Bi-directional rotating grinding chemical machinery system

A technology of chemical machinery and two-way rotation, which is applied in grain processing and other directions, and can solve problems such as inability to adjust in time, single grinding products, and low degree of automatic control, so as to reduce inaccurate precision, reduce waste in efficiency, and increase processing power Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0022] Embodiments of the present invention refer to Figure 1-5 shown.

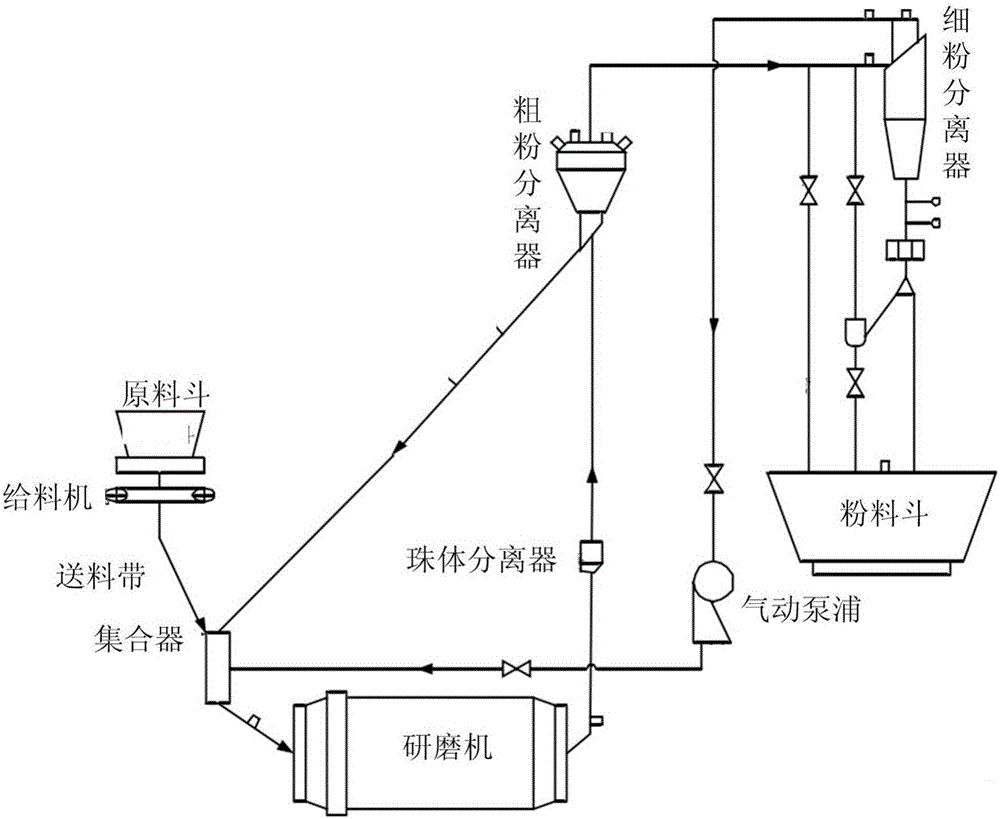

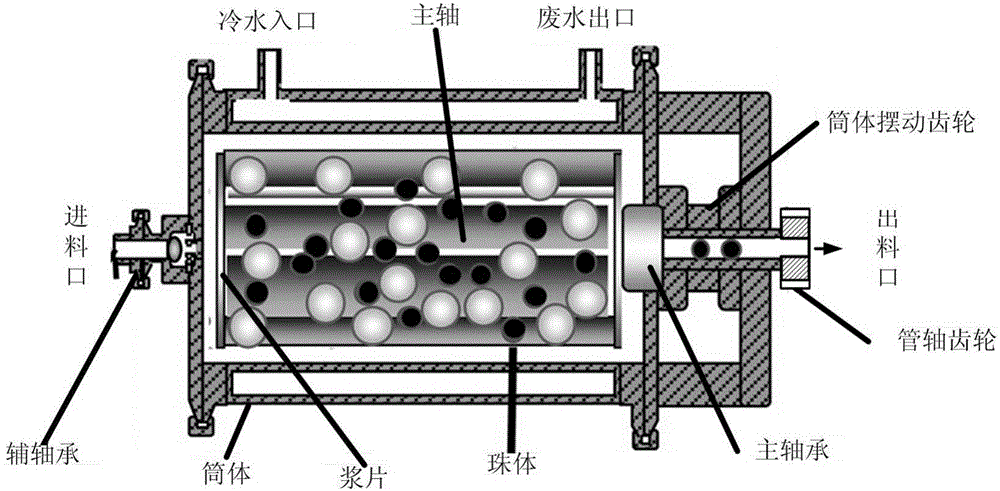

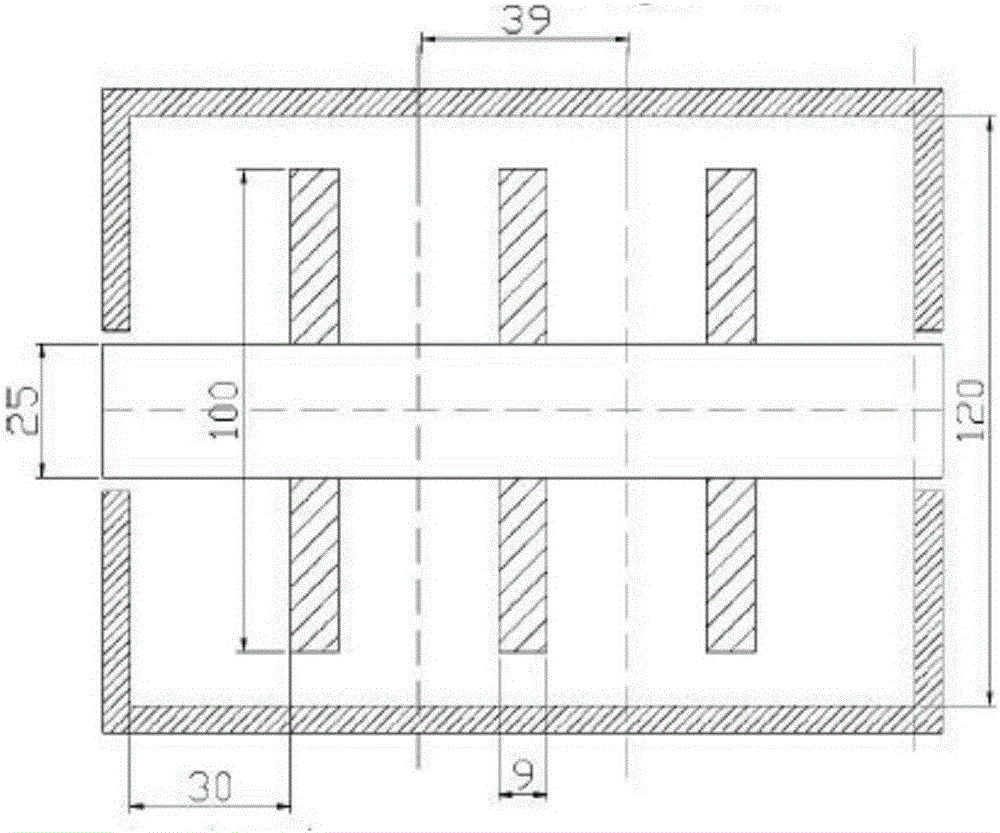

[0023] A two-way rotating grinding chemical mechanical system, which includes a grinding part and a control system. The grinding part includes a raw material hopper, a feeder, a collector, a feeding belt, a grinder, a bead separator, a coarse powder Powder separator, powder hopper, fan, valve and pipeline, as shown in the figure, the raw material enters the collector through the feeder, gathers with other powders and enters the grinder through the feeding belt, and the grinder grinds the material to form primary processing powder The raw material enters the bead separator through the pipeline, separates the beads and returns them to the grinder, the separated raw powder enters the coarse powder separator through the pipeline, separates the oversized raw powder and enters the coll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com