A hydraulic pumping unit

A pumping unit and hydraulic technology, which is applied in the field of hydraulic pumping units, can solve the problems of bulky size, poor balance effect of pumping units, troublesome transportation and installation, etc., to ensure firmness and stability, reduce self-weight load, and reduce noise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with embodiment, the present invention is further described, and following embodiment is illustrative, not restrictive, can not limit protection scope of the present invention with following embodiment.

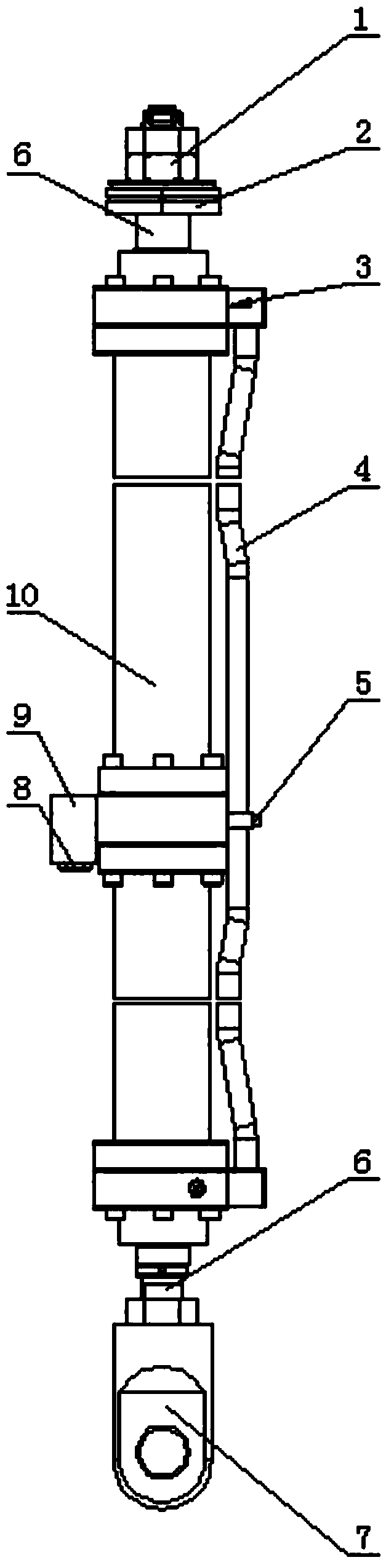

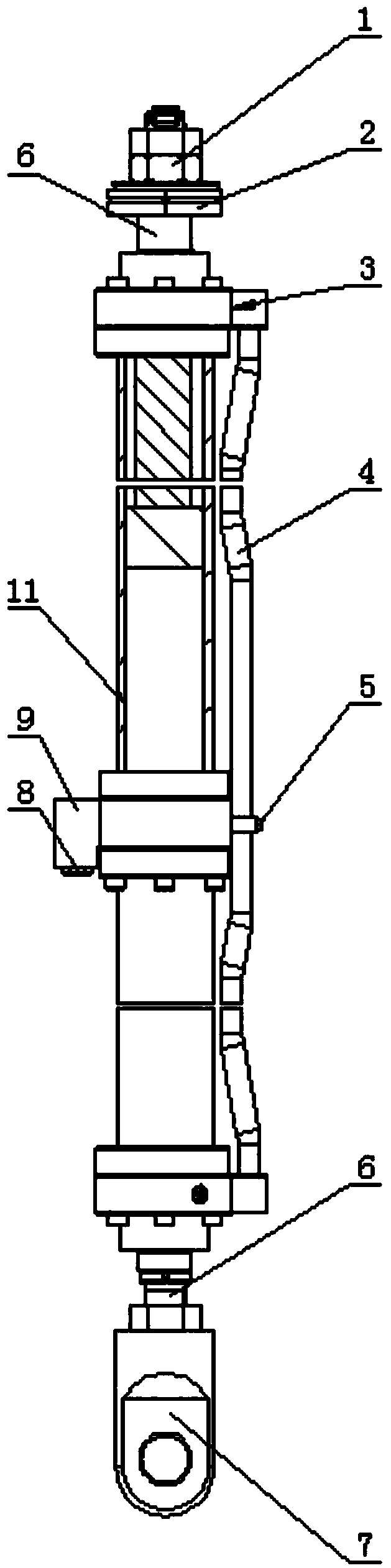

[0014] A hydraulic pumping unit, the innovation of the present invention is that it includes two hydraulic cylinders 10, the rear cavities of the two hydraulic cylinders are relatively fixed and installed, and the insides of the two rear cavities communicate with each other to form a cavity 11, and the two hydraulic cylinders A cylinder oil port 3 is formed in the front cavity of the cylinder, and the oil ports of the two cylinders are communicated through an oil pipe 4, and an oil port 5 is formed in the side wall of the oil pipe, and the two piston rod ends of the two hydraulic cylinders are located at the same vertical In the straight line, reciprocating up and down, the ends of the two piston rods of the hydraulic cylinder are respectively used ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com