Water-pressure-caused plugging drill hole water pressing test method

A pressurized water test and drilling technology, which is applied in construction and other directions, can solve the problems of prone to stuck hole accidents, poor sealing of drill pipes, and low operating efficiency, so as to improve detection work efficiency, good pressure maintaining effect, and prevent hole stuck accidents low rate effect

Active Publication Date: 2016-10-12

CHINA POWER CONSRTUCTION GRP GUIYANG SURVEY & DESIGN INST CO LTD

View PDF7 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] There are many kinds of pressure water test methods mainly due to the different ways of plugging. The conventional drilling pressure water test probe is integrated with the drilling rig. There are two types of single plug and double plug. Both of them are plugged on the drill pipe. The cavity in the drill pipe injects water into the plug cavity. This method is generally carried out during the drilling construction process. Because the construction needs to be interrupted, a

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

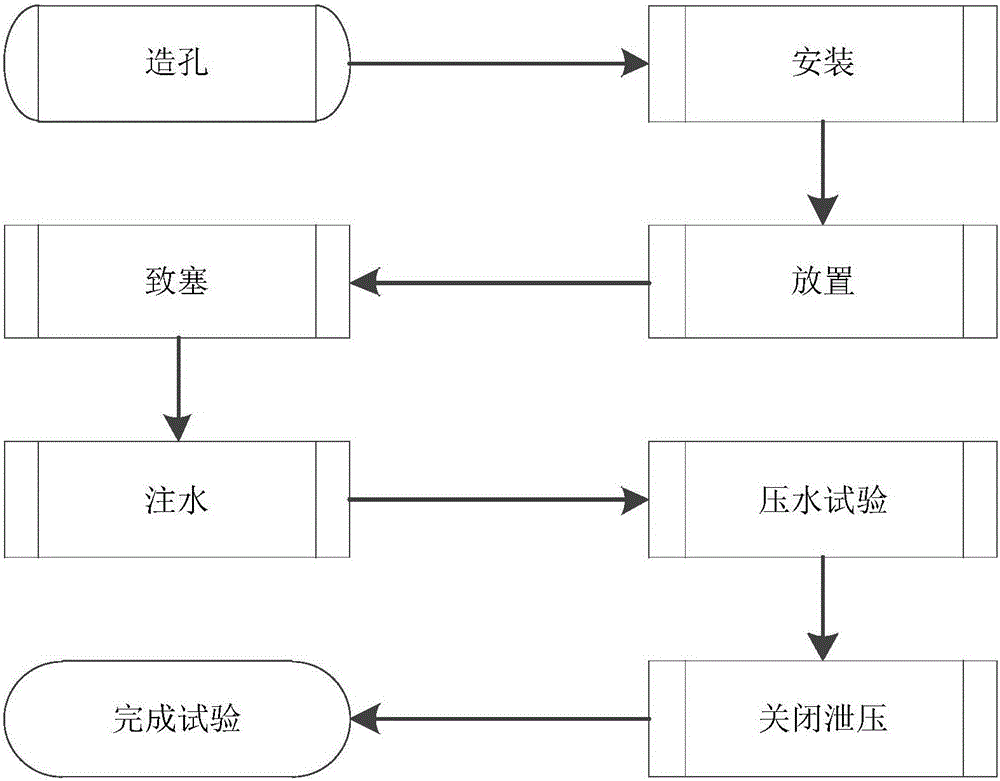

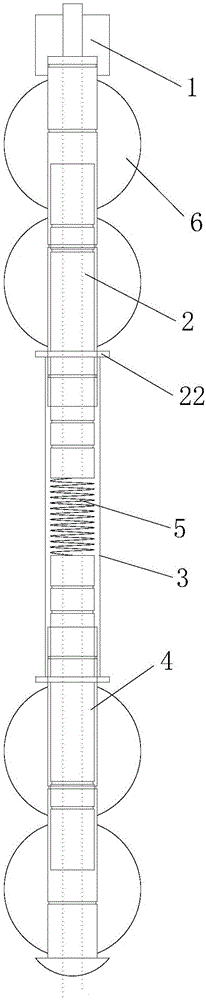

The invention provides a water-pressure-caused plugging drill hole water pressing test method. The method includes the following steps of 1, hole forming; 2, mounting; 3, placement; 4, plugging causing; 5, water injection; 6, conduction of a water pressing test; 7, closing of pressure relief; 8, completing of the test. By means of the method, detection work efficiency is improved, after a hole is drilled, the test on the hole is conducted continuously at a time, and the test time of each hole segment is less than 1 hour; survey precision is improved, the plugging causing pressure is sufficient, the pressure maintaining effect is good, and the test precision is two times higher than that of a drilling machine water pressing test; the hole clamping accident rate is low, only one water pipe is adopted for a whole probe, no oil pipe exists, few accessories of the probe exist, site operation is facilitated, and hole clamping accidents are reduced.

Description

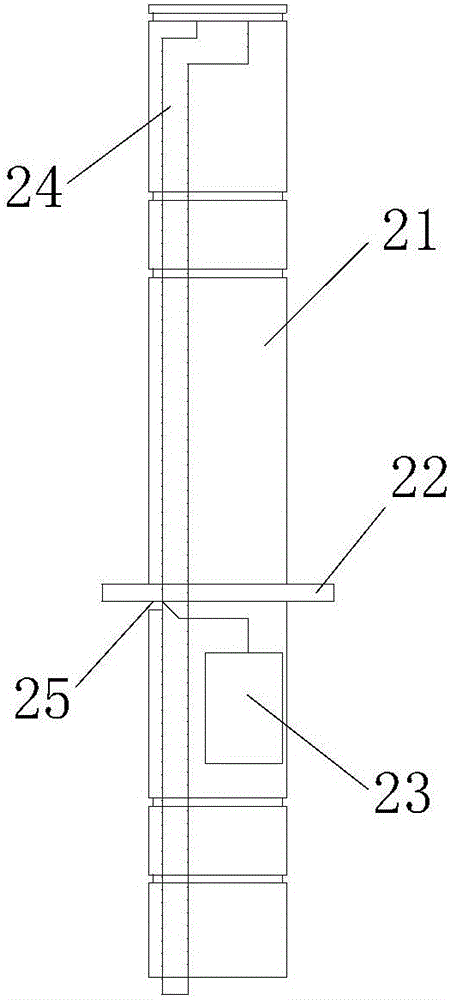

technical field [0001] The invention relates to a water pressure test method for hydraulic plugging drilling, which belongs to the technical field of engineering construction detection. Background technique [0002] Borehole pressure water test is a commonly used method for geological exploration and underground engineering construction testing. The working method is to artificially install two plugs at a certain depth of the borehole, and then inject high-pressure water into them. When the pressure balance is reached, record on the surface. Injection flow rate, pressure and pressure stabilization time, and finally these recorded data are substituted into the corresponding calculation formula of borehole pressure water test to calculate the leakage coefficient of the test section. [0003] There are many kinds of pressure water test methods mainly due to the different ways of plugging. The conventional drilling pressure water test probe is integrated with the drilling rig. T...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): E21B47/117

CPCE21B47/117

Inventor 王波

Owner CHINA POWER CONSRTUCTION GRP GUIYANG SURVEY & DESIGN INST CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com