An air filter for an engine with a detachable filter element

An air filter and engine technology, which is applied to engine components, machines/engines, combustion air/combustion-air treatment, etc., can solve the problems of difficult cleaning, disassembly, and replacement of filter elements, and improve filtration efficiency. and the cleanliness of filtration, meeting air supply requirements, and quick and convenient disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

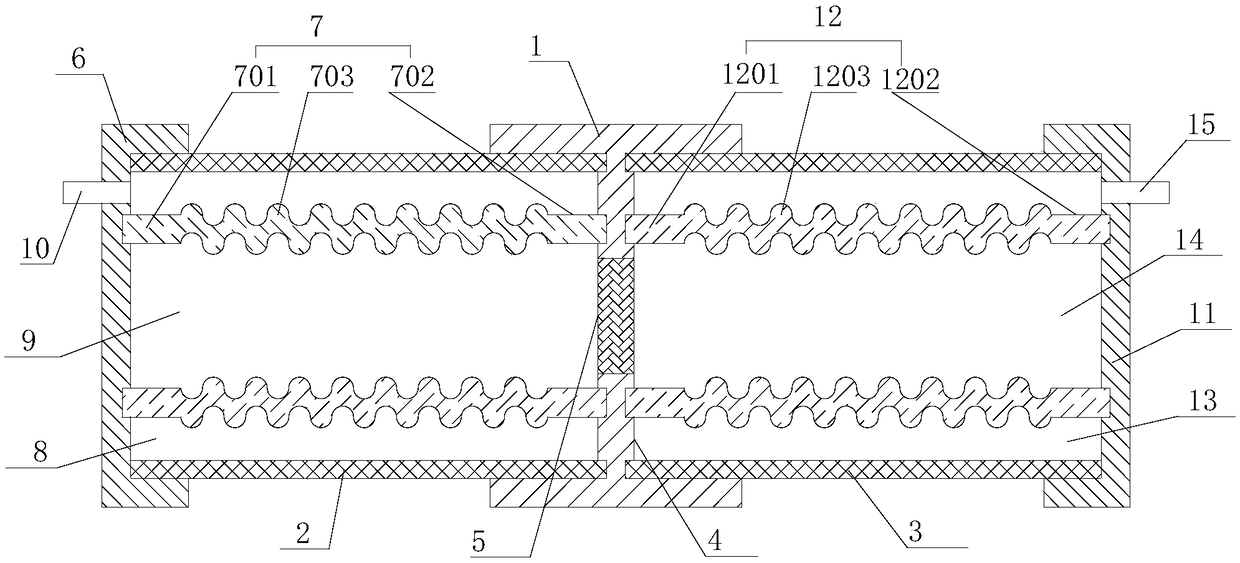

[0017] refer to figure 1 , the present invention proposes an engine air filter with detachable filter elements, including a first filter body 1, a second filter body 2, a third filter body 3, a first filter body 1, a second filter body 2, a third filter body The filter body 3 is a cylinder structure with both ends open, wherein:

[0018] The inner wall of the first filter body 1 is provided with an annular retaining ring 4, and the first filter element 5 is detachably installed in the annular retaining ring 4. In this embodiment, the first filter element 5 is a multi-layer filter net, and is directed from the air inlet 10 to the outlet. In the direction of the air port 15, the filter hole diameter of the filter screen decreases gradually. One side of the annular stop ring 4 is provided with a concentrically arranged first and second annular clip grooves, and the other side of the annular stop ring 4 is provided with a concentrically arranged third and fourth annular clip groo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com