A turbocharger bearing sleeve and turbocharger

A turbocharger and bearing sleeve technology, applied in the direction of machines/engines, engine components, mechanical equipment, etc., can solve the problems of angular contact ceramic bearings scattered, supercharger damage, rubbing shells, etc., to achieve reliability , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

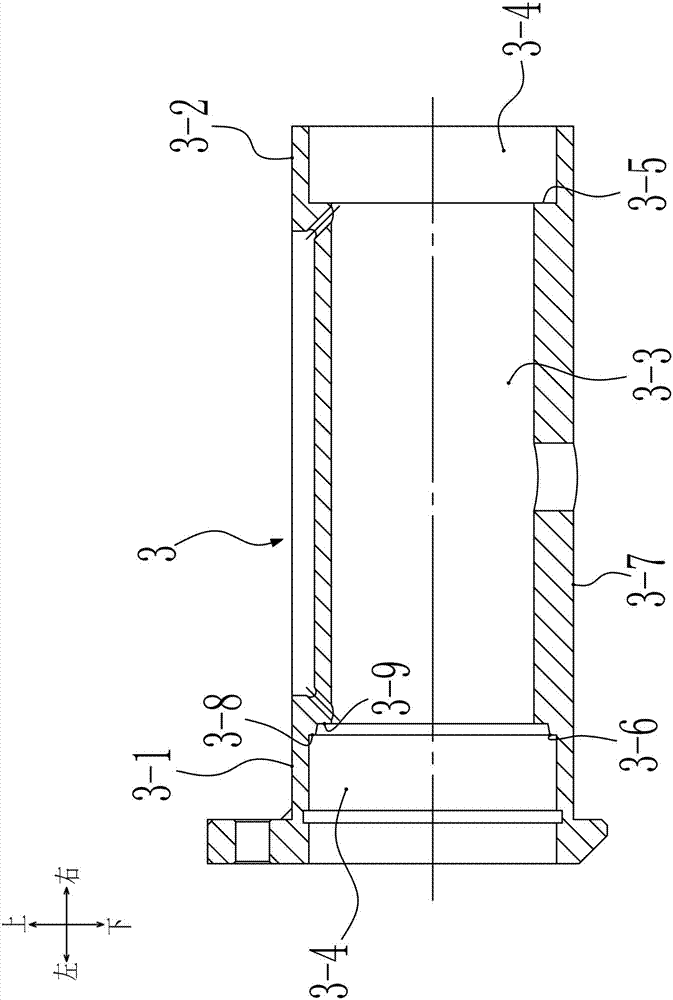

[0023] Such as figure 1 A turbocharger bearing sleeve is shown, which includes a straight sleeve body 3-7, the sleeve body 3-7 has a shaft hole 3-3 passing through along its axis, the sleeve The inner sides of the pressure end 3-1 and the scroll end 3-2 of the body 3-7 are provided with a bearing positioning hole 3-4 coaxial with the shaft hole 3-3, and the diameter of the bearing positioning hole 3-4 is larger than the The diameter of the shaft hole 3-3, the bottom of the bearing positioning hole 3-4 of the pressure end 3-1 is provided with an annular boss 3-6, and the diameter of the annular boss 3-6 is smaller than that of the bearing The diameter of the positioning hole 3-4 is larger than the diameter of the shaft hole 3-3. The shaft hole 3-3, the annular boss 3-6 and the bearing positioning hole 3-4 form a stepped hole. Specifically, on the side of the pressure end 3-1, the first shoulder 3-8 is formed between the outer end surface of the annular boss 3-6 and the inner ...

Embodiment 2

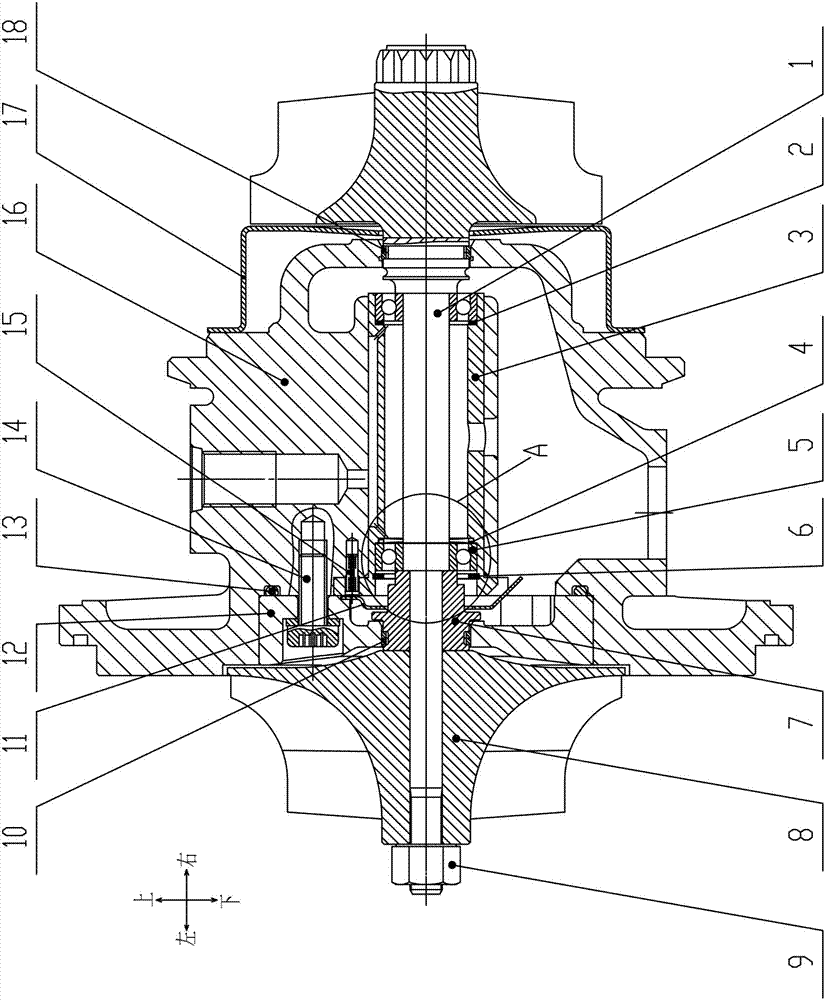

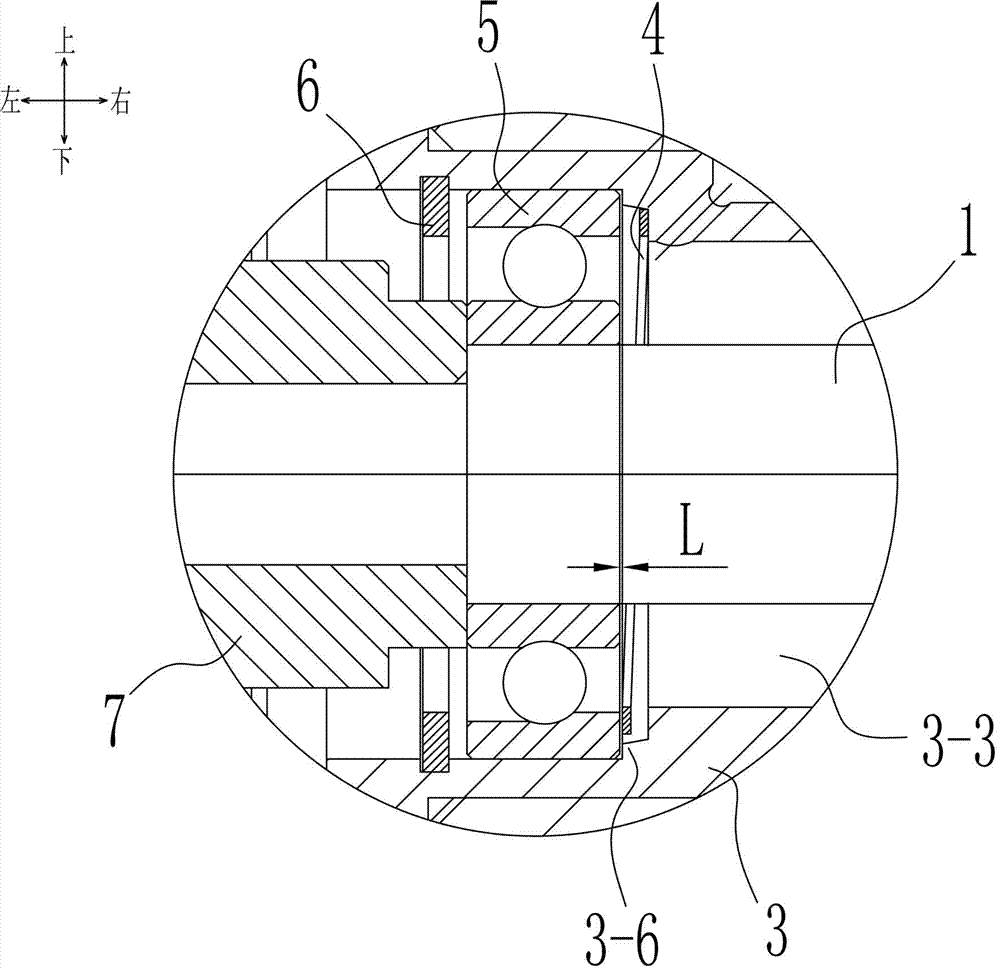

[0026] Such as figure 2 and 3 Shown is a turbocharger, which includes a bearing body 16, a turbine rotor shaft 1, a pressure end seal ring 10, an oil baffle plate 11, an O-ring 13, an oil seal screw 14, a spring pin 15, and a heat shield 17. Turbine end seal ring 18, oil seal cover 12, shaft seal sleeve 7, compressor impeller 8 and impeller lock nut 9, and also include bearing sleeve 3 and two angular contact bearings 5 as described in Embodiment 1; The oil seal cover 12 fixes and connects the shaft bearing sleeve 3 into the bearing body 16, the shaft seal sleeve 7 and the compressor impeller 8 are sequentially arranged on the turbine rotor shaft 1, and the turbine The impeller lock nut 9 at the left end of the rotor shaft 1 is fastened.

[0027] The two angular contact bearings 5 are set on the turbine rotor shaft 1, the bearing sleeve 3 is set on the turbine rotor shaft 1, and the two angular contact bearings 5 are arranged on the bearing sleeve 3 In the bearing po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com