program which is a Linux program uploaded to a code library by a specified user; performing quality detection on the target program, and if the target program passes the quality detection, obtaining a plurality of dynamic link libraries called by the target program; obtaining a newly added dynamic link library from the plurality of dynamic link libraries to obtain a to-be-detected dynamic link library; obtaining a symbol table containedin the dynamic link library to be detected; obtaining a plurality of function names contained in the symbol table; judging whether repeated function names exist in the plurality of function names ornot; and if repeated function names exist in the plurality of function names, sending a risk prompt that the target program has a link library calling error. The invention further provides a program detection device and a computer readable storage medium. Running errors caused by calling the dynamic link library by the program can be avoided, and the running stability of the program can be improved.

Owner:PING AN SECURITIES CO LTD

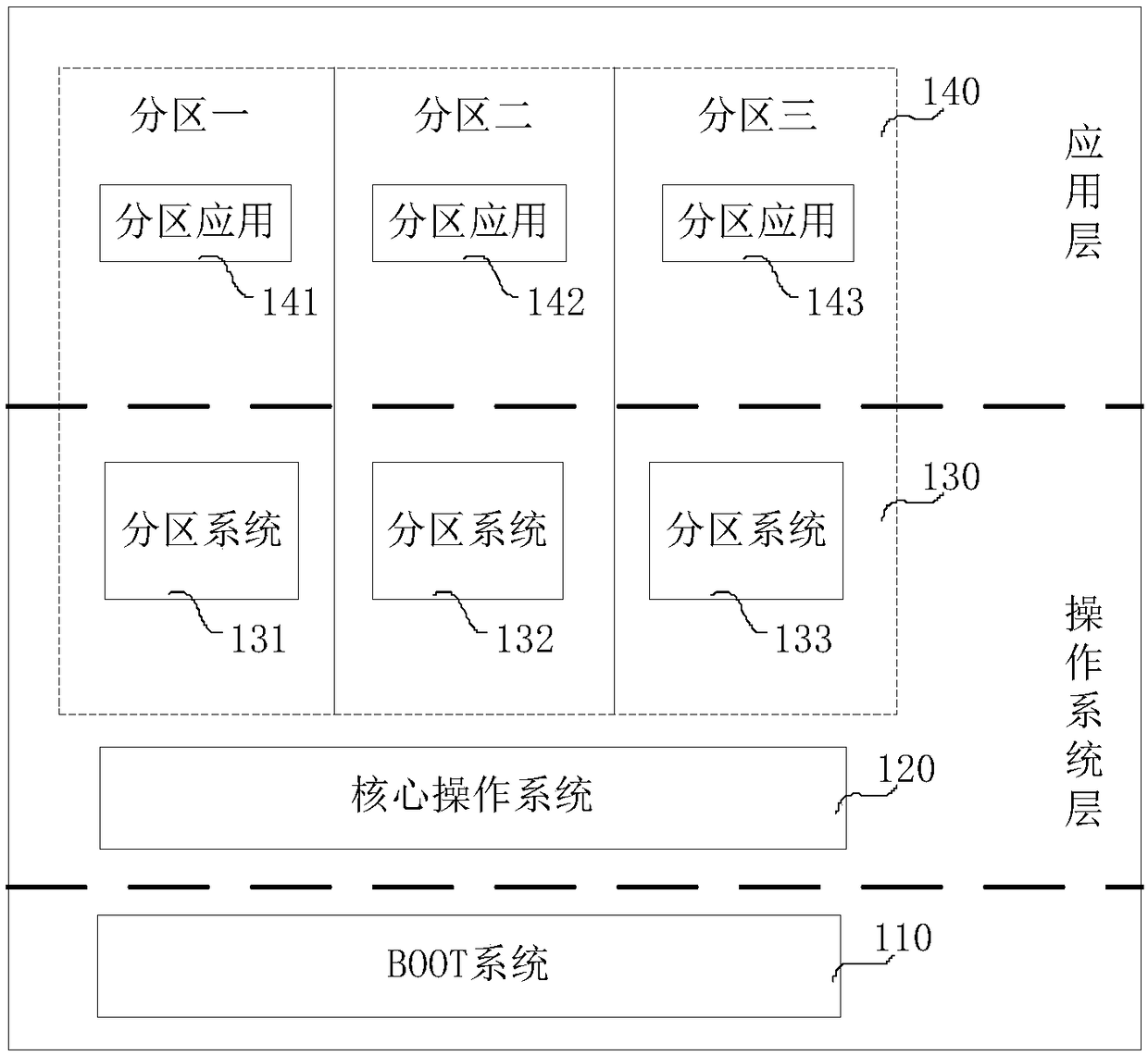

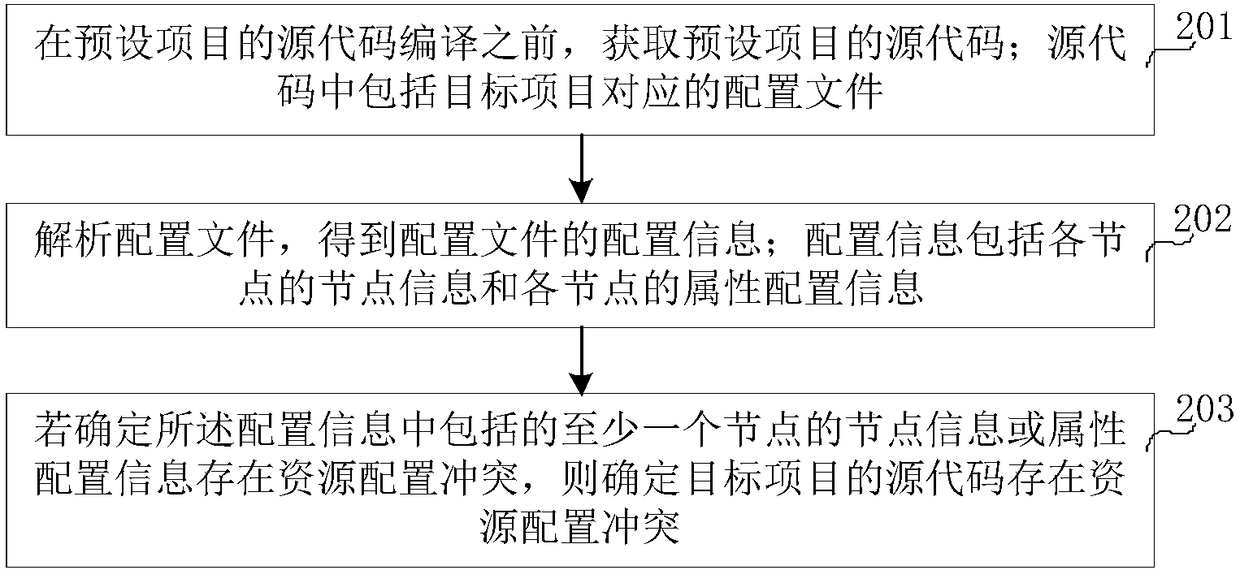

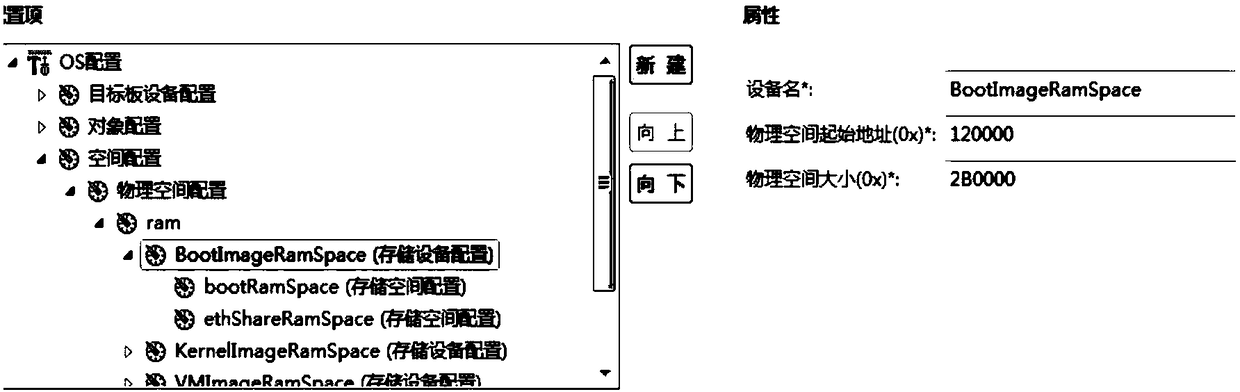

Resource configuration detection method and device for operating system

ActiveCN108108300AAvoid running errorsShorten the timeSoftware testing/debuggingOperational systemConfiguration item

The embodiment of the invention relates to the technical field of communication, in particular to a resource configuration detection method and device for an operating system for realizing a purpose that whether system resource configuration has conflicts or not before compiling to avoid the operation errors of the operating system due to the conflict of the system resource configuration. Before the source code of a target item is compiled, the source code of the target item is obtained; the source code comprises a configuration file corresponding to the target item; the configuration file isanalyzed to obtain the configuration information of the configuration file; the configuration information comprises the node information and the attribute configuration information of each node; and if a determining result shows that the node information or the attribute configuration information contained in the configuration information has a resource configuration conflict, the determining result shows that the source code of the target item has the resource configuration conflict. Therefore, before the source code of the operating system of the target item is compiled, whether the resourceconfiguration of the operating system has the conflicts or not is detected, so that the operation errors of the operating system due to the system resource configuration conflict can be avoided, andtime for solidifying the operating program again can be saved.

Owner:KYLAND TECH CO LTD +1

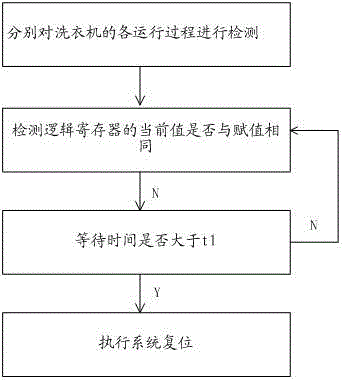

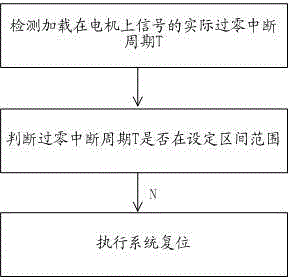

Method for detecting and processing faults of washing machine

ActiveCN106149284AGuaranteed safe operationAvoid running errorsOther washing machinesControl devices for washing apparatusProcessor registerSafety control

The invention discloses a method for detecting and processing faults of a washing machine. The method comprises steps as follows: a PC (program counter) pointer detection step: all operational processes of the washing machine are detected; whether a current value of a logic register is equal to an assignment or not is detected after ending of all subprograms, if the current value is different from the assignment, the PC pointer is judged to break down, and the operational process in which the current fault of the washing machine occurs is recorded according to the assignment; when the PC pointer is judged to break down, a user waits for the time t1 and continuously detects whether the current value of the logic register is equal to the assignment, if the current value of the logic register is equal to the assignment, the subprogram is executed continuously, and otherwise, system reset is executed. With the method for detecting and processing the faults of the washing machine, internal operation errors of algorithms of the washing machine are avoided, the faults are detected by the system before the user finds out the faults, and corresponding safety control measures are taken, so that safe operation of the washing machine is guaranteed.

Owner:QINGDAO HAIER WASHING MASCH CO LTD

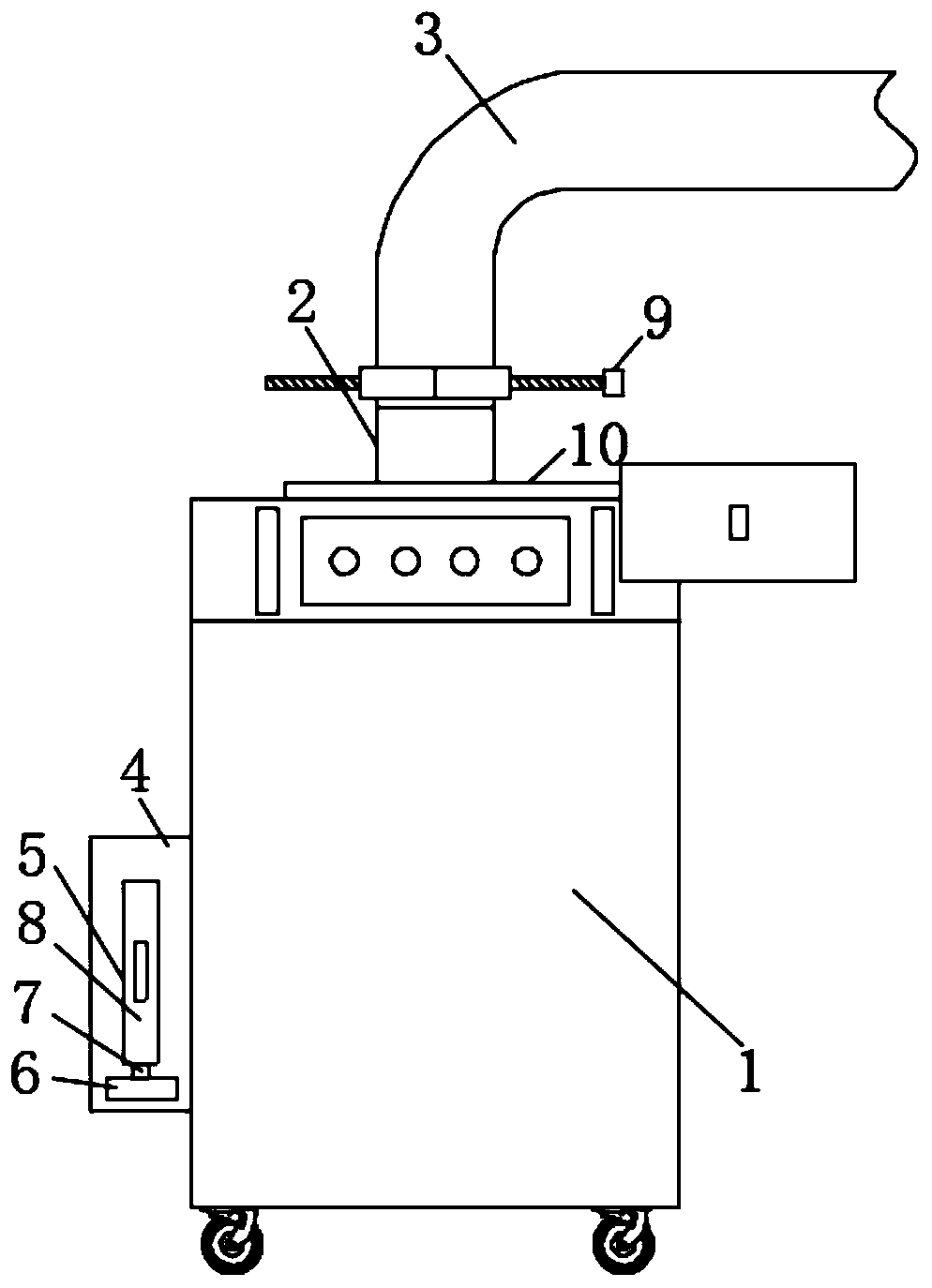

Dust disposing device

InactiveCN110614262AIncrease the number of repairsEasy to clean and replaceSleeve/socket jointsFouling preventionSlide plate

The invention discloses a dust disposing device. The dust disposing device comprises a machine body, a pipe opening and an air conveying pipe. A fixing frame is arranged on the side face of the machine body, and a sliding mechanism is arranged on the surface of the fixing frame. The sliding mechanism comprises a sliding plate, a connecting column and a square frame. The outer side of the square frame is sleeved with a gauze sleeve, and a stabilizing mechanism is arranged at the top of the machine body. The stabilizing mechanism comprises a fixing beam, a screw rod, sliding blocks and stabilizing semi-rings, wherein the fixing beam is in a vertical state, and the screw rod perpendicularly penetrates through the fixing beam. Through the designed fixing frame, the sliding mechanism and the gauze sleeve, heat dissipating holes in the side face of the machine body are covered by the gauze sleeve, and it is avoided that dust enters the machine body from the heat dissipating holes, the faultoccurrence rate is increased, and the maintenance times of the machine body are increased; the gauze sleeve is easy and convenient to wash and replace and convenient to use; and through the designed stabilizing mechanism, the air conveying pipe arranged on the outer side of the pipe opening in a sleeving mode is sleeved with and fixed by the two stabilizing semi-rings, and it is avoided that connection of the air conveying pipe and the pipe opening is not tight enough.

Owner:杭州兔研工业设计有限公司

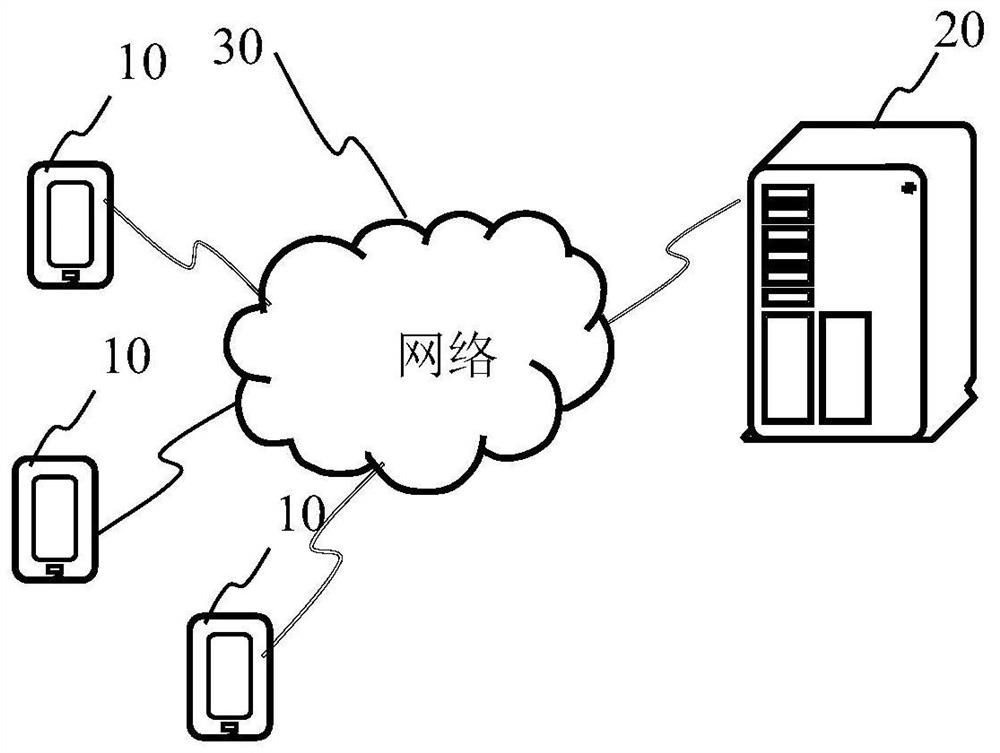

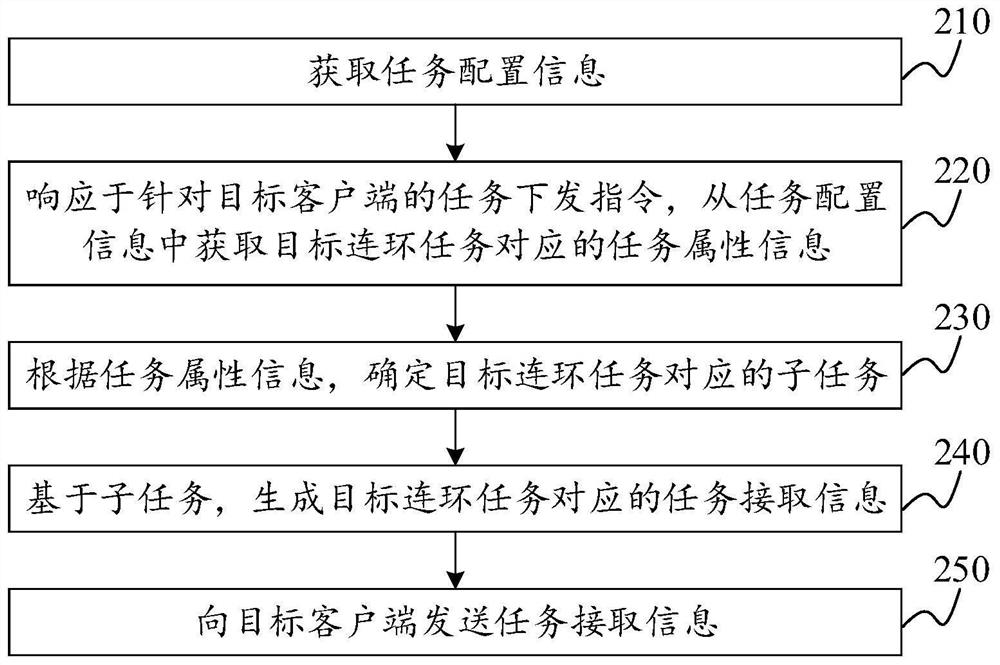

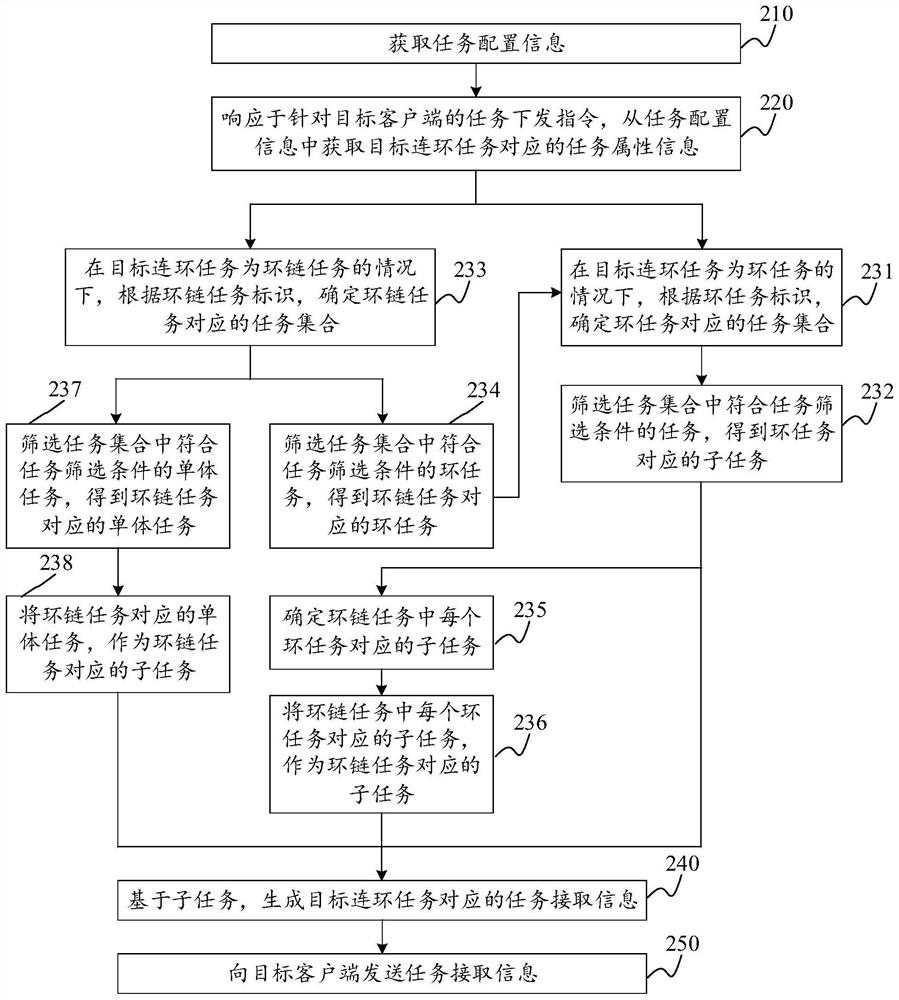

Task processing method and device, equipment, storage medium and product

PendingCN114047918AReduce workloadAvoid running errorsSoftware designCode compilationComputer hardwareProgram logic

The invention discloses a task processing method and device, equipment, a storage medium and a product, and belongs to the technical field of computers. The method comprises the following steps: acquiring task configuration information; in response to a task issuing instruction for the target client, obtaining task attribute information corresponding to the target serial task from the task configuration information; according to the task attribute information, determining sub-tasks corresponding to the target serial tasks; generating task receiving information corresponding to the target serial task based on the subtasks; and sending the task receiving information to the target client. In the technical scheme provided by the embodiment of the invention, for each serial task, the subtask corresponding to the serial task can be determined according to the task attribute information of the serial task in the task configuration information, and then the task receiving information of the serial task is generated according to the subtask and is sent to the client, so that the client receives the serial task. Through the universal task processing flow, program logic development and planning configuration work of the task system are separated, and the application development efficiency is improved.

Owner:TENCENT TECH (SHENZHEN) CO LTD

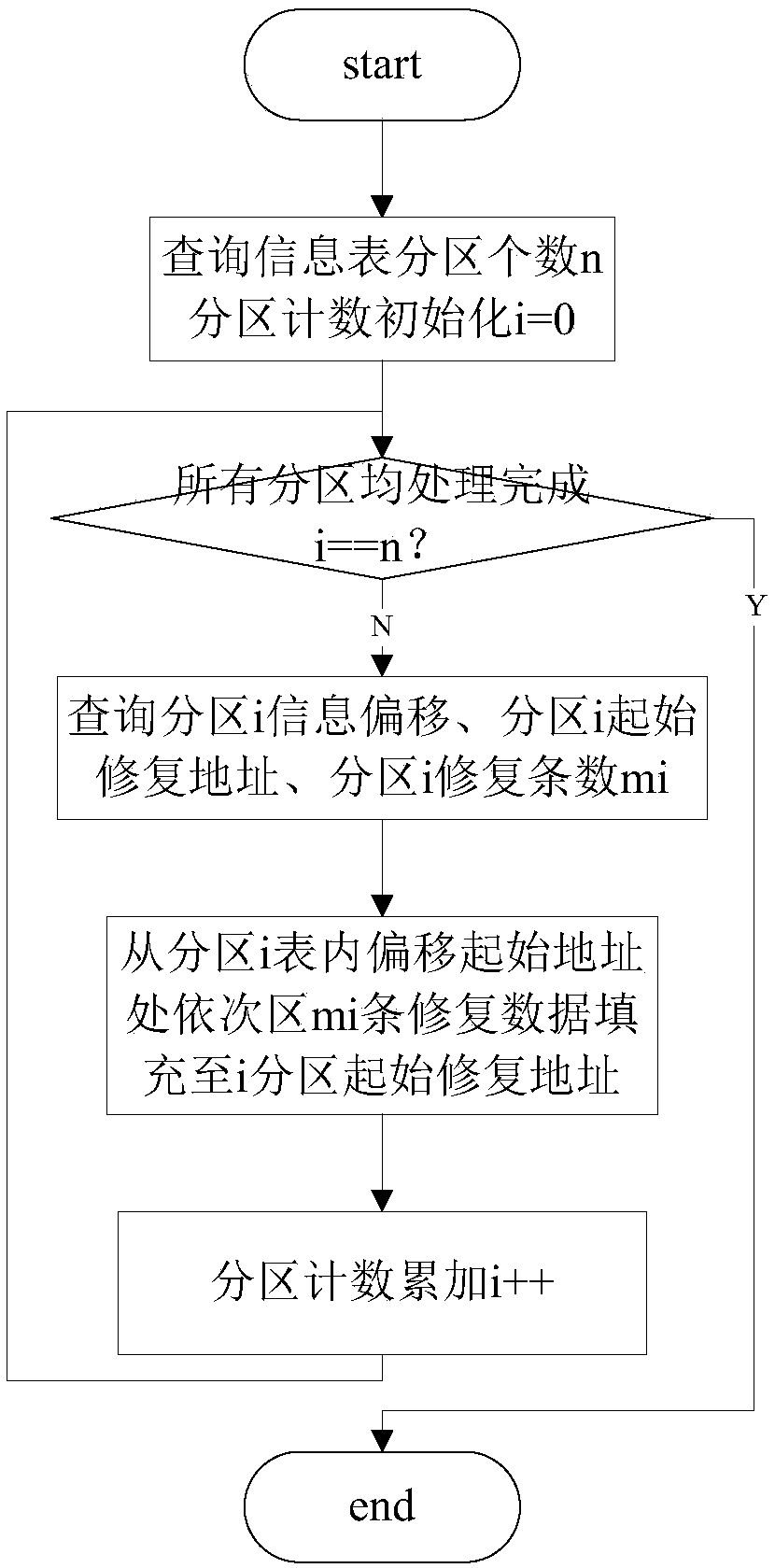

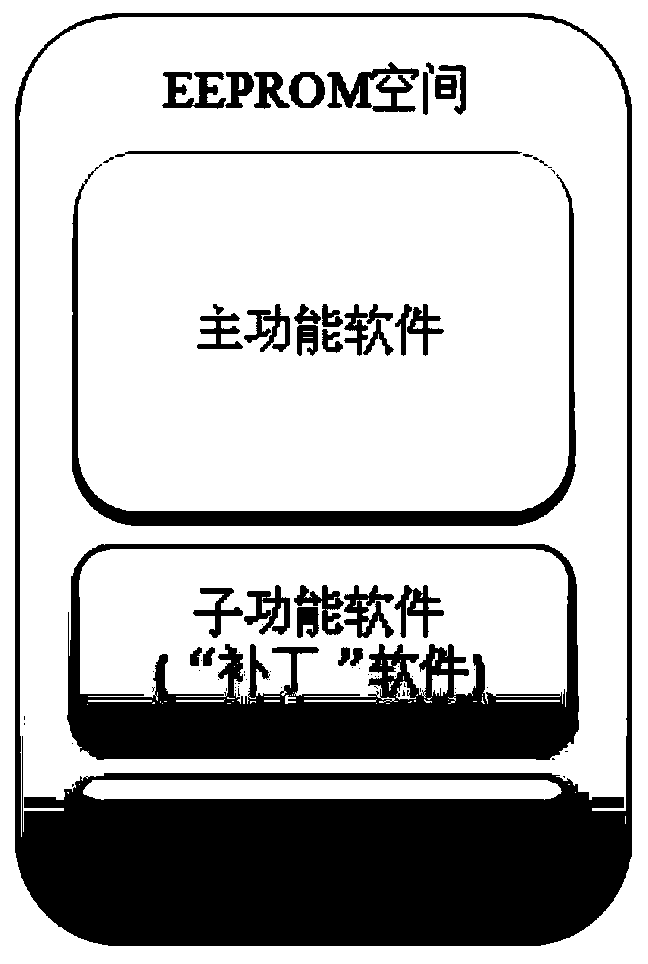

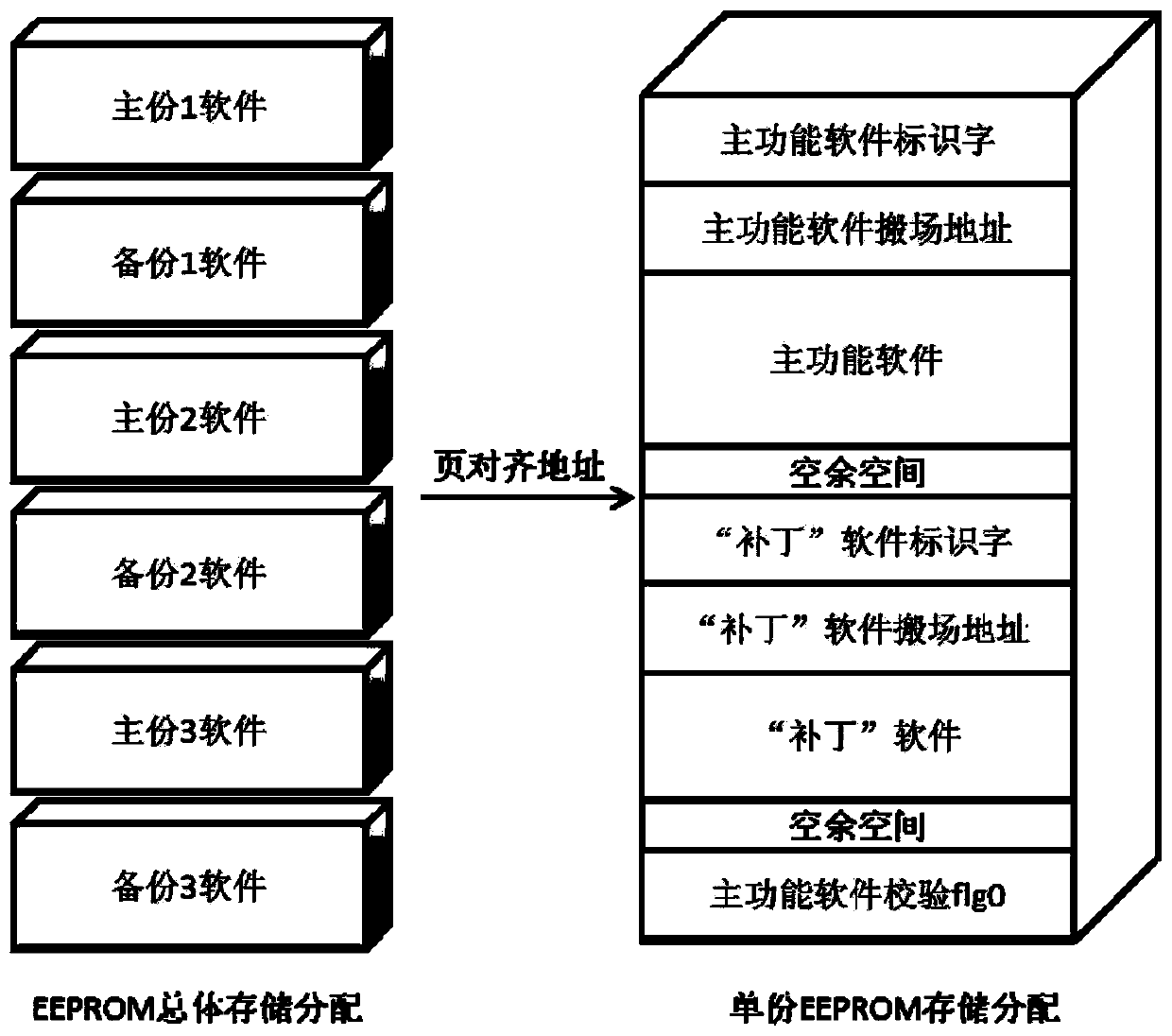

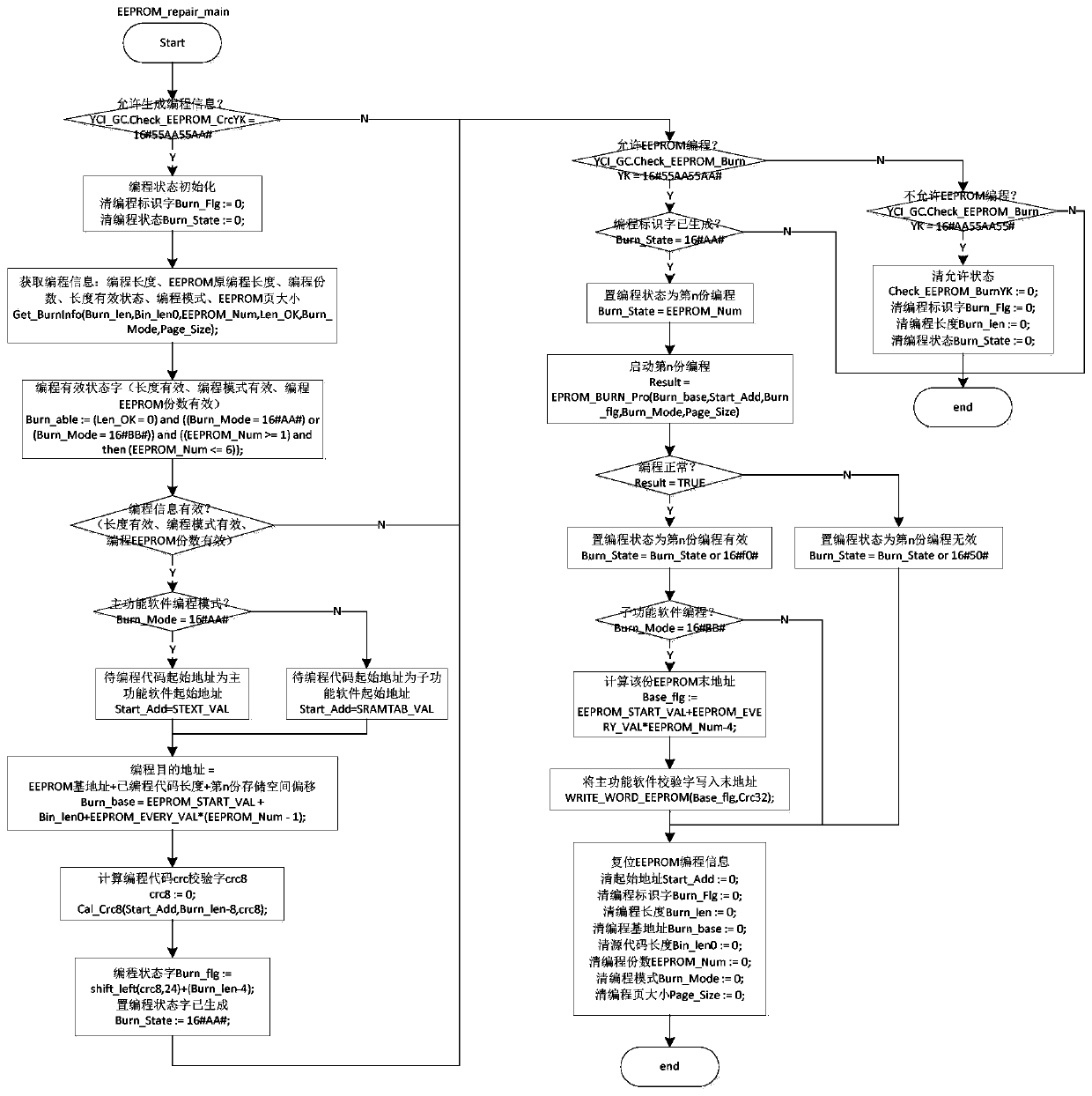

Multi-mode satellite-borne software EEPROM on-orbit programming method

ActiveCN111158660AVariety of programming modesRealize programming and burningRedundant data error correctionEnergy efficient computingSoftware engineeringDynamic programming

The invention discloses a multi-mode satellite-borne software EEPROM (Electrically Erasable Programmable Read-Only Memory) on-orbit programming method which comprises the following steps: S1, after main function software is loaded and operated, generating an EEPROM programming information table through an instruction injection number; S2, using EEPROM software for dynamic programming; S3, guidingsoftware to run according to EEPROM software programming storage information; and S4, shielding the sub-function software through single address programming. According to the method, a programming mode is selected; the functions of main function software programming, sub-function software programming, EEPROM local address modification and the like in a software dynamic running state can be realized; the invention discloses a plurality of EEPROM on-orbit programming methods and guide operation mechanisms of satellite-borne software. The main function software and the sub-function software sharethe EEPROM storage area, whether the sub-function software is moved to run can be judged when the software is guided to run, running of the main function software is not affected when the sub-function software is not moved, and errors caused by incompatibility of the main function software and the sub-function software can be prevented; and the sub-function software can be quickly shielded in a single address repair mode.

Owner:SHANGHAI AEROSPACE CONTROL TECH INST

Data processing method and device, electronic equipment and storage medium

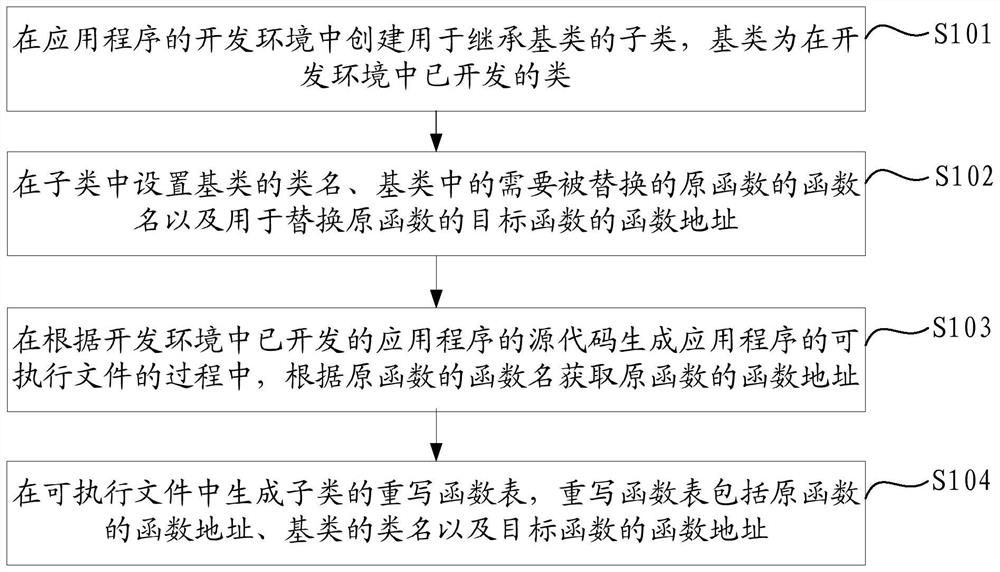

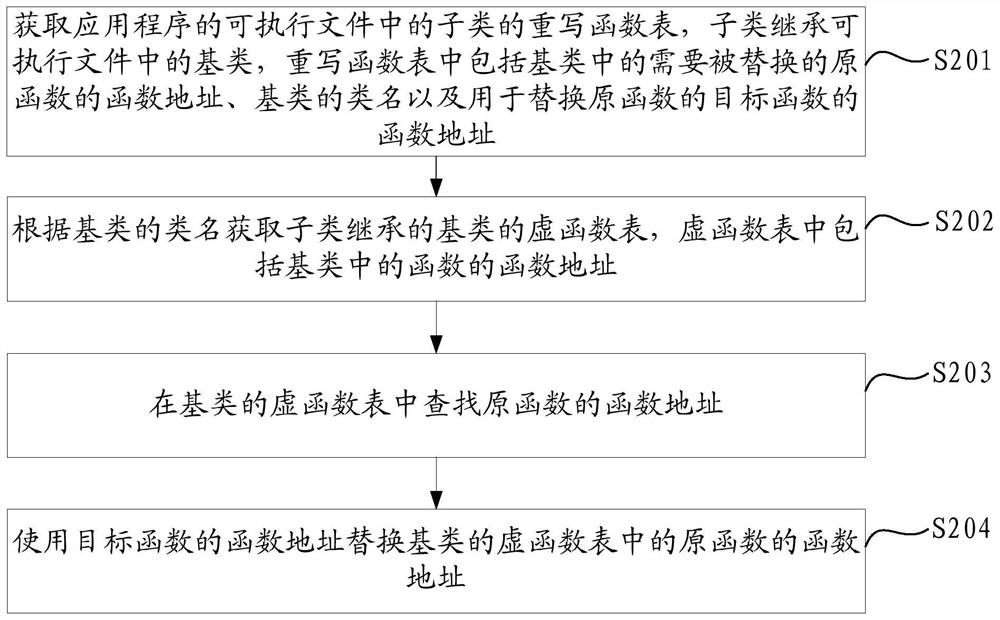

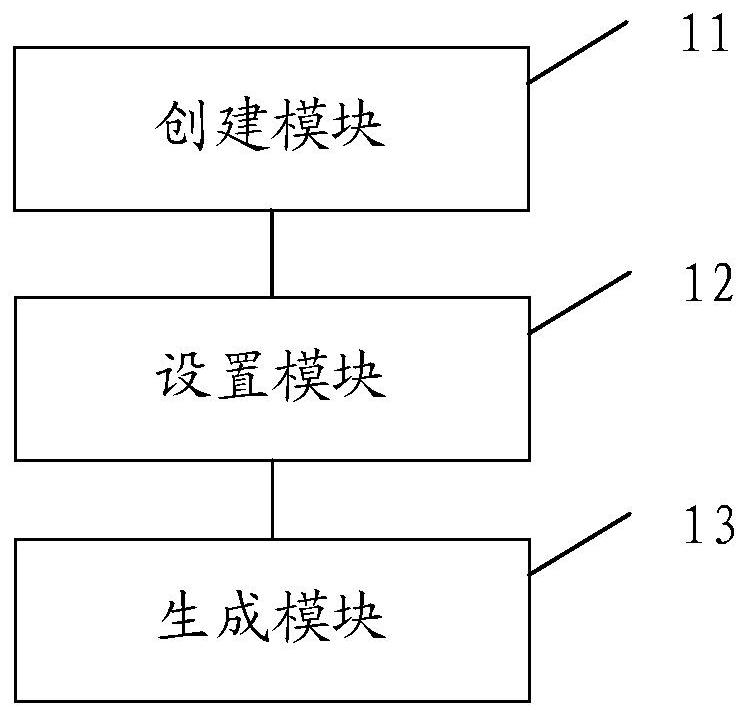

PendingCN113590091AAvoid substitutionAvoid running errorsProgramming languages/paradigmsBase classSoftware engineering

The invention provides a data processing method and device, electronic equipment and a storage medium. The method comprises: obtaining rewriting function table of a subclass in an executable file of an application program, wherein the subclass inherits a base class in the executable file, and the rewriting function table comprises a function address of an original function needing to be replaced in the base class, a class name of the base class and a function address of a target function used for replacing the original function; determining a virtual function table of the base class inherited by the subclass, wherein the virtual function table comprises a function address of a function in the base class; searching the function address of the original function in the virtual function table of the base class; and replacing the function address of the original function in the virtual function table of the base class with the function address of the target function. Thus, the situation that the function address of the target function is used for replacing the function address which should not be replaced in the virtual function table is avoided, the situation of replacement errors is avoided, then the situation that a wrong function is called when the application program calls the function later is avoided, and then running errors of the application program can be avoided.

Owner:WUBA

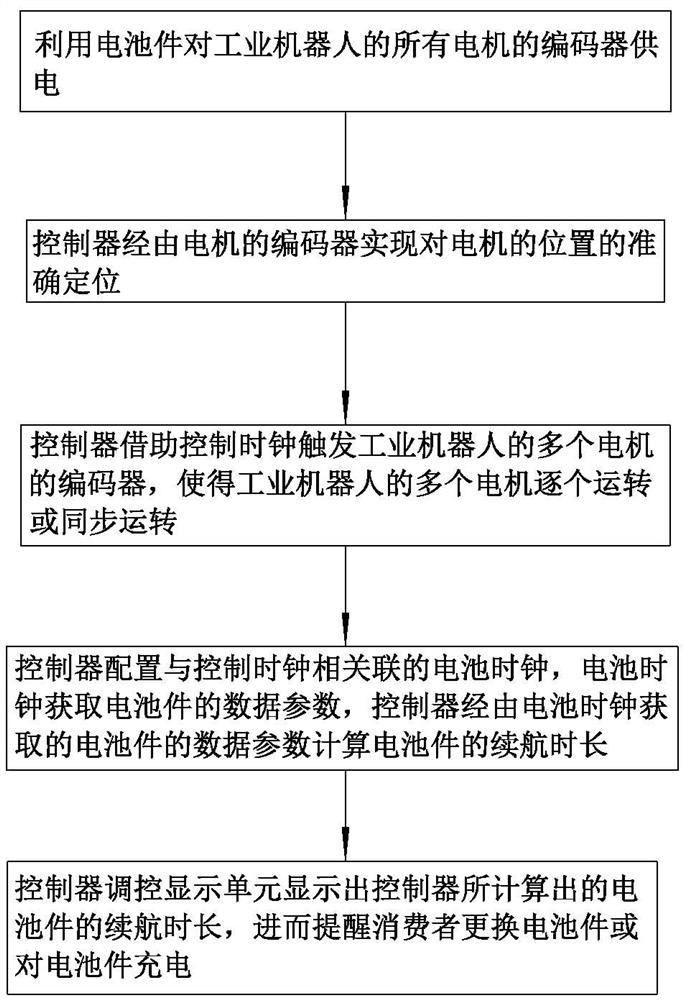

Industrial robot battery clock method

ActiveCN112388674AGuaranteed running accuracyEnable direct monitoringManipulatorElectrical batteryControl engineering

The invention relates to the technical field of industrial robots, and particularly discloses an industrial robot battery clock method. The industrial robot battery clock method comprises the following steps that a battery piece which supplies power to encoders of a plurality of motors of an industrial robot is configured; a controller is configured, wherein the controller positions the positionsof the motors through encoders of the motors; the controller is provided with a control clock, and the controller triggers the encoders of the multiple motors of the industrial robot based on the control clock to enable the motors of the industrial robot to operate one by one or synchronously; the controller is provided with a battery clock, and the battery clock is used for acquiring data parameters of the battery piece; the controller calculates the endurance duration of the battery piece according to the data parameters, acquired by the battery clock, of the battery piece, and a display unit displays the endurance duration, calculated by the controller, of the battery piece; and direct monitoring of the battery piece is achieved by watching the endurance duration,displayed by the display unit of the battery piece, motor operation errors caused by electric quantity exhaustion of the battery piece are avoided, and the operation accuracy of the industrial robot is guaranteed.

Owner:中铭谷智能机器人(广东)有限公司

Power system embedded software remote dynamic upgrade method and system

ActiveCN108196873BSecurity upgradeReliable upgradeSoftware engineeringElectric power systemSoftware engineering

The invention discloses a method and system for remote dynamic upgrading of embedded software in a power system, which includes the following steps: remotely loading a software upgrade information table and a software upgrade code to a device node to be upgraded in the power system; when the device node " When the "idle" task is running (when all system tasks are not running), the information is verified according to the software upgrade information table, and if the verification is correct, the software dynamic upgrade is performed. The invention ensures the safety and reliability of the software upgrading process through the control of information verification and interruption.

Owner:SHANDONG UNIV OF SCI & TECH

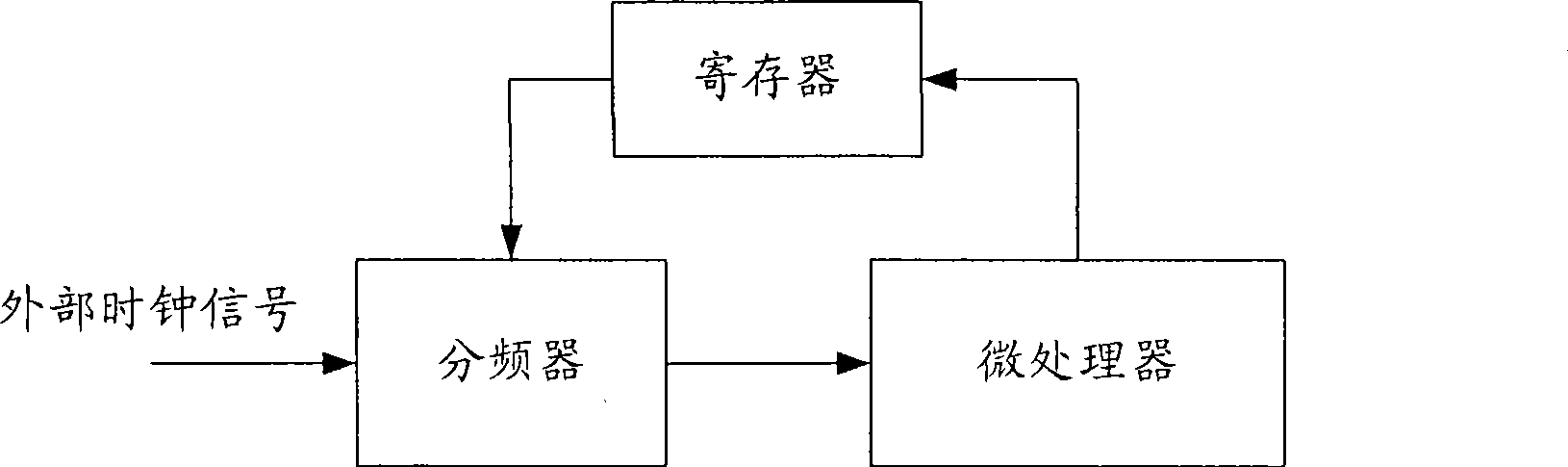

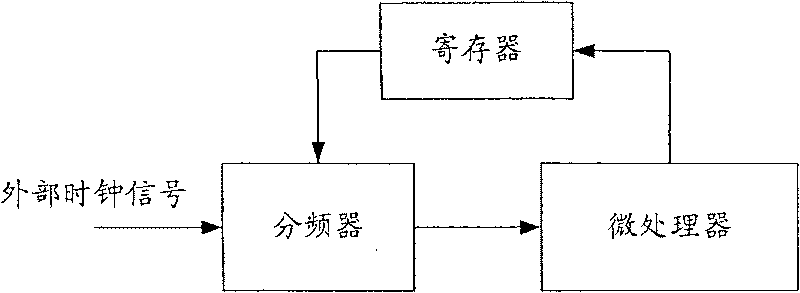

Frequency-adjusting device

ActiveCN101446845BAvoid running errorsSolve the problem of sudden change in duty cycleGenerating/distributing signalsProcessor registerElectronic information

The invention relates to a frequency-adjusting device which comprises a microprocessor, a first register and a frequency-adjusting circuit. The microprocessor sets up a frequency division coefficientaccording to self workload or a working state; the first register stores the frequency division coefficient set up by the microprocessor; and the frequency adjusting circuit uses the read frequency division coefficient as a first frequency division coefficient; the first frequency division coefficient is compared with a delayed second frequency division coefficient and counted according to an effective comparison signal and a clock signal of the second frequency division coefficient; if the counting value equals to a first threshold value, a working clock signal is a low level signal; and whenthe counting value is smaller than the first threshold value or equals to a second threshold value, the working clock signal is a clock signal corresponding to the second frequency division coefficient. When the frequency division coefficients change, a duty cycle of the working clock signal of the device shows no mutation, thereby causing smooth transition to be achieved between working clock signals before and after the change of the frequency division coefficients. The device can be widely applied to electronic information systems.

Owner:RDA MICROELECTRONICS SHANGHAICO LTD

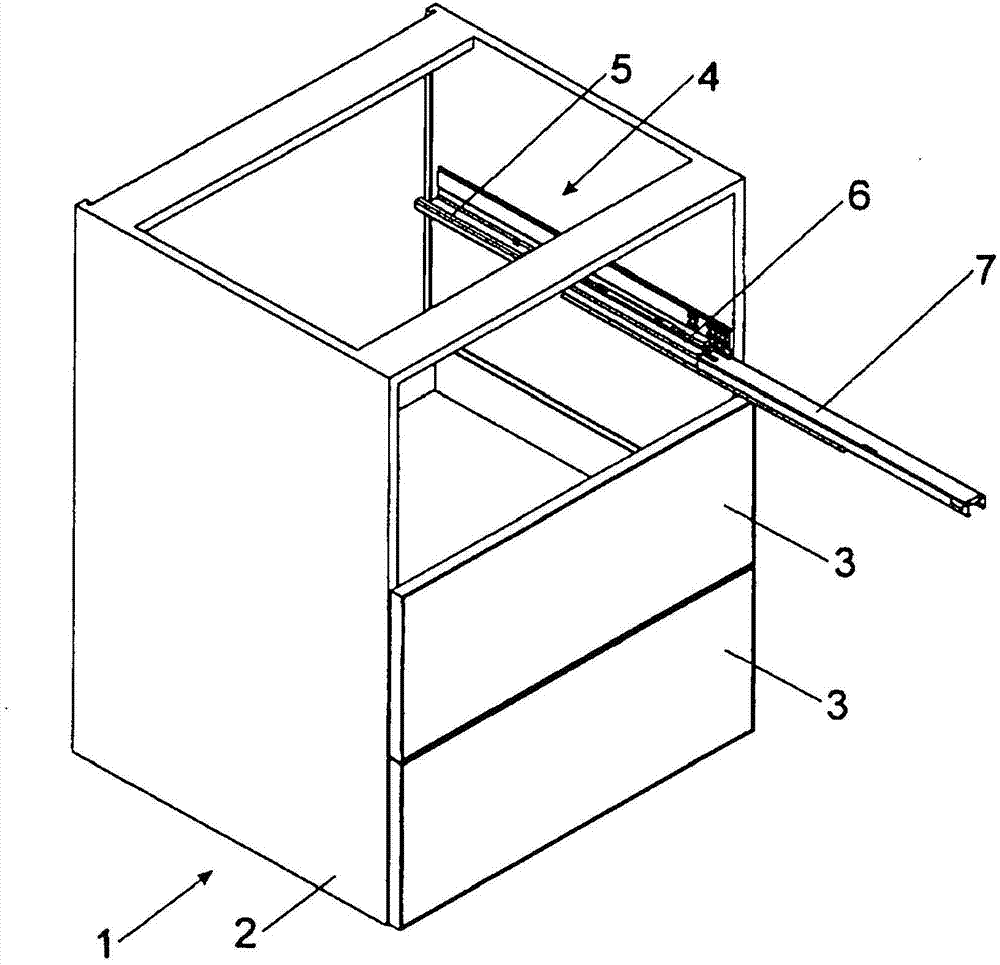

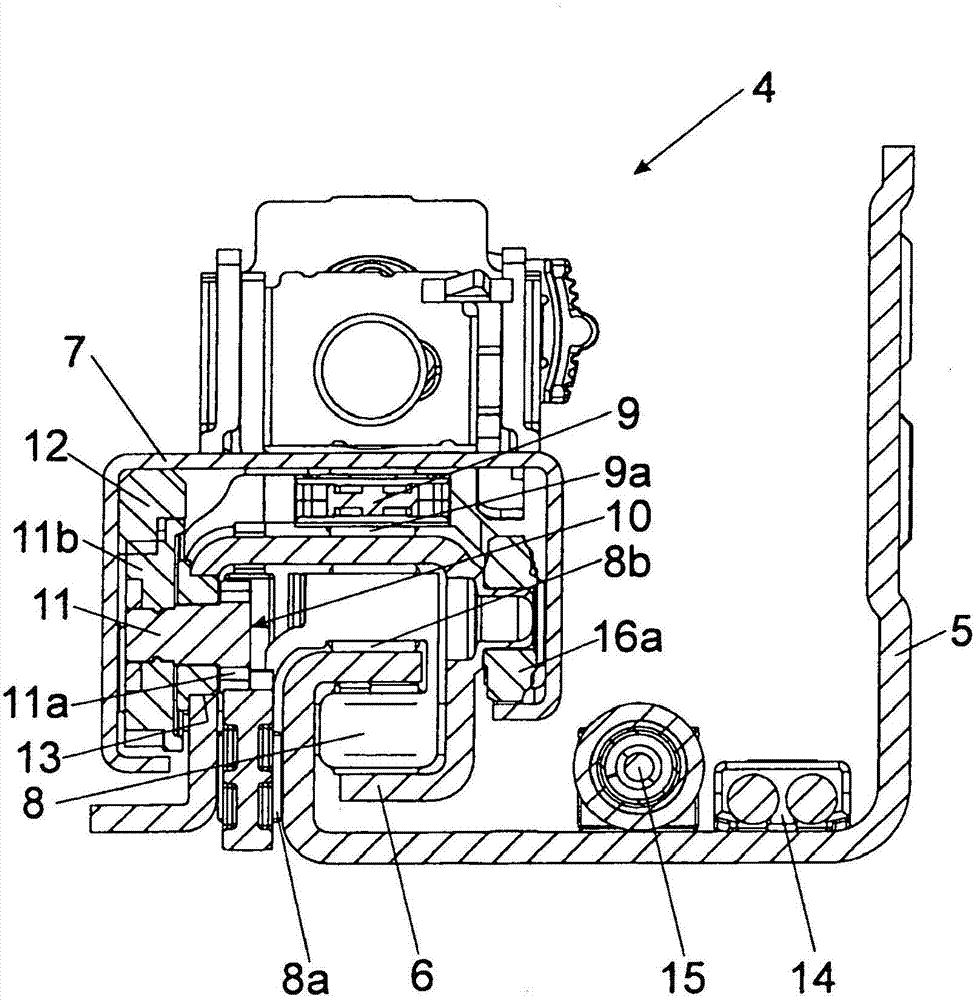

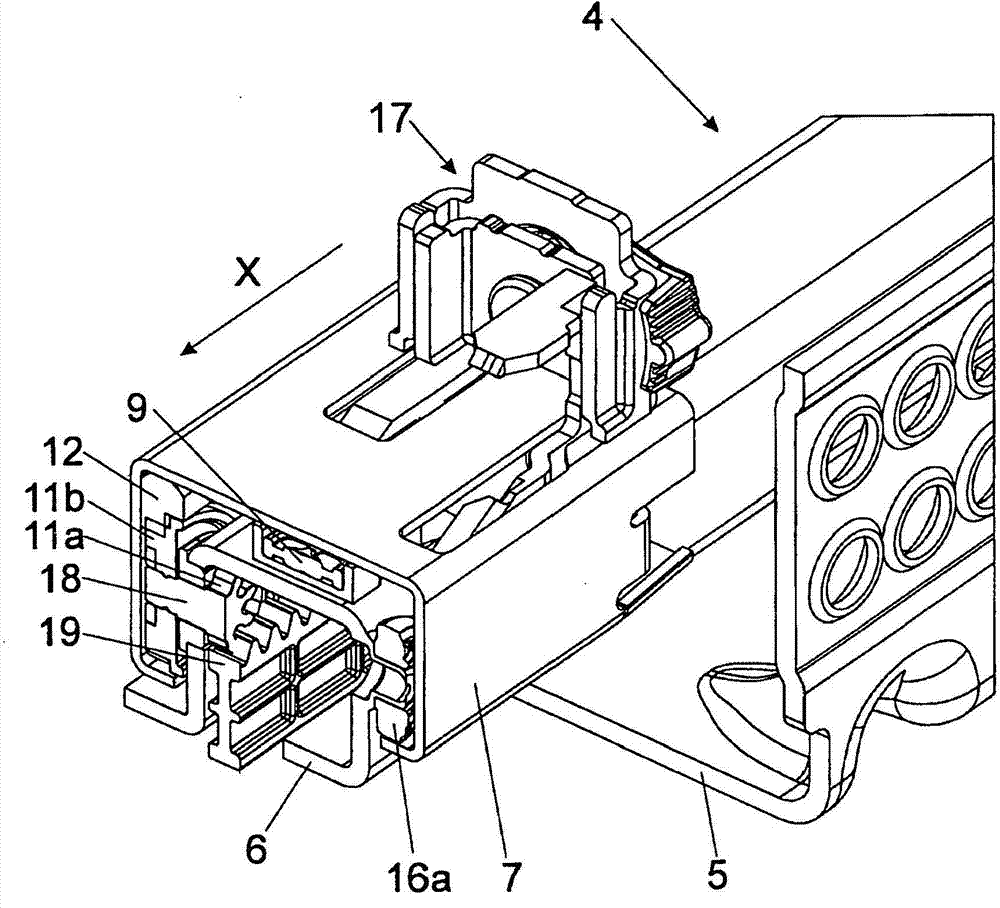

Pull-out guide for drawers

A pull-out guide for drawers has a carcass rail, a drawer rail, and a central rail which is moveably mounted between the carcass rail and the drawer rail. At least one carriage is mounted in moveable manner between at least two rails of the pull-out guide. A synchronization apparatus avoids running faults of the pull-out guide, and the synchronization apparatus has at least one synchronization wheel which interacts firstly with the one carriage and secondly with a running surface which is arranged on one of the rails. The synchronization wheel is in the form of a gear with two pinions with different diameters. The first pinion and the second pinion are connected to one another in a rotationally fixed manner, wherein, when one pinion moves, the other pinion also moves.

Owner:JULIUS BLUM GMBH

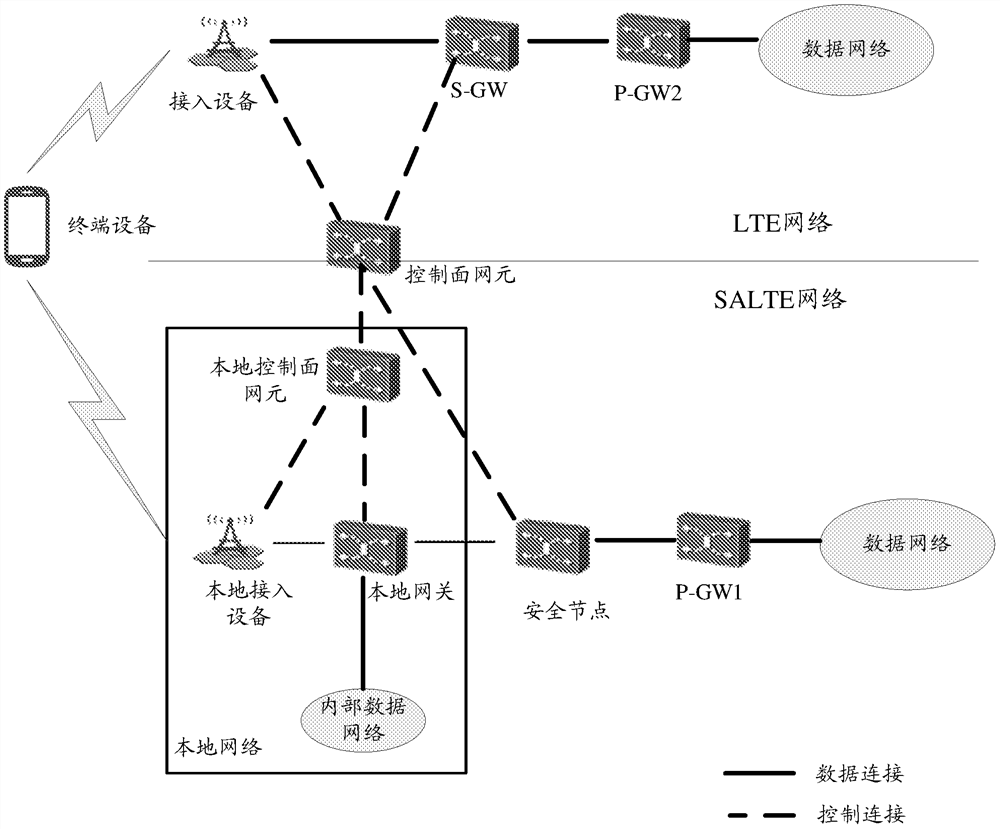

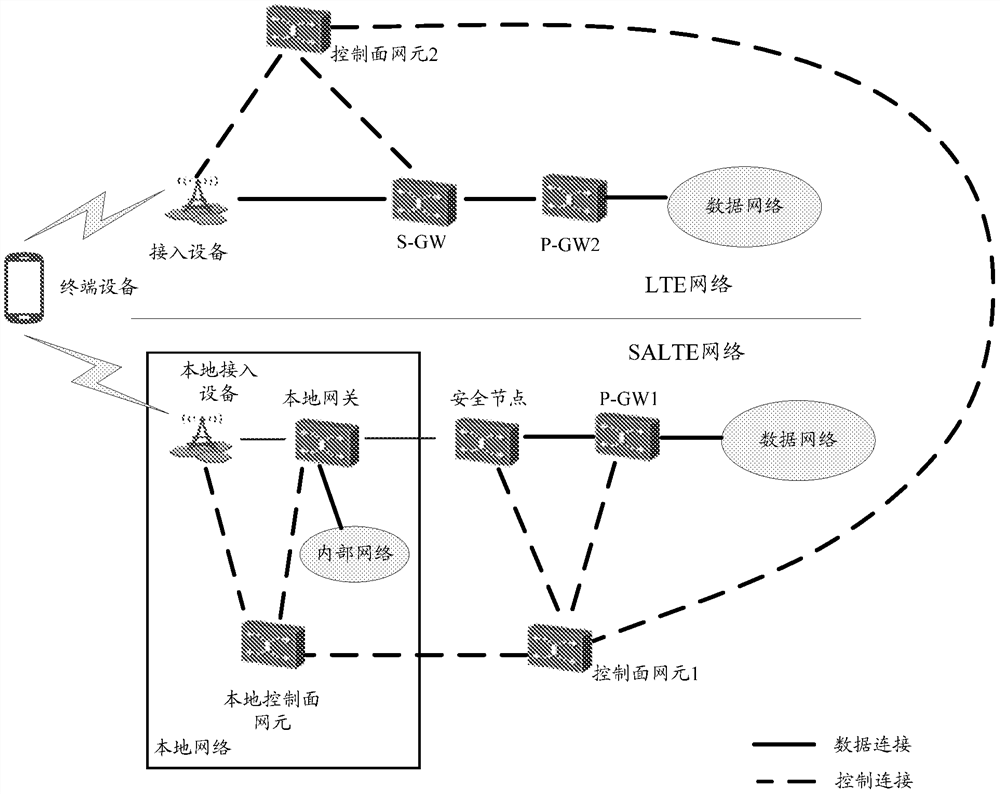

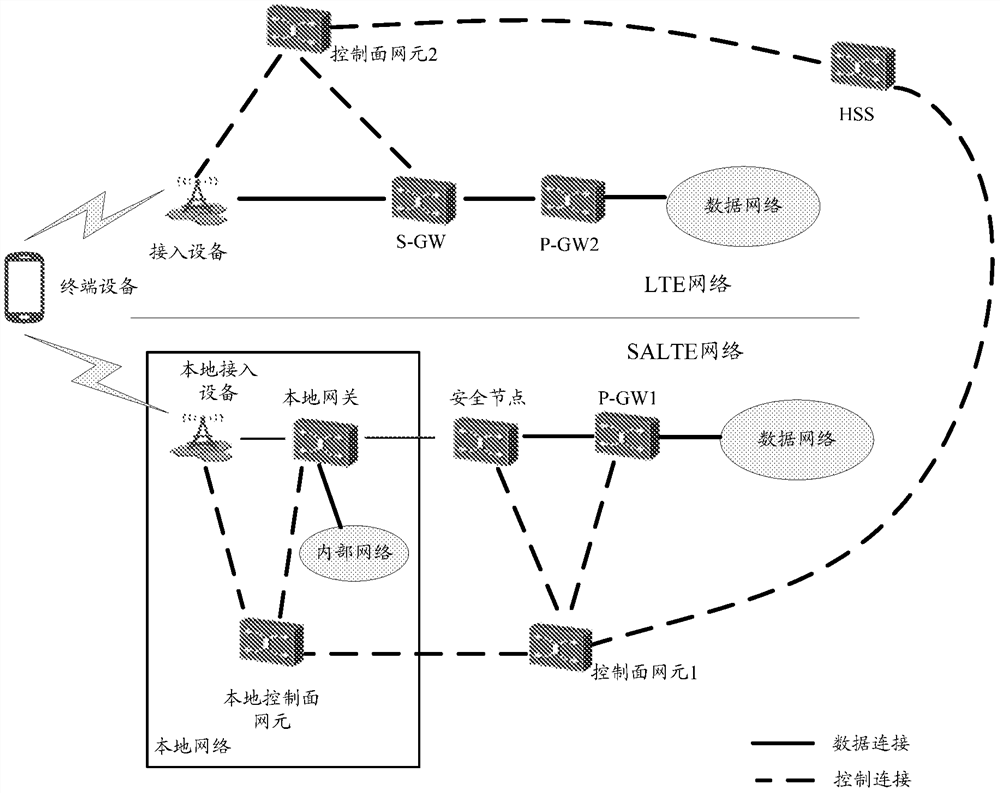

Method and device for network access control

ActiveCN109417490BImplement access controlAvoid running errorsPower managementAssess restrictionEngineeringReal-time computing

A network access control method and device, used to solve the problem in the prior art that when a terminal device establishes a data connection with a network and forcibly establishes a data connection with another network, a network connection error or a terminal device operation error occurs. The method is: when the first network device determines that the terminal device has established the second data connection with the second network, control the terminal device to stop establishing the first data connection with the first network, or control the terminal device to disconnect The second data connection is opened, so that the first data connection can be successfully established. In this way, it can be ensured that there is a data connection between the terminal device and a network, and that the terminal device can normally transmit data.

Owner:HUAWEI TECH CO LTD

An interface calling method, device and terminal

ActiveCN104881318BAvoid running errorsImprove compatibilityMultiprogramming arrangementsProgram code adaptionClient-side scriptingComputer compatibility

An interface calling method, an interface calling device and a terminal, which can improve the compatibility of a browser. The method comprises: receiving an interface calling instruction, the interface calling instruction carrying an interface identifier and parameters, corresponding to an interface which needs to be called for loading a client script (S101); when a browser kernel, which is currently operated in a browser, is not a target browser kernel corresponding to the client script, and a first interface function, which is provided by the currently operated browser kernel and corresponds to the interface identifier, is different from a second interface function, which is provided by the target browser kernel and corresponds to the interface identifier, acquiring a pre-set target interface function, which corresponds to the interface identifier, of the currently operated browser kernel (S102); and taking the parameters as input parameters of the target interface function, and calling the target interface function (S103).

Owner:ZHUHAI BAOQU TECH CO LTD

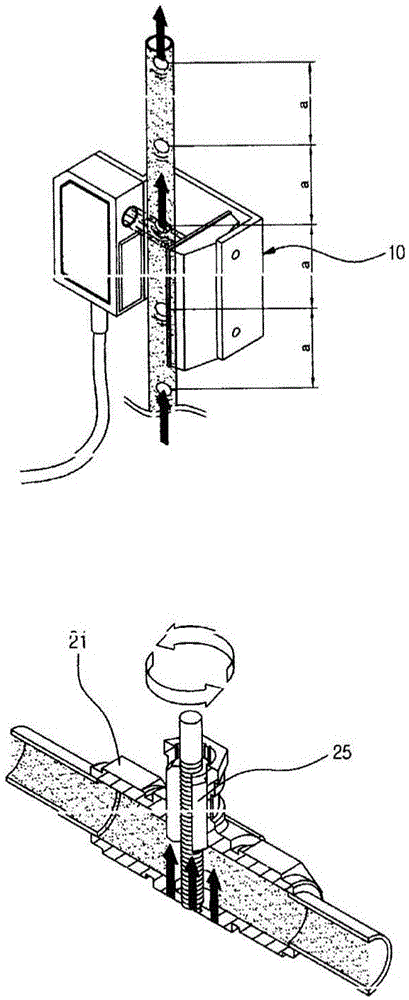

Apparatus for sensing and controlling gas supply amount, and method for sensing and controlling gas supply amount thereby

ActiveCN106455529AAccurate identificationAccurate target supplyVolume/mass flow measurementInvestigating moving fluids/granular solidsInterior spaceProduct gas

The present invention relates to an apparatus for sensing and controlling a gas supply amount, and a method for sensing and controlling a gas supply amount thereby, the apparatus being configured so as to be capable of continuously maintaining the originally preset supply amount while allowing the gas supply amount to be sensed in real time by a light sensor on the basis of the number of bubbles generated at an arbitrarily set time difference when target gas flows in a tube, thereby being capable of identifying more accurately the supply amount or faulty supply state, wherein a series of automated devices control the pressure of the tube in real time so as to precisely realize a target supply amount according to gas supply information obtained from the light sensor, thereby actively preventing malfunction. The apparatus comprises: a tube (1) which allows target gas to flow from the bottom to the top; a sensing unit (10), engaged with the external surface of the tube, for sensing the number of bubbles of the target gas, which sequentially moves for a predetermined period of time in the inner space of the tube, in real time, through application of the light sensor on the basis of signal information of a light emitting diode and a transistor positioned to correspond to each other; a control unit for receiving bubble information from the sensing unit and determining whether the bubble information matches the target gas supply amount in comparison to a preset time; and a pressure adjustment unit (20), operated by signals obtained from the control unit, for determining whether to block the inner space of the tube in a manner that the pressure adjustment unit (20) rotates at an angle proportional to the number of pulses provided through a motor, thereby varying the number of bubbles during a certain period of time to match the target gas supply amount.

Owner:ECINU

Method and device for sending loop detection message

ActiveCN106209561BImprove the efficiency of sending and receiving messagesImprove efficiencyNetworks interconnectionStart timeTimer

The application provides a method and an apparatus for sending loop detection messages. The method comprises the steps of aiming at each port, acquiring a random number, and determining message sending start time of each port by utilizing the random number; if the message sending start time of a certain port is out, determining a message sending batch of the certain port by utilizing all VLANs (Virtual Local Area Networks) corresponding to the certain port, and sending a loop detection message according to the message sending batch; and creating a timer for the certain port, setting timeout of the timer as a first preset interval, so that the certain port sends the loop detection message at a time interval equal to the first preset interval according to the message sending batch. According to the application, different message sending start time is obtained by different random numbers, so that time when each port sends the loop detection message is dispersed, and the number of the loop detection messages sent at the same time is reduced. Moreover, network equipment sends out the loop detection message of each port according to the batch, so that the number of sending the loop detection messages at the same time is further reduced.

Owner:HANGZHOU DPTECH TECH

Blackboard eraser device based on automatic control and using method thereof

PendingCN107901682ARealize the automatic erasing functionSimple structureBoard cleaning devicesAutomatic controlGear wheel

The invention discloses a blackboard eraser device based on automatic control and a using method thereof. The blackboard eraser device comprises a gear and a rack engaged with the gear; a motor is connected to the gear and connected with a brush, wherein the motor drives the brush to move in the rack direction; both of the two ends of the brush are connected with rollers; and guide rails allowingthe rollers to roll are arranged under the rollers, and the length of each guide rail is no less than that of the rack. The problems that an existing automatic cleaning blackboard eraser is complex instructure, poor in using effect and high in cost are solved.

Owner:YULIN UNIV

On-line monitoring and control method of fault alarm system for aluminum electrolysis crane silo material level

Relating to the field of aluminum electrolysis equipment, the invention discloses a control method for an aluminum electrolysis crown block stock bin material level online monitoring and fault alarm system. The method consist of: judging the stock bin charging and motion state, if no charging behavior occur and the stock bin is at a stationary state, letting an MCU module communicate with a slot control machine to obtain the information that whether an aluminum electrolysis cell needs charging; if the aluminum electrolysis cell needs charging at the moment, carrying out charging and calculating the charging speed; and if the charging speed is normal, the stock bin is fault-free, if the charging speed is too slow, blocking can occur to the stock bin or fault can occur to the equipment, starting an audible and visual alarm. The method provided by the invention utilizes a weighing sensor to collect the stock bin quality data and calculates the raw material charging speed, then judges whether a discharge port is blocked, and gives an audible and visual alarm and requires overhauling. The method provided by the invention can achieve real-time online monitoring and control of the stock bin material level, at the same time detects stock bin blocking information in the first time so as to avoid blocking worsening. According to the invention, the structure and operation steps are simple, thus being easy to implement.

Owner:CHONGQING UNIV

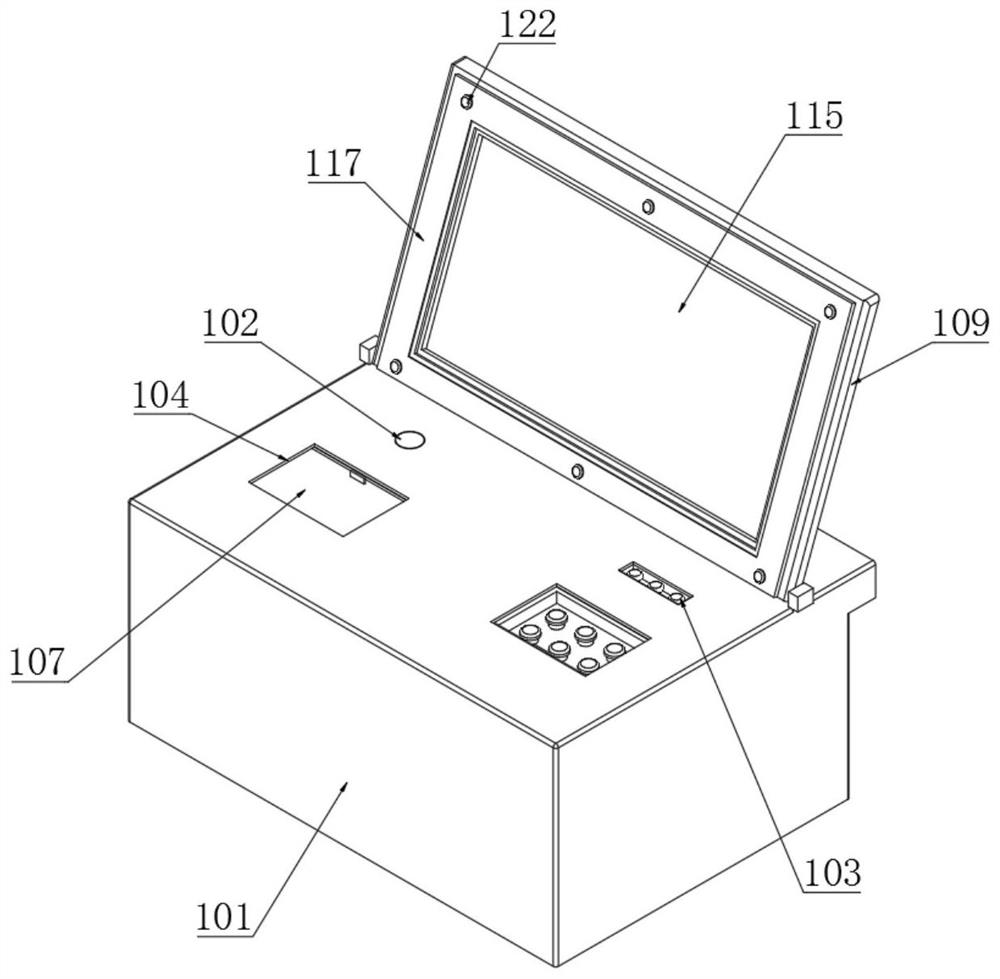

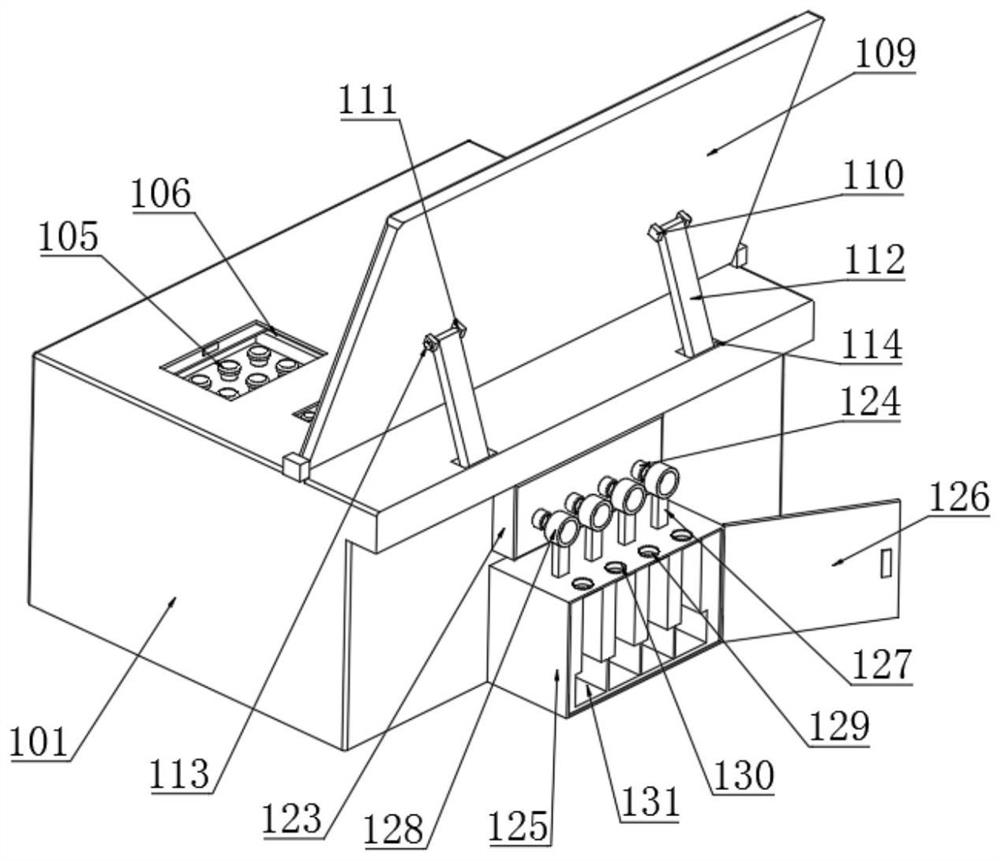

An easy-to-operate elevator installation, maintenance, and debugging simulation system

ActiveCN112218452BScientific and reasonable structureEasy to useCasings with display/control unitsCasings/cabinets/drawers detailsStructural engineeringControl theory

The invention discloses an easy-to-operate elevator installation, maintenance, and debugging simulation system. The top of the operating table is symmetrically provided with a button placement groove, and the inside of the button placement groove is fixedly installed with an operation button. The top of the button placement groove is provided with a rectangular groove, and the rectangular groove The inside of the cover is slidingly installed with a cover plate, one end of the top of the cover plate is fixedly connected with a pull block, one end of the top of the console is rotated by a movable shaft to install a display screen mounting plate, and the back side of the display screen mounting plate is symmetrically fixed and fixed with a shaft seat, The middle part of the shaft seat is movably installed with a rotating shaft. The present invention plays a role of support and protection by arranging a limit ring sleeve to prevent the natural sagging of the cable from causing pressure on the connection between the cable and the connecting plug, thereby causing the connection of the cable to be damaged. It is easy to be broken and damaged, which improves the service life of the device, reduces the chance of cable loosening, ensures the normal operation of the device, and separates the cables from each other, which is convenient for operators to overhaul.

Owner:北京凯盛安达电梯服务有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com