Patents

Literature

42results about How to "Real-time monitoring of material level" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

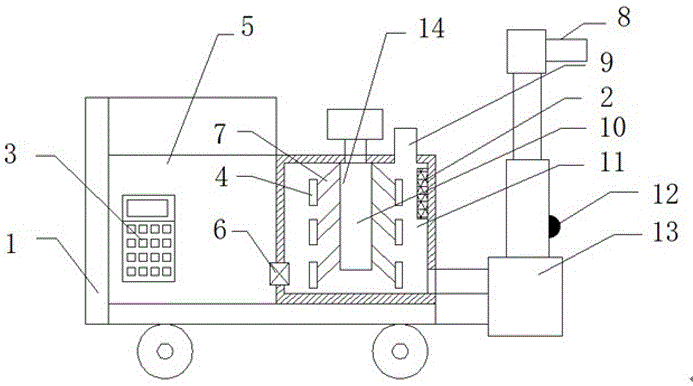

Coating spraying and brushing mechanical equipment

InactiveCN106076707AStir wellReasonable structural designBuilding constructionsLiquid spraying apparatusEngineeringMechanical equipment

The invention discloses coating spraying and brushing mechanical equipment. The coating spraying and brushing mechanical equipment comprises a supporting frame. An air compressor is arranged on the left side above the supporting frame. An electromagnetic valve is electrically connected with a control device through a wire. A feeding port is formed in the right side above a material storage tank. A stirring device is arranged in the material storage tank and internally provided with a stirring shaft. The stirring shaft is provided with stirring fins. Turbulent flow blocks are arranged at the end portions of the stirring fins. A rotating base is arranged at the right end of the supporting frame. A spraying head is arranged above the rotating base. An infrared sensor is arranged on the right side wall of the rotating base and electrically connected with the control device through a wire. The coating spraying and brushing mechanical equipment has the beneficial effects of being reasonable in structural design, easy to operate, convenient to use, practical and the like, meanwhile, the spraying efficiency and quality can be greatly improved, and the coating spraying and brushing mechanical equipment can be extensively used and popularized.

Owner:LIUZHOU YIHE TECH

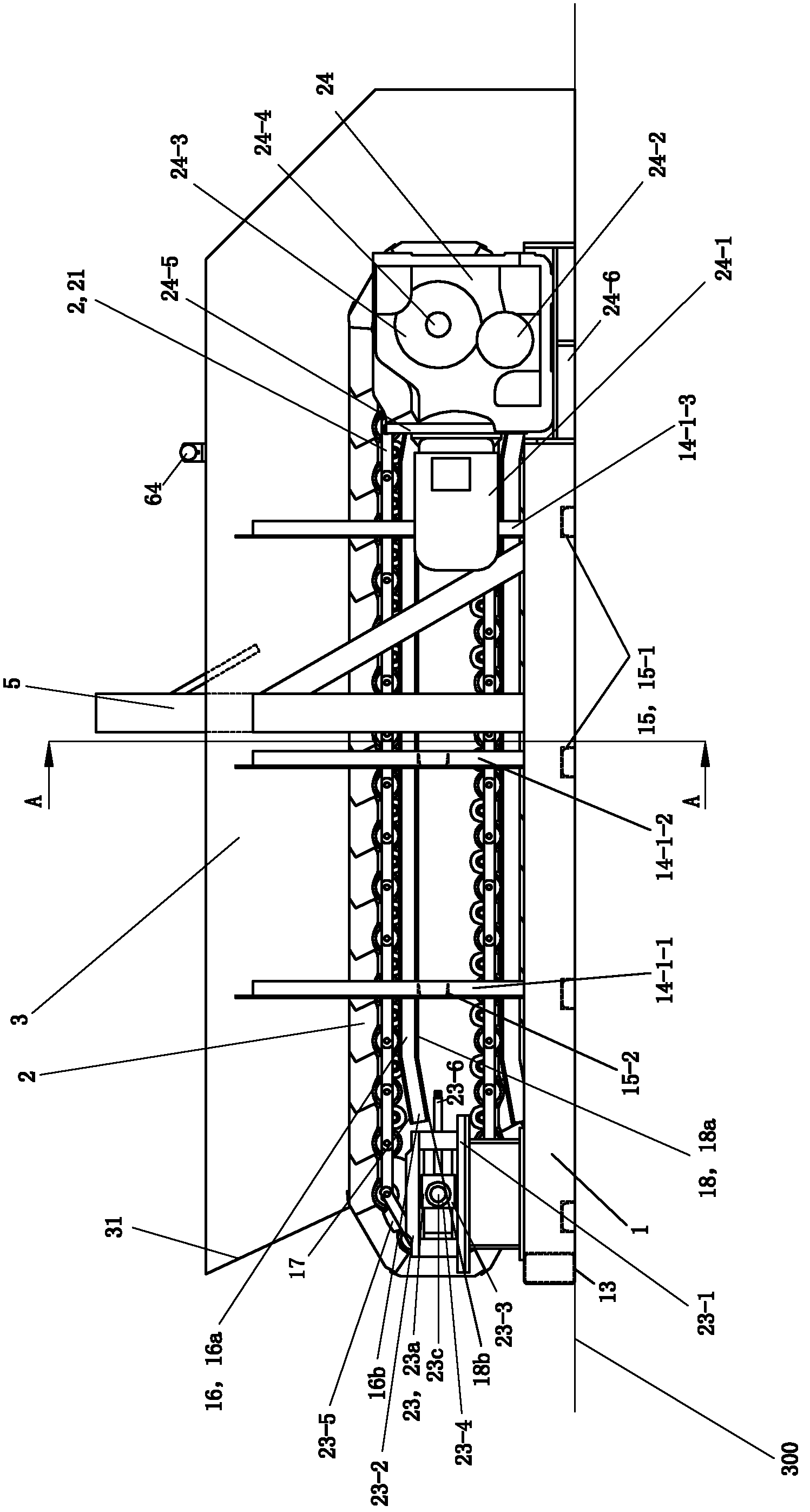

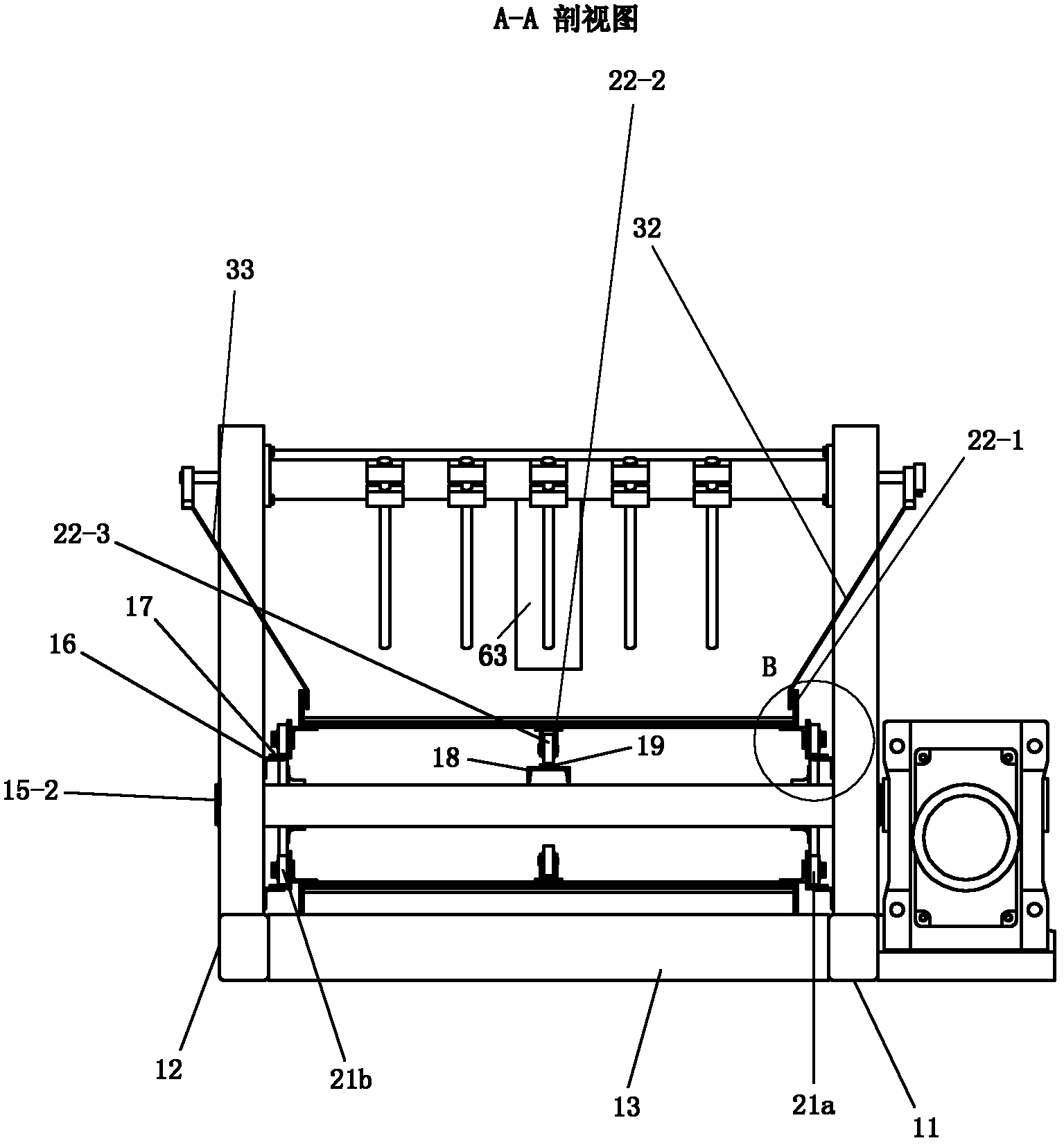

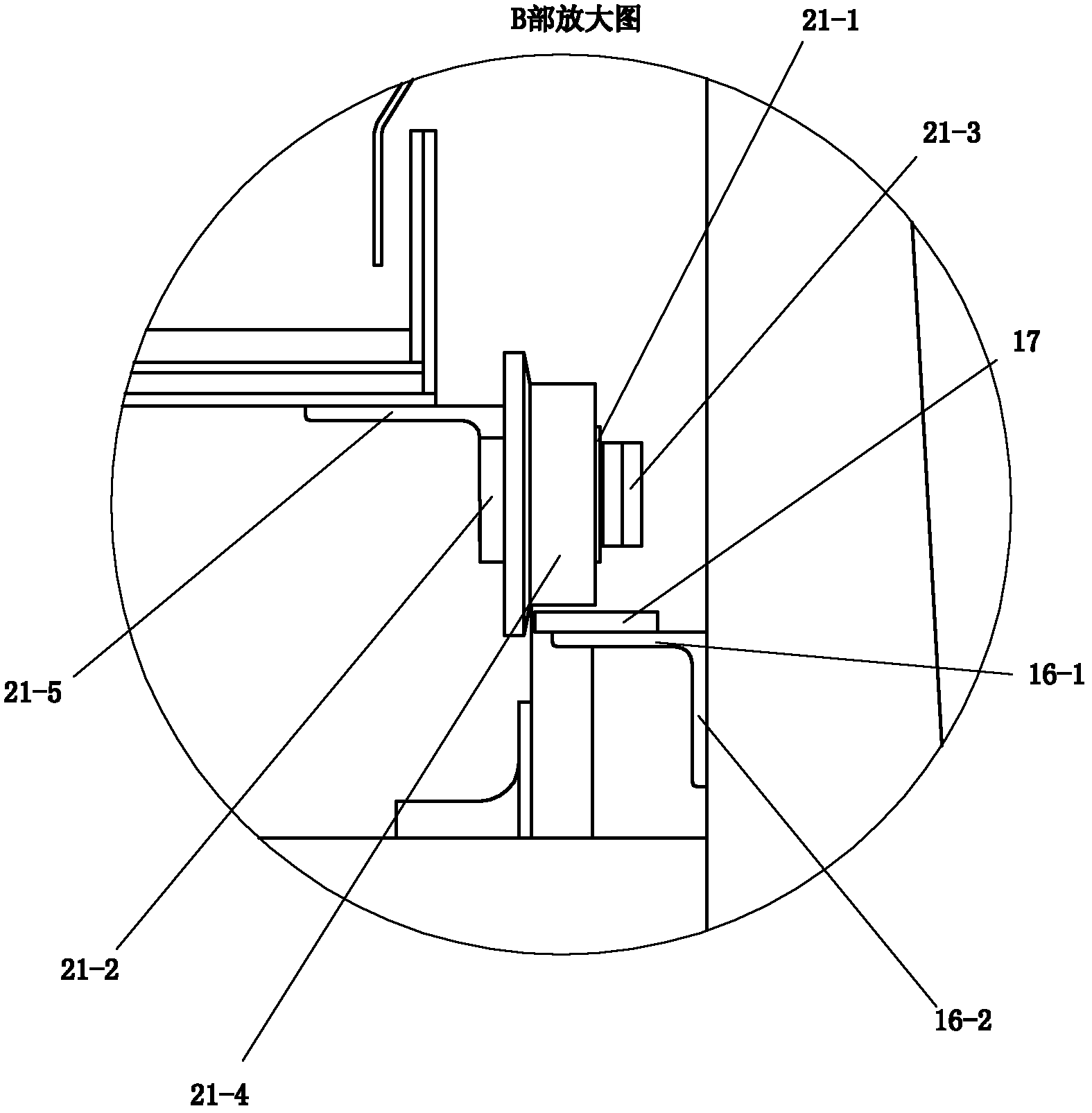

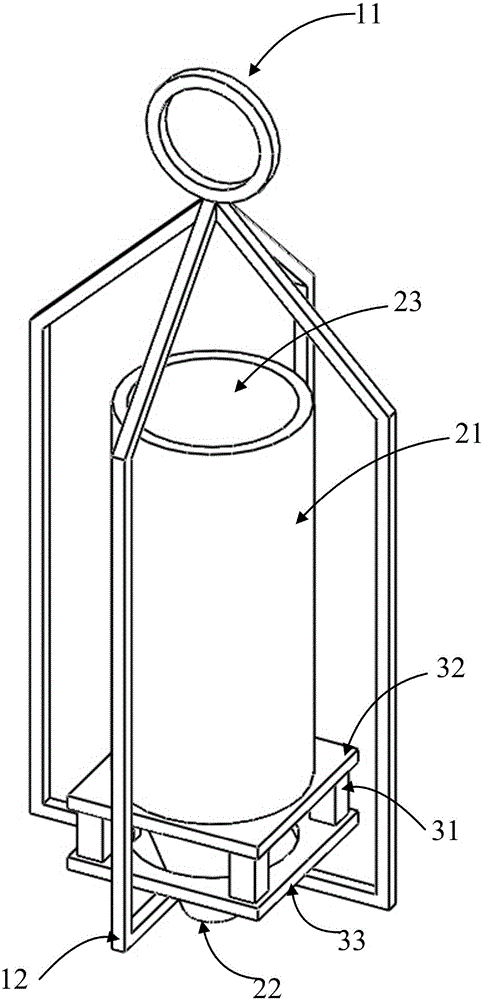

Garbage feeder

InactiveCN102491056AGuaranteed continuous feedingGuaranteed thicknessConveyorsControl devices for conveyorsEngineeringMechanical engineering

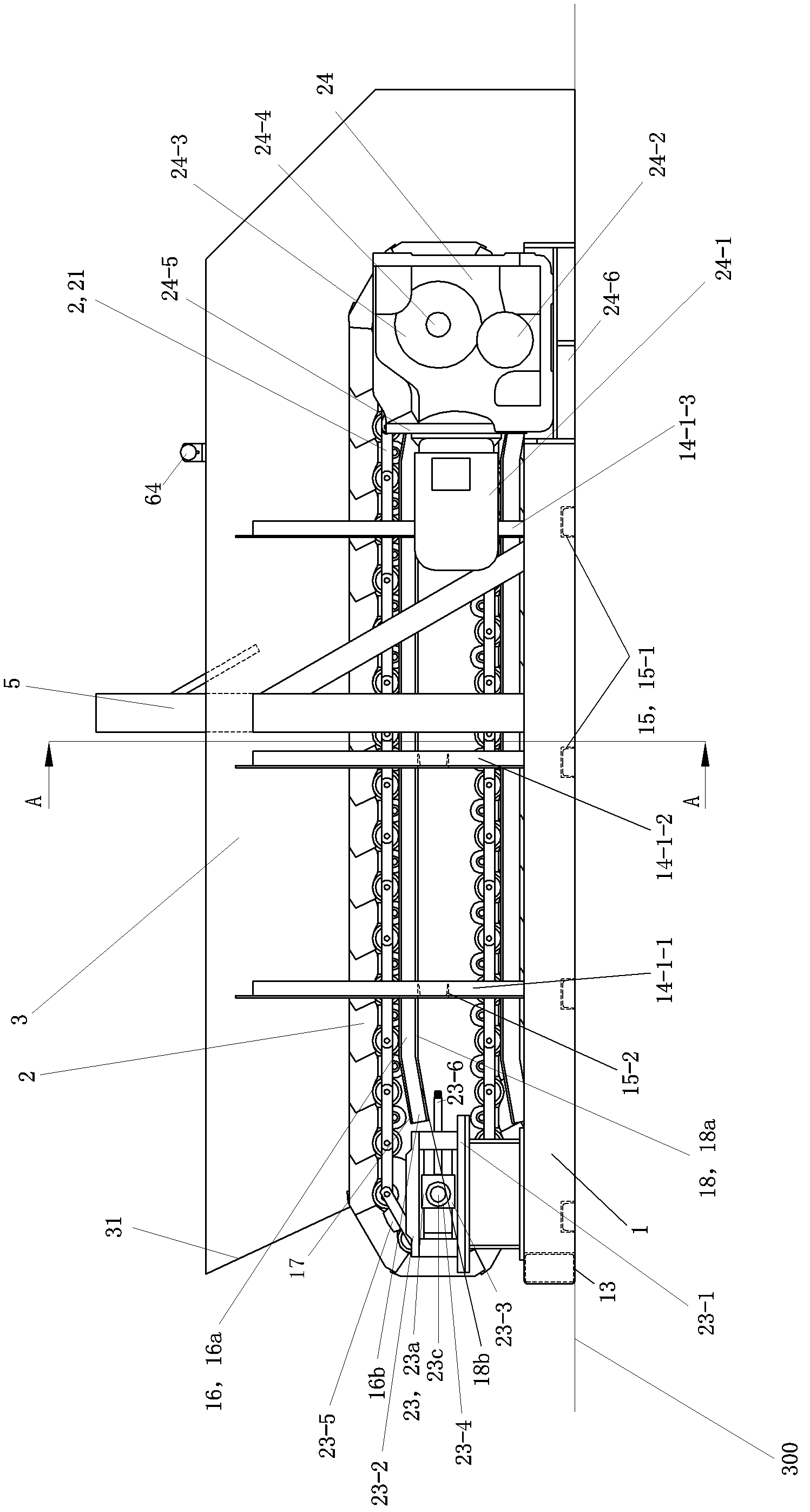

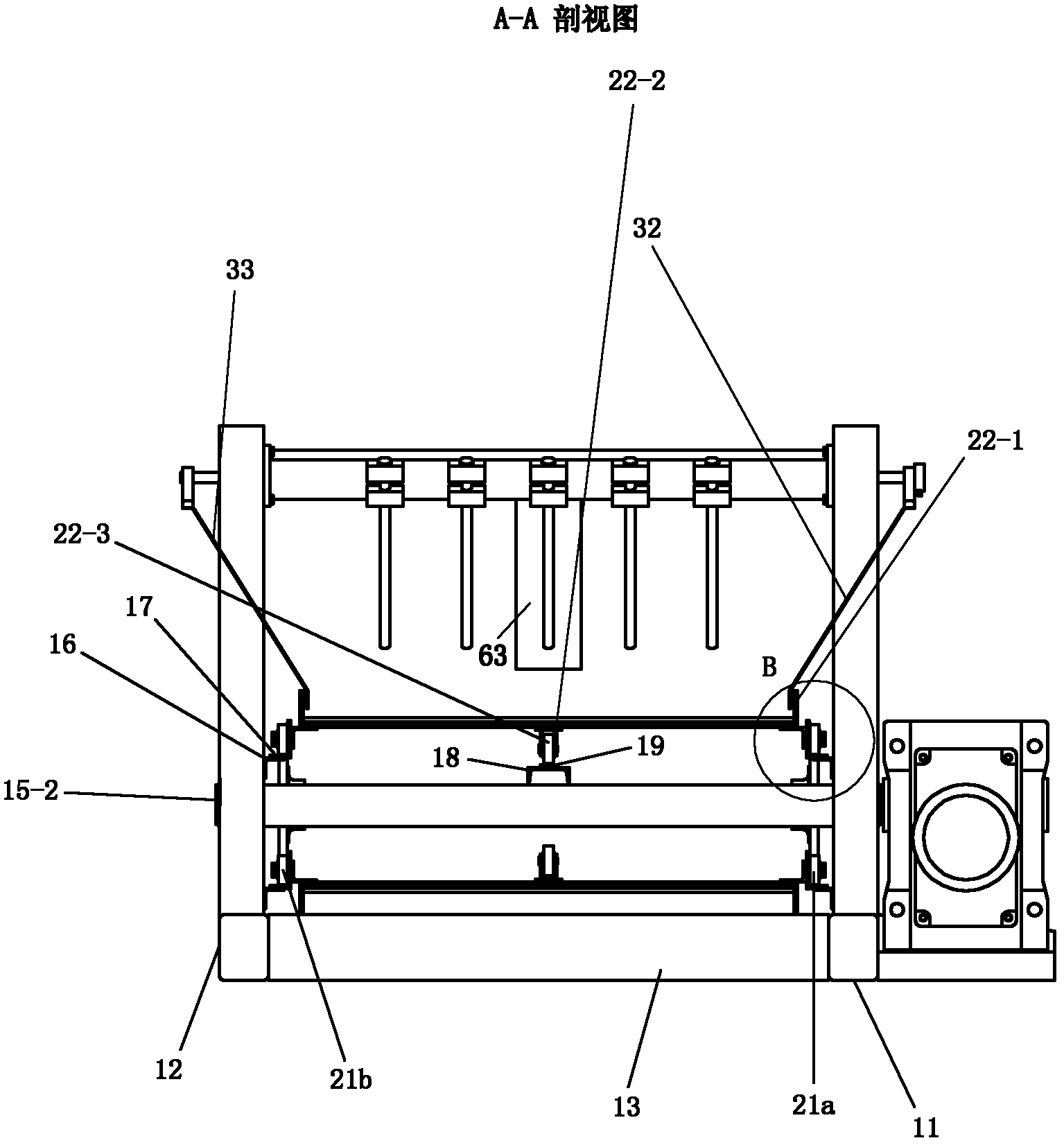

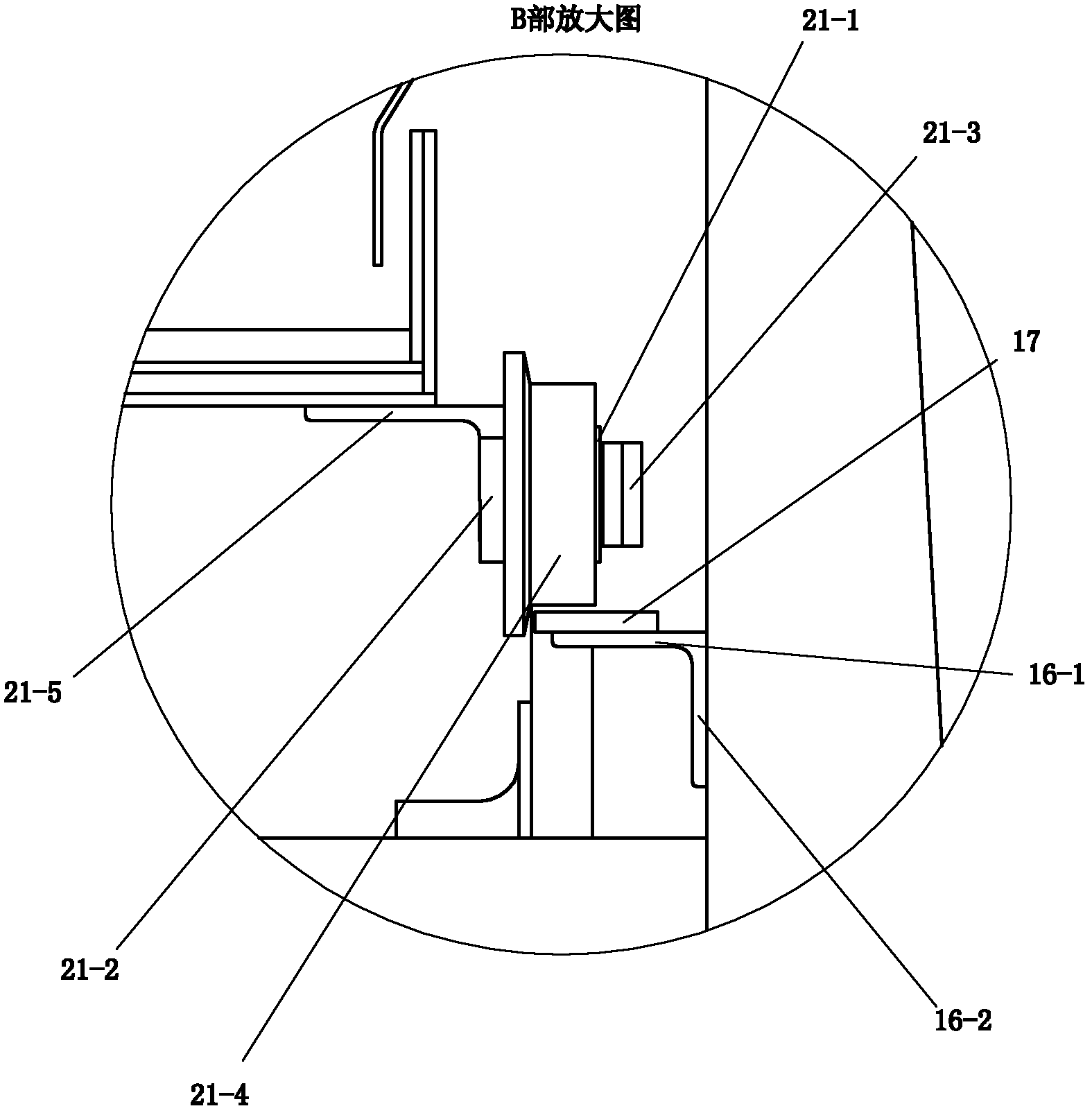

The invention discloses a garbage feeder, which comprises a machine frame, a conveying device and a guiding tank, wherein the conveying device is arranged on the machine frame; and the guiding tank is fixed on the machine frame and positioned above and on the right side of the conveying device. The garbage feeder is characterized by also comprising a blending device and a feed level feedback device. The machine frame comprises supporting posts, a connecting cross beam and supporting wheel bearers, wherein 1 to 3 supporting wheel bearers are used. Each feeding plate of the conveying device hasa roller support, the number of the roller supports is the same as that of the supporting wheel bearers, and each roller support is rotationally connected with a corresponding supporting roller. The supporting roller of each corresponding feeding plate is contacted with a supporting wheel bearer in a rolling manner. The blending device comprises a main frame body and comb teeth. The comb teeth are arranged on the main frame body. The blending device is arranged in the middle of the left and right direction of the machine frame. The comb teeth are positioned above the conveying device. The feed level feedback device is transversely spun over the guiding tank from the front to the back and is positioned above the part, which is on the right side of the blending device, of the conveying device.

Owner:江苏金陵环保科技有限公司

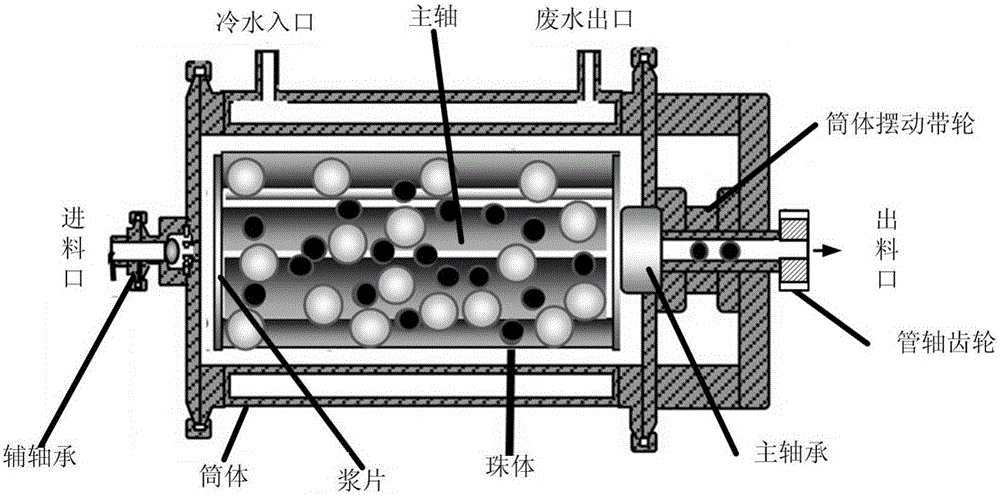

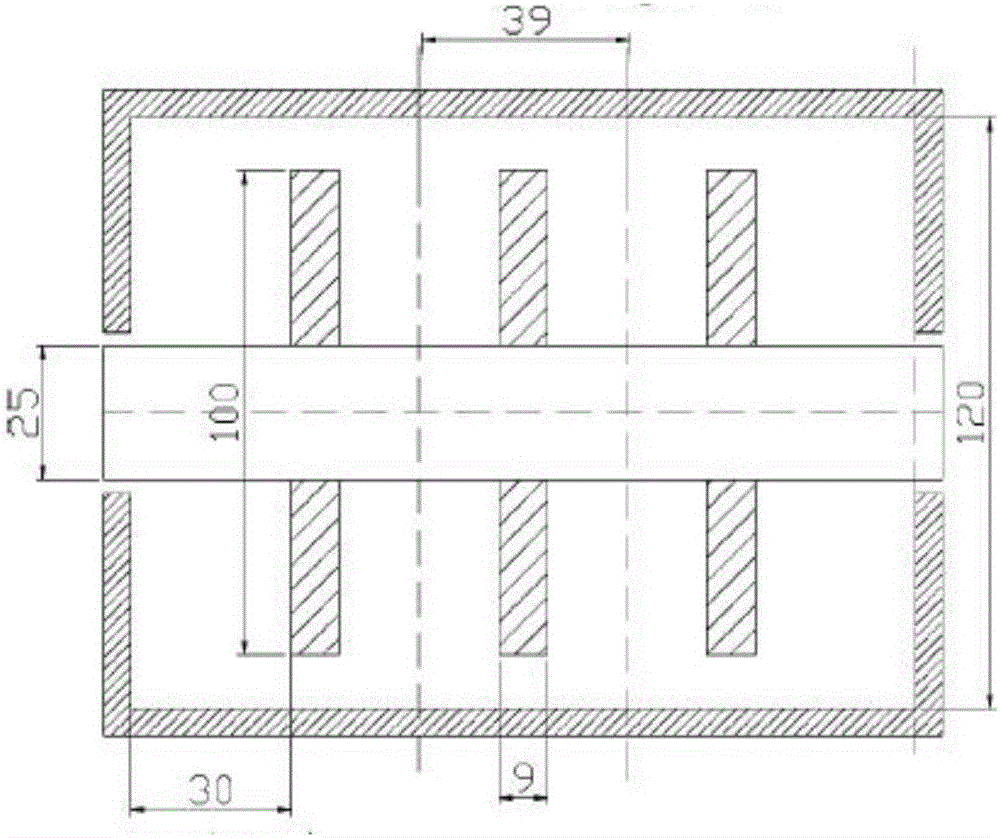

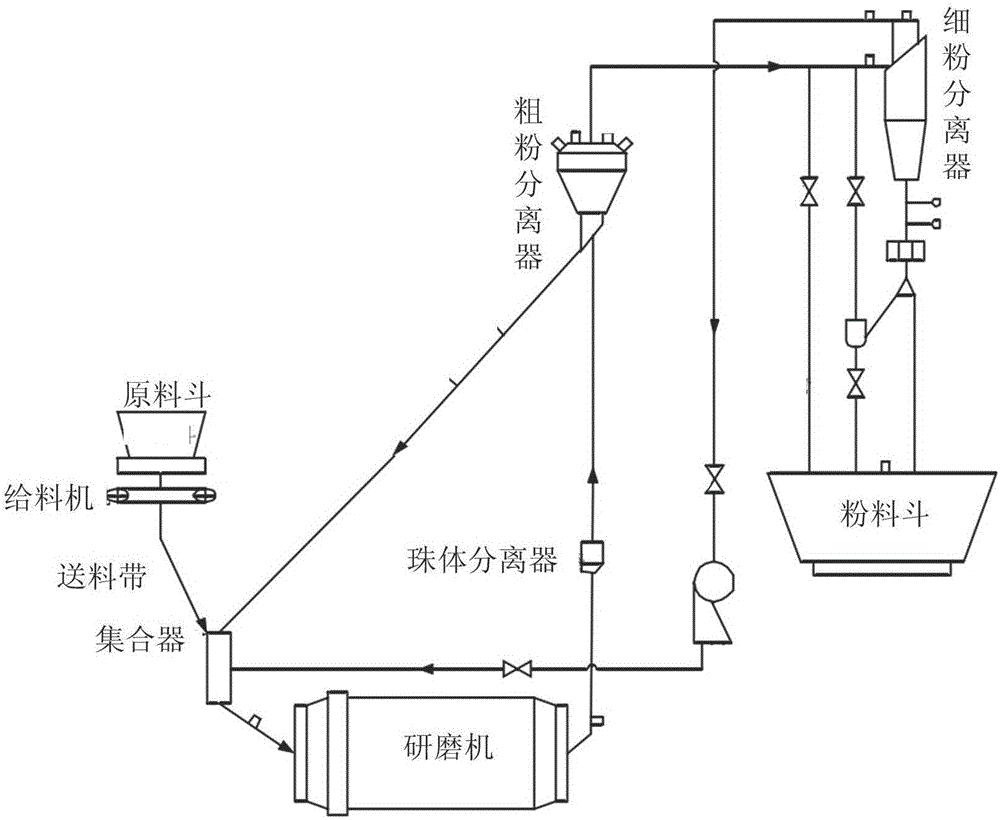

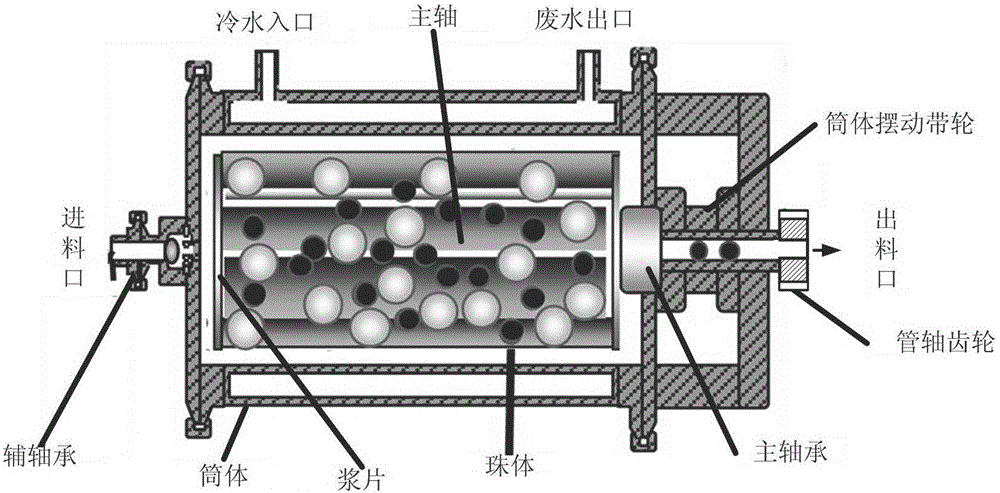

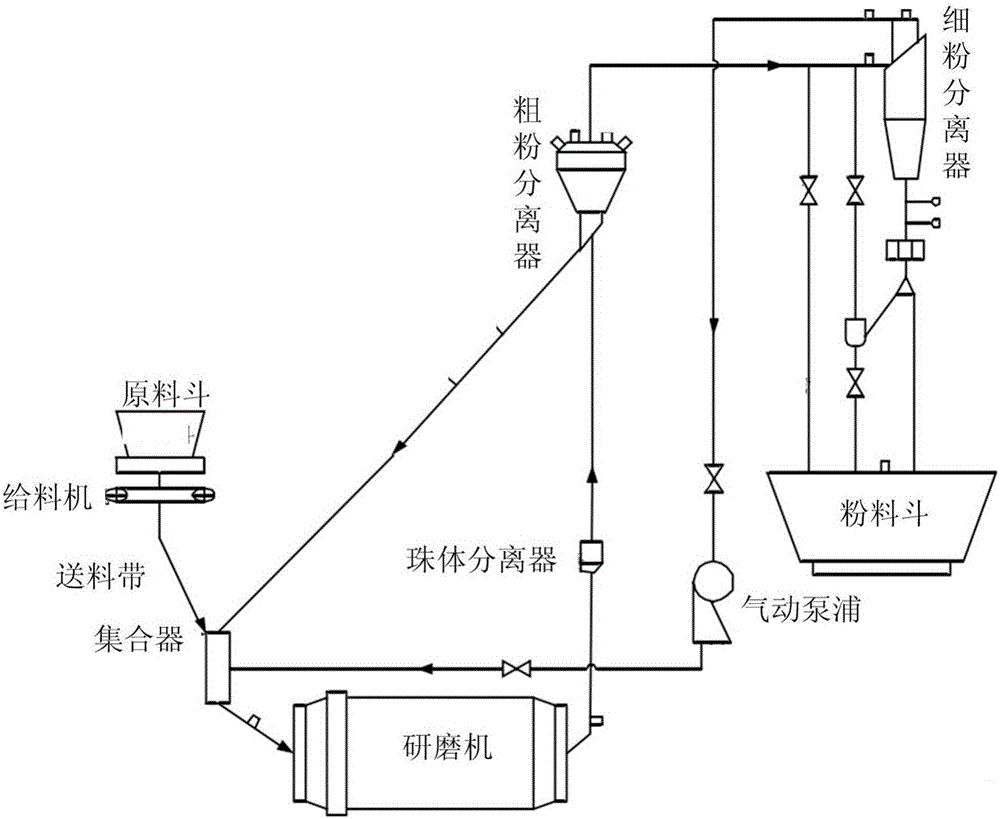

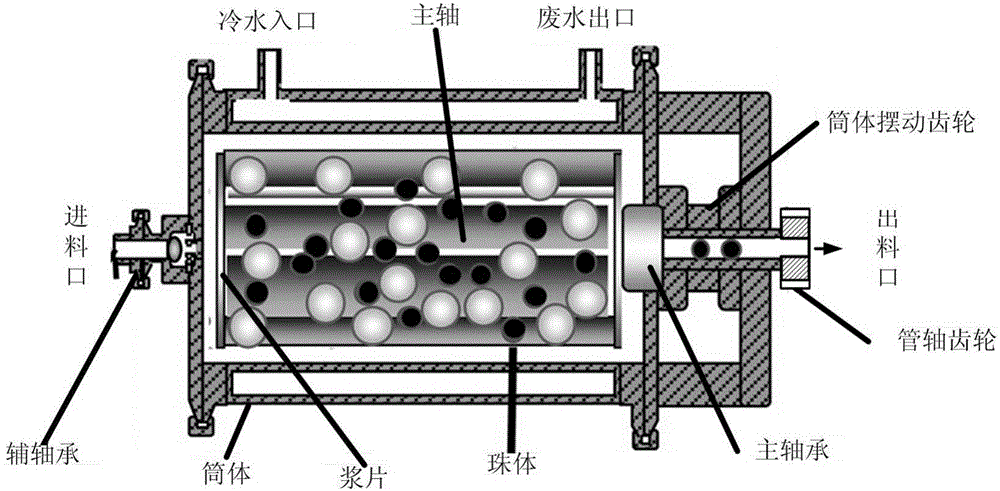

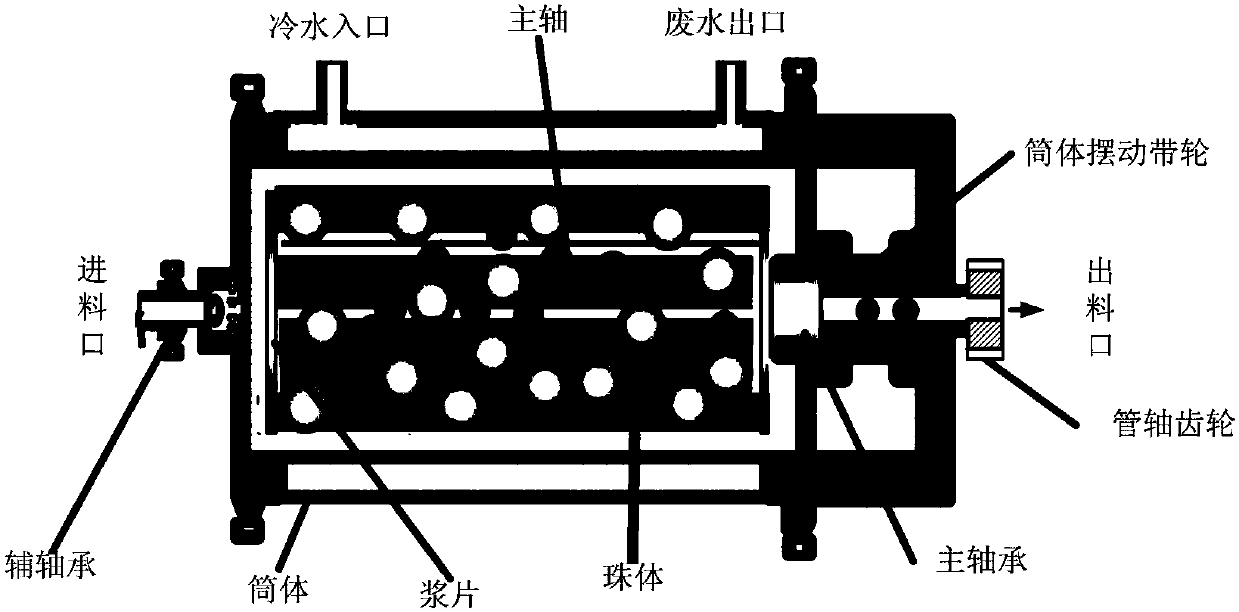

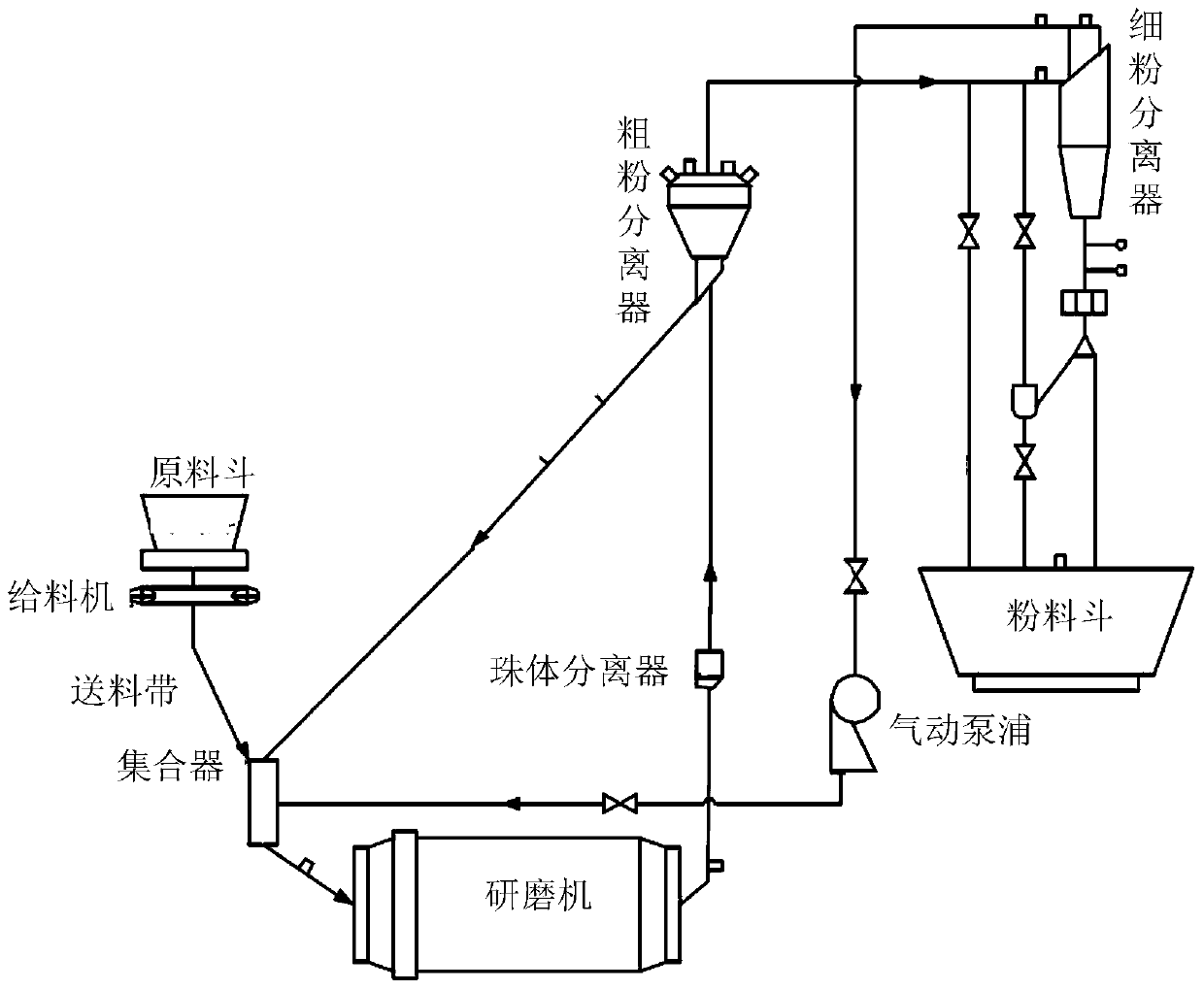

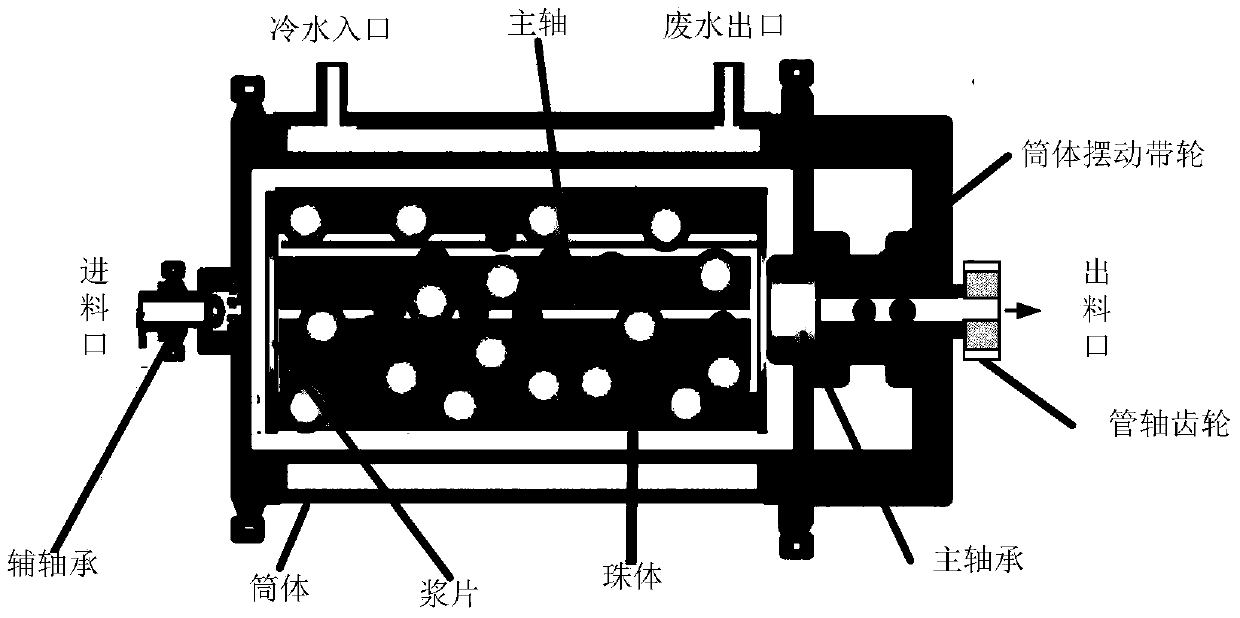

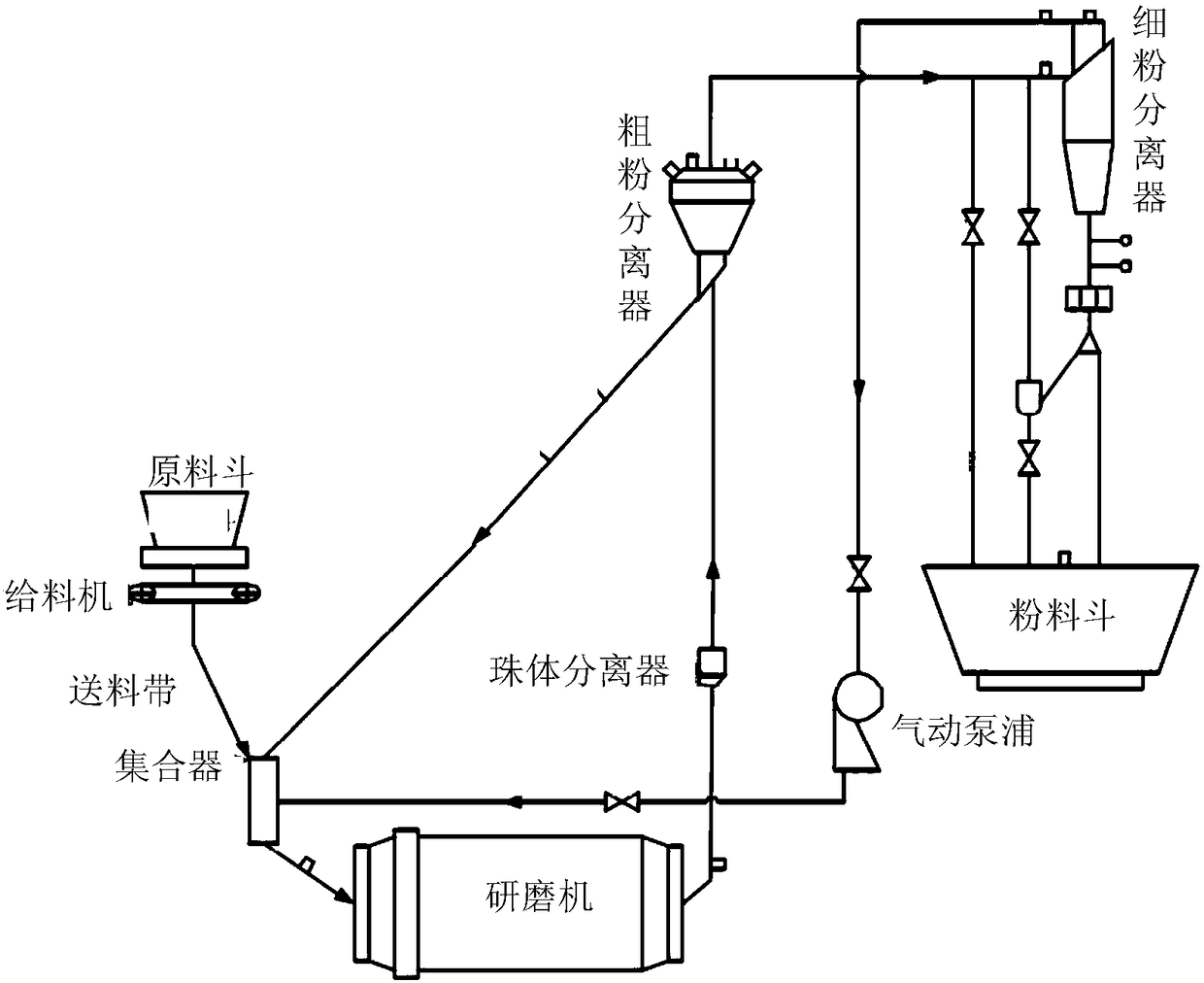

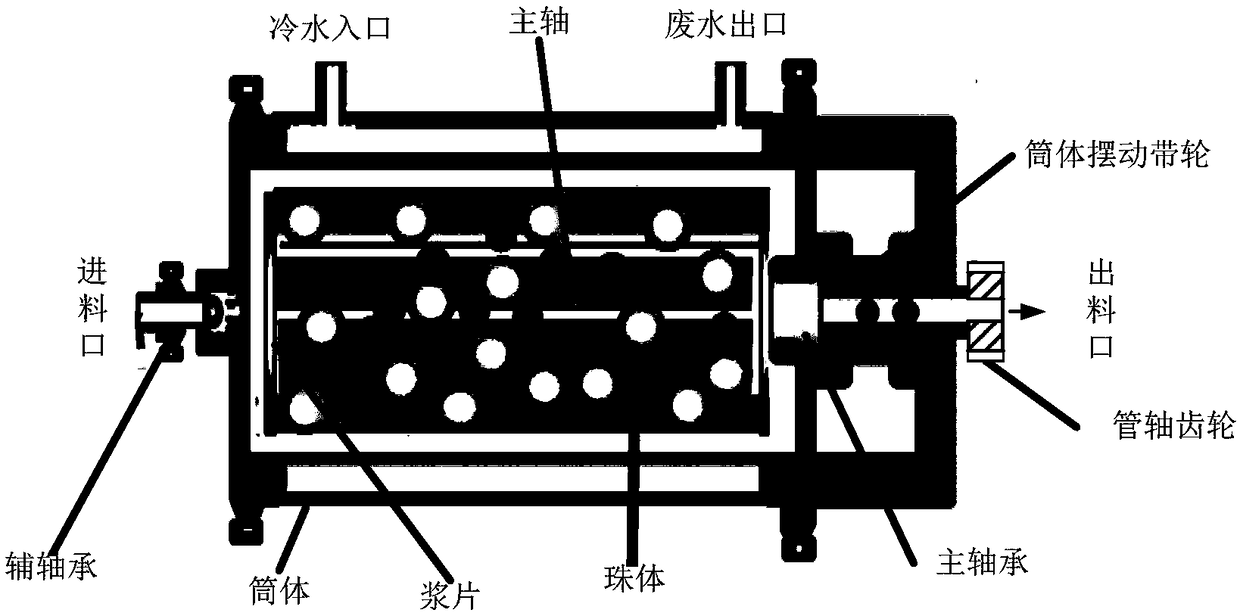

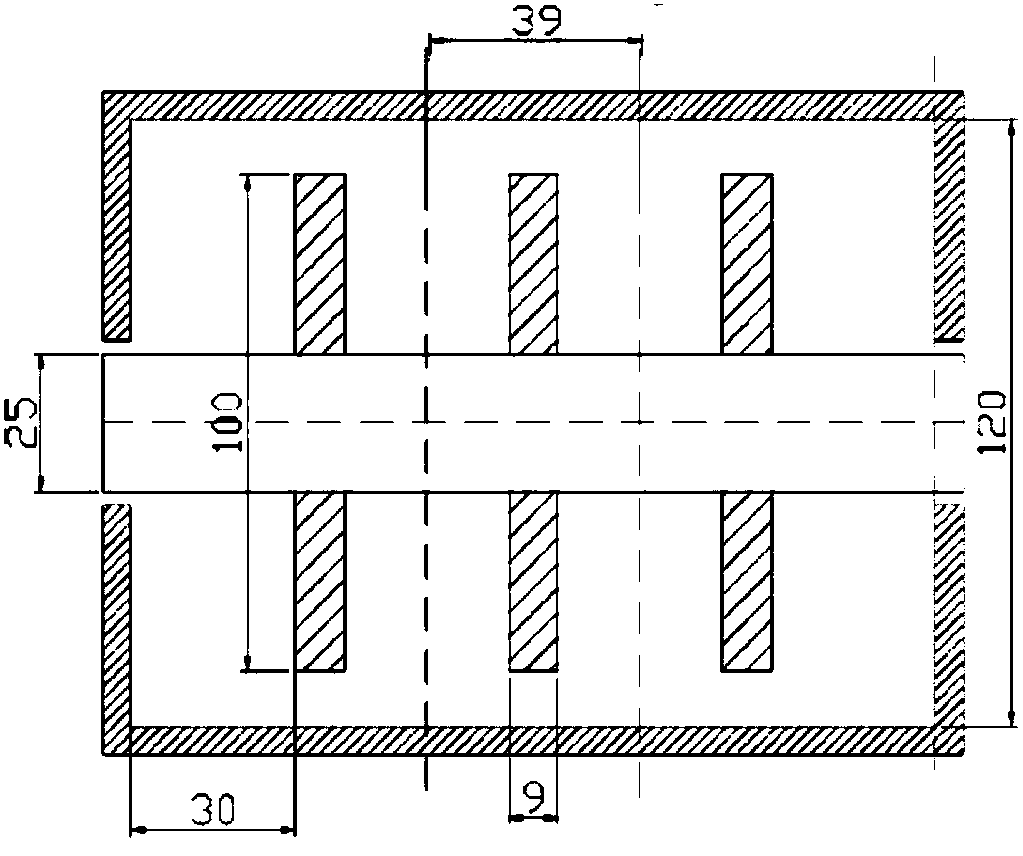

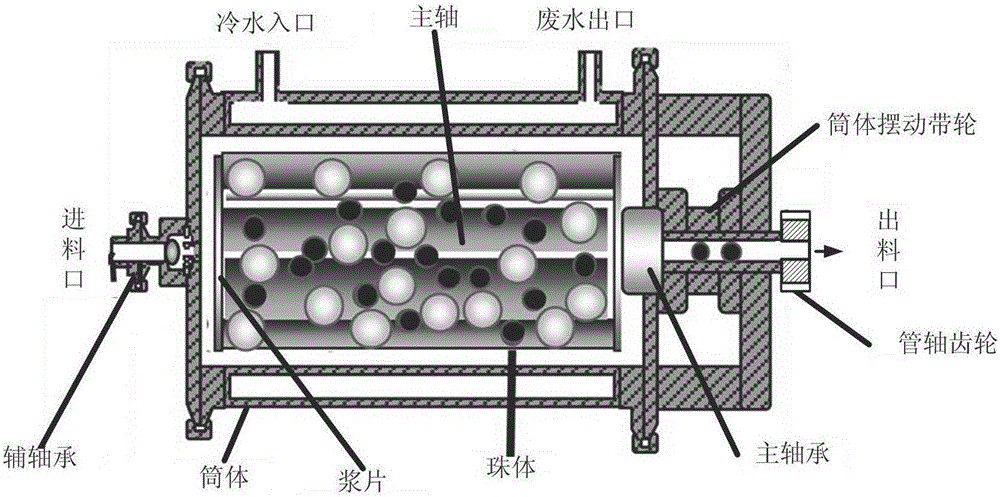

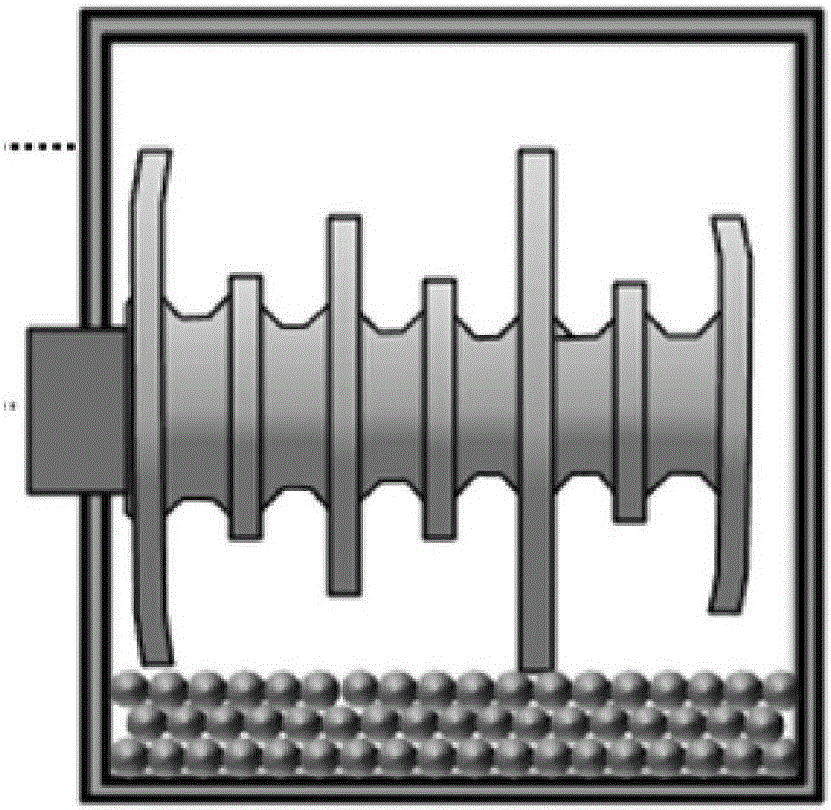

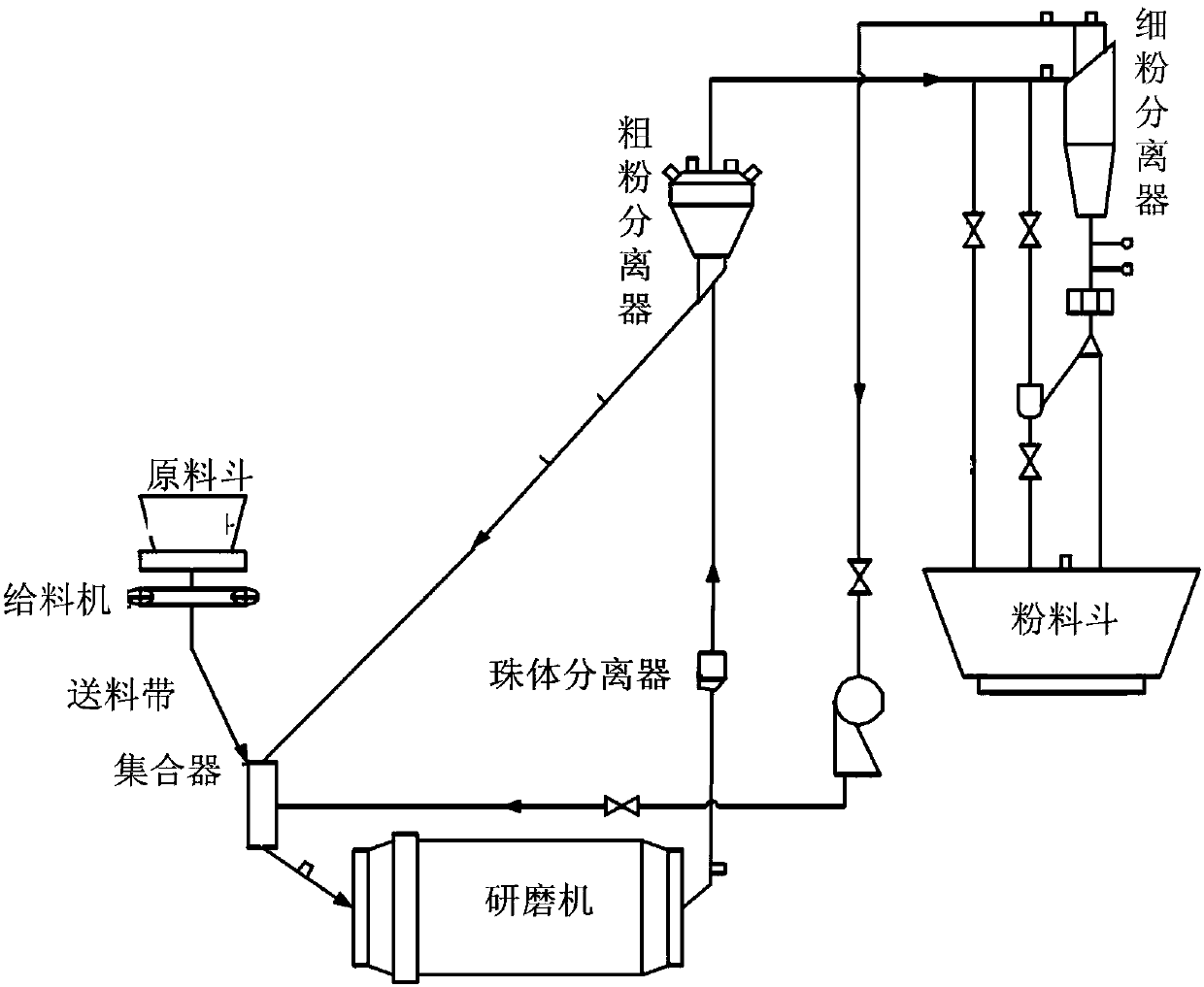

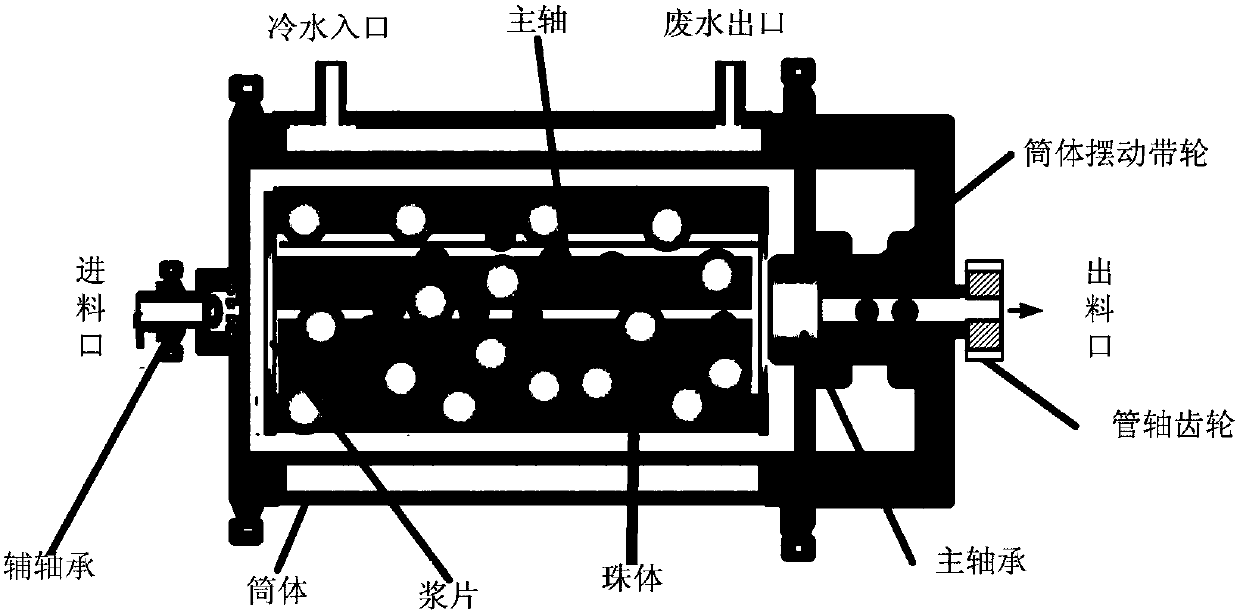

Grinding chemical machine system for fuzzy control over main shaft motor

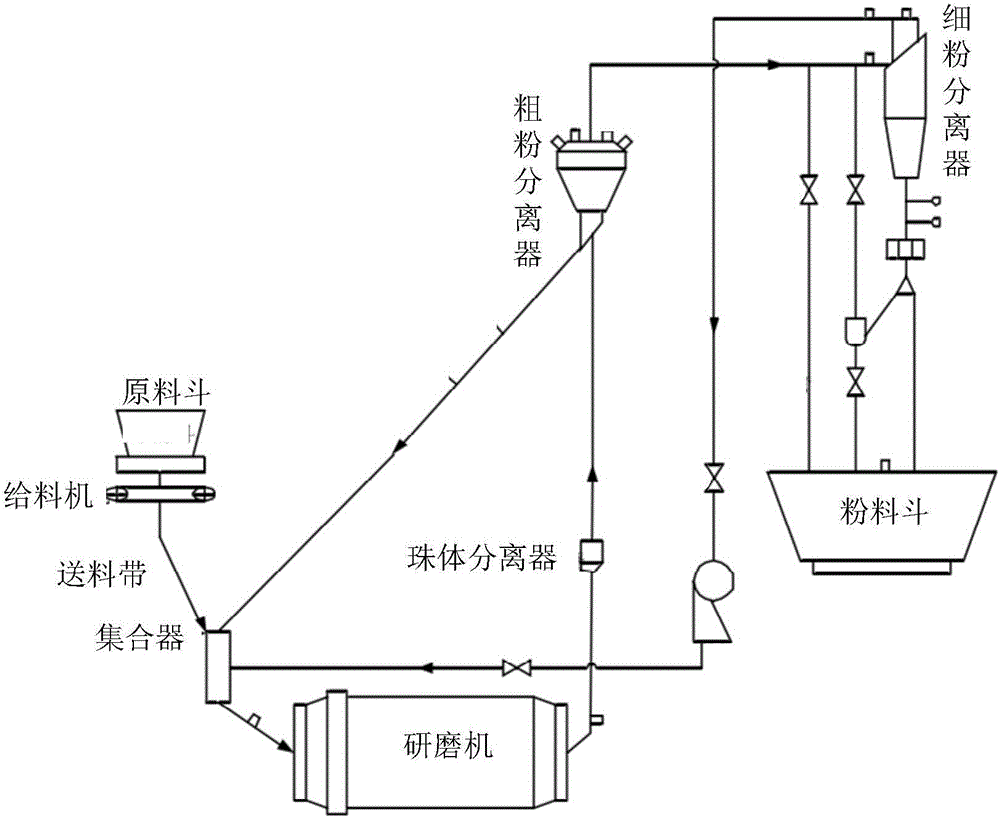

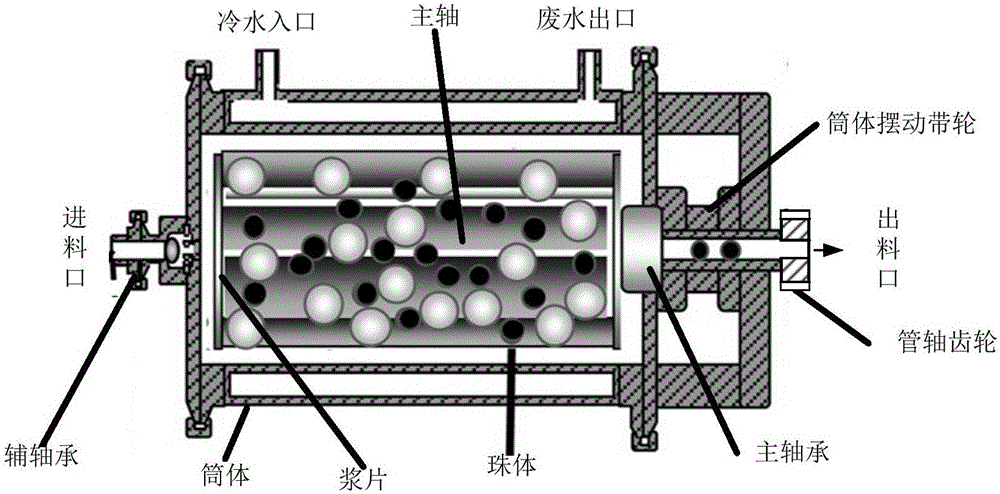

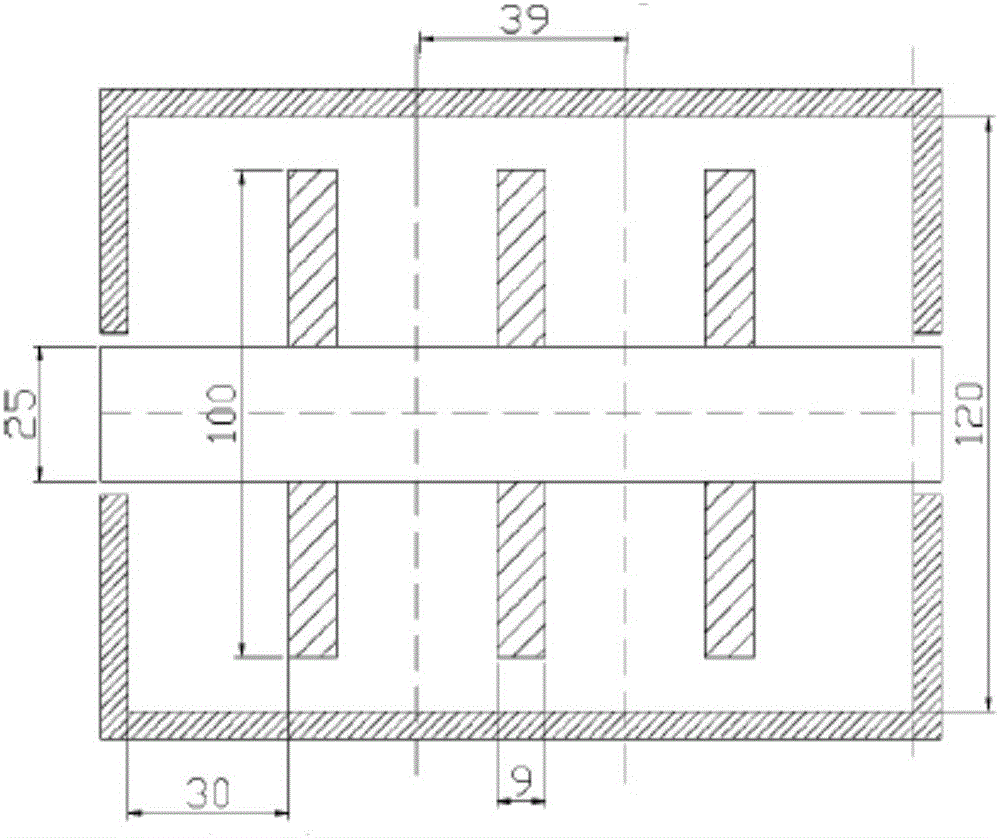

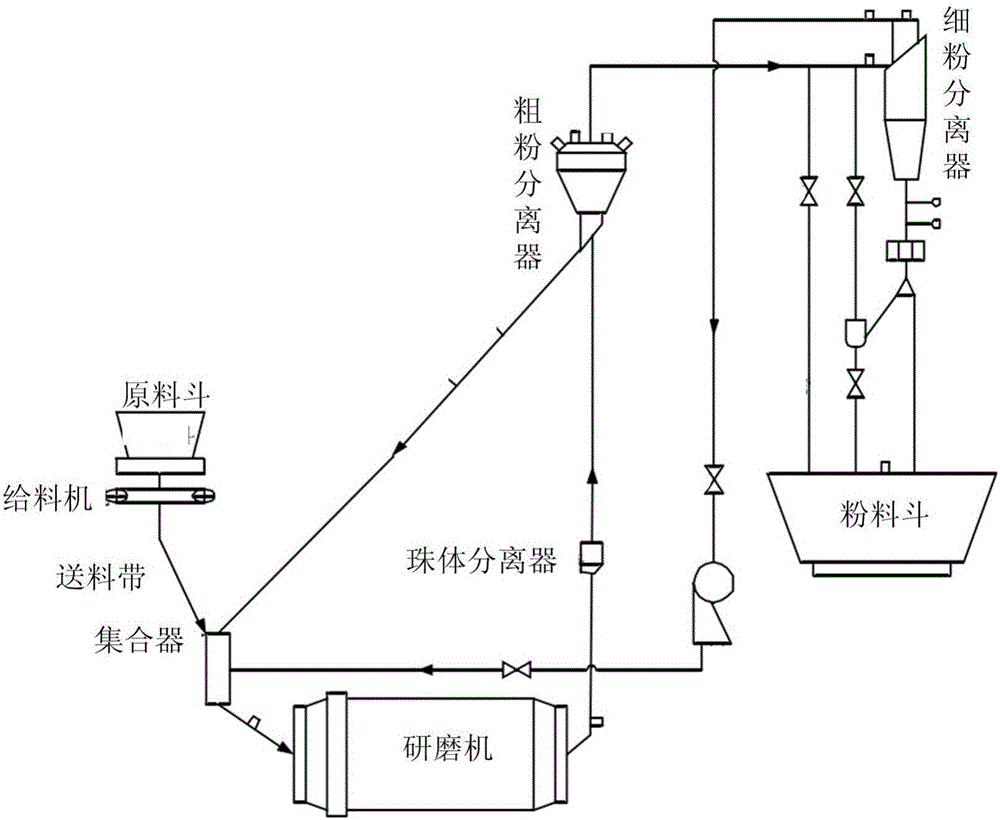

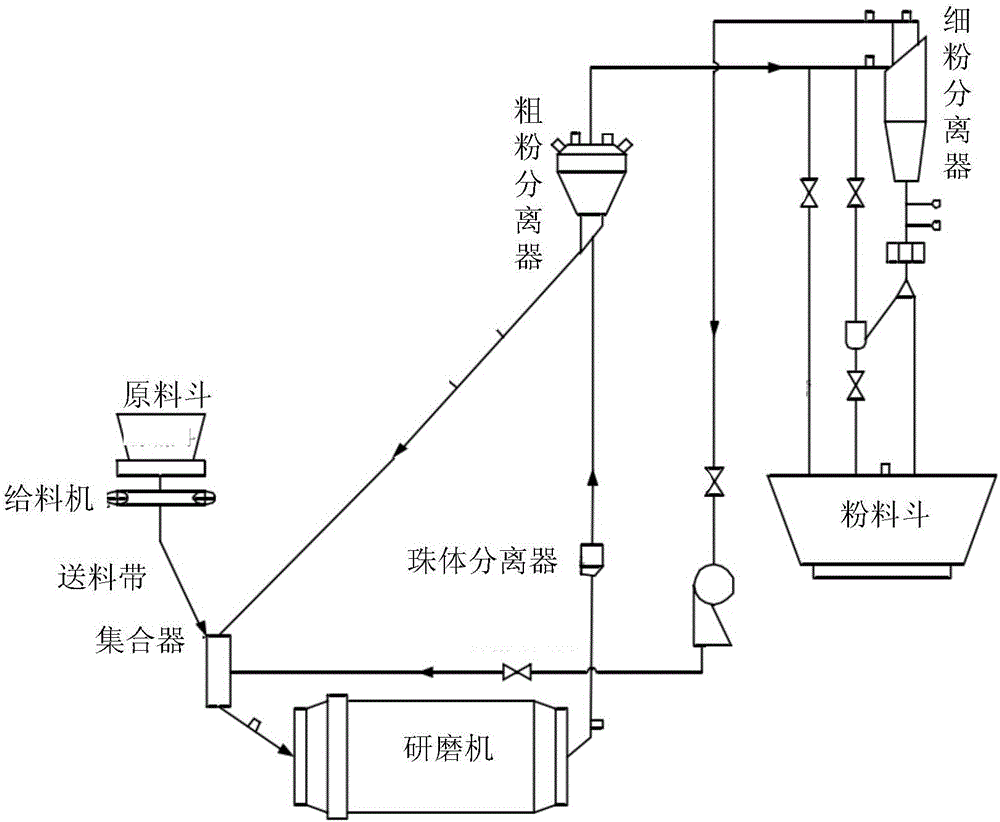

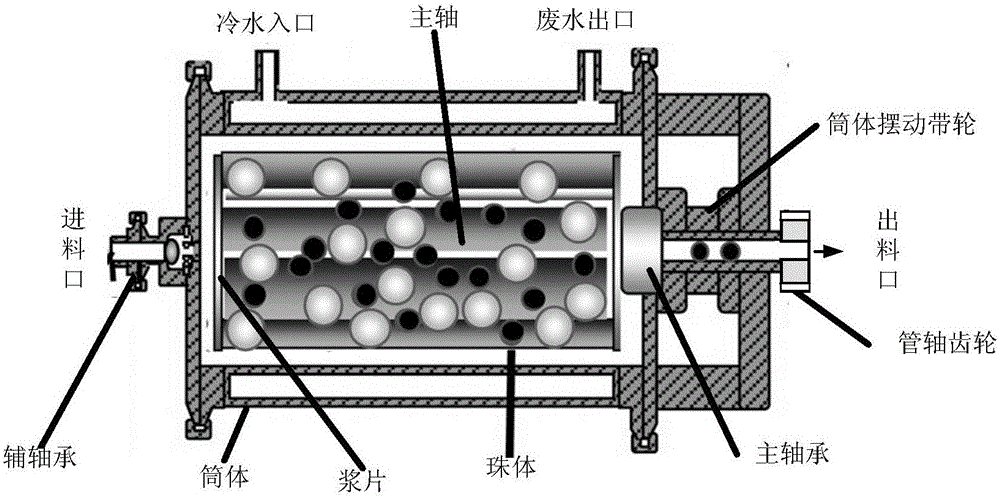

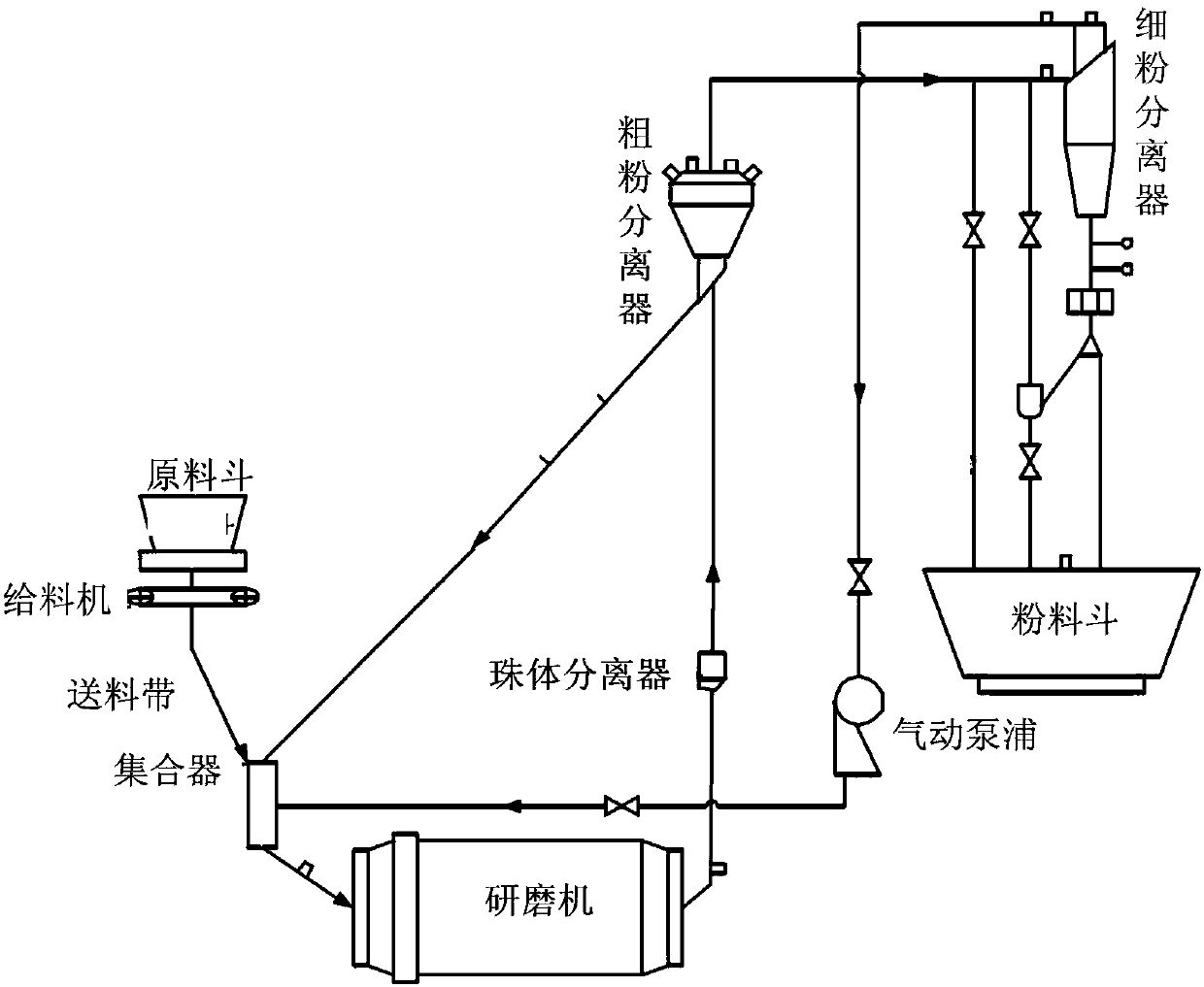

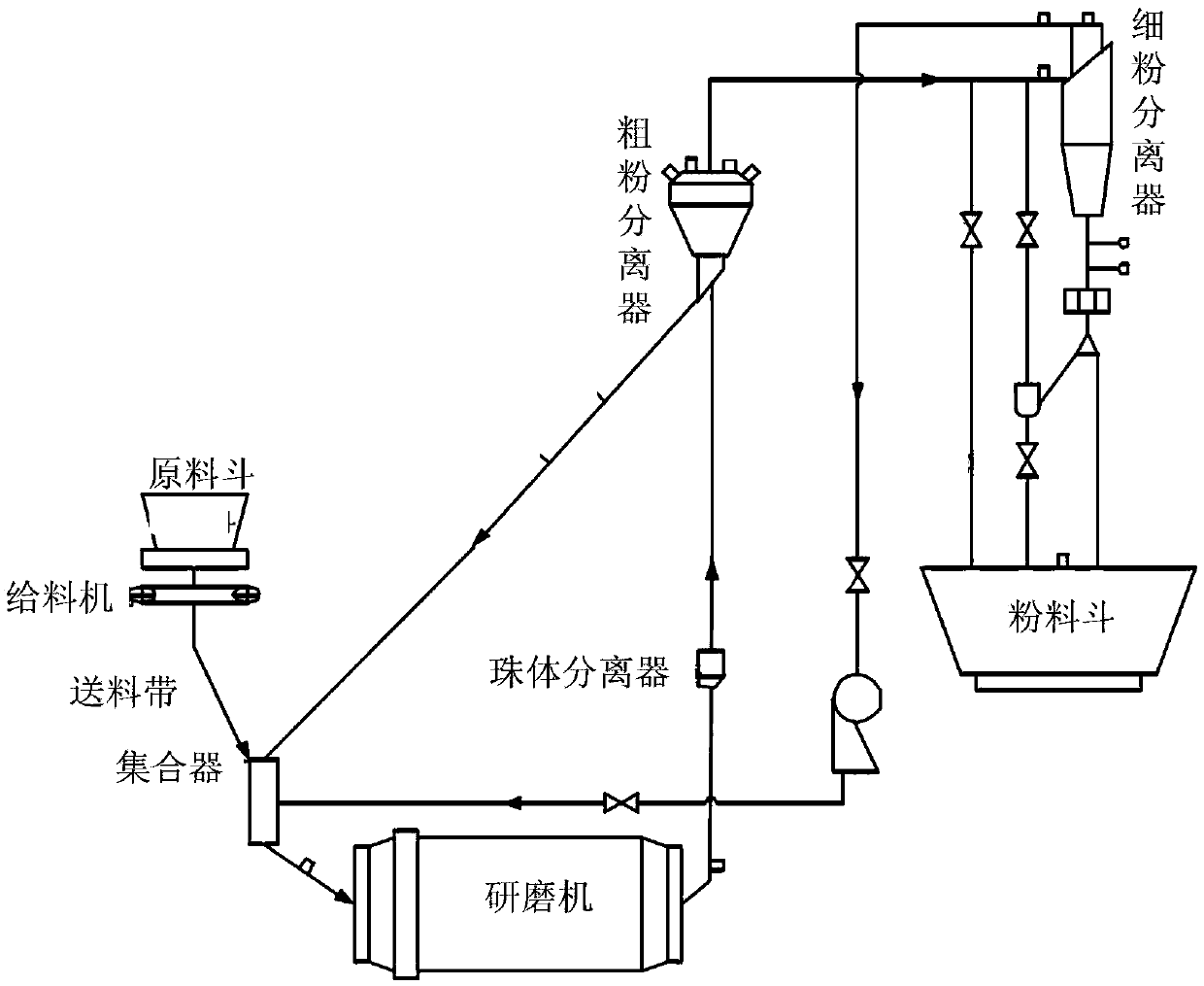

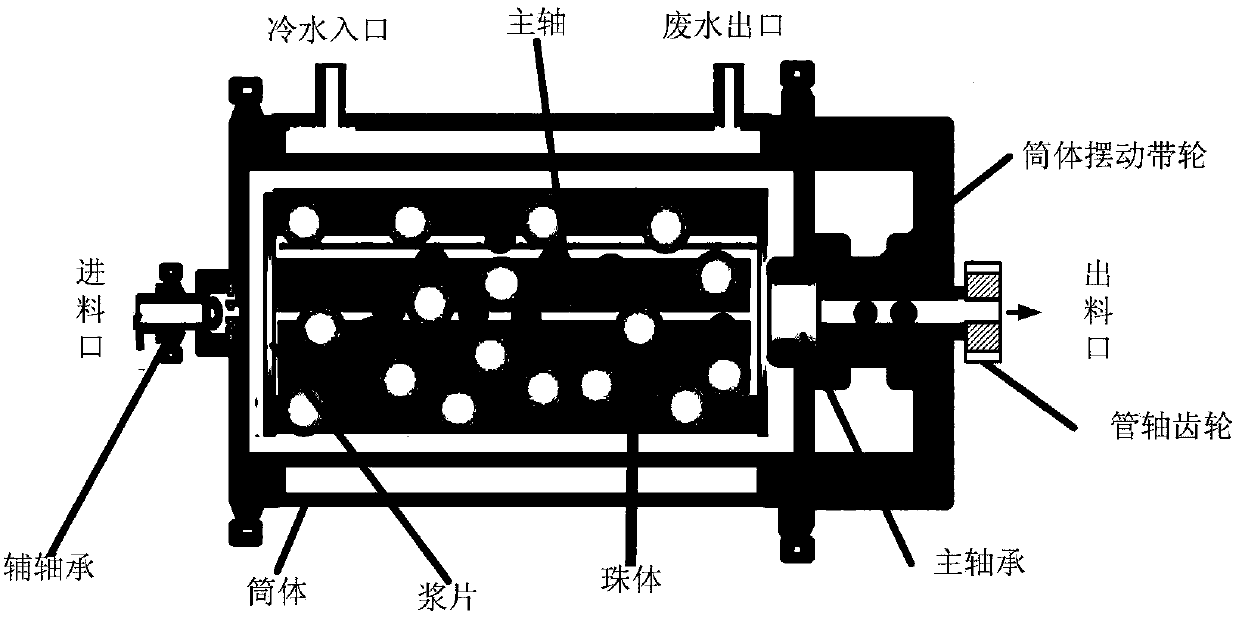

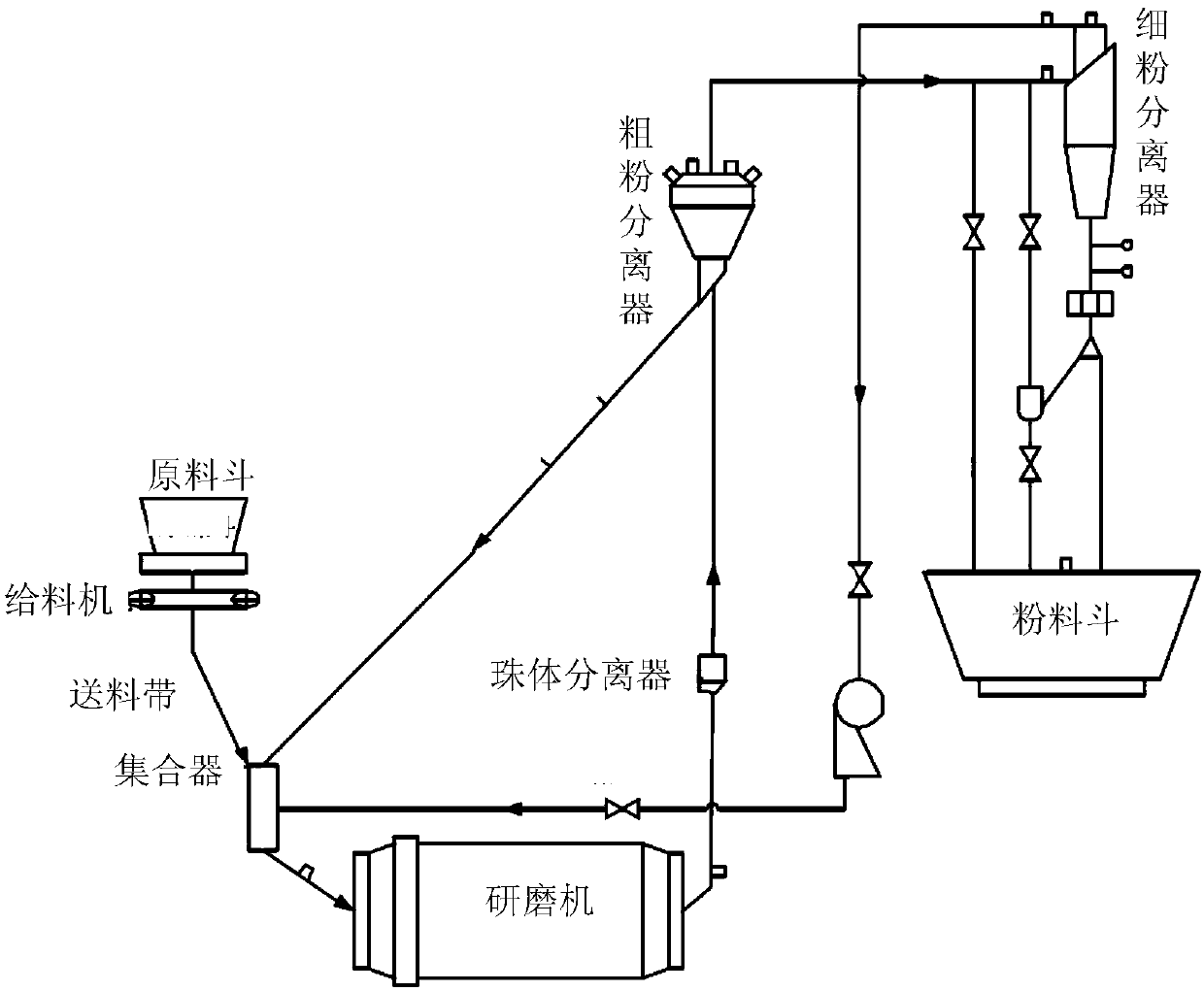

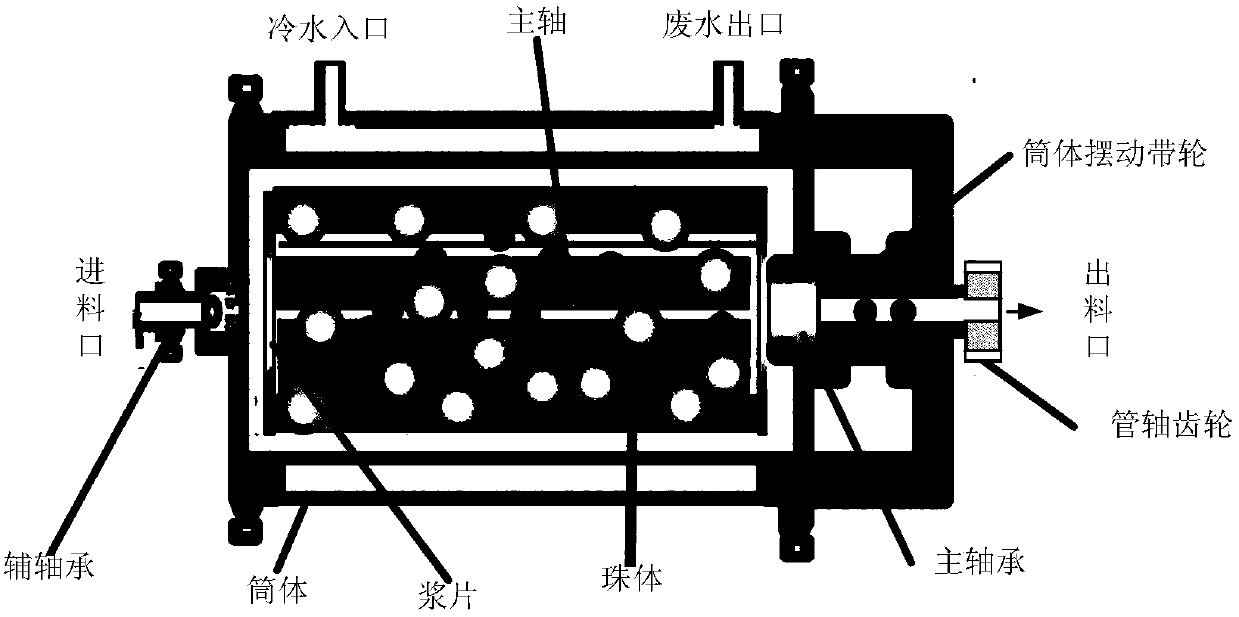

InactiveCN106179625AEfficient processingIncrease processing effortsGrain treatmentsControl systemSlurry

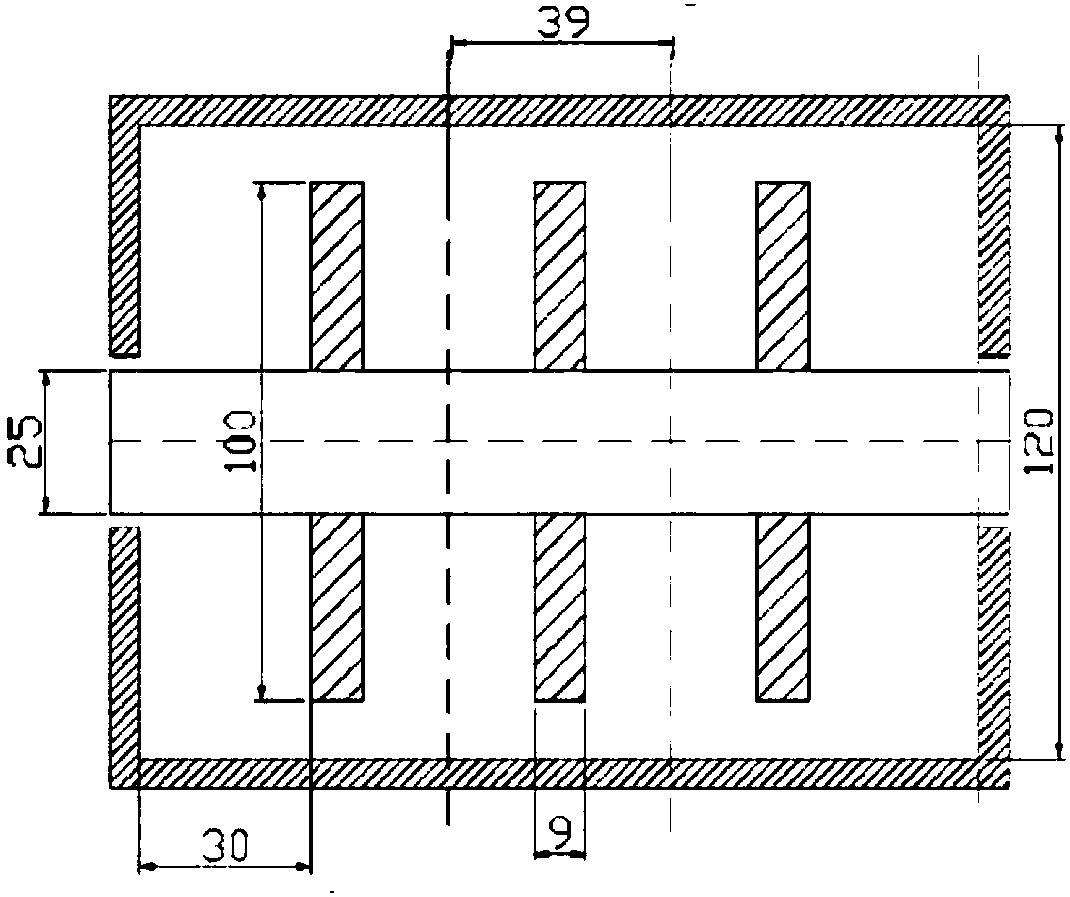

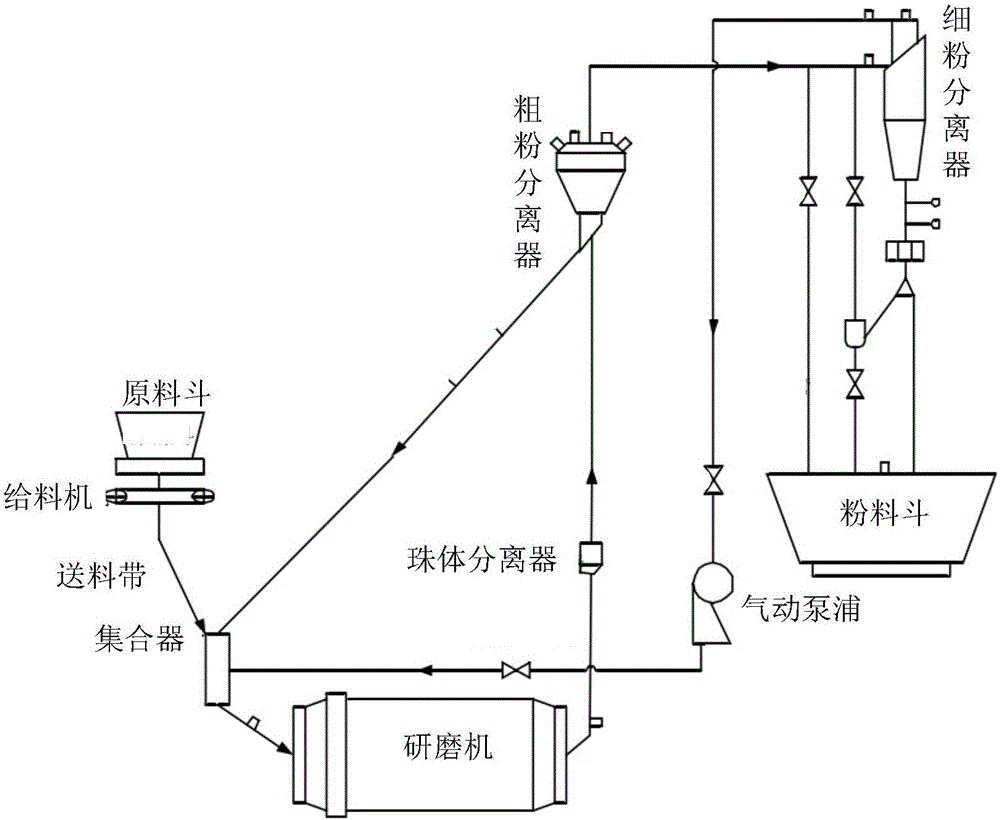

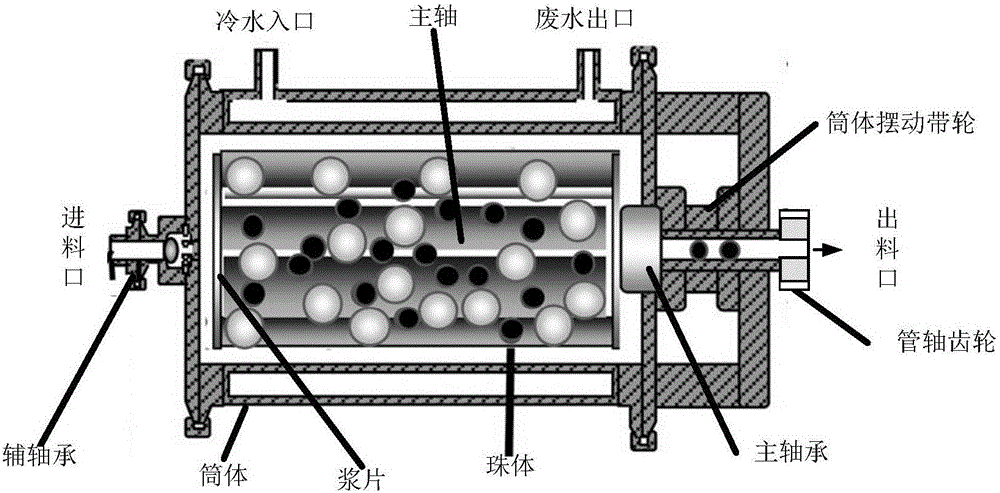

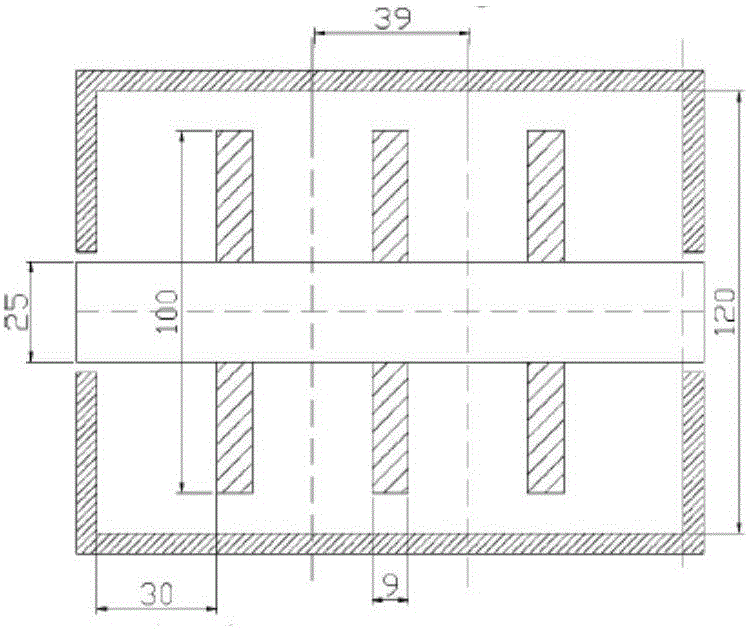

The invention relates to a grinding chemical machine system for fuzzy control over a main shaft motor. The grinding chemical machine system is characterized by comprising a grinding part and a control system. The grinding part comprises a raw material hopper, a feeder, a collector, a feeding belt, a grinder, a ball body separator, a coarse powder separator, a fine powder separator, a powder hopper, a draught fan, a valve and a pipe. The grinder is provided with a feeding opening, a discharging opening, a barrel, a main bearing, an auxiliary bearing, a slurry sheet, a ball body, a main shaft, a barrel swing belt wheel and a pipe shaft gear; and the main shaft is driven by the main shaft motor to rotate, and the barrel swing belt wheel is driven by a step motor to periodically do reciprocated rotation with a certain angle.

Owner:QINGDAO UNIV

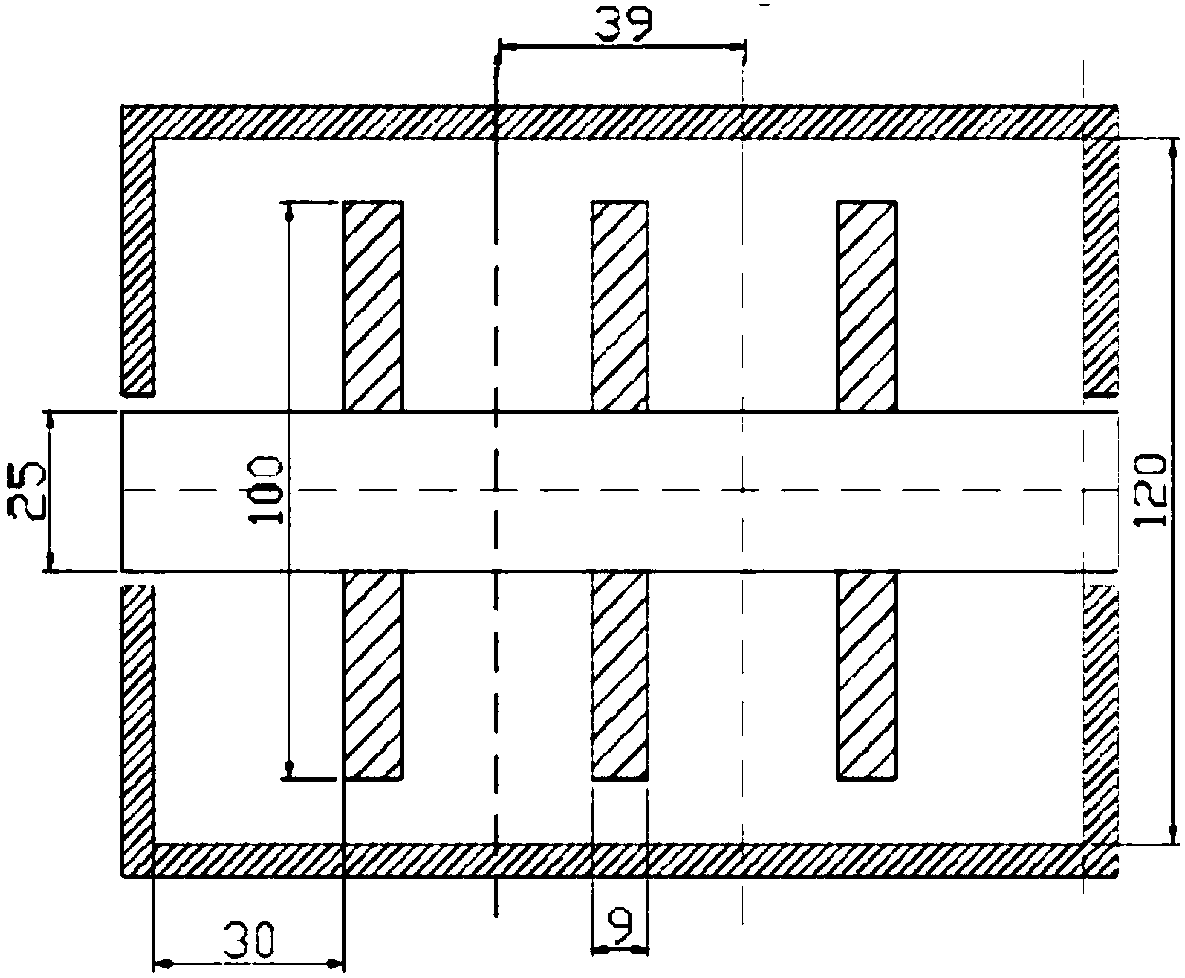

Chemical grinding machine system with double-layer barrel wall

InactiveCN106179629AEfficient processingIncrease processing effortsGrain treatmentsControl systemElectric machinery

A chemical grinding machine system with a double-layer barrel wall is characterized by comprising a grinding part and a control system, wherein the grinding part comprises a raw material bucket, a feeding machine, a collector, a feeding belt, a grinding miller, a bead body separator, a coarse powder separator, a fine powder separator, a powder bucket, a fan, a valve and a pipeline; the grinding miller provided with a feed port, a discharge port, a cylinder, a main bearing, an auxiliary bearing, a blade, a bead body, a spindle, a cylinder swing belt wheel and a pipe shaft gear; the spindle is driven by a spindle motor to rotate; and the cylinder swing belt wheel is driven by a stepping motor to perform reciprocating rotation for a certain angle periodically.

Owner:QINGDAO UNIV

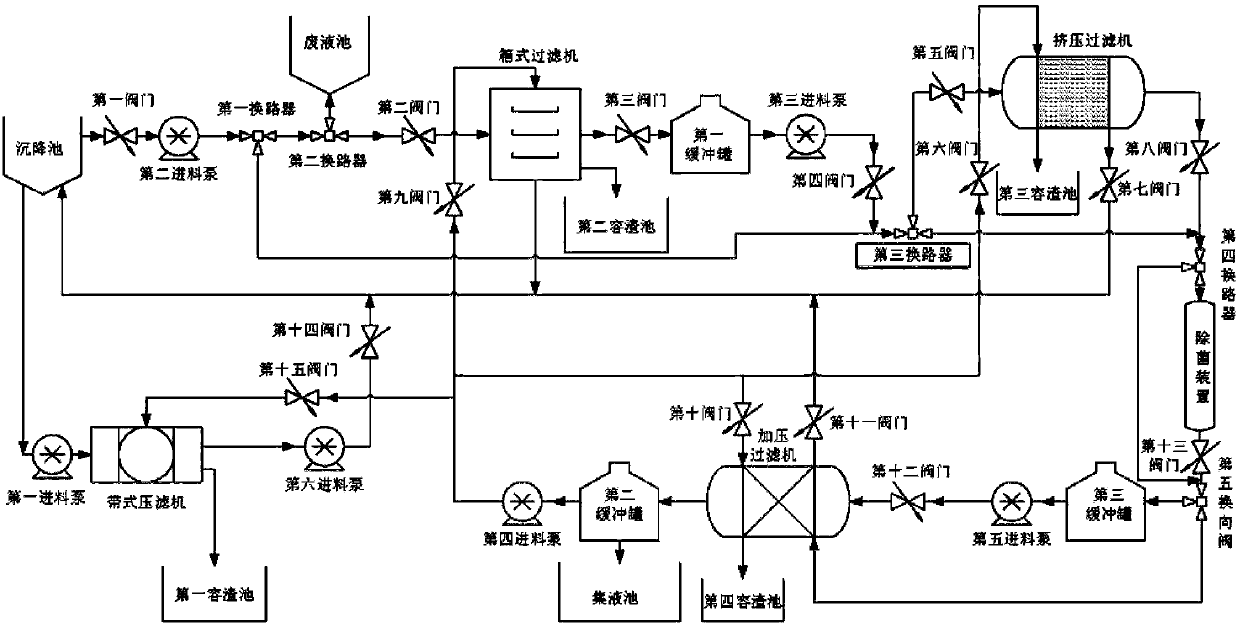

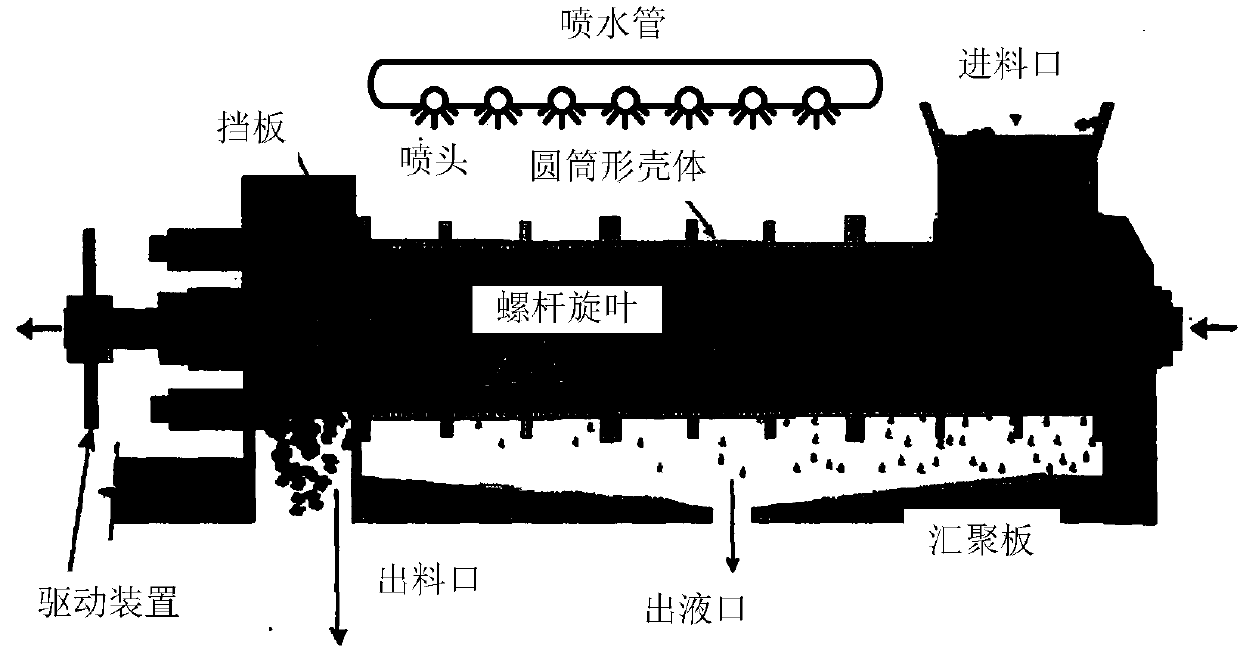

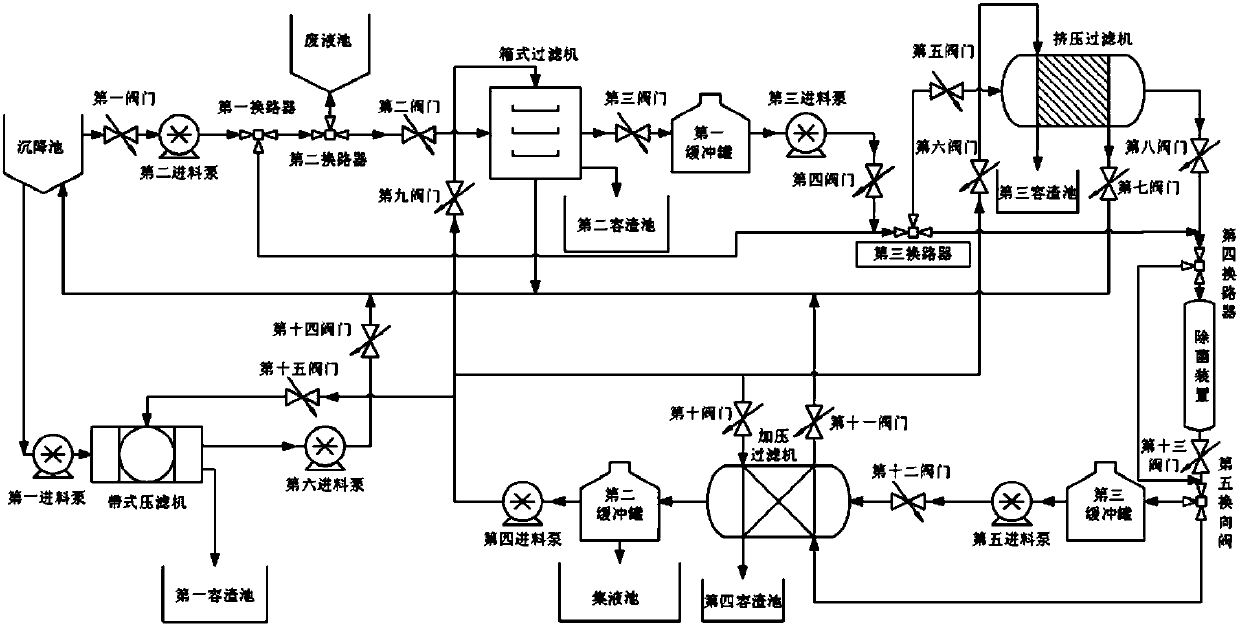

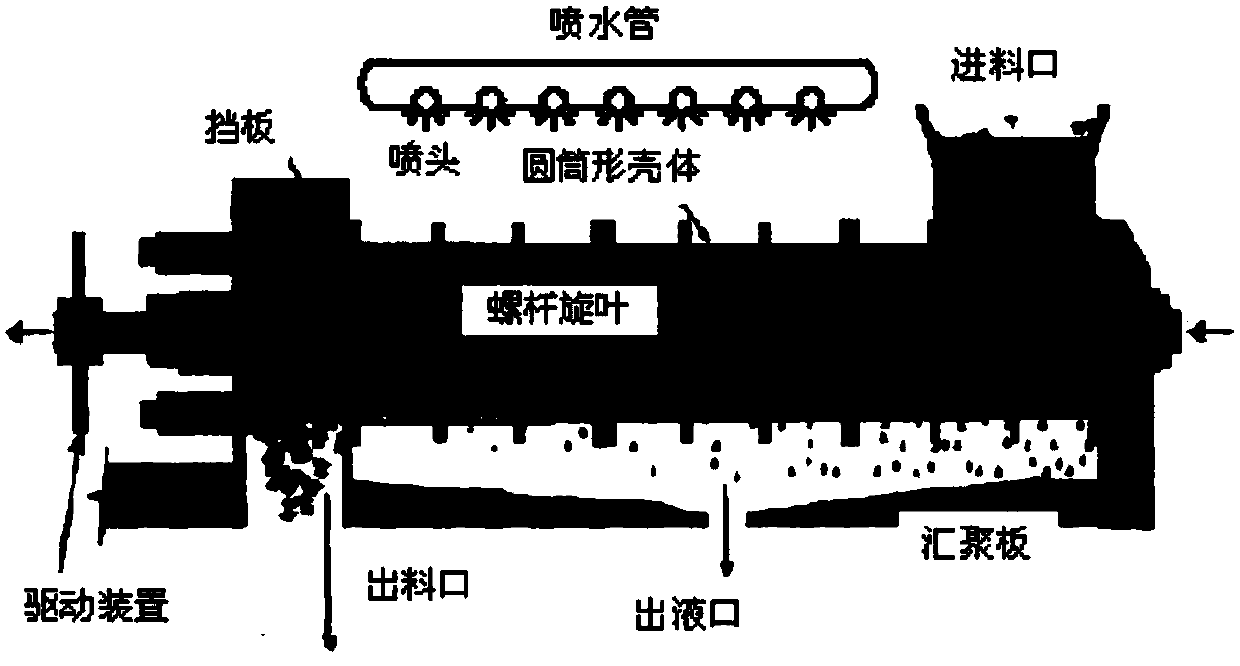

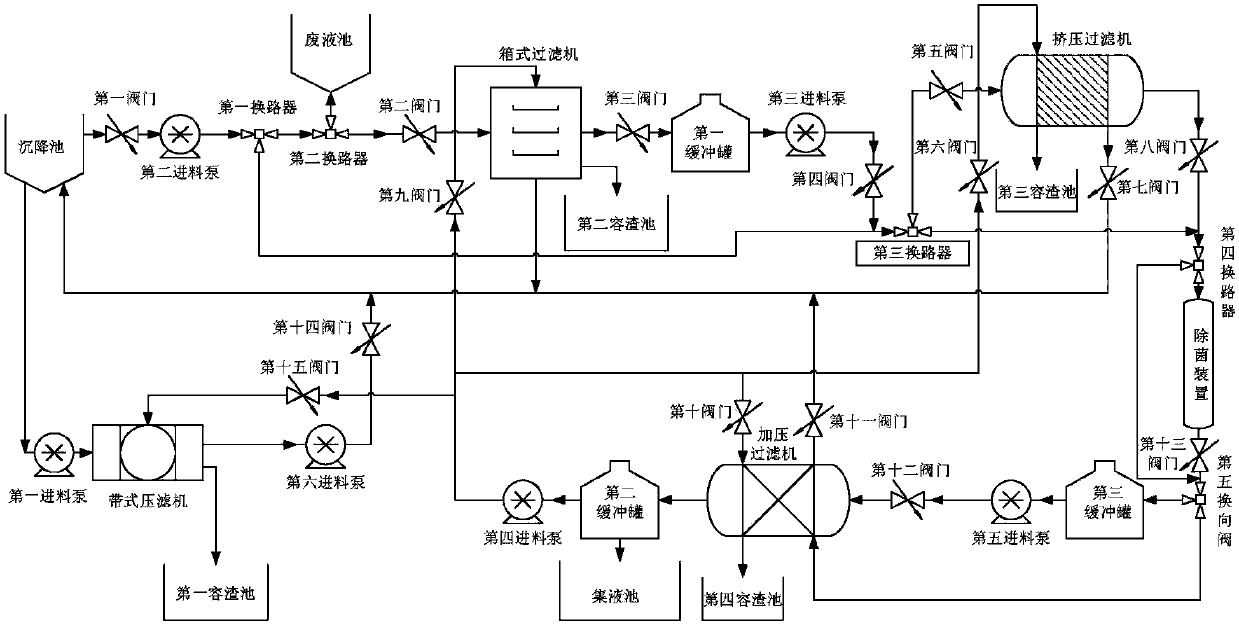

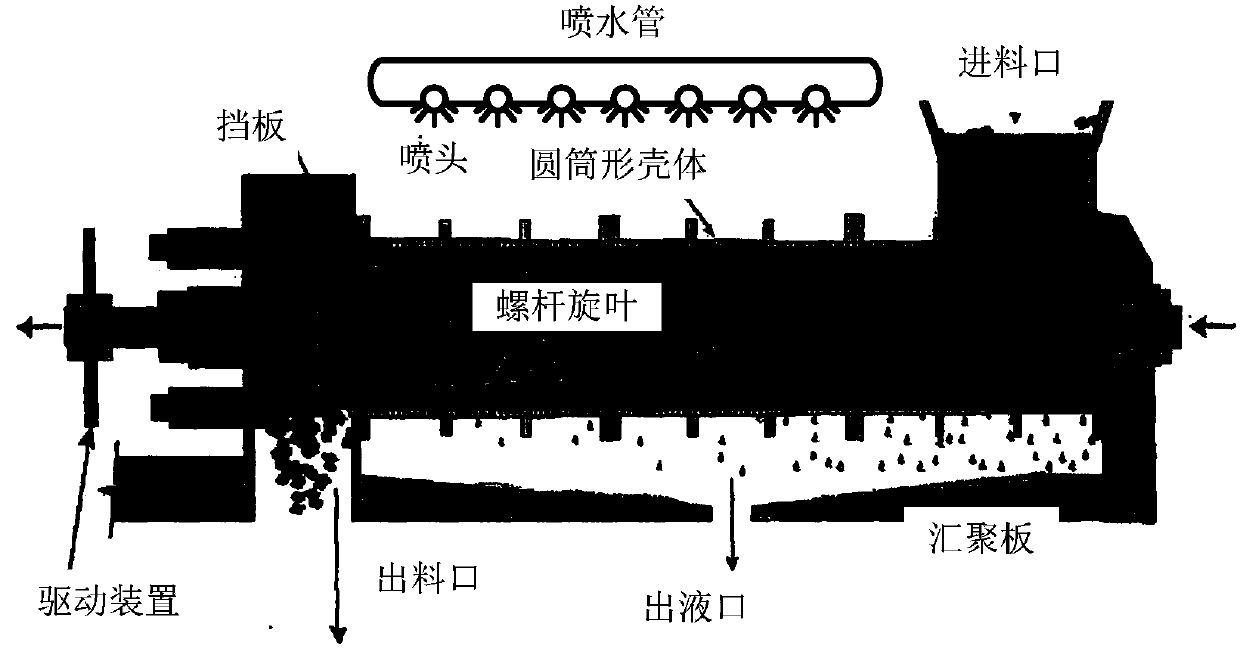

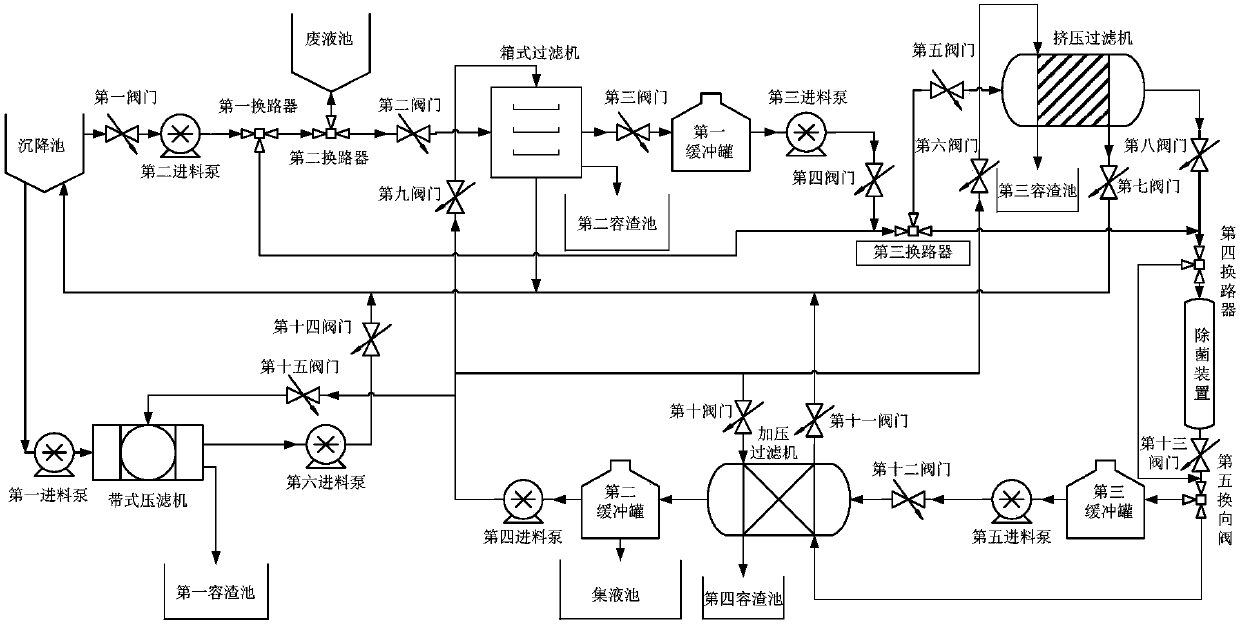

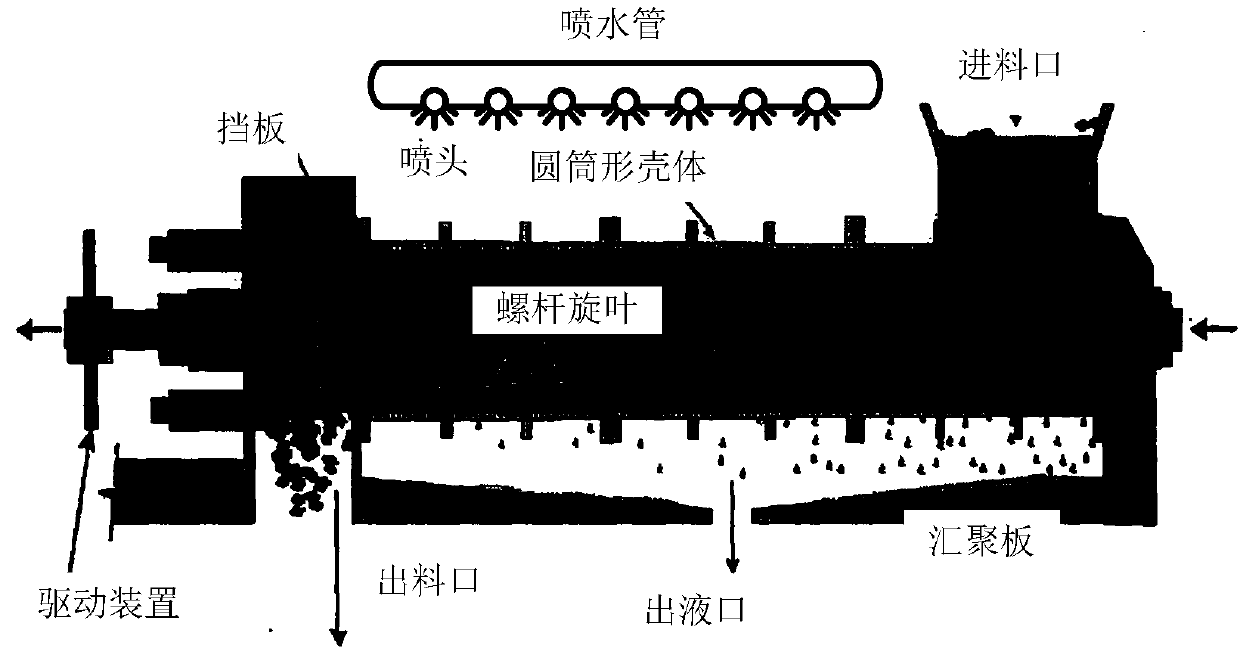

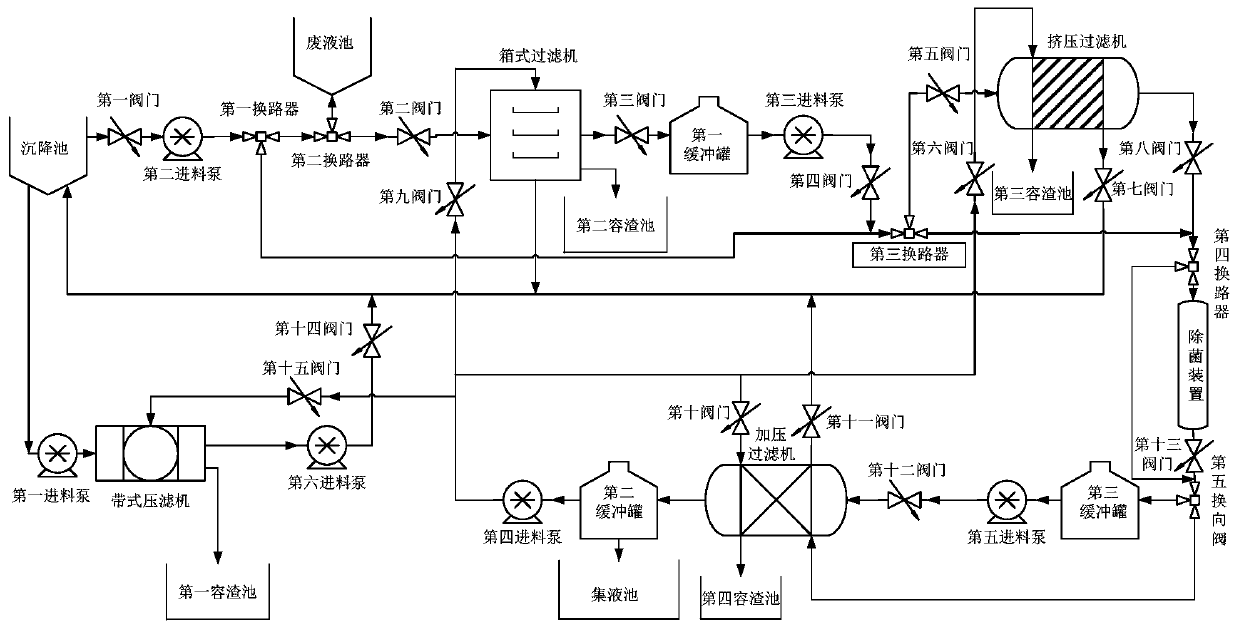

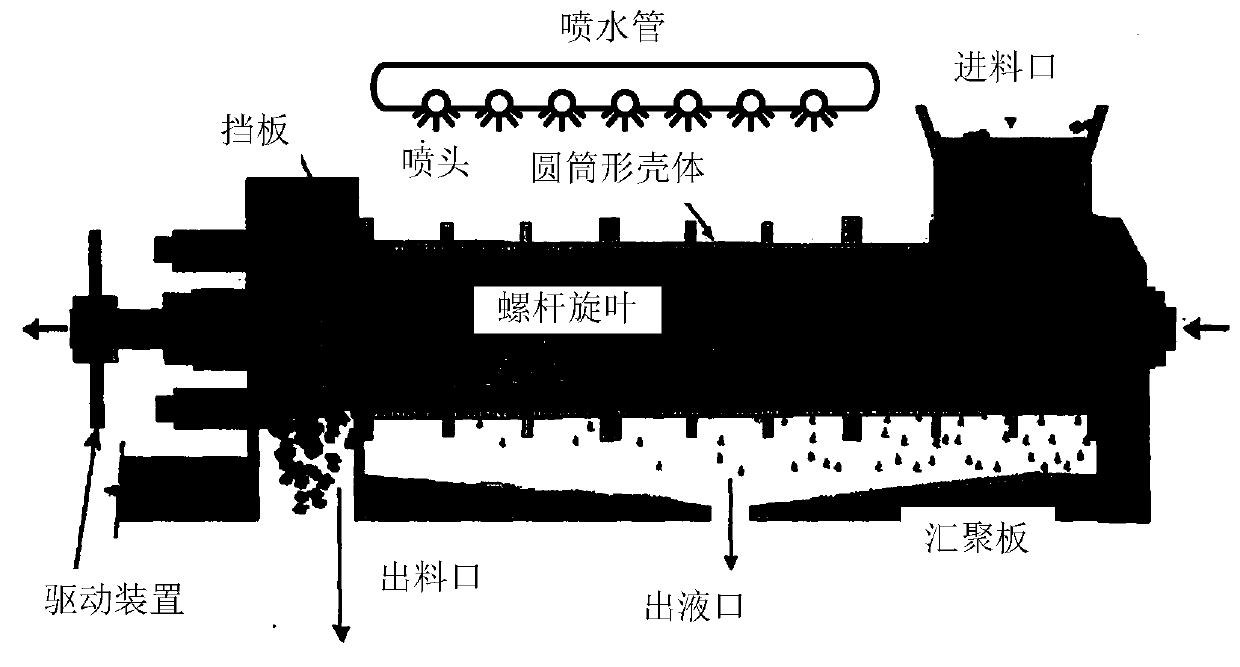

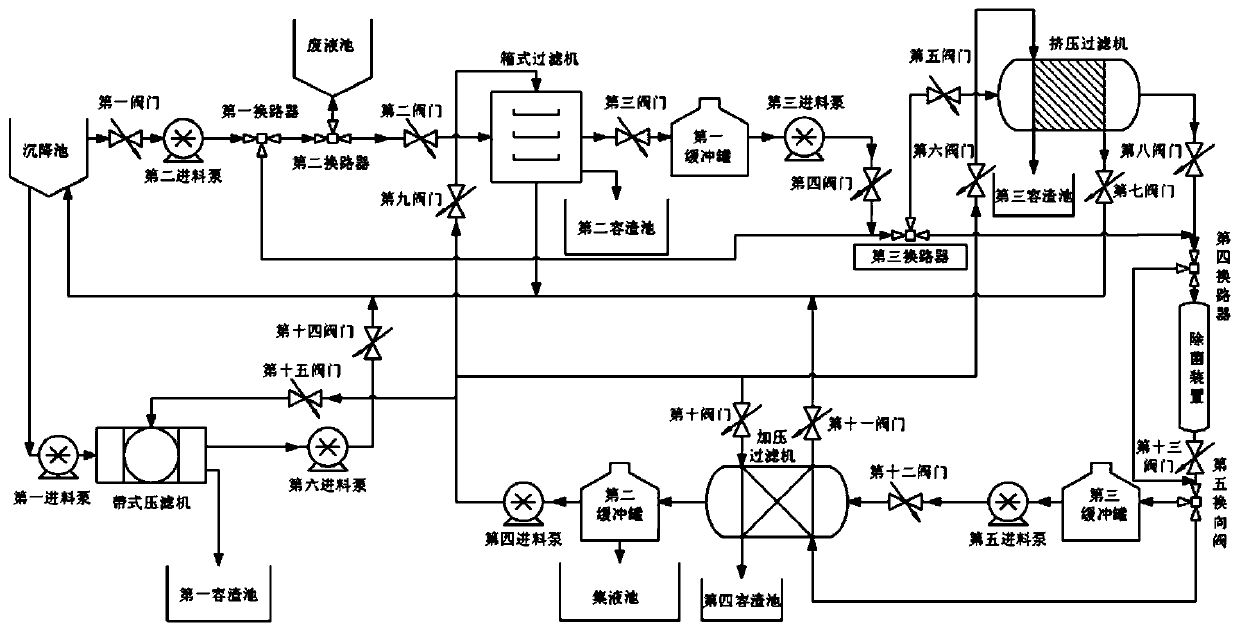

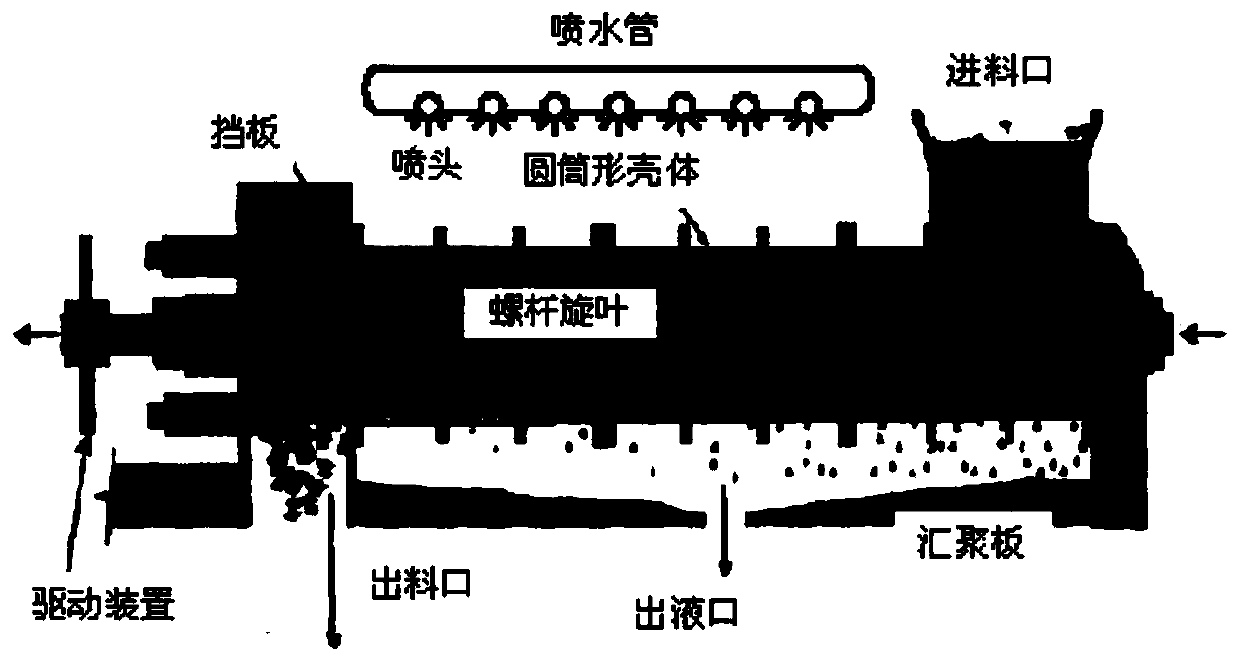

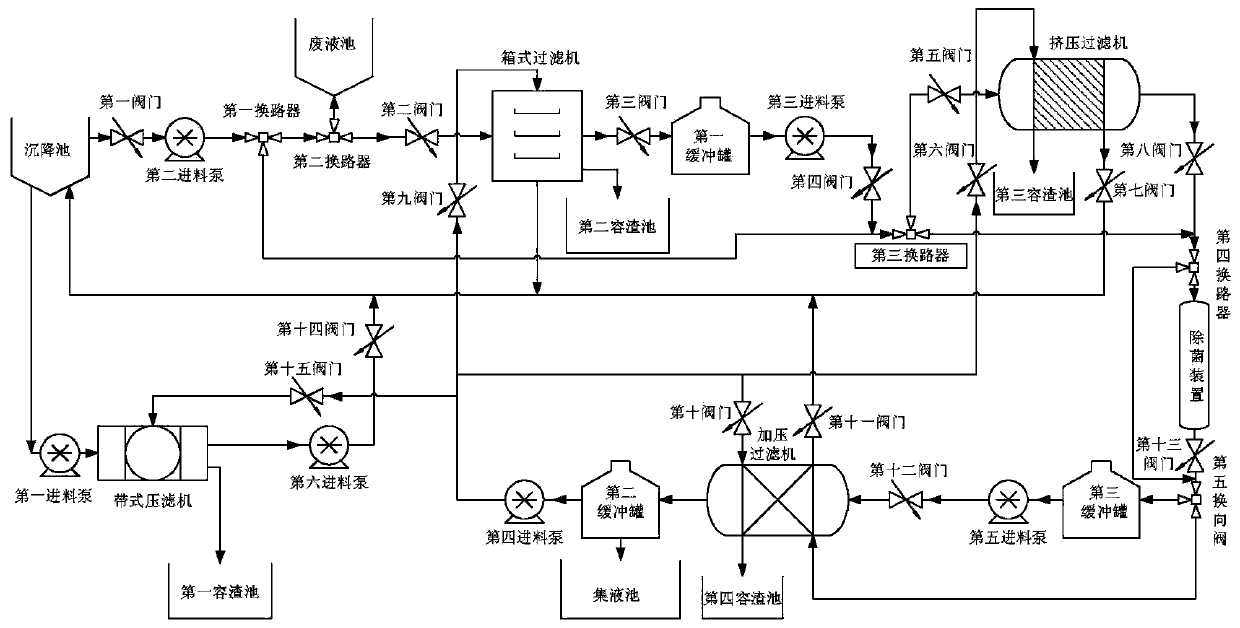

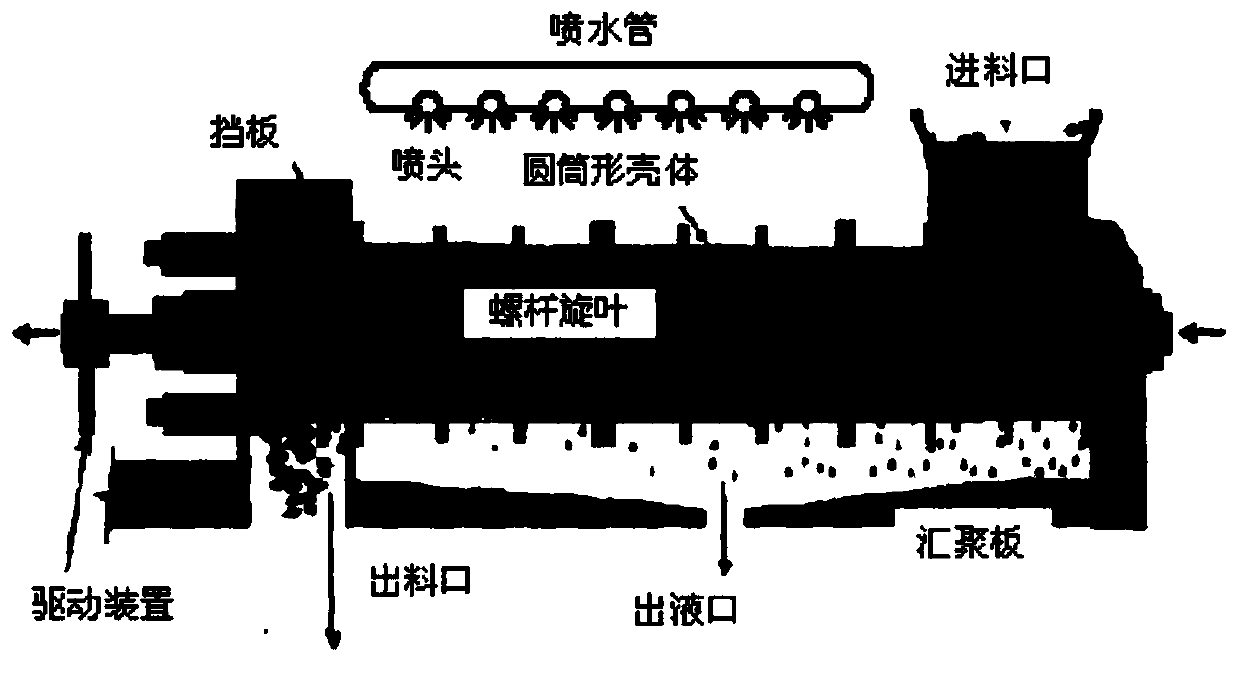

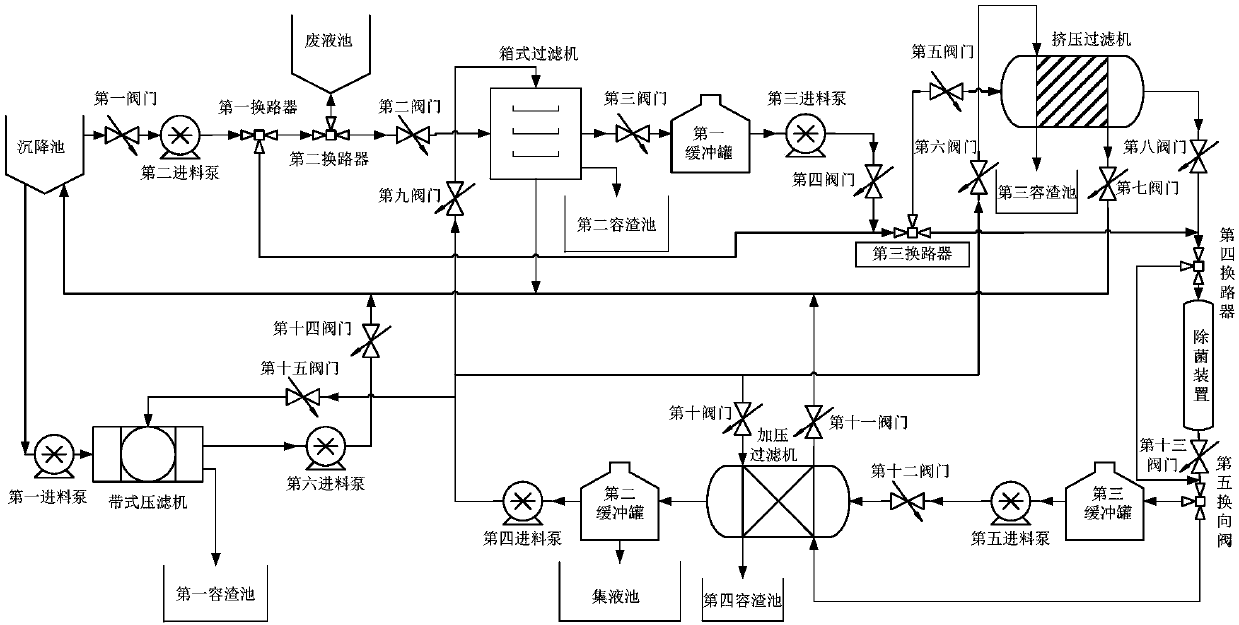

Chemical slurry squeezing filtration system

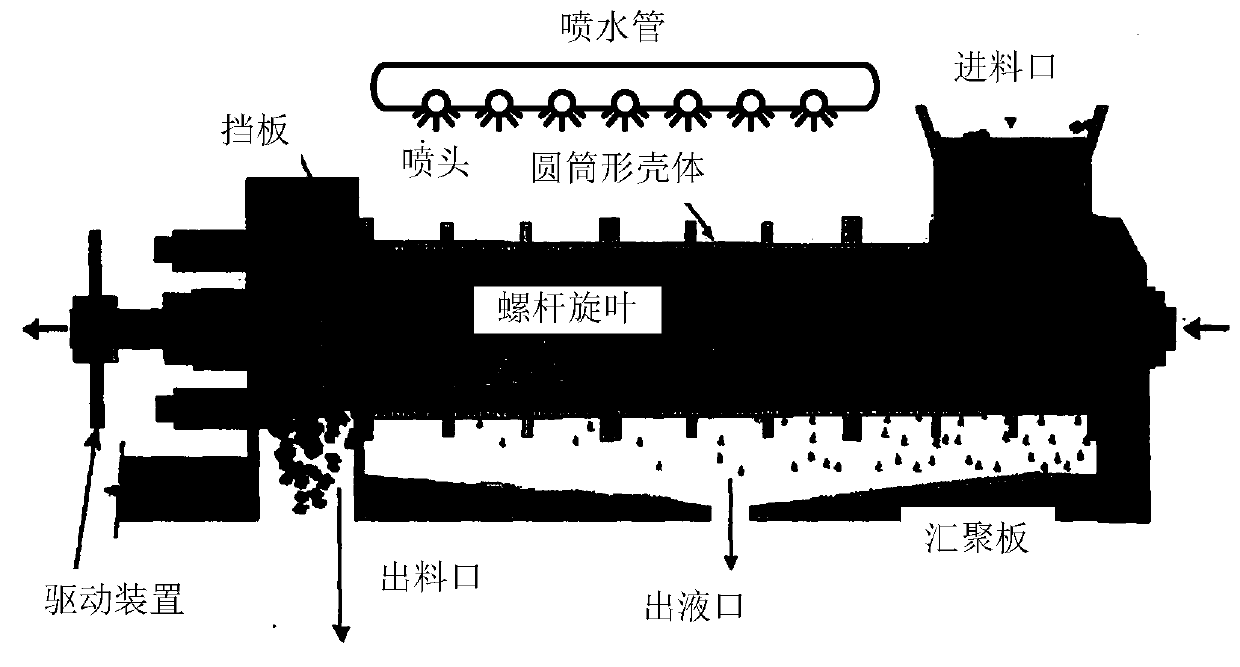

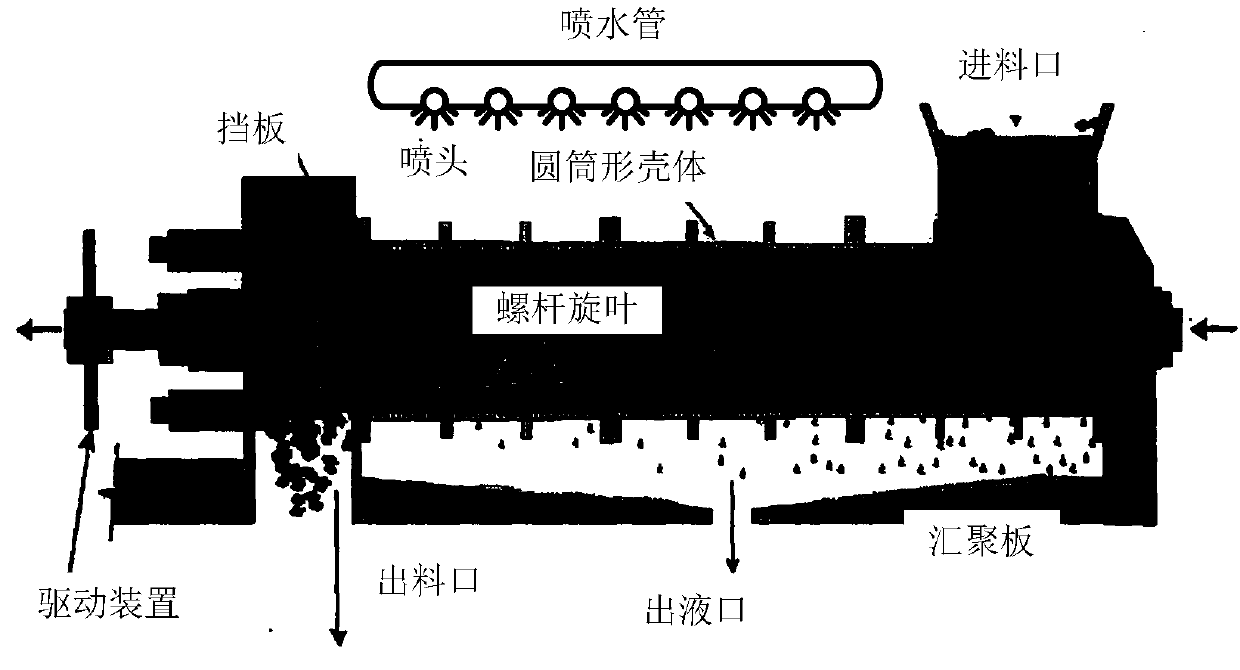

ActiveCN107670385ARealize processing and manufacturingFilter thoroughlyWater treatment parameter controlSpecific water treatment objectivesSlagFiltration

The invention discloses a chemical slurry squeezing filtration system. The system comprises one belt filter press, one box filter, one pressure filter, one squeezing filter, one sterilization device,one sedimentation tank, one waste liquid pool, one liquid collection pool, four slag storage tanks, three buffer tanks, six feeding pumps, five circuit switches and fifteen valves. The squeezing filter comprises a waster spray pipe, a cylindrical housing, screw vanes, a driving motor and a gathering plate. The screw vanes are arranged at intervals.

Owner:山东辰安化学有限公司

Grinding chemical machine system achieving feeding speed fuzzy control

InactiveCN106179627AIncrease processing effortsImprove crushing efficiencyGrain treatmentsMain bearingEngineering

A grinding chemical machine system achieving feeding speed fuzzy control is characterized by comprising two parts including a grinding part and a control system; the grinding part comprises a raw material hopper, a feeding machine, a collector, a feeding belt, a grinding machine, a bead separator, a coarse powder separator, a fine powder separator, a powder hopper, a draught fan, a valve and a pipeline; the grinding machine is provided with a feeding port, a discharging port, a barrel, a main bearing, an auxiliary bearing, a slurry piece, beads, a spindle, a barrel swinging belt wheel and a pipe shaft gear; and the spindle is driven by a spindle motor to rotate, and the barrel swinging belt wheel is driven by a stepping motor to periodically rotate in a reciprocating manner by a certain angle.

Owner:QINGDAO UNIV

Bi-directional rotating grinding chemical machinery system

InactiveCN106179631AEfficient processingIncrease processing effortsGrain treatmentsControl systemEngineering

Disclosed is a bi-directional rotating grinding chemical machinery system. The bi-directional rotating grinding chemical machinery system is characterized by comprising a grinding portion and a control system, wherein the grinding portion comprises a raw material bucket, a material feeder, a collector, a material conveying belt, a grinding machine, a ball separator, a coarse powder separator, a fine powder separator, a powder bucket, a fan, valves and pipelines; the grinding machine is provided with a material inlet, a material outlet, a barrel, a main bearing, an auxiliary bearing, blades, balls, a main shaft, a barrel swinging gear and a pipe shaft gear; the main shaft is driven to rotate through a main shaft motor; and the barrel swinging gear is driven to perform reciprocating rotation periodically at a certain angle through a stepping motor.

Owner:QINGDAO UNIV

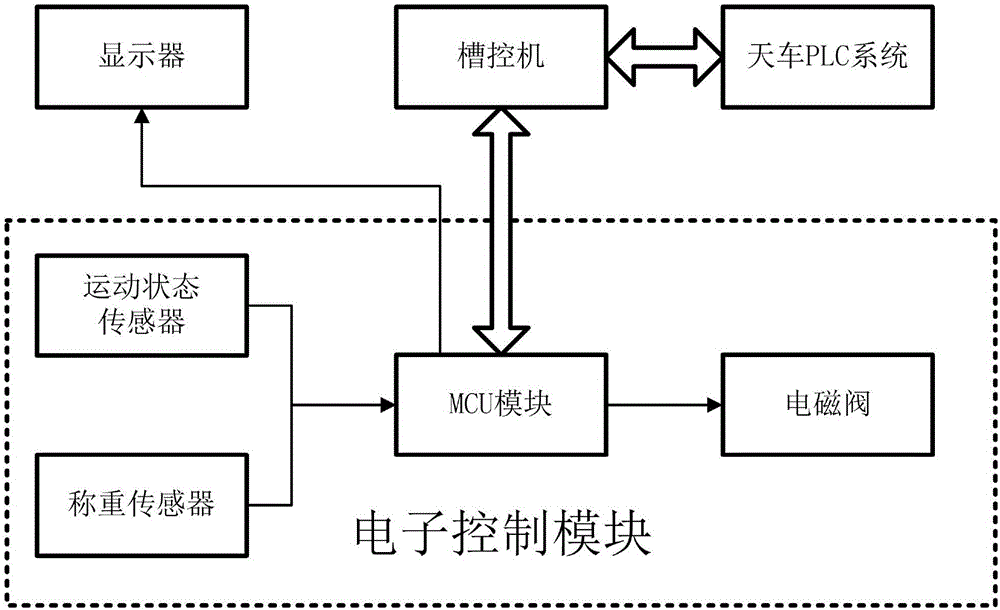

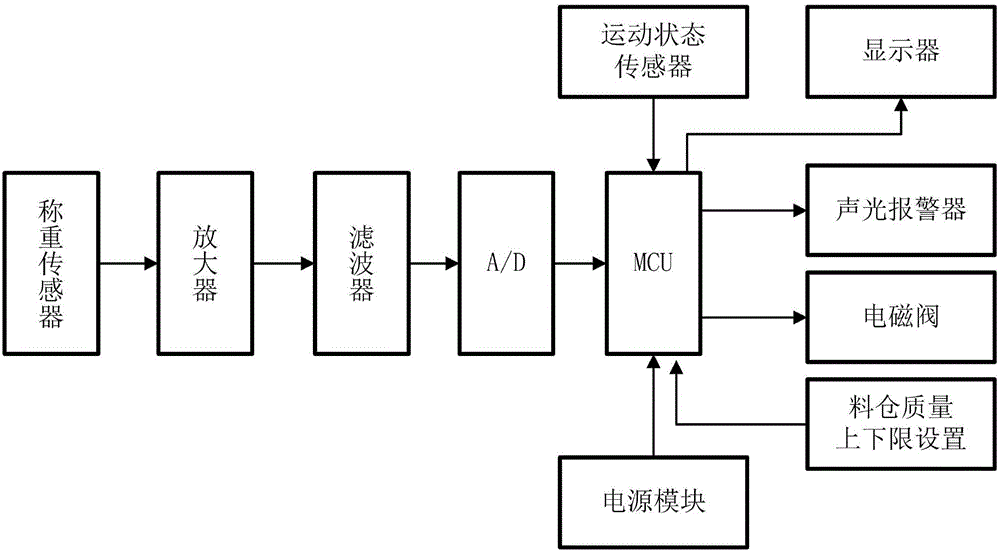

Control method for aluminum electrolysis crown block stock bin material level online monitoring and fault alarm system

Relating to the field of aluminum electrolysis equipment, the invention discloses a control method for an aluminum electrolysis crown block stock bin material level online monitoring and fault alarm system. The method consist of: judging the stock bin charging and motion state, if no charging behavior occur and the stock bin is at a stationary state, letting an MCU module communicate with a slot control machine to obtain the information that whether an aluminum electrolysis cell needs charging; if the aluminum electrolysis cell needs charging at the moment, carrying out charging and calculating the charging speed; and if the charging speed is normal, the stock bin is fault-free, if the charging speed is too slow, blocking can occur to the stock bin or fault can occur to the equipment, starting an audible and visual alarm. The method provided by the invention utilizes a weighing sensor to collect the stock bin quality data and calculates the raw material charging speed, then judges whether a discharge port is blocked, and gives an audible and visual alarm and requires overhauling. The method provided by the invention can achieve real-time online monitoring and control of the stock bin material level, at the same time detects stock bin blocking information in the first time so as to avoid blocking worsening. According to the invention, the structure and operation steps are simple, thus being easy to implement.

Owner:CHONGQING UNIV

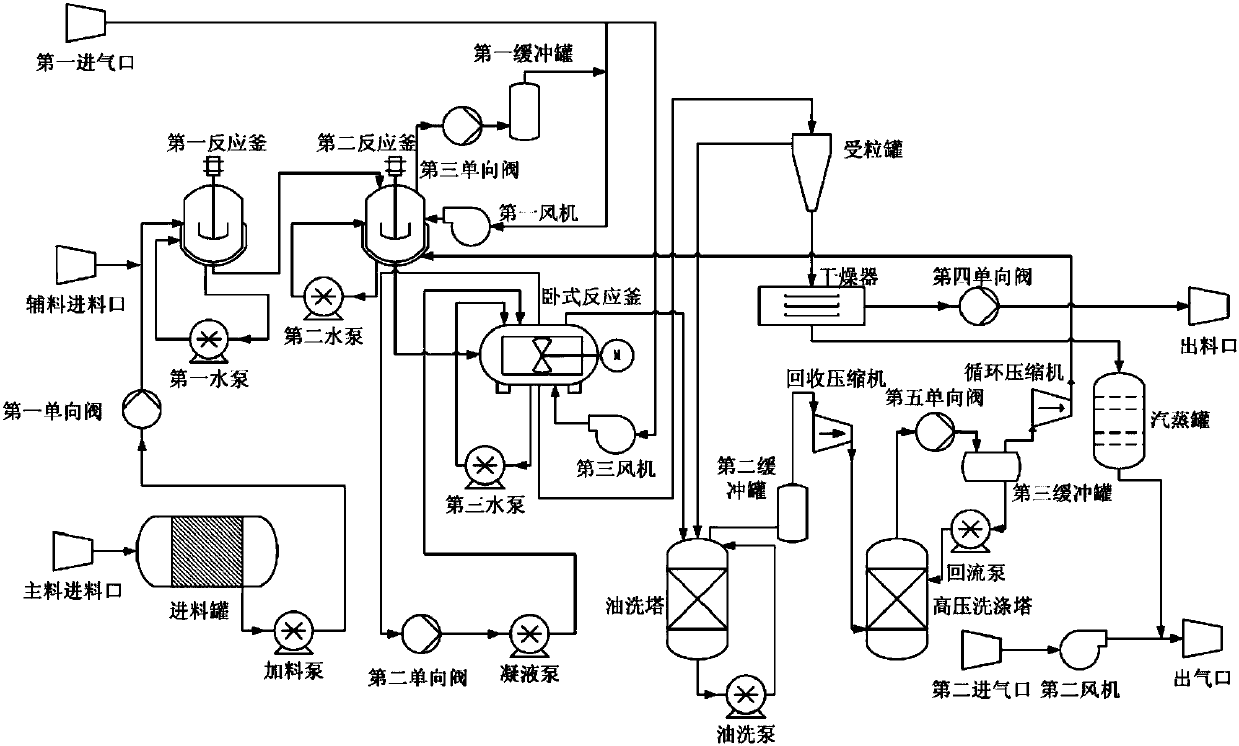

Chemical mechanical system with T-type paddle horizontal reactor

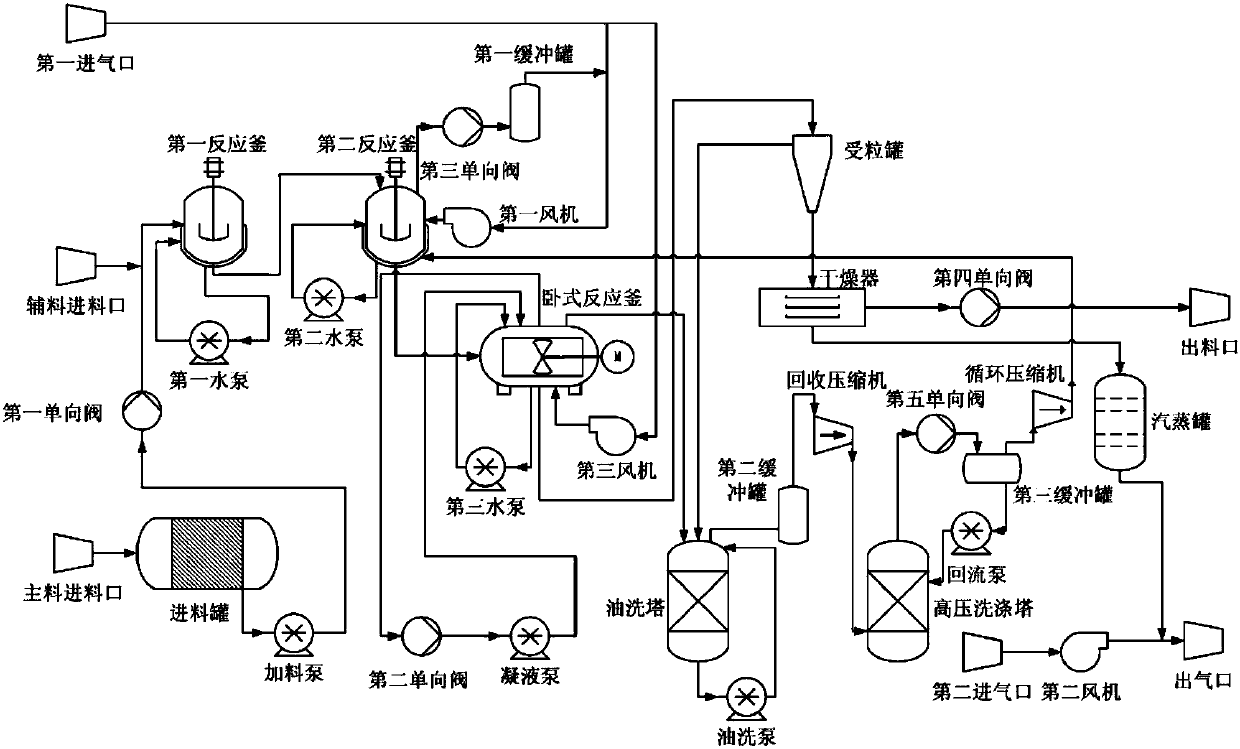

InactiveCN107670611ARealize processing and manufacturingEnables multiple reaction processingSequential/parallel process reactionsRotary stirring mixersCompound (substance)Engineering

The invention discloses a chemical mechanical system with a T-type paddle horizontal reactor. A horizontal stirring paddle of a horizontal stirrer is a T-type paddle and is prepared from stainless steel. A distance between the tail end of the T-type paddle and the inner wall of a horizontal tank is in a range of 3-5mm and is larger than the maximum particle diameter of the stirred material. The system comprises the 96 T-type paddles divided into 24 groups uniformly distributed along an axial direction of a horizontal stirring shaft at equal intervals and a ratio of the thickness to length of the T-type paddle is 1: 10. The four T-type paddles in each group are uniformly distributed along the circumferential direction of the horizontal stirring shaft at an angle of 90 degrees. The two adjacent groups of the T-type paddles are arranged at 0 degree along the circumferential direction of the horizontal stirring shaft. The back surface of each T-type paddle is provided with reinforcing ribs.

Owner:SHANDONG LONGSHENGHE CHEM CO LTD

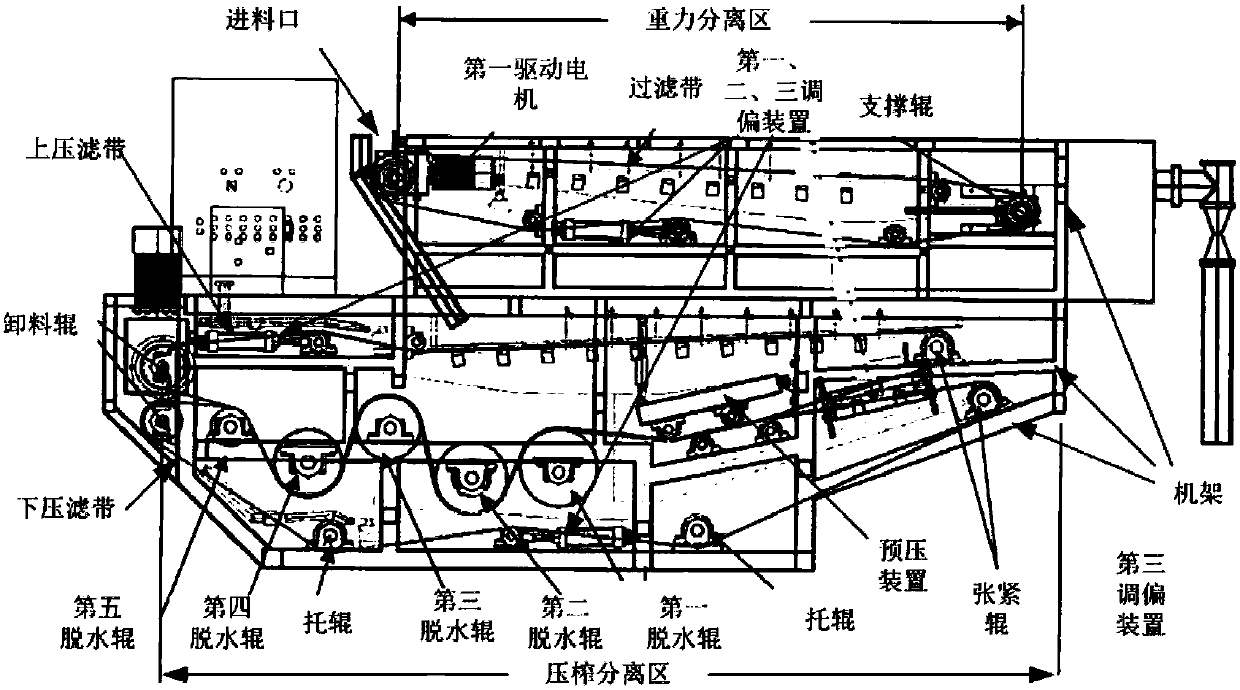

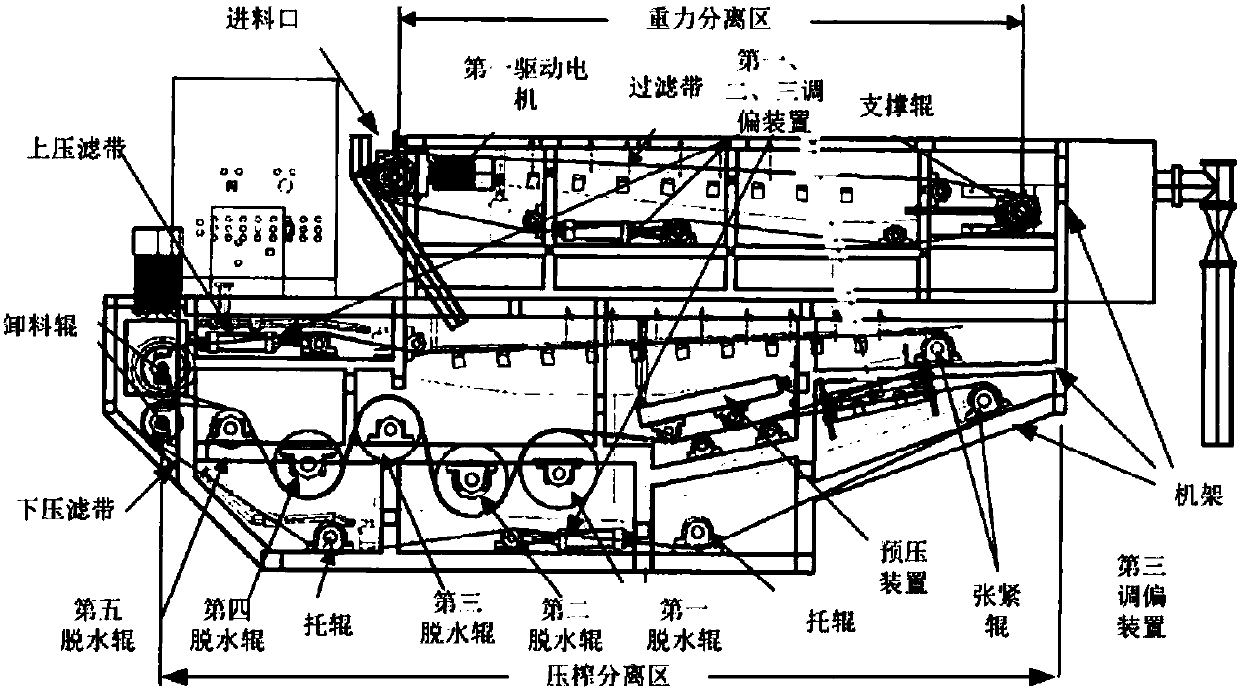

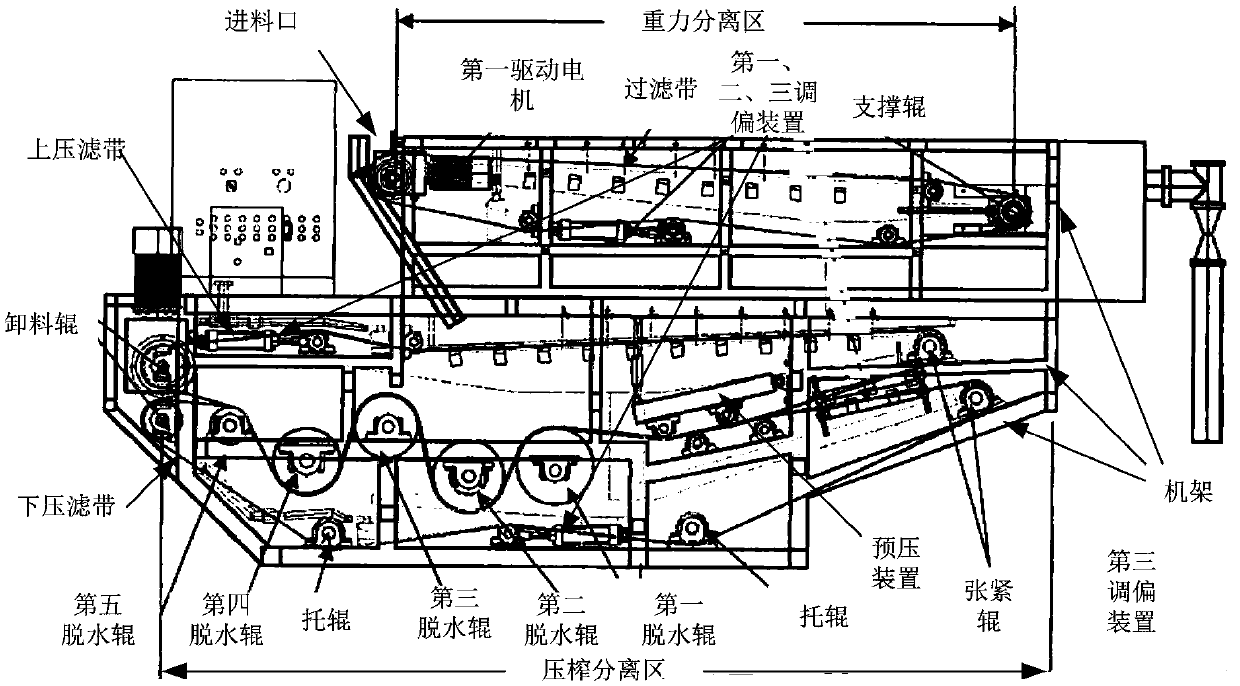

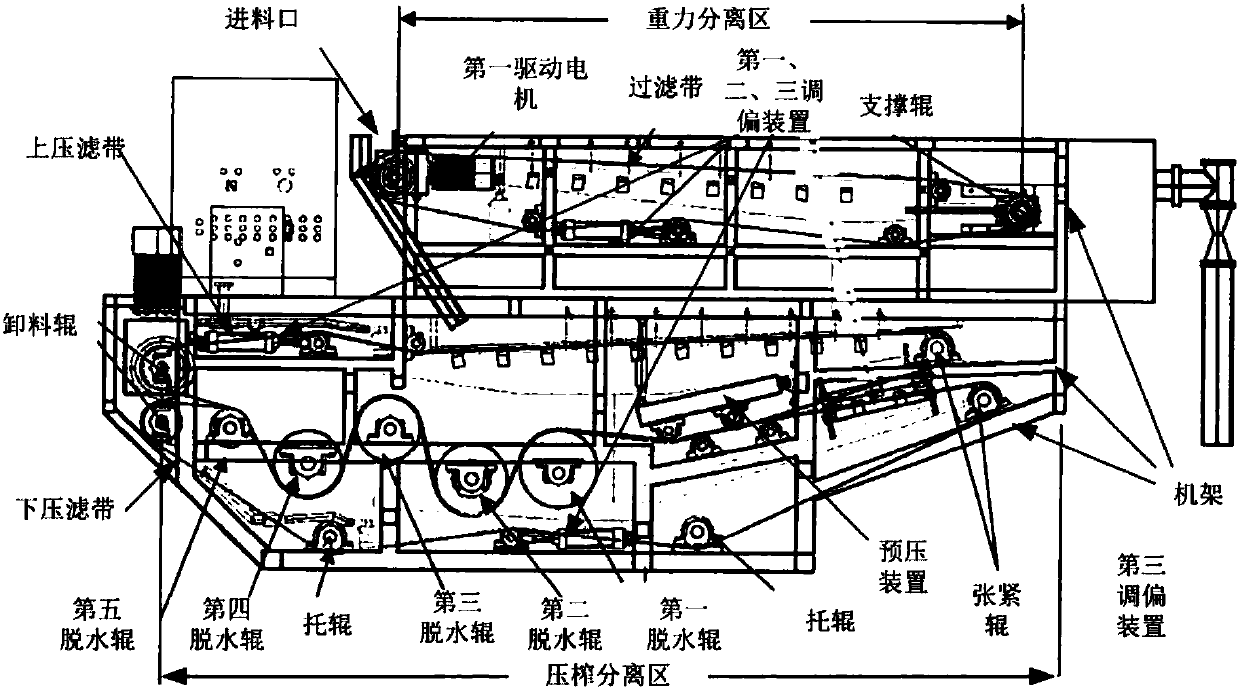

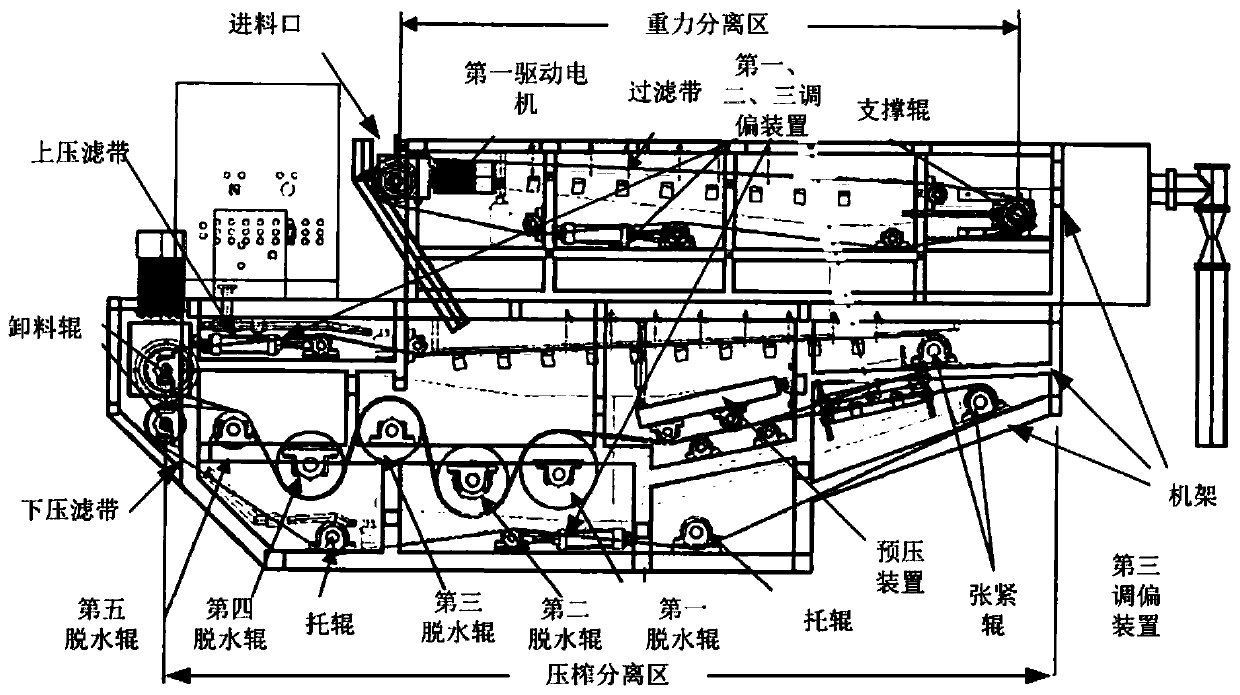

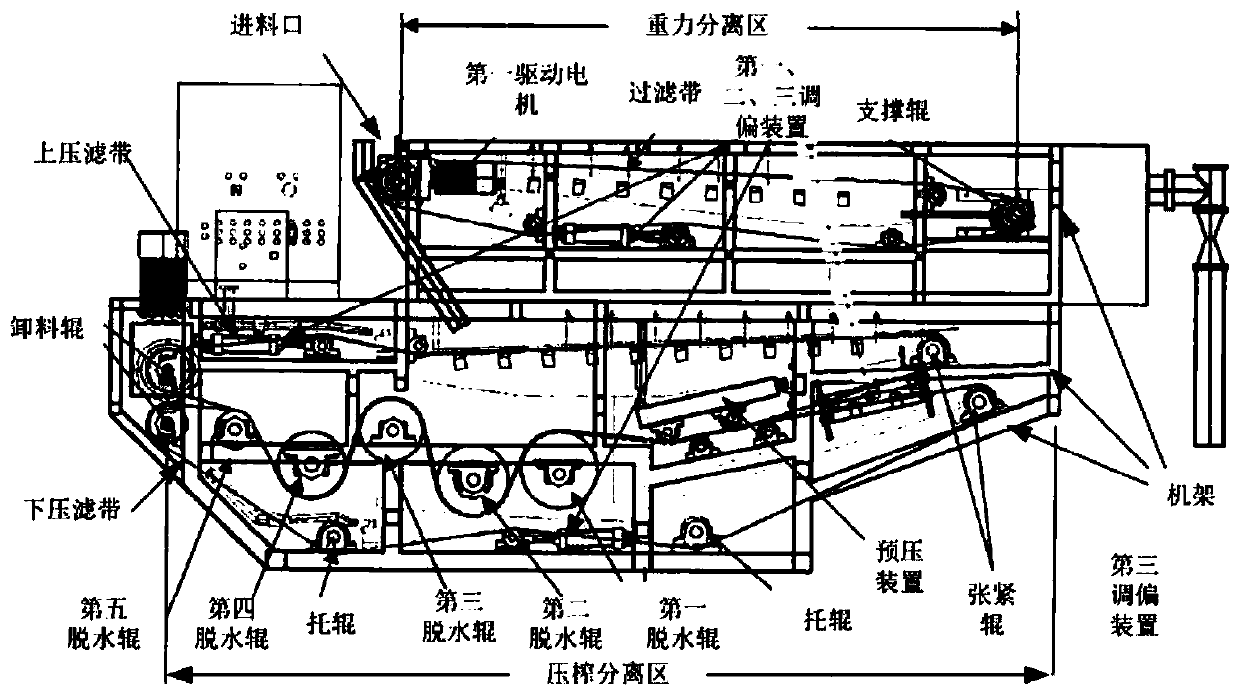

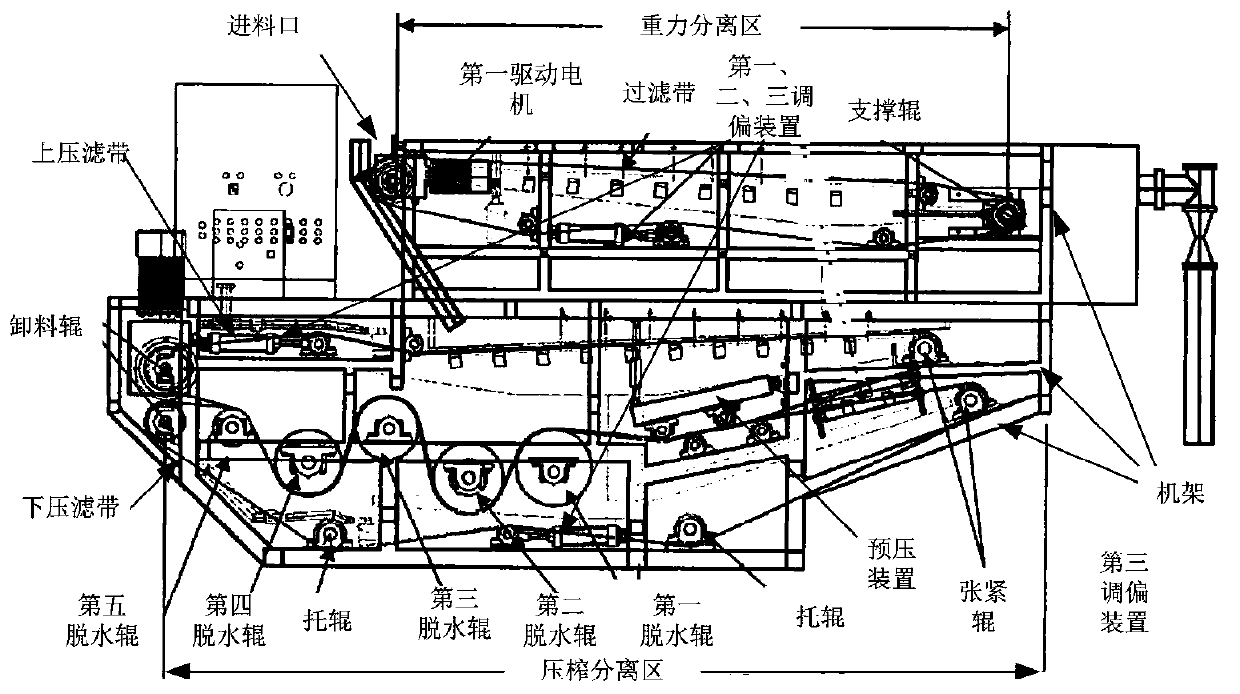

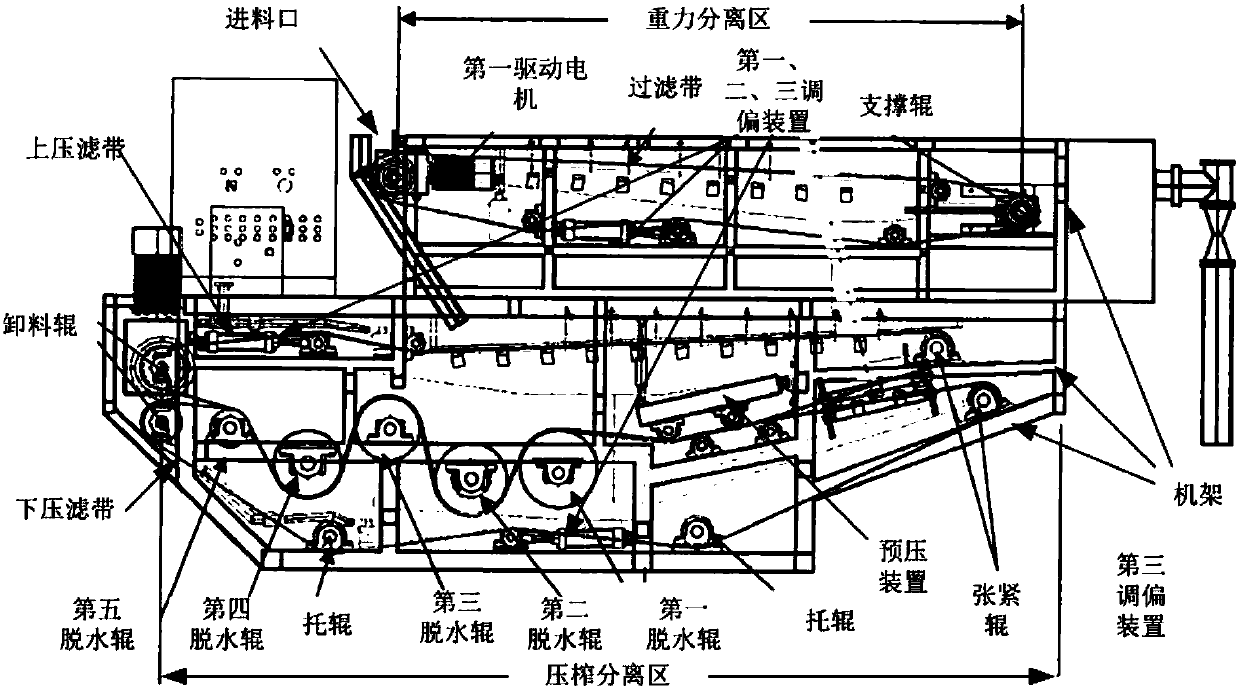

Filter press system with dewatering wheel system

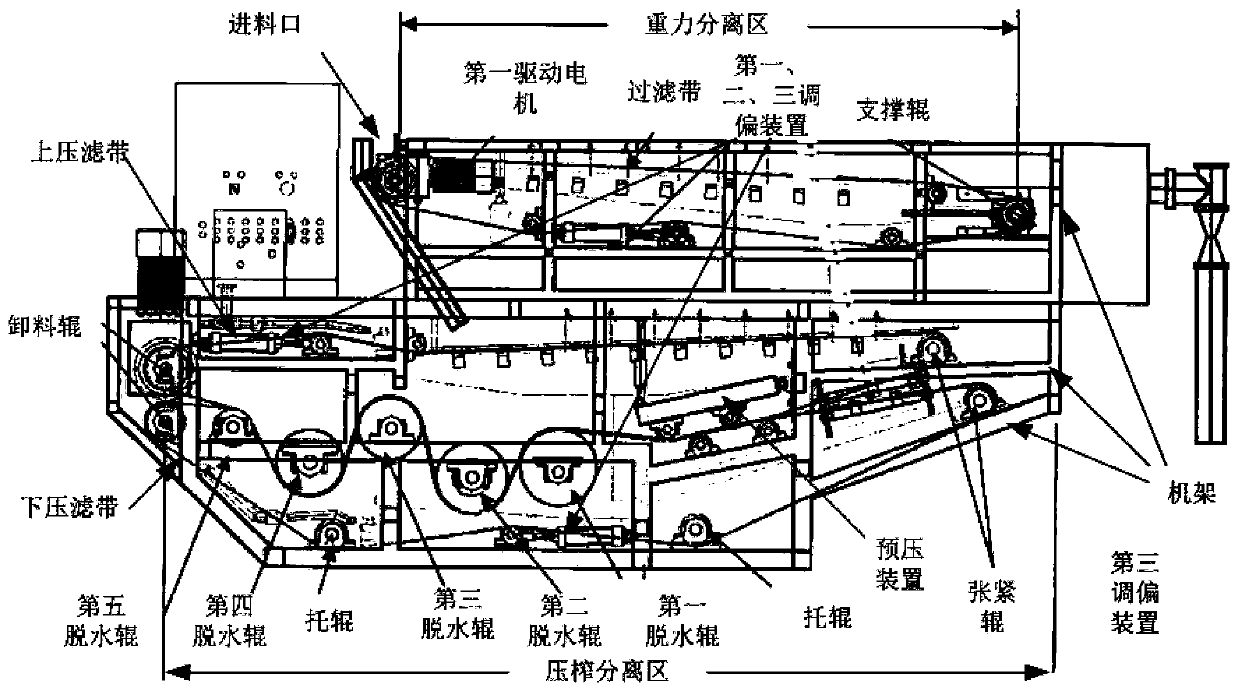

ActiveCN107670387AExtended gravity separation timeFiltration pressure is highWater treatment parameter controlSpecific water treatment objectivesSlagGravity separation

The invention discloses a filter press system with a dewatering wheel system. The filter press system comprises one belt filter press, one box filter, one pressure filter, one squeezing filter, one sterilization device, one sedimentation tank, one waste liquid pool, one liquid collection pool, four slag storage tanks, three buffer tanks, six feeding pumps, five circuit switches and fifteen valves.The belt filter press comprises a frame, a gravity separation zone, a squeezing separation zone and a liquid guide device. The squeezing separation zone comprises a second driving motor, a third driving motor, a pre-pressing device, an upper pressure filtering belt, a lower pressure filtering belt, a tensioning roller, a discharge roller, a dewatering roller system, a carrier roller, a second deviation adjustment device and a third deviation adjustment device. The dewatering roller system comprises five dewatering rollers respectively arranged in the upper pressure filtering belt and the lower pressure filtering belt.

Owner:福州清河源环保科技有限公司

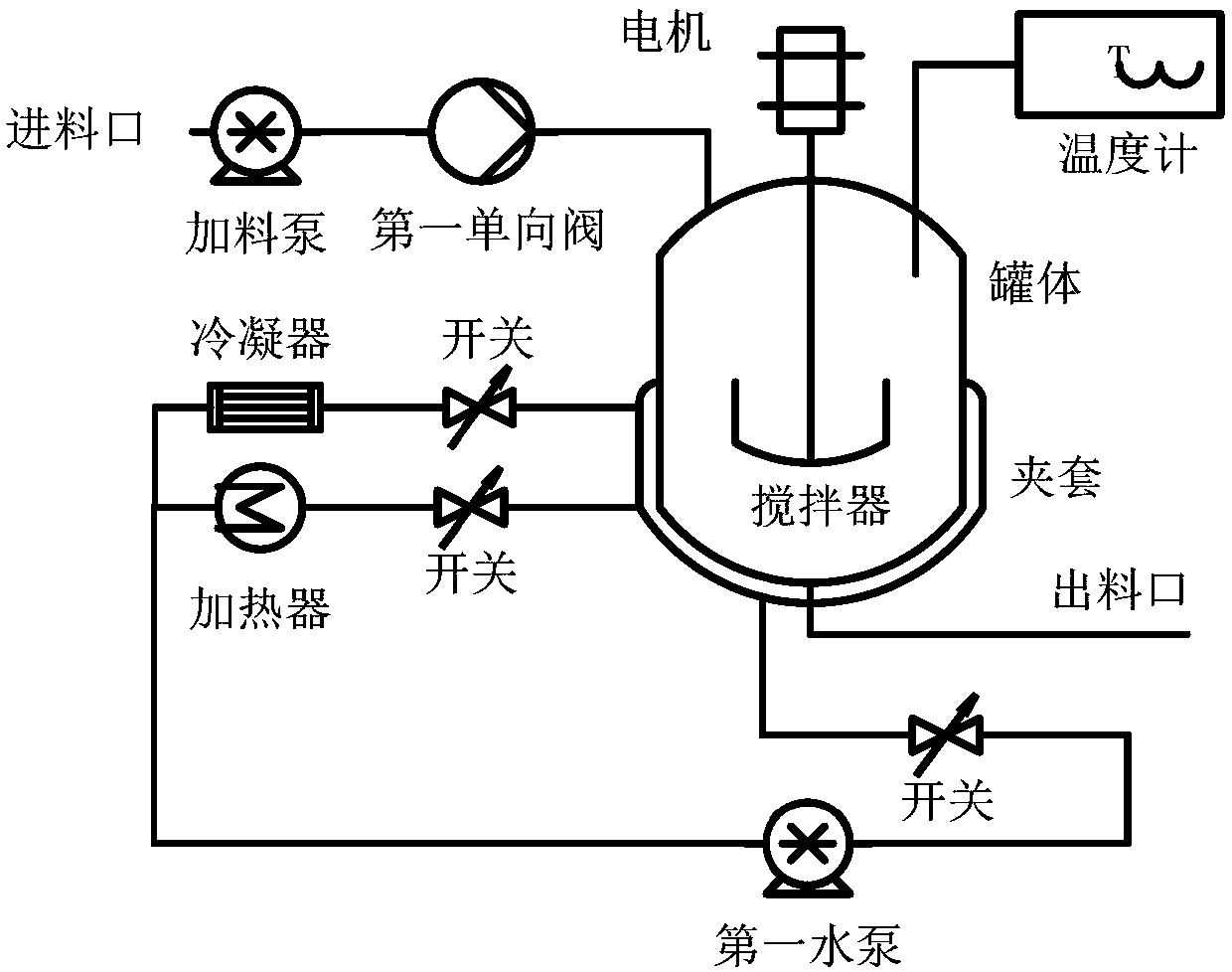

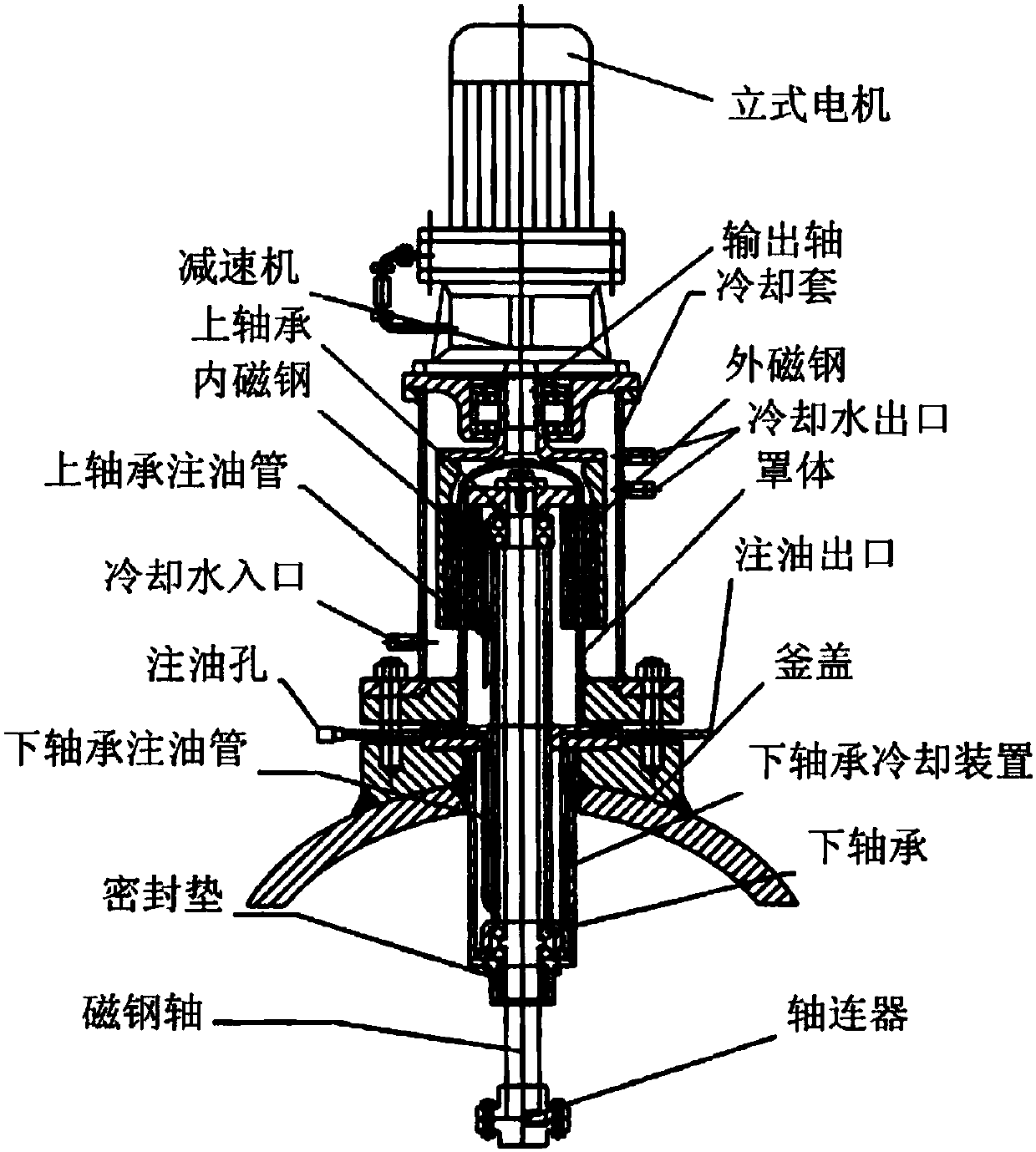

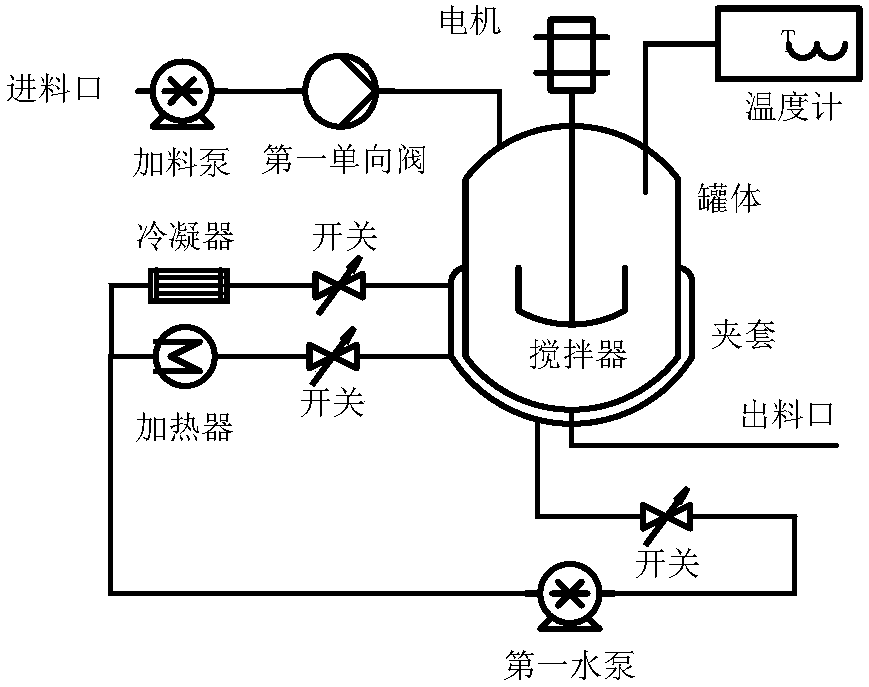

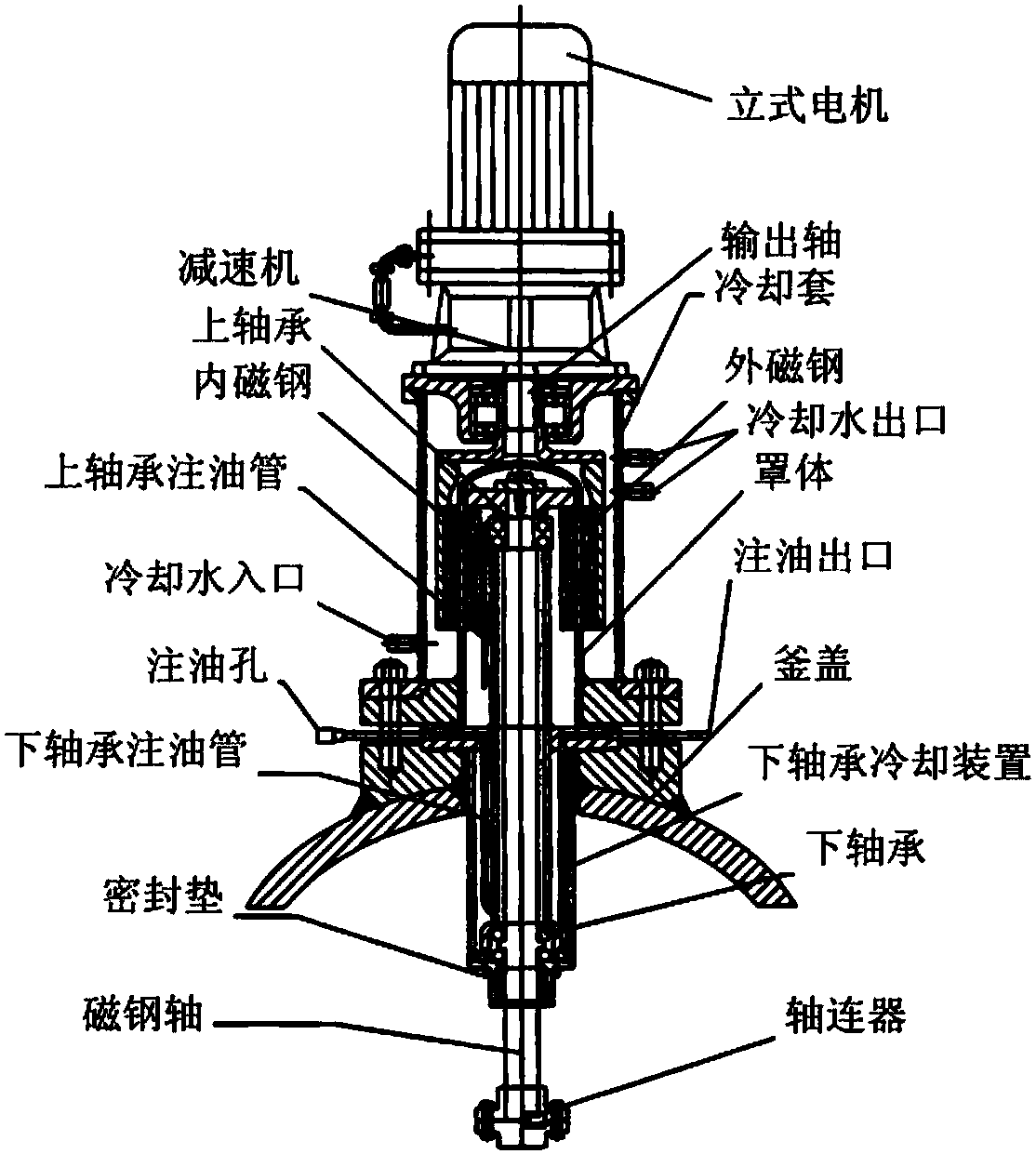

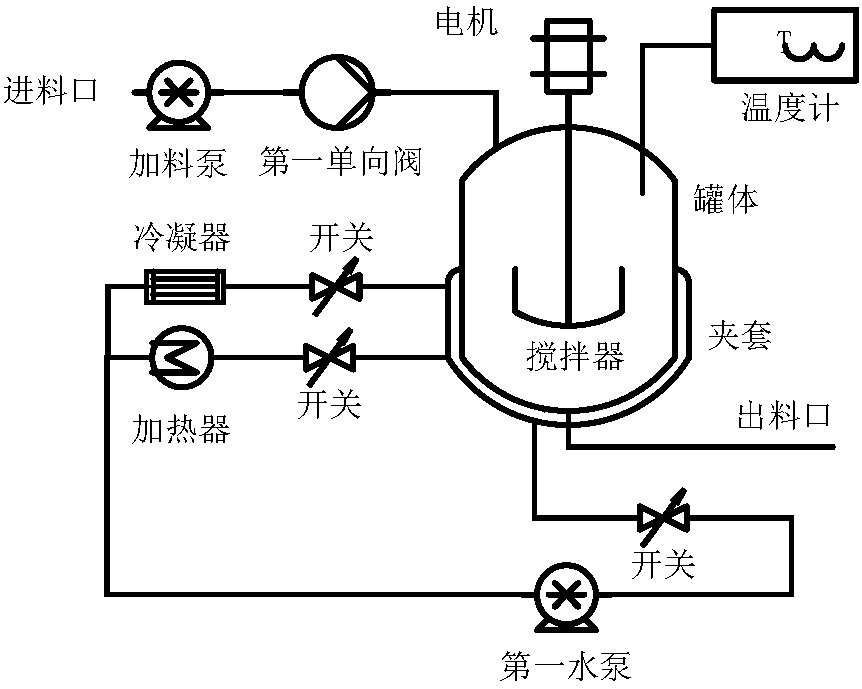

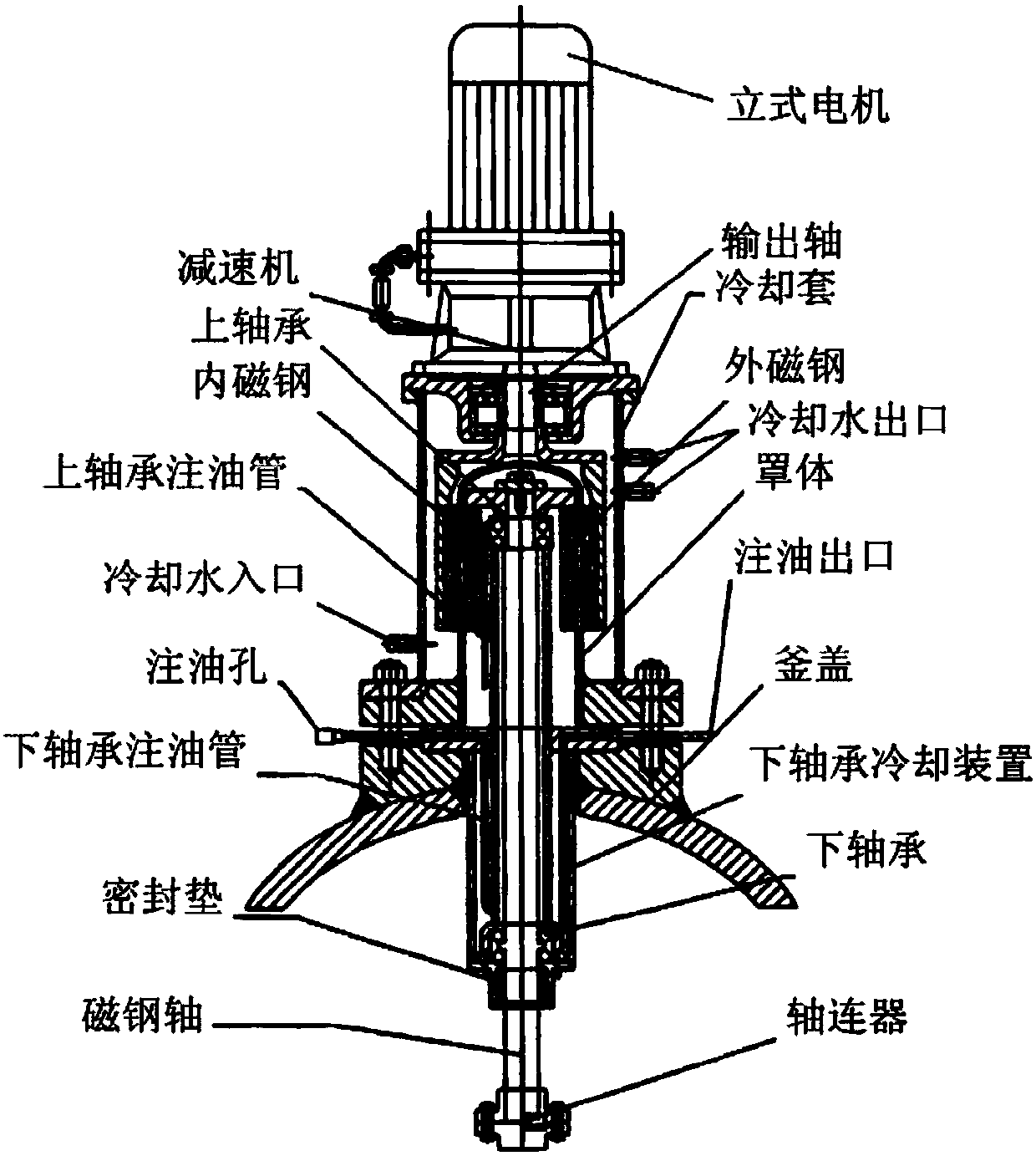

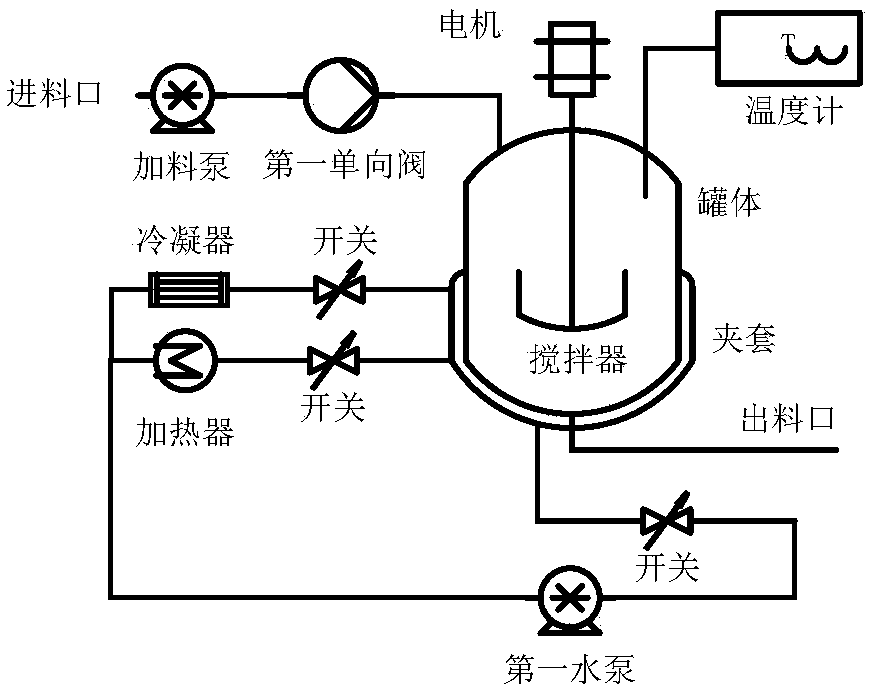

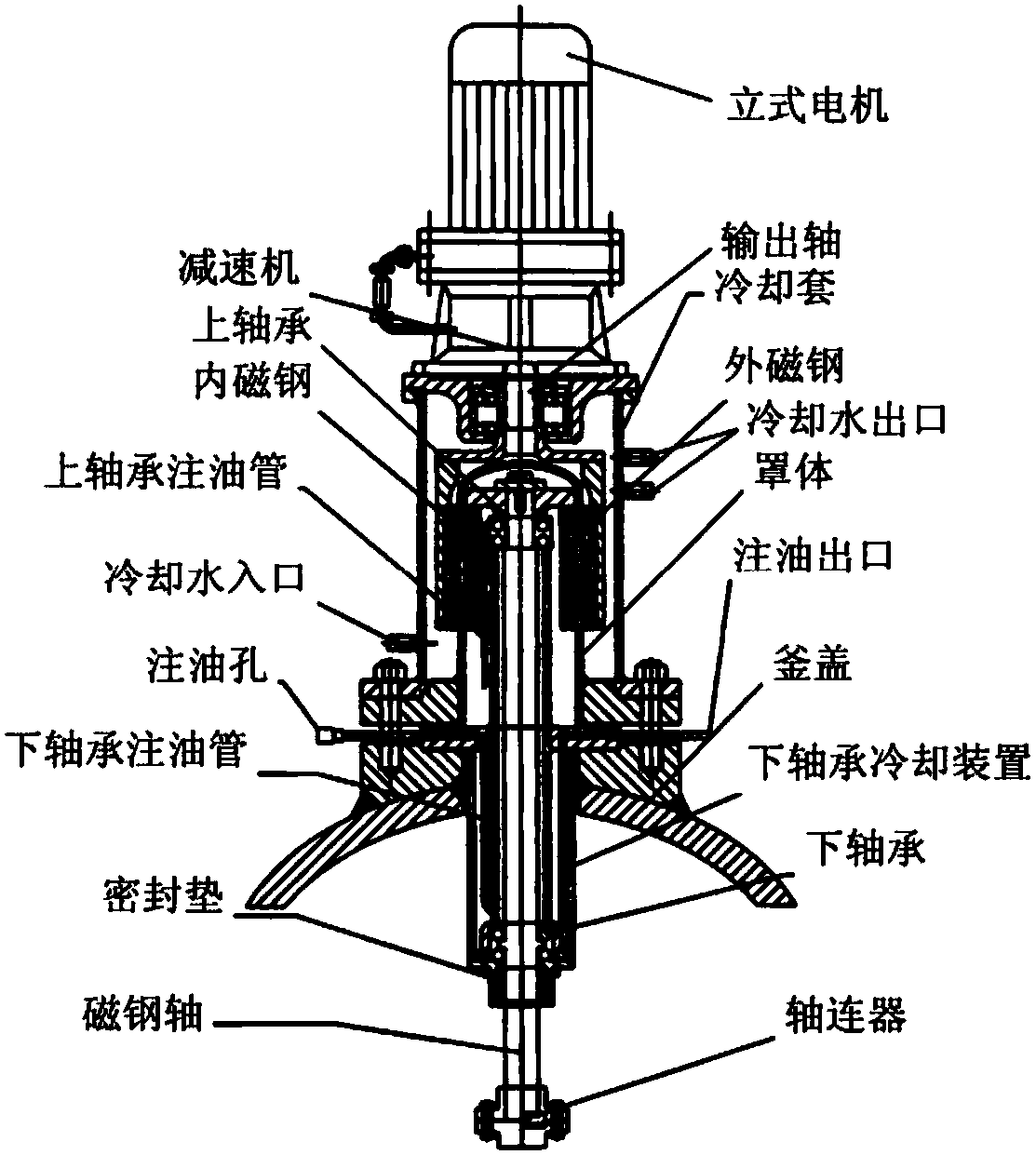

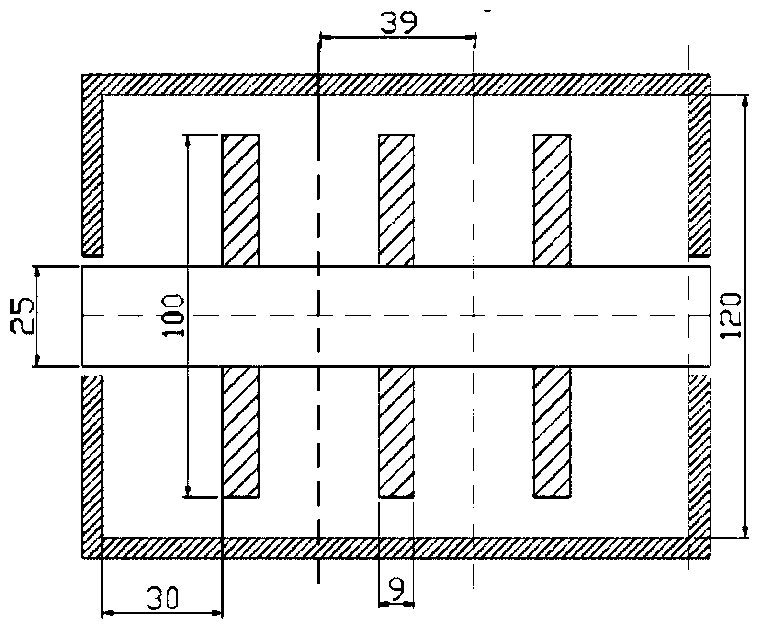

Chemical mechanical system with magnetic torque adjustable reactor

InactiveCN107670610ARealize processing and manufacturingEnables multiple reaction processingProcess control/regulationChemical/physical/physico-chemical stationary reactorsElectromagnetic driveMechanical system

The invention discloses a chemical mechanical system with a magnetic torque adjustable reactor. A first reactor is an electromagnetic driven reactor with a magnetic torque adjustment function. A stirrer comprises a magnetic driver, a vertical stirring shaft and a vertical stirring paddle. A vertical stirring paddle is arranged on the vertical stirring shaft. The magnetic driver is connected to thevertical stirring shaft and drives the vertical stirring shaft to rotate so that a stirring function is realized.

Owner:SHANDONG LONGSHENGHE CHEM CO LTD

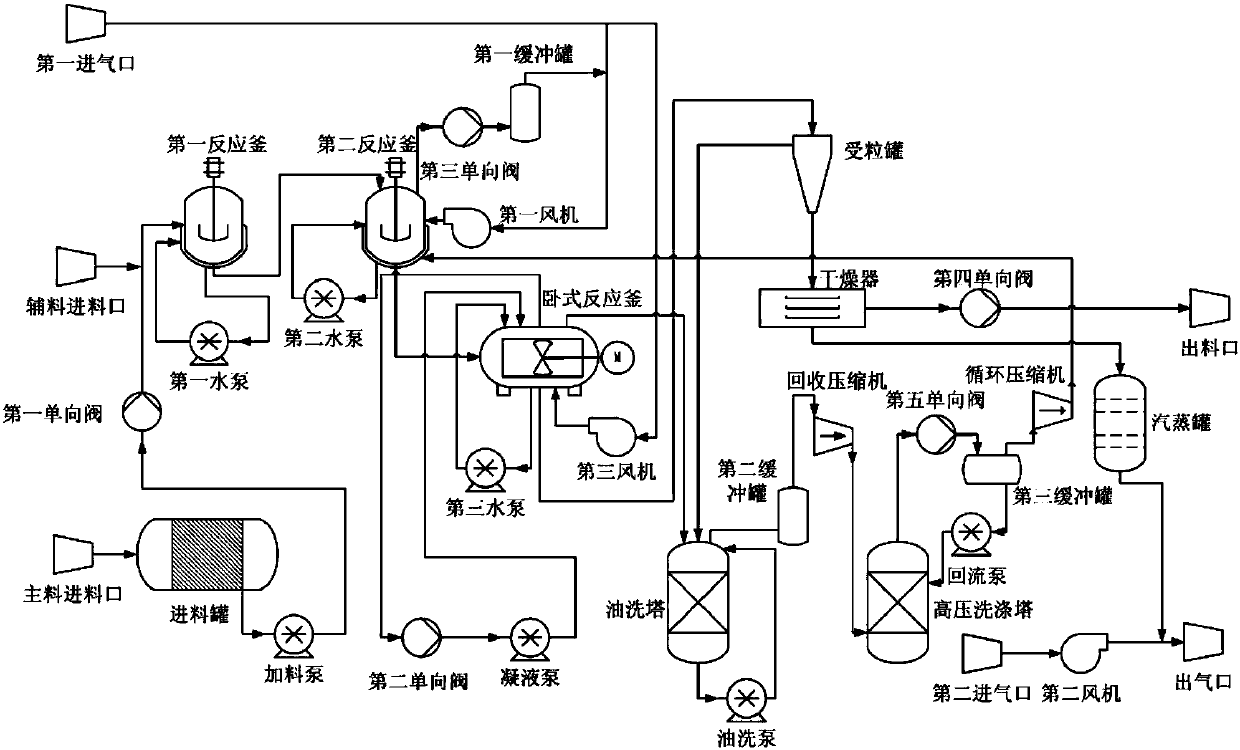

Mixing chemical mechanical system with function of multi-sensor monitoring

InactiveCN107670612ARealize processing and manufacturingEnables multiple reaction processingProcess control/regulationChemical/physical/physico-chemical stationary reactorsEngineeringAmplifier

The invention discloses a mixing chemical mechanical system with a function of multi-sensor monitoring. The mixing chemical mechanical system comprises a master control station and sensors. A master control computer receives signals from the sensors through a sampling circuit, a filter circuit, an amplifier, a holding circuit and an A / D converter. The sensors comprise a rotation speed sensor, a thermometer, a pressure sensor, a vibration sensor and a noise sensor.

Owner:SHANDONG XINHUA LONGXIN CHEM

Chemical slurry pressure filter system

ActiveCN107670393ARealize processing and manufacturingFilter thoroughlyLavatory sanitoryDisinfectionBall bearingSlag

The invention discloses a chemical slurry pressure filter system. The system comprises one belt filter press, one box filter, one pressure filter, one squeezing filter, one sterilization device, one sedimentation tank, one waste liquid pool, one liquid collection pool, four slag storage tanks, three buffer tanks, six feeding pumps, five circuit switches and fifteen valves. The pressure filter comprises a driving motor, a clutch, a transmission shaft, a distributor head, a ball bearing, a left end cover, an outer cylinder main body, a sealing cover plate, a sealing spacer block, a filter screen, an inner cylinder main body, a drainage pipe, a packing seal, a right end cover, a roller bearing, an outer cylinder support base, a side support, a scraper discharge device, an unloading box, a reducer and a lubrication device.

Owner:宝应县有机食品质量监督检验中心

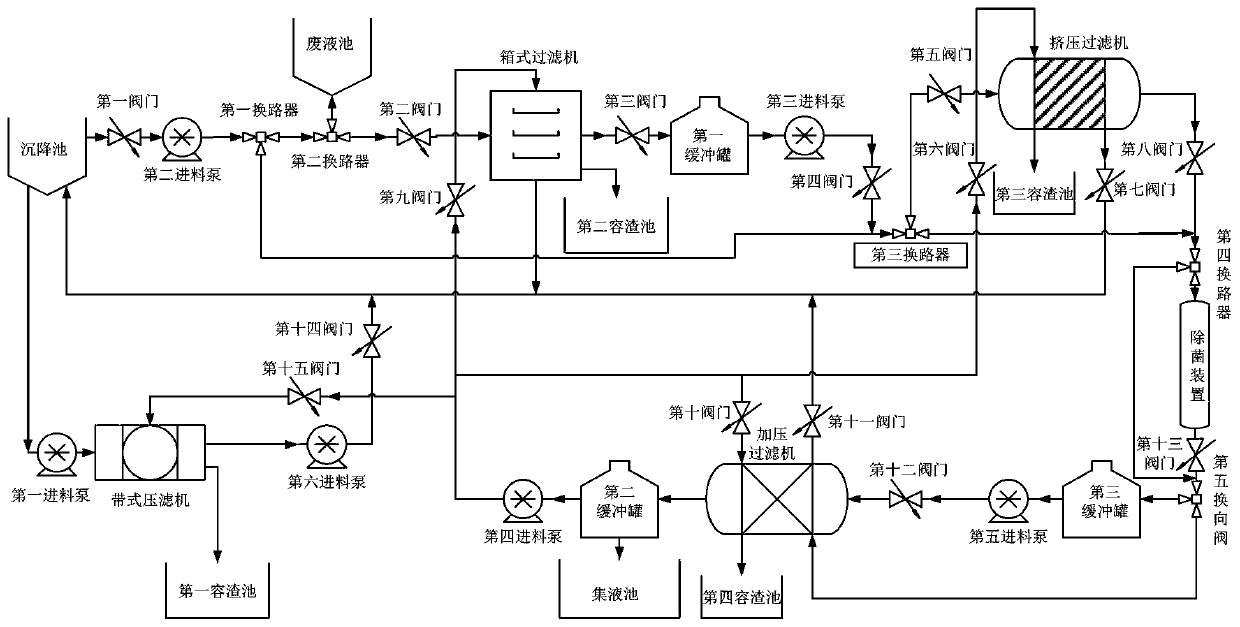

Chemical slurry separation system with function of material level judgment

ActiveCN107670384ARealize processing and manufacturingFilter thoroughlyWater treatment parameter controlSpecific water treatment objectivesBuffer tankSlag

The invention discloses a chemical slurry separation system with a function of material level judgment. The chemical slurry separation system comprises one belt filter press, one box filter, one pressure filter, one squeezing filter, one sterilization device, one sedimentation tank, one waste liquid pool, one liquid collection pool, four slag storage tanks, three buffer tanks, six feeding pumps, five circuit switches, fifteen valves, a main control computer and sensors. The main control computer receives signals from the sensors and controls the fifteen valves, five circuit switches, six feeding pumps, box filter, belt filter press, squeezing filter and pressure filter.

Owner:SHANDONG XINHUA LONGXIN CHEM

Grinding chemical machinery system with fuzzy control over barrel temperature

ActiveCN106179630AEfficient processingIncrease processing effortsGrain treatmentsControl systemFuzzy control system

The invention discloses a grinding chemical machinery system with fuzzy control over the barrel temperature. The system is characterized in that the grinding chemical machinery system comprises a grinding part and a control system part; the grinding part comprises a raw material hopper, a feeder, a collector, a feeding belt, a grinder, a bead separator, a coarse powder separator, a fine powder separator, a powder hopper, a fan, a valve and a pipeline; the grinder is provided with a material inlet, a material outlet, a barrel, a main bearing, an auxiliary bearing, a pulp piece, beads, a spindle, a barrel swing belt pulley and a tubular shaft gear; the spindle is driven by a spindle motor to rotate; and the barrel swing belt pulley is driven by a stepping motor to rotate reciprocally and periodically at a certain angle.

Owner:DONGYING DAOYI BIOLOGICAL MEDICINE TECH CO LTD

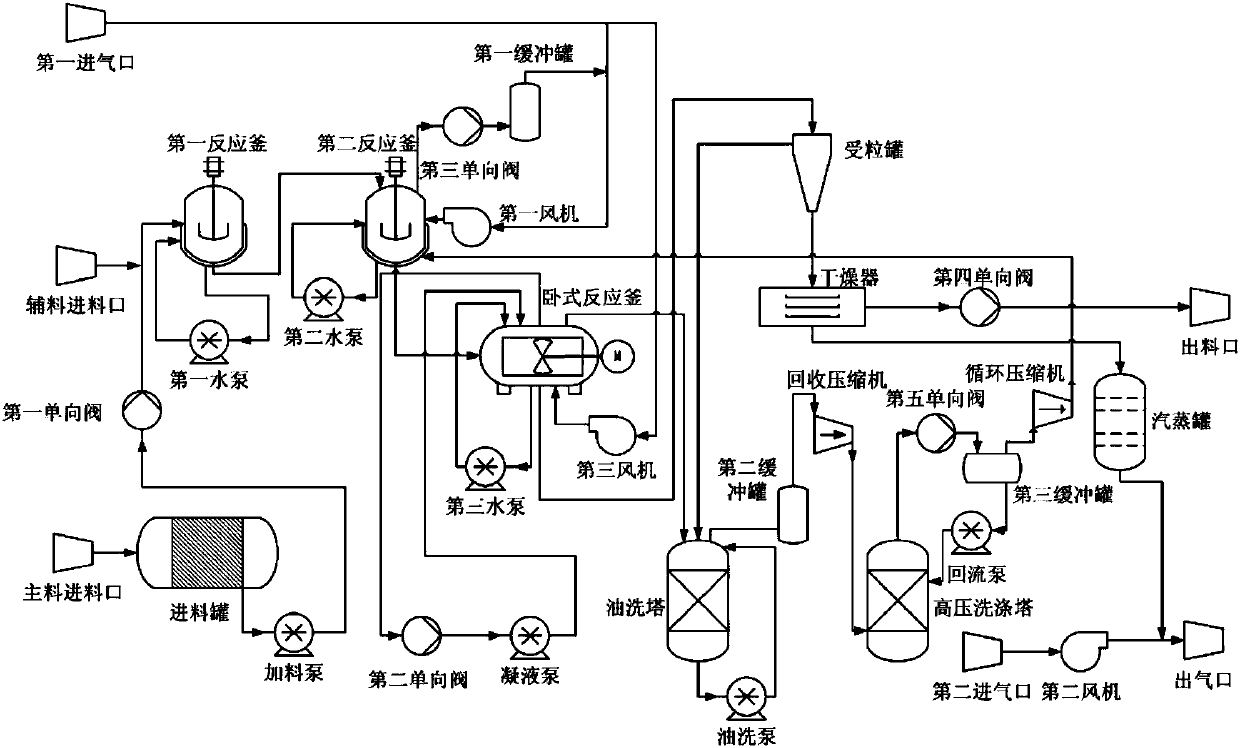

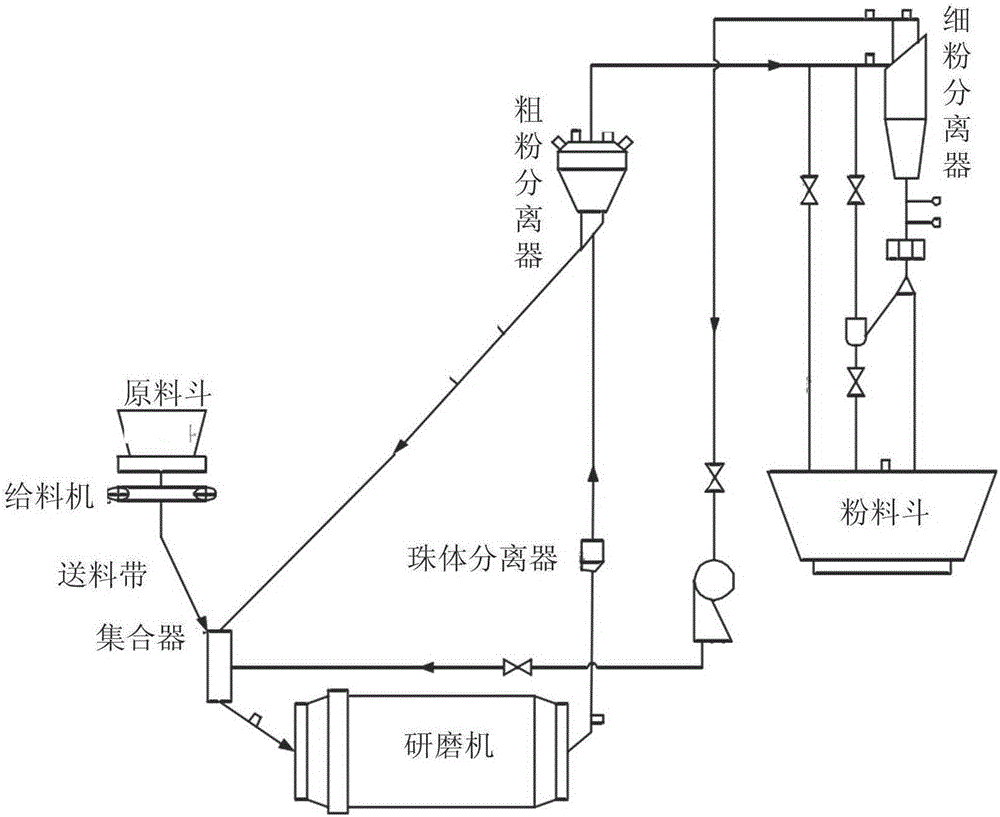

A double-cycle grinding chemical machinery system for powder materials

InactiveCN106179626BEfficient processingIncrease processing effortsGrain treatmentsControl systemMetallurgy

The invention discloses a double-circulation powder grinding chemical machinery system. The system is characterized in that the double-circulation powder grinding chemical machinery system comprises a grinding part and a control system part; the grinding part comprises a raw material hopper, a feeder, a collector, a feeding belt, a grinder, a bead separator, a coarse powder separator, a fine powder separator, a powder hopper, a fan, a valve and a pipeline; the grinder is provided with a material inlet, a material outlet, a barrel, a main bearing, an auxiliary bearing, a pulp piece, beads, a spindle, a barrel swing belt pulley and a tubular shaft gear; the spindle is driven by a spindle motor to rotate; and the barrel swing belt pulley is driven by a stepping motor to rotate reciprocally and periodically at a certain angle.

Owner:DONGE AGRI PLASTIC IND CO LTD

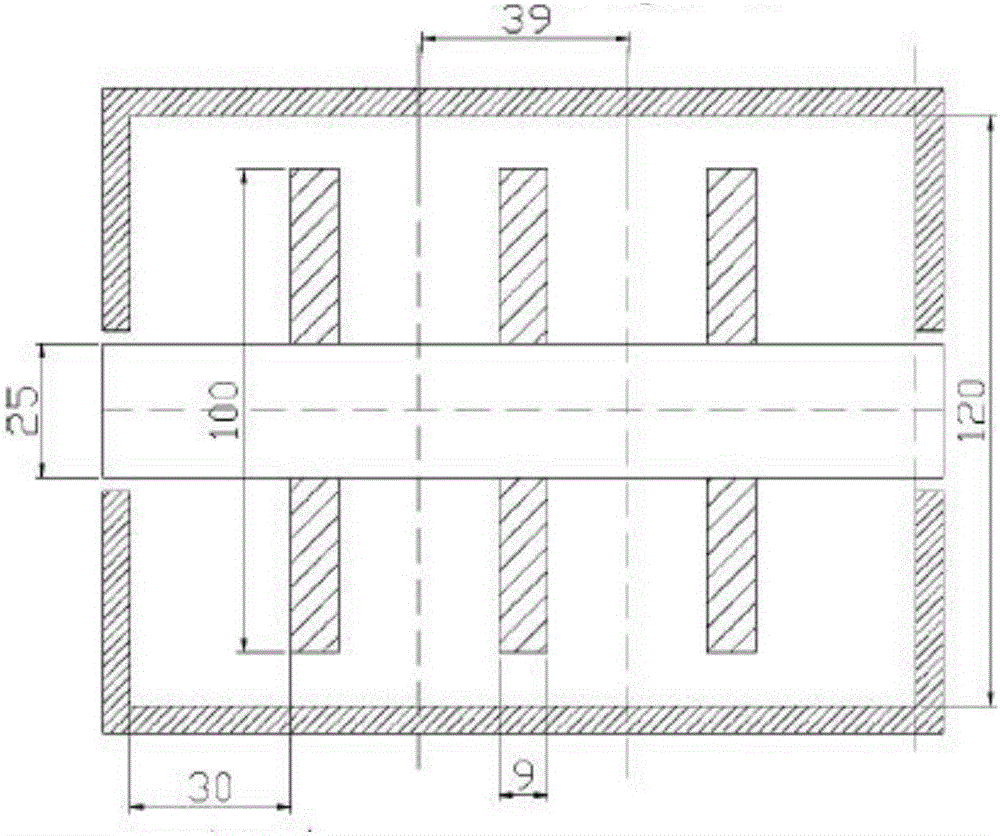

Chemical mechanical system with inner baffle horizontal reactor

ActiveCN107670600ARealize processing and manufacturingEnables multiple reaction processingProcess control/regulationChemical/physical/physico-chemical stationary reactorsPetroleum engineeringMechanical system

The invention discloses a chemical mechanical system with an inner baffle horizontal reactor. The horizontal reactor comprises a horizontal tank, a horizontal agitator and a horizontal jacket. The horizontal jacket is arranged in the middle of the horizontal tank. The horizontal jacket and the horizontal tank form a closed annular sandwich layer. Four baffles are arranged in the horizontal tank, are uniformly arranged at axial positions of the reactor at equal intervals, are semicircular and respectively form angles of 0 degree, 90 degrees, 180 degrees and 270 degrees with the plane. A ratio of the baffle thickness to diameter is 1: 20.

Owner:TONGXIANG RONGLI CHEM

A grinding chemical mechanical system with two types of beads

InactiveCN106179628BEfficient processingIncrease processing effortsGrain treatmentsControl systemCompound (substance)

The invention discloses a grinding chemical engineering mechanical system with large and small two ball bodies. The system is characterized by comprising two parts of a grinding part and a control system; the grinding part includes a raw material hopper, a feeder, a collector, a feeding belt, a grinder, a ball body separator, a thick powder separator, a fine powder separator, a powder hopper, a fan, a valve and a pipeline; the grinder has a feed port, a discharge port, a cylinder, a main bearing, an auxiliary bearing, a pulp piece, ball bodies, a main shaft, a cylinder swing belt wheel and a pipe shaft gear; the main shaft is driven to rotate by the main shaft motor; and the cylinder swing belt wheel is driven by the stepper motor to perform periodic reciprocating rotation by a certain angle.

Owner:QINGDAO UNIV

A filter box system capable of judging transmission effectiveness

InactiveCN107670378BRealize processing and manufacturingFilter thoroughlyFiltration circuitsBuffer tankSlag

The invention discloses a filter box system with a function of determining effectiveness of a transmission device. The filter box system comprises one belt filter press, one box filter, one pressure filter, one squeezing filter, one sterilization device, one sedimentation tank, one waste liquid pool, one liquid collection pool, four slag storage tanks, three buffer tanks, six feeding pumps, five circuit switches and fifteen valves. The box filter comprises multiple stacked filter boxes. A spray pipe, a movable plate, a filter plate, a fixed plate, a frame and a transmission device are arrangedin each filter box. Through comparing the transmission device power and the current driving power, it is determined if the current transmission device works normally.

Owner:冀小锋

A multi-sensor chemical slurry separation system

ActiveCN107670386BRealize processing and manufacturingFilter thoroughlyWater treatment parameter controlSpecific water treatment objectivesSlagBuffer tank

The invention discloses a chemical slurry separation system with multiple sensors. The chemical slurry separation system comprises one belt filter press, one box filter, one pressure filter, one squeezing filter, one sterilization device, one sedimentation tank, one waste liquid pool, one liquid collection pool, four slag storage tanks, three buffer tanks, six feeding pumps, five circuit switches,fifteen valves, a master control station and sensors. The master control station is used for receiving signals from the sensors and controlling the fifteen valves, the five circuit switches, the sixfeeding pumps, the box filter, the belt filter press, the squeezing filter and the pressure filter.

Owner:河北奥盛生物科技有限公司

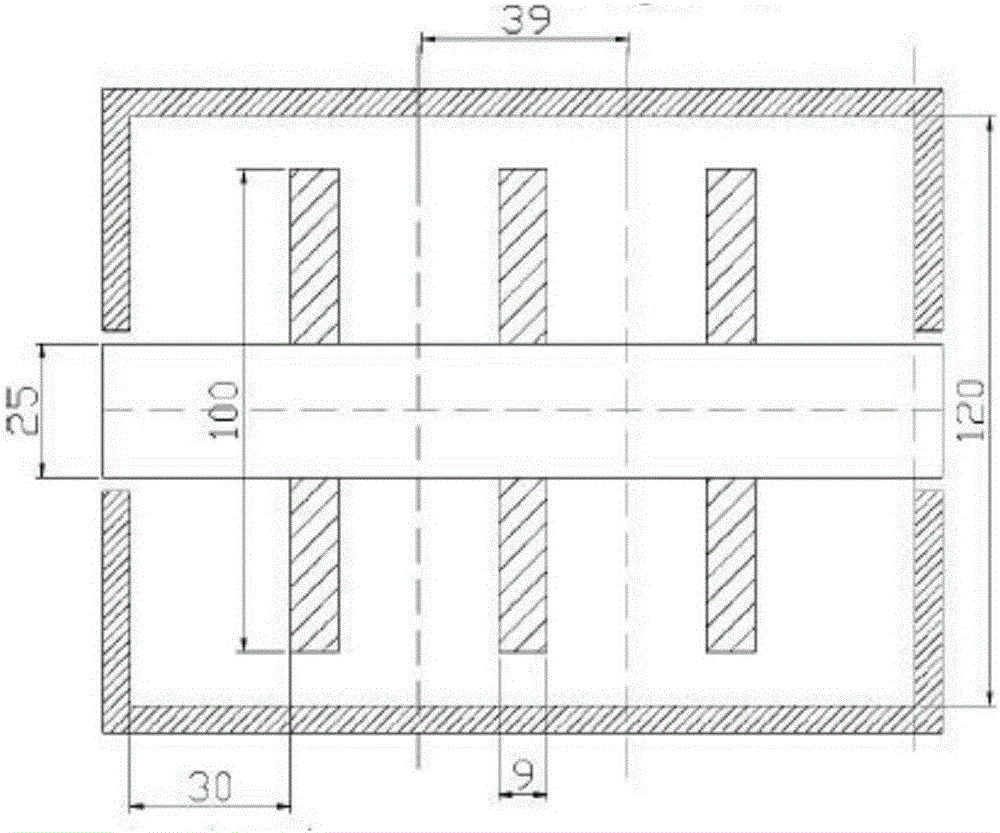

A grinding chemical machinery system for shuttle-shaped paddles

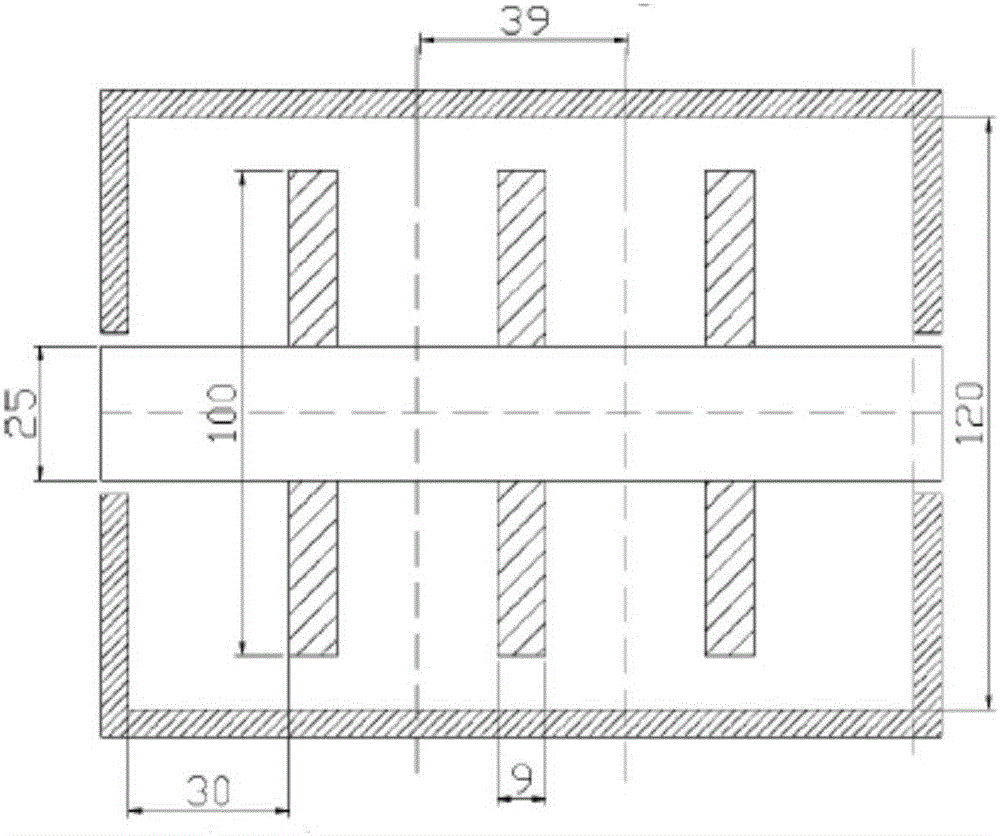

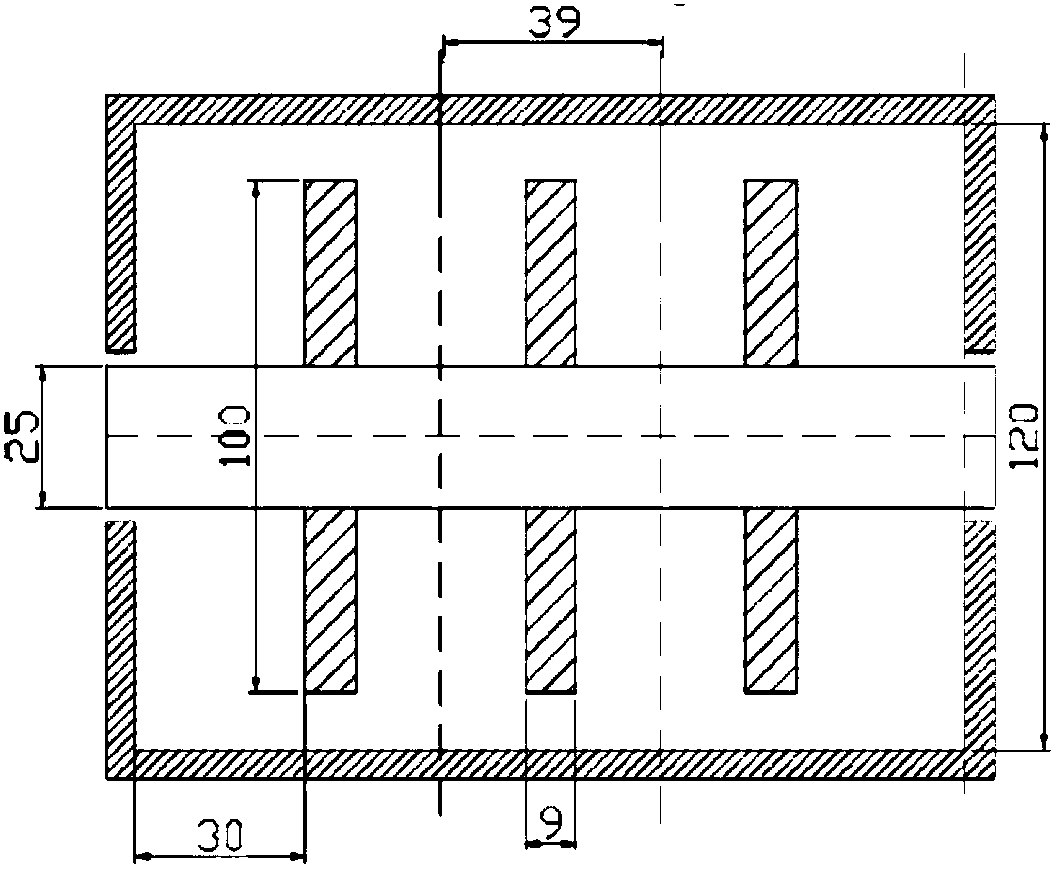

ActiveCN106111268BEfficient processingIncrease processing effortsGrain treatmentsLine tubingControl system

The invention relates to a grinding chemical mechanical system with fusiform blades. The system is characterized by comprising two parts: a grinding part and a control system, wherein the grinding part comprises a raw material hopper, a feeder, a collector, a feeding belt, a grinder, a bead separator, a coarse powder separator, a fine powder separator, a powder hopper, a fan, a valve and a pipeline, wherein the grinder is provided with a feed inlet, a discharge opening, a cylinder, a main bearing, an auxiliary bearing, blades, beads, a main shaft, a cylinder swinging belt wheel and a pipe shaft gear; the main shaft is driven by a main shaft motor to rotate and the cylinder swinging belt wheel is driven by a stepping motor to perform a reciprocation rotation reciprocation rotation at a certain angle.

Owner:宝应县有机食品质量监督检验中心

A filter press system with a dehydration train

ActiveCN107670387BRealize processing and manufacturingFilter thoroughlyWater treatment parameter controlSpecific water treatment objectivesSlagBuffer tank

The invention discloses a filter press system with a dewatering wheel system. The filter press system comprises one belt filter press, one box filter, one pressure filter, one squeezing filter, one sterilization device, one sedimentation tank, one waste liquid pool, one liquid collection pool, four slag storage tanks, three buffer tanks, six feeding pumps, five circuit switches and fifteen valves.The belt filter press comprises a frame, a gravity separation zone, a squeezing separation zone and a liquid guide device. The squeezing separation zone comprises a second driving motor, a third driving motor, a pre-pressing device, an upper pressure filtering belt, a lower pressure filtering belt, a tensioning roller, a discharge roller, a dewatering roller system, a carrier roller, a second deviation adjustment device and a third deviation adjustment device. The dewatering roller system comprises five dewatering rollers respectively arranged in the upper pressure filtering belt and the lower pressure filtering belt.

Owner:福州清河源环保科技有限公司

A filter system with separate gravity separation

ActiveCN107670376BRealize processing and manufacturingFilter thoroughlyFiltration circuitsAdaptive controlPolyesterFiltration

Owner:福州清河源环保科技有限公司

A Grinding Chemical Machinery System Monitored by Multiple Sensors

InactiveCN106140405BEfficient processingIncrease processing effortsGrain treatmentsControl systemCompound (substance)

A grinding chemical machinery system capable of achieving multi-sensor monitoring is characterized by comprising a grinding part and a control system, wherein the grinding part comprises a raw material hopper, a feeder, a collector, a feeding belt, a grinder, a bead body separator, a coarse powder separator, a fine powder separator, a powder hopper, a fan, a valve and a pipeline; the grinder is provided with a feeding port, a discharging port, a barrel, a main bearing, an auxiliary bearing, paddles, bead bodies, a main shaft, a barrel swing belt wheel and a pipe shaft gear; and the main shaft is driven by a main shaft motor to rotate, and the barrel swing belt wheel is driven by a stepping motor to periodically rotate in a reciprocating mode at a certain angle.

Owner:QINGDAO UNIV

Filter box system with function of determining effectiveness of transmission device

InactiveCN107670378ARealize processing and manufacturingFilter thoroughlyFiltration circuitsSlagBuffer tank

The invention discloses a filter box system with a function of determining effectiveness of a transmission device. The filter box system comprises one belt filter press, one box filter, one pressure filter, one squeezing filter, one sterilization device, one sedimentation tank, one waste liquid pool, one liquid collection pool, four slag storage tanks, three buffer tanks, six feeding pumps, five circuit switches and fifteen valves. The box filter comprises multiple stacked filter boxes. A spray pipe, a movable plate, a filter plate, a fixed plate, a frame and a transmission device are arrangedin each filter box. Through comparing the transmission device power and the current driving power, it is determined if the current transmission device works normally.

Owner:冀小锋

Garbage feeder

InactiveCN102491056BGuaranteed continuous feedingGuaranteed thicknessConveyorsControl devices for conveyorsEngineeringMechanical engineering

The invention discloses a garbage feeder, which comprises a machine frame, a conveying device and a guiding tank, wherein the conveying device is arranged on the machine frame; and the guiding tank is fixed on the machine frame and positioned above and on the right side of the conveying device. The garbage feeder is characterized by also comprising a blending device and a feed level feedback device. The machine frame comprises supporting posts, a connecting cross beam and supporting wheel bearers, wherein 1 to 3 supporting wheel bearers are used. Each feeding plate of the conveying device hasa roller support, the number of the roller supports is the same as that of the supporting wheel bearers, and each roller support is rotationally connected with a corresponding supporting roller. The supporting roller of each corresponding feeding plate is contacted with a supporting wheel bearer in a rolling manner. The blending device comprises a main frame body and comb teeth. The comb teeth are arranged on the main frame body. The blending device is arranged in the middle of the left and right direction of the machine frame. The comb teeth are positioned above the conveying device. The feed level feedback device is transversely spun over the guiding tank from the front to the back and is positioned above the part, which is on the right side of the blending device, of the conveying device.

Owner:江苏金陵环保科技有限公司

A grinding chemical machinery system with cylinder temperature fuzzy control

ActiveCN106179630BEfficient processingIncrease processing effortsGrain treatmentsLine tubingControl system

The invention discloses a grinding chemical machinery system with fuzzy control over the barrel temperature. The system is characterized in that the grinding chemical machinery system comprises a grinding part and a control system part; the grinding part comprises a raw material hopper, a feeder, a collector, a feeding belt, a grinder, a bead separator, a coarse powder separator, a fine powder separator, a powder hopper, a fan, a valve and a pipeline; the grinder is provided with a material inlet, a material outlet, a barrel, a main bearing, an auxiliary bearing, a pulp piece, beads, a spindle, a barrel swing belt pulley and a tubular shaft gear; the spindle is driven by a spindle motor to rotate; and the barrel swing belt pulley is driven by a stepping motor to rotate reciprocally and periodically at a certain angle.

Owner:DONGYING DAOYI BIOLOGICAL MEDICINE TECH CO LTD

Grinding chemical mechanical system with fusiform blades

ActiveCN106111268AEfficient processingIncrease processing effortsGrain treatmentsControl systemEngineering

The invention relates to a grinding chemical mechanical system with fusiform blades. The system is characterized by comprising two parts: a grinding part and a control system, wherein the grinding part comprises a raw material hopper, a feeder, a collector, a feeding belt, a grinder, a bead separator, a coarse powder separator, a fine powder separator, a powder hopper, a fan, a valve and a pipeline, wherein the grinder is provided with a feed inlet, a discharge opening, a cylinder, a main bearing, an auxiliary bearing, blades, beads, a main shaft, a cylinder swinging belt wheel and a pipe shaft gear; the main shaft is driven by a main shaft motor to rotate and the cylinder swinging belt wheel is driven by a stepping motor to perform a reciprocation rotation reciprocation rotation at a certain angle.

Owner:宝应县有机食品质量监督检验中心

A grinding chemical mechanical system with double-layer barrel walls

InactiveCN106179629BEfficient processingIncrease processing effortsGrain treatmentsControl systemGear wheel

A chemical grinding machine system with a double-layer barrel wall is characterized by comprising a grinding part and a control system, wherein the grinding part comprises a raw material bucket, a feeding machine, a collector, a feeding belt, a grinding miller, a bead body separator, a coarse powder separator, a fine powder separator, a powder bucket, a fan, a valve and a pipeline; the grinding miller provided with a feed port, a discharge port, a cylinder, a main bearing, an auxiliary bearing, a blade, a bead body, a spindle, a cylinder swing belt wheel and a pipe shaft gear; the spindle is driven by a spindle motor to rotate; and the cylinder swing belt wheel is driven by a stepping motor to perform reciprocating rotation for a certain angle periodically.

Owner:QINGDAO UNIV

Grinding chemical engineering mechanical system with large and small two ball bodies

InactiveCN106179628AIncrease processing effortsImprove crushing efficiencyGrain treatmentsMain bearingEngineering

The invention discloses a grinding chemical engineering mechanical system with large and small two ball bodies. The system is characterized by comprising two parts of a grinding part and a control system; the grinding part includes a raw material hopper, a feeder, a collector, a feeding belt, a grinder, a ball body separator, a thick powder separator, a fine powder separator, a powder hopper, a fan, a valve and a pipeline; the grinder has a feed port, a discharge port, a cylinder, a main bearing, an auxiliary bearing, a pulp piece, ball bodies, a main shaft, a cylinder swing belt wheel and a pipe shaft gear; the main shaft is driven to rotate by the main shaft motor; and the cylinder swing belt wheel is driven by the stepper motor to perform periodic reciprocating rotation by a certain angle.

Owner:QINGDAO UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com