Method for detecting and processing faults of washing machine

A technology of fault detection and processing method, which is applied in the field of washing machines, can solve problems such as program fault detection, and achieve the effects of ensuring safe operation, preventing internal operation errors, and preventing continuous water ingress

Active Publication Date: 2016-11-23

QINGDAO HAIER WASHING MASCH CO LTD

View PDF3 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] In order to solve the current technical problem that there is no special detection of program faults in the running process of the washing machine, the present invention proposes a washing machine fault detection and processing method, which can solve the above problems

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0038] Embodiment 1. This embodiment proposes a washing machine fault detection and processing method, which includes the following steps:

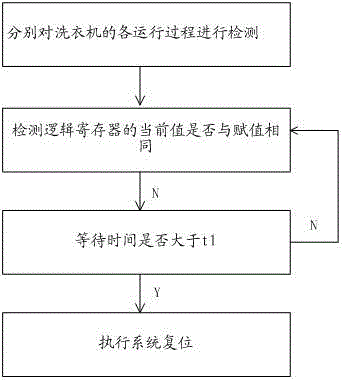

[0039] PC pointer detection steps, such as figure 1 Shown:

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

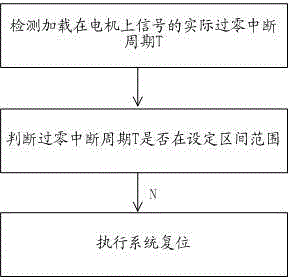

The invention discloses a method for detecting and processing faults of a washing machine. The method comprises steps as follows: a PC (program counter) pointer detection step: all operational processes of the washing machine are detected; whether a current value of a logic register is equal to an assignment or not is detected after ending of all subprograms, if the current value is different from the assignment, the PC pointer is judged to break down, and the operational process in which the current fault of the washing machine occurs is recorded according to the assignment; when the PC pointer is judged to break down, a user waits for the time t1 and continuously detects whether the current value of the logic register is equal to the assignment, if the current value of the logic register is equal to the assignment, the subprogram is executed continuously, and otherwise, system reset is executed. With the method for detecting and processing the faults of the washing machine, internal operation errors of algorithms of the washing machine are avoided, the faults are detected by the system before the user finds out the faults, and corresponding safety control measures are taken, so that safe operation of the washing machine is guaranteed.

Description

technical field [0001] The invention belongs to the technical field of washing machines, and in particular relates to a washing machine fault detection and processing method. Background technique [0002] The current washing machine software program detection method only performs related processing on the door switch control signal, uses two IO ports to detect the door switch signal, and scans and reads the door switch signal input port every 10ms. If the input signal read continuously for 100ms remains unchanged, Then the signals of the two IO ports are calculated and assigned to the buffer register. As long as one IO port detects that the door is open, it is considered as the door is open, and the display board communicates with the power control board. Using CRC 8-bit check, the display When the board receives the door open or fails to communicate with the power control board for 3 seconds, it will control the motor to stop. This method cannot detect other faults of the ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): D06F33/02D06F39/00

CPCD06F33/00D06F33/46D06F2103/18D06F33/47D06F37/42D06F2105/52D06F33/44

Inventor 杨林陈瑜薛凯方大丰于亮亮

Owner QINGDAO HAIER WASHING MASCH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com